Understanding the Components of a Four Wheeler

In the realm of automotive mechanics, comprehending the layout of essential vehicle elements is crucial for effective maintenance and repair. Each component plays a vital role in ensuring optimal performance and safety. Grasping the arrangement and function of these elements empowers both enthusiasts and professionals alike.

Moreover, a detailed representation of these mechanical structures aids in troubleshooting common issues. By visualizing how each segment interconnects, one can more easily identify potential problems and solutions. This knowledge not only enhances repair skills but also promotes a deeper appreciation for automotive engineering.

Overall, familiarizing oneself with the configuration of vehicle components lays the foundation for a more proficient understanding of automotive systems. Whether for personal use or professional growth, this knowledge serves as a valuable asset in navigating the complexities of modern vehicles.

Gaining insight into the various components of vehicles can enhance understanding of their functionality and maintenance. This article outlines essential sections that delve into the crucial elements that constitute these machines, providing a comprehensive overview for enthusiasts and learners alike.

Introduction to Vehicle Components

This section will introduce the significance of familiarizing oneself with the different elements of vehicles, highlighting their roles and importance in overall performance.

Engine Overview

Detailing the main functions of the engine, this part will cover its importance as the powerhouse of any vehicle.

Transmission System

A discussion on how the transmission transfers power from the engine to the wheels, explaining different types.

Suspension and Steering Mechanisms

- Definition and importance of suspension systems

- How steering systems function

Braking Systems

Exploring various braking mechanisms, their types, and how they contribute to vehicle safety.

Electrical Systems

Understanding the electrical components that support various functions such as lighting, ignition, and infotainment.

Fuel System

- Overview of fuel delivery processes

- Types of fuel systems

Exhaust System

Discussing the role of exhaust systems in emissions control and engine efficiency.

Body and Frame

Examining the structural components that provide safety and aerodynamics.

Tires and Wheels

- Types of tires and their applications

- Importance of wheel alignment and balance

Maintenance Tips

Providing practical advice on how to care for each component to ensure longevity and optimal performance.

Key Components of Four Wheeler Systems

Understanding the essential elements of automotive systems is crucial for effective maintenance and performance optimization. These fundamental components work in harmony to ensure the vehicle operates smoothly and efficiently.

The primary systems can be categorized as follows:

- Engine: The heart of the vehicle, responsible for converting fuel into motion.

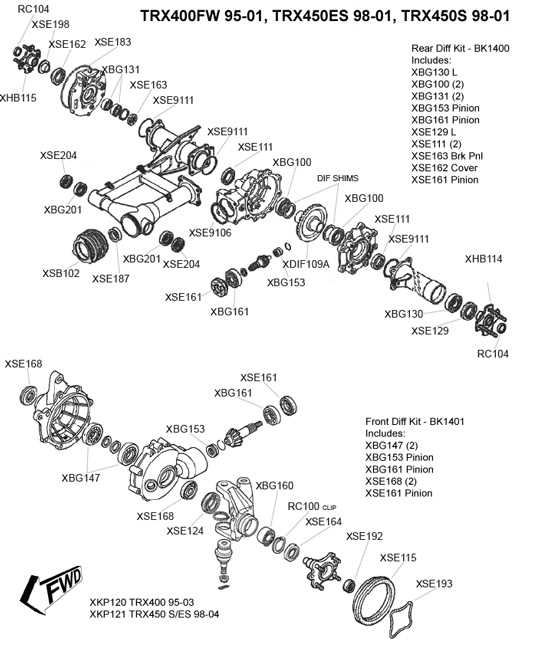

- Transmission: This system transmits power from the engine to the wheels, enabling movement.

- Suspension: Designed to absorb shocks and maintain tire contact with the road for a smooth ride.

- Braking System: Essential for safety, this system slows down or stops the vehicle when necessary.

- Steering Mechanism: Provides control over the direction of the vehicle.

Each of these systems consists of various components that play significant roles in overall functionality. Regular inspections and maintenance of these elements are vital for optimal performance and longevity.

