Complete Guide to Wheel Horse 48 Inch Mower Deck Parts Diagram

Maintaining your lawn equipment is essential for ensuring its optimal performance and longevity. A thorough understanding of the individual elements that make up your machinery can significantly enhance your ability to troubleshoot issues and execute repairs. This section aims to provide valuable insights into the various components involved in the cutting apparatus, equipping you with the knowledge needed for effective maintenance.

In this guide, we will explore the arrangement and functionality of crucial elements within the cutting mechanism. By familiarizing yourself with the layout and roles of these components, you will be better prepared to identify wear and tear, as well as make informed decisions regarding replacements or upgrades. A well-maintained apparatus not only improves efficiency but also contributes to a healthier lawn.

Whether you’re a seasoned enthusiast or a newcomer to lawn care, having access to a detailed overview of these components can empower you in your maintenance efforts. Understanding how each part interacts within the system is key to achieving the best results. Let’s delve into the specifics and enhance your operational knowledge.

Understanding Wheel Horse Mower Deck

This section focuses on the essential components and mechanisms involved in the cutting apparatus of a specific lawn care machine. Understanding these elements is crucial for maintenance, troubleshooting, and ensuring optimal performance during grass trimming tasks.

Key Components

- Cutting Blades

- Spindle Assemblies

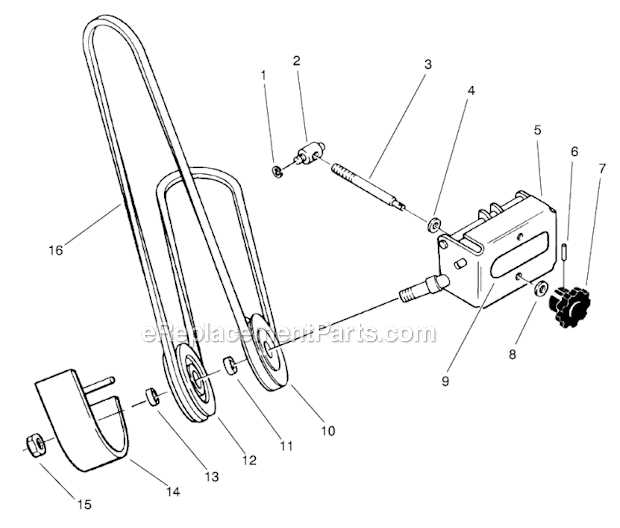

- Belts and Pulleys

- Chassis Mounting

- Height Adjustment Mechanisms

Maintenance Tips

- Regularly check and sharpen the cutting blades to ensure a clean cut.

- Inspect the belts for wear and replace them if necessary.

- Lubricate moving parts to reduce friction and extend lifespan.

- Keep the underside clean to prevent grass buildup and improve efficiency.

By familiarizing yourself with these aspects, you can enhance the longevity and effectiveness of your machine, ensuring a well-manicured lawn.

