Exploring Wheel Horse Parts Diagrams

This section delves into the intricate arrangement of various elements that contribute to the functionality of a specific machinery model. By exploring these components, one can gain valuable insights into how each piece interacts within the system, ensuring optimal performance and efficiency.

Recognizing the significance of each individual segment is crucial for anyone interested in maintenance or repair. A comprehensive overview of the assembly allows enthusiasts and technicians alike to familiarize themselves with the essential roles played by each item, facilitating a deeper understanding of the entire setup.

In this guide, detailed representations of the components will be provided, highlighting their placement and connection points. Such information is vital for troubleshooting issues, as well as for conducting routine maintenance effectively, thereby prolonging the lifespan of the equipment.

This section provides an in-depth exploration of the machinery associated with lawn and garden maintenance. Understanding the components of this equipment is essential for effective maintenance and operation. With various models available, familiarity with individual components can enhance the user’s experience and prolong the life of the equipment.

Key Components of Garden Machinery

The efficiency and performance of outdoor machinery heavily rely on its various elements. Each part plays a crucial role in the overall functionality, making it imperative for users to recognize and comprehend these components. Below is a breakdown of some of the essential components:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the machine, providing necessary energy for operation. |

| Transmission | This element transfers power from the engine to the wheels, facilitating movement. |

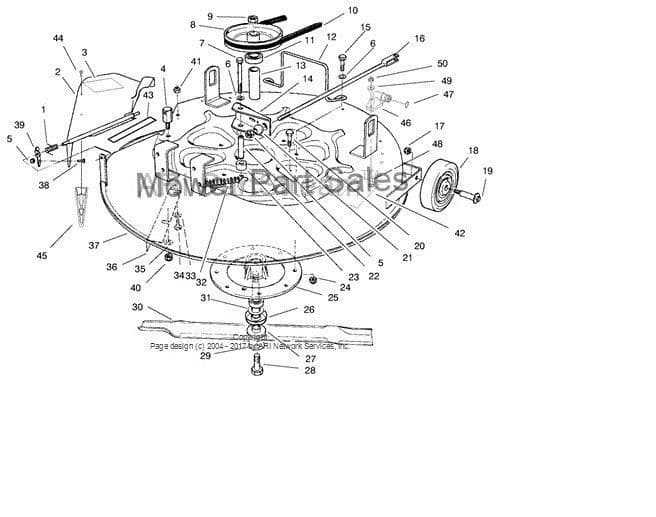

| Deck | The structure that houses the cutting mechanism, crucial for maintaining a clean cut. |

| Wheels | These provide mobility and stability, enabling the machine to traverse various terrains. |

| Controls | The interface that allows the operator to manipulate the machine’s functions effectively. |

Maintenance Tips for Longevity

Regular upkeep is vital for the longevity of outdoor machinery. Users should ensure that all components are well-maintained, lubricated, and inspected for wear and tear. Taking proactive steps can significantly enhance performance and prevent costly repairs.

Essential Components of Wheel Horse

Understanding the vital elements that contribute to the overall functionality of this equipment is crucial for maintenance and optimal performance. Each component plays a significant role in ensuring that the machinery operates smoothly and efficiently, from the driving mechanism to the support systems. Familiarity with these integral parts allows users to diagnose issues and perform necessary repairs effectively.

Key Elements and Their Functions

Here are some of the primary components and their respective roles in the machinery:

| Component | Function |

|---|---|

| Engine | Powers the equipment and drives the mechanical systems. |

| Transmission | Transfers power from the engine to the wheels, allowing for movement. |

| Chassis | Provides the frame and structure for mounting all components. |

| Steering Mechanism | Enables directional control and maneuverability. |

| Electrical System | Controls ignition, lighting, and other electronic functions. |

Maintenance Tips

Regular inspection and upkeep of these essential elements are necessary for prolonging the lifespan of the machinery. Ensure to check fluid levels, replace worn parts, and keep the equipment clean to maintain its performance.

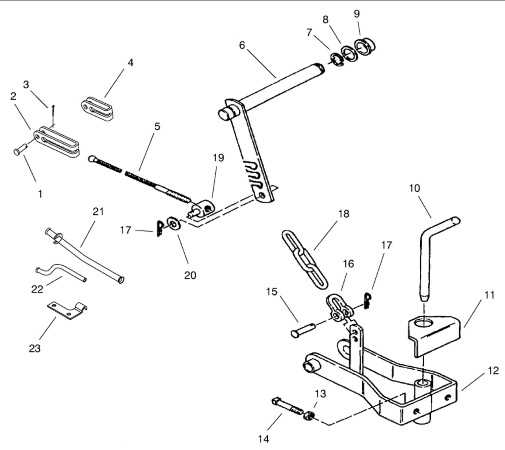