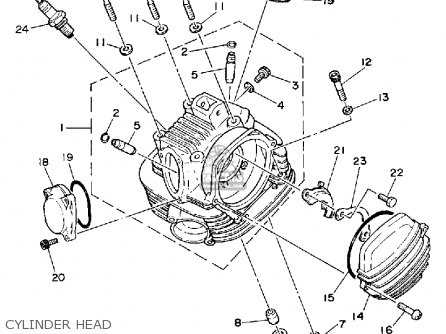

Overview of Engine Functionality

The engine serves as the heart of a vehicle, transforming fuel into motion through a complex series of processes. Understanding its operation is crucial for both maintenance and performance optimization.

Key functions of an engine include:

- Combustion: The process of igniting fuel to generate energy.

- Power Generation: The conversion of fuel energy into mechanical work.

- Cooling: The management of heat produced during combustion to prevent overheating.

- Lubrication: The reduction of friction between moving components to enhance efficiency and longevity.

By grasping these fundamental operations, one can appreciate the intricate design and functionality that drive automotive machinery.

Transmission Types and Their Roles

The transmission system is a crucial component in any vehicle, responsible for transferring power from the engine to the wheels. Understanding the different kinds of transmissions can provide insight into their functionalities and contributions to overall performance.

There are several categories of transmission systems, each designed for specific driving conditions and requirements:

- Manual Transmission: This type requires the driver to manually shift gears, offering greater control and engagement with the vehicle.

- Automatic Transmission: In this system, gear shifts occur automatically, enhancing convenience and ease of use for the driver.

- Continuously Variable Transmission (CVT): Unlike traditional systems, CVT provides a seamless range of gear ratios, optimizing engine performance and fuel efficiency.

- Dual-Clutch Transmission (DCT): This type utilizes two clutches for faster gear changes, blending the benefits of manual and automatic systems.

Each transmission type plays a distinct role in enhancing the driving experience, impacting factors such as acceleration, fuel economy, and overall vehicle handling.

Suspension Systems Explained

The functionality of a vehicle’s framework relies significantly on its suspension mechanism, which plays a crucial role in ensuring comfort and stability. This system serves as a link between the chassis and the wheels, absorbing shocks and providing support during various driving conditions.

There are several key components within this system that contribute to its overall effectiveness. The shock absorbers help dampen the impact of bumps, while springs support the weight of the vehicle and maintain a proper ride height. Additionally, control arms allow for wheel movement while ensuring alignment and stability during turns.

Understanding the suspension structure not only enhances driving experience but also aids in maintenance decisions. Regular checks on these elements can prevent unexpected issues and extend the lifespan of the vehicle.

Brake Mechanisms in Detail

Brake systems are essential components that ensure the safe operation of vehicles. Their primary function is to reduce speed or bring the vehicle to a complete stop when needed. Various designs and technologies are employed to achieve optimal performance, reliability, and safety, making understanding these mechanisms crucial for both manufacturers and users.

Types of Brake Systems

There are primarily two types of brake systems utilized in modern vehicles: disc brakes and drum brakes. Disc brakes feature a flat, round disc that rotates with the wheel, while drum brakes consist of a cylindrical drum that encases the brake shoes. Each type has its advantages and disadvantages regarding heat dissipation, maintenance, and effectiveness in different driving conditions.

Working Principles

Brake systems operate based on friction. When the driver applies pressure to the brake pedal, hydraulic fluid is sent to the brake components. In disc brakes, this pressure causes brake pads to clamp down on the disc, creating friction that slows the wheel. In drum brakes, the brake shoes expand against the drum’s inner surface, generating the necessary friction to reduce speed. Understanding these principles is essential for diagnosing issues and ensuring proper maintenance.

Electrical Systems and Wiring Layouts

This section delves into the intricate network of electrical components and their configurations within vehicles. Understanding the flow of electricity and the connections between various elements is crucial for optimal performance and maintenance. The layout ensures that all systems function seamlessly, from powering the engine to operating essential accessories.

Overview of Electrical Components

The electrical framework comprises several key elements, including the battery, alternator, fuses, and wiring harnesses. Each component plays a vital role in generating and distributing electrical energy throughout the vehicle. A well-organized structure allows for efficient energy transfer and reduces the likelihood of faults.

Wiring Layout and Schematics

A clear wiring layout is essential for troubleshooting and repairs. It illustrates how each component is interconnected, highlighting the pathways for electrical flow. Technicians often refer to these layouts to diagnose issues, ensuring that repairs are made swiftly and accurately. Proper schematics facilitate a deeper understanding of the vehicle’s electrical system, promoting effective maintenance practices.