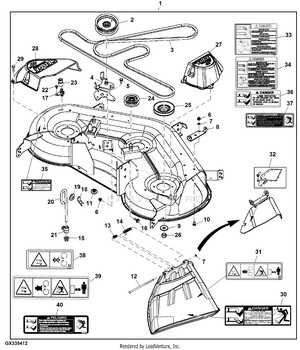

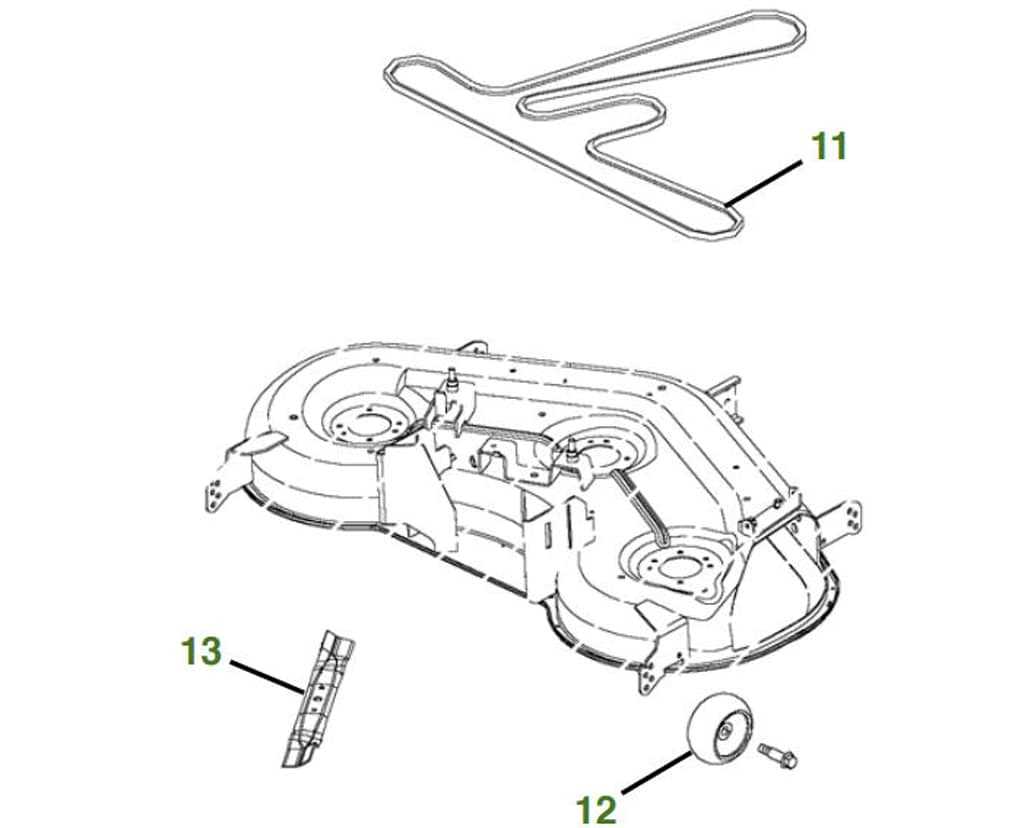

Components of the 48” Mower Deck

This section delves into the essential elements that comprise a specific cutting apparatus. Understanding these components is crucial for maintaining efficiency and performance. Each part plays a significant role in the overall functionality, contributing to effective grass management and durability.

| Component | Description |

|---|---|

| Cutting Blade | Vital for achieving a clean cut, this sharp element rotates at high speed to trim grass effectively. |

| Spindle Assembly | This mechanism supports the blade and allows for smooth rotation, ensuring optimal cutting performance. |

| Housing | The protective casing that encloses the blade assembly, designed to minimize debris escape and enhance safety. |

| Lift Mechanism | Enables adjustment of the cutting height, allowing users to tailor the grass length according to preferences. |

| Wheel Assembly | Facilitates mobility and stability during operation, aiding in maneuverability over various terrains. |

Importance of Proper Maintenance

Regular upkeep of outdoor machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a decline in efficiency, increased wear and tear, and costly repairs. By adhering to a consistent maintenance schedule, operators can prevent potential issues and enhance the overall functionality of their equipment.

Enhancing Performance

Keeping machinery in peak condition significantly boosts its performance. Routine checks and timely replacements of essential components help maintain power and efficiency. This not only ensures that tasks are completed effectively but also contributes to a smoother operation, reducing strain on the machine.

Cost-Effectiveness

Investing time and effort into regular maintenance can save money in the long run. Preventive care minimizes the risk of major breakdowns, which often require expensive repairs or part replacements. By prioritizing upkeep, users can extend the lifespan of their equipment and avoid unexpected financial burdens.

Common Issues with Mower Decks

Maintaining a healthy cutting apparatus is crucial for achieving a pristine lawn. Various complications can arise during usage, impacting performance and efficiency. Understanding these frequent challenges can help users identify and resolve issues promptly, ensuring optimal operation.

1. Uneven Cutting

One of the most prevalent problems is an inconsistent cutting height, which can leave patches of grass taller than others. This can result from misalignment or damage to the blades. Regular checks and adjustments can mitigate this issue.

2. Clogging

Debris build-up is another common concern. Grass clippings, leaves, and dirt can accumulate, obstructing flow and reducing effectiveness. Regular cleaning after use can help maintain smooth performance and prevent clogs.

3. Blade Dullness

Dull blades can tear rather than cut grass, leading to a frayed appearance and increased vulnerability to pests. Routine sharpening is essential for maintaining blade efficiency and promoting healthier growth.

4. Vibration and Noise

Excessive vibration or unusual sounds may indicate loose components or imbalanced blades. Identifying and tightening loose parts or realigning blades can improve operation and prolong the lifespan of the equipment.

5. Rust and Corrosion

Exposure to moisture can lead to rust, compromising structural integrity. Applying protective coatings and storing equipment in a dry place can help prevent this issue and maintain longevity.

By staying vigilant and addressing these common issues, users can enhance the functionality and durability of their cutting equipment, ensuring a well-maintained lawn throughout the seasons.

Tools Needed for Repair Tasks

When undertaking maintenance or repair activities, having the right equipment is crucial for efficiency and effectiveness. Various tools are essential for different aspects of the task, ensuring that you can tackle any challenge that arises during the process.

Below is a list of common tools that will help you during your repair endeavors:

- Wrenches: Useful for loosening or tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are essential for removing screws.

- Pliers: Great for gripping and twisting wires or small components.

- Socket Set: Provides versatility for various sizes of fasteners.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for electrical diagnostics and troubleshooting.

- Safety Gear: Includes gloves, goggles, and ear protection to ensure safety during repairs.

Having these tools at your disposal will make the repair process smoother and more efficient, helping you achieve the best results possible.

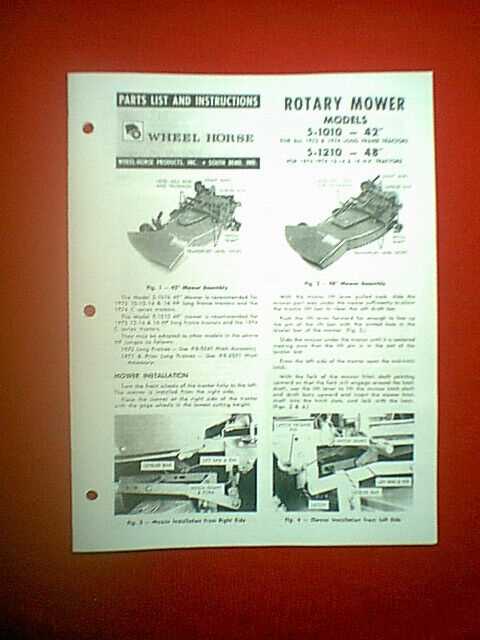

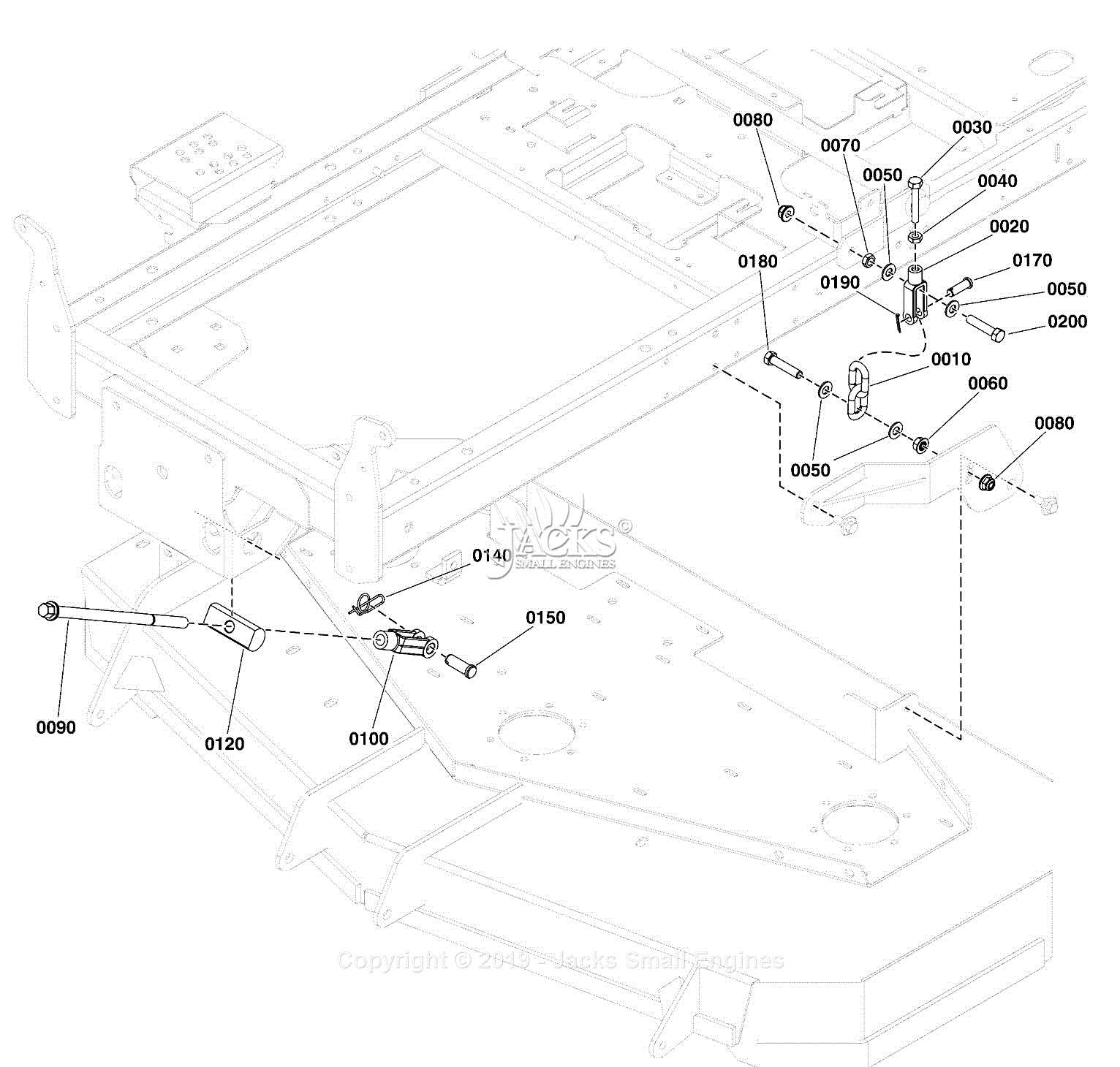

Step-by-Step Assembly Guide

This section provides a detailed procedure for putting together essential components of your outdoor cutting equipment. Following these instructions will ensure a smooth assembly process, leading to optimal performance.

- Gather Necessary Tools:

- Socket wrench set

- Screwdrivers (flathead and Phillips)

- Safety gloves

- Work light

- Prepare Your Workspace:

- Choose a flat, dry area.

- Ensure good lighting for visibility.

- Keep all components within reach.

- Inspect Components:

- Check for any damage or missing pieces.

- Lay out parts in an organized manner.

- Assemble the Base:

- Begin with the main chassis.

- Secure any necessary brackets using the appropriate fasteners.

- Attach Additional Components:

- Follow the specific sequence as outlined in your manual.

- Ensure each part is tightly secured to avoid future issues.

- Final Checks:

- Verify all connections are tight.

- Inspect for any loose items.

- Clean the workspace after assembly.

By adhering to these steps, you’ll ensure that your equipment is ready for effective operation, enhancing its longevity and reliability.

Where to Find Replacement Parts

Maintaining your outdoor equipment often requires sourcing various components for repair and upkeep. Whether you’re looking for essential pieces or specific accessories, knowing where to find reliable sources is crucial for ensuring optimal performance.

Online Retailers: Numerous e-commerce platforms specialize in garden and landscaping tools. These websites typically offer extensive inventories, competitive pricing, and the convenience of home delivery. Popular sites like Amazon and eBay provide user reviews to help assess quality.

Local Dealerships: Authorized dealers in your area can be valuable resources. They not only carry original equipment but also provide expert advice and support. This option is especially beneficial for those seeking specific or hard-to-find items.

Repair Shops: Many local repair services stock commonly needed components. In addition, these shops can often order specialized items, ensuring that you receive the right fit for your machinery.

Online Forums and Communities: Engaging with online groups dedicated to gardening equipment can yield insights and recommendations on where to acquire necessary supplies. Members often share their experiences and can point you toward reputable sources.

Second-Hand Markets: Thrift stores, garage sales, and online marketplaces can sometimes have hidden gems. While this option may require more effort, it can lead to significant savings if you’re willing to search.