Fuel System Components and Diagram

The fuel delivery system plays a crucial role in ensuring that an engine operates efficiently and effectively. This section will explore the key elements involved in this process, highlighting their functions and relationships within the overall setup.

Key Components of the Fuel Delivery System

- Fuel Tank: Stores the fuel until it is needed for combustion.

- Fuel Pump: Transfers the fuel from the tank to the engine at the appropriate pressure.

- Fuel Filter: Removes impurities and debris from the fuel to protect the engine components.

- Fuel Injectors: Sprays the fuel into the combustion chamber in a fine mist for optimal combustion.

- Pressure Regulator: Maintains the correct pressure of the fuel supplied to the engine.

Understanding the Flow of Fuel

- The fuel is drawn from the tank by the pump.

- The fuel passes through the filter to remove any contaminants.

- The clean fuel is then delivered to the injectors.

- The injectors atomize the fuel and inject it into the engine for combustion.

- The pressure regulator ensures that the fuel is delivered at a consistent pressure.

By understanding the components and their functions, one can appreciate how crucial the fuel delivery system is for engine performance and reliability.

Steering and Control Elements Overview

The steering and control components are crucial for ensuring safe and precise navigation of vehicles. They facilitate the driver’s ability to guide the automobile effectively, impacting overall maneuverability and responsiveness.

Key Components

Among the essential elements are the steering wheel, which allows for directional adjustments, and the control levers, responsible for managing various vehicle functions. These components work together harmoniously, enabling a seamless driving experience.

Importance of Maintenance

Regular inspection and maintenance of steering and control systems are vital for optimal performance. Neglecting these aspects can lead to potential hazards on the road. Ensuring that all components are functioning properly not only enhances safety but also prolongs the vehicle’s lifespan.

Exhaust System Parts and Functions

The exhaust mechanism in a vehicle plays a crucial role in managing gases produced during combustion. It ensures that these gases are safely expelled, enhancing engine efficiency and performance. Understanding the components of this system and their respective roles is essential for maintaining optimal functionality and compliance with environmental standards.

Key Components

This section highlights the main components involved in the exhaust assembly, along with their respective functions:

| Component | Function |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders and directs them into the exhaust pipe. |

| Catalytic Converter | Transforms harmful emissions into less harmful substances before they exit the system. |

| Muffler | Reduces noise produced by the exhaust gases as they are expelled from the vehicle. |

| Exhaust Pipe | Guides exhaust gases from the manifold to the rear of the vehicle, ensuring proper ventilation. |

Importance of Maintenance

Regular inspection and maintenance of the exhaust system are vital for ensuring that it operates efficiently. Any leaks or damage can lead to decreased performance and increased emissions, making it crucial to address issues promptly.

Cooling System Overview and Diagrams

The cooling mechanism in vehicles plays a crucial role in maintaining optimal operating temperatures. It ensures that the engine and other components function efficiently, preventing overheating and potential damage. This section delves into the fundamental elements of this system, illustrating its configuration and operation.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant, transferring it to the air. |

| Water Pump | Circulates coolant throughout the system to regulate temperature. |

| Thermostat | Controls the flow of coolant based on temperature, ensuring efficiency. |

| Coolant Reservoir | Holds excess coolant and helps maintain system pressure. |

| Hoses | Transport coolant between components, facilitating heat exchange. |

Maintenance and Replacement Tips

Ensuring the longevity and optimal performance of your vehicle requires regular upkeep and timely substitution of components. This section outlines essential practices to maintain functionality and safety, focusing on preventative measures and when to consider part changes.

Regular Inspection and Care

Routine checks play a crucial role in identifying wear and tear before they escalate into significant issues. Focus on examining key systems such as brakes, engine, and suspension. Keeping an eye on fluid levels and filters will also contribute to overall efficiency.

When to Replace Components

Understanding the signs that indicate a need for component replacement can save time and resources. Look out for unusual noises, decreased performance, or warning lights on the dashboard. Adhering to the manufacturer’s recommendations for service intervals is vital.

| Component | Signs of Wear | Replacement Interval |

|---|---|---|

| Brakes | Squeaking, grinding sounds | Every 30,000 to 70,000 miles |

| Oil Filter | Engine noise, poor performance | Every 5,000 to 7,500 miles |

| Tires | Uneven wear, low tread depth | Every 25,000 to 50,000 miles |