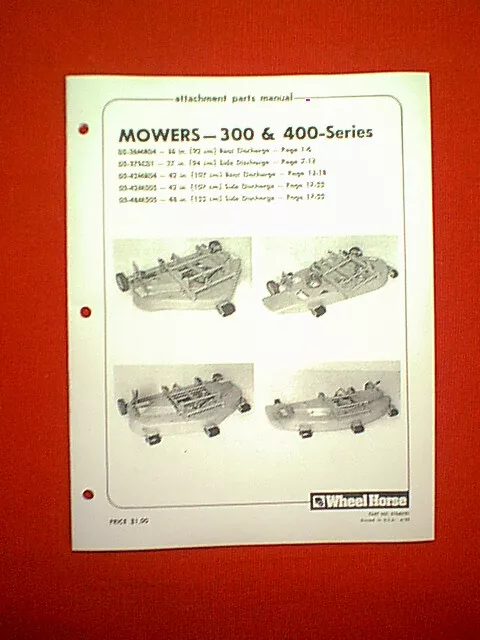

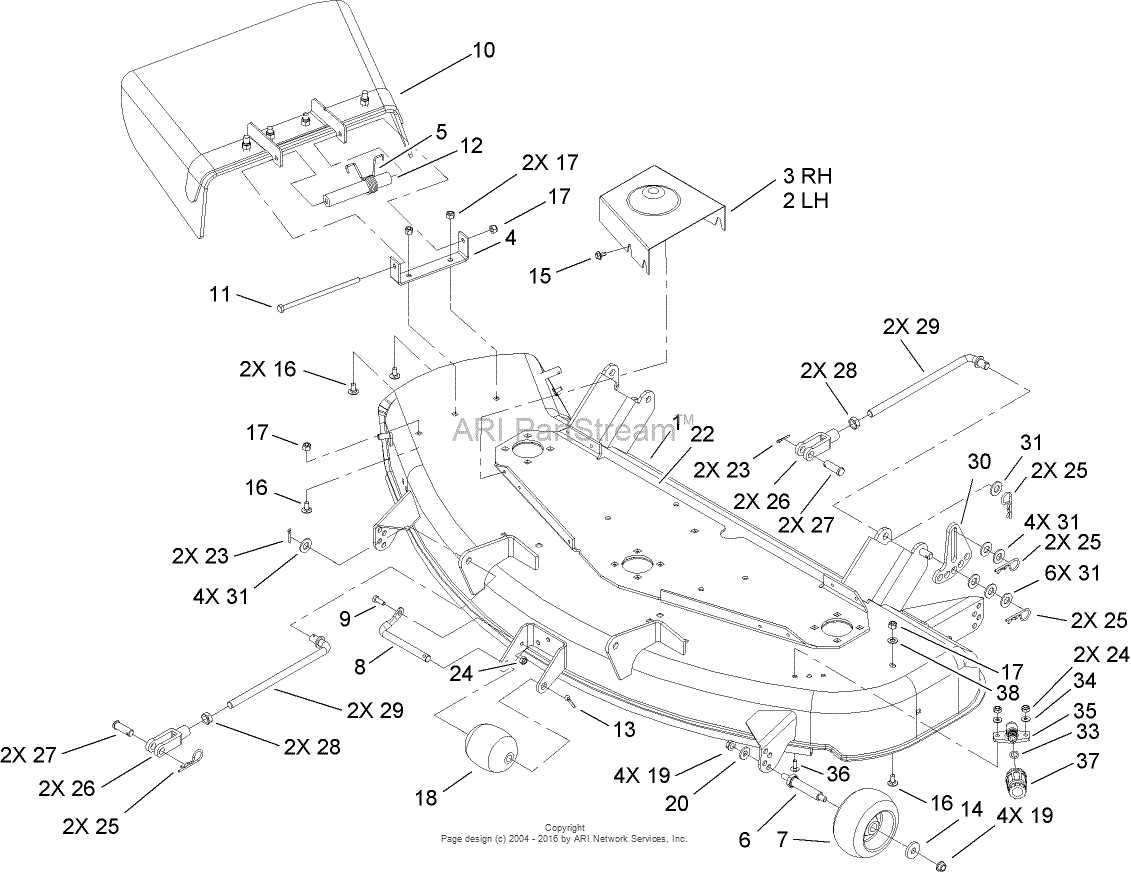

Diagram Overview of Key Parts

This section aims to provide a comprehensive look at the essential components involved in the operation of a cutting mechanism. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Essential Components

The primary elements include the cutting blades, which are vital for achieving a clean cut, and the drive system that powers them. Additionally, the housing structure protects these moving parts while facilitating efficient grass collection.

Maintenance Tips

Regular inspection of these critical components can prevent wear and tear. Lubrication of moving parts is necessary to ensure smooth operation, while sharpening blades will enhance cutting efficiency. Familiarity with these key elements will significantly contribute to the reliability of the entire system.

How to Troubleshoot Mower Problems

When it comes to maintaining your outdoor equipment, identifying and resolving issues can often be challenging. Knowing how to systematically approach these difficulties will help you restore functionality and ensure a smooth operation. By examining common symptoms and applying a logical troubleshooting process, you can effectively diagnose and fix many prevalent concerns.

Identify the Symptoms

The first step in addressing any malfunction is to observe the symptoms closely. Is the machine not starting? Does it produce an unusual noise? Are there problems with cutting efficiency? Pay attention to any irregularities and make a note of them. This information will be crucial in pinpointing the root cause.

Check the Basics

Once you have identified the symptoms, it’s essential to check the fundamental components. Start with the fuel supply; ensure there is enough quality fuel in the tank. Next, examine the battery and electrical connections for any signs of wear or damage. Also, inspect the air filter and spark plug, as these elements can significantly impact performance. Regular maintenance of these parts can prevent many common issues from arising.

By following these steps and being thorough in your evaluation, you can tackle most challenges that arise with your equipment. Remember, a methodical approach is often the key to successful repairs.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is crucial for maintaining the efficiency and longevity of your equipment. By being vigilant about these signs, you can prevent more significant issues and ensure optimal performance. Regular inspections can help identify problems early, saving time and resources in the long run.

Common Indicators

Look for any unusual noises or vibrations during operation, as these may signify underlying mechanical problems. Additionally, check for visible damage, such as cracks or excessive rust on components. Worn-out belts and blades can also exhibit signs of wear, including fraying or dull edges, which affect cutting efficiency.

Maintenance Recommendations

To mitigate wear and extend the life of your machinery, establish a routine maintenance schedule. This should include cleaning, lubrication, and timely replacement of worn parts. Regularly consulting the manufacturer’s guidelines will provide specific recommendations tailored to your equipment.

Comparing Deck Types for Efficiency

When it comes to maintaining a pristine lawn, the type of cutting mechanism used can significantly influence performance and overall results. Different designs offer various benefits and drawbacks, affecting factors such as maneuverability, cutting quality, and maintenance requirements. Understanding these differences allows users to make informed choices that enhance their efficiency in yard care.

Design Variations and Their Impact

There are several design variations, each tailored to specific landscaping needs. For instance, some configurations are optimized for wide areas, allowing for quick coverage and fewer passes. In contrast, others excel in navigating tight spaces, making them ideal for intricate gardens. The choice of design not only affects the speed of operation but also the quality of the finished cut.

Maintenance and Longevity Considerations

Durability and ease of maintenance are crucial factors in selecting a cutting system. Some designs require more frequent adjustments and part replacements, while others are built for longevity with minimal upkeep. Investing in a model that balances performance and maintenance can lead to long-term savings and consistent results. Ultimately, evaluating these aspects can lead to improved efficiency and satisfaction with lawn care tasks.

Expert Tips for Long-lasting Performance

Maintaining optimal functionality of your equipment requires attention and care. By following a few essential practices, you can significantly extend the lifespan and efficiency of your tools. These recommendations focus on routine maintenance, timely repairs, and proper usage to ensure that your machinery operates smoothly for years to come.

Regular cleaning is crucial. Accumulated debris can cause wear and tear, leading to decreased performance. Make it a habit to clear away grass, dirt, and other residues after each use. This simple step will prevent rust and corrosion, keeping your components in excellent condition.

Inspecting moving parts should become a standard part of your maintenance routine. Look for signs of wear, such as fraying belts or loose bolts. Addressing these issues promptly can prevent more significant problems down the line. Additionally, lubricating components regularly helps reduce friction and enhances overall efficiency.

Using quality fuel and oil is another vital factor in ensuring long-lasting performance. Poor-quality products can lead to engine damage and other operational issues. Always choose reputable brands and follow the manufacturer’s recommendations for optimal results.

Lastly, store your equipment properly when not in use. Keeping it in a dry, protected area will shield it from the elements and prolong its lifespan. By implementing these expert tips, you can enjoy reliable performance and avoid unnecessary repairs.

Frequently Asked Questions About Decks

This section addresses common inquiries regarding the essential components that contribute to efficient lawn maintenance. Understanding these elements can enhance your experience and ensure proper upkeep of your outdoor equipment.

-

What should I consider when maintaining my equipment?

Regular inspections, cleaning, and lubrication are crucial for optimal performance. Ensure all moving parts are free of debris and check for any signs of wear.

-

How often should I replace blades?

It’s recommended to inspect the blades at least once a season. Replace them if they show signs of damage or dullness to maintain effective cutting performance.

-

What are the signs of wear and tear?

Common indicators include uneven cutting, excessive vibrations, and strange noises during operation. Addressing these issues promptly can prevent further damage.

-

Can I use aftermarket components?

While aftermarket parts can be cost-effective, ensure they meet the required specifications to avoid compatibility issues that may affect performance.

-

What is the best way to store my equipment during the off-season?

Clean the machinery thoroughly, remove any fuel, and store it in a dry, sheltered location. Protecting it from the elements can prolong its lifespan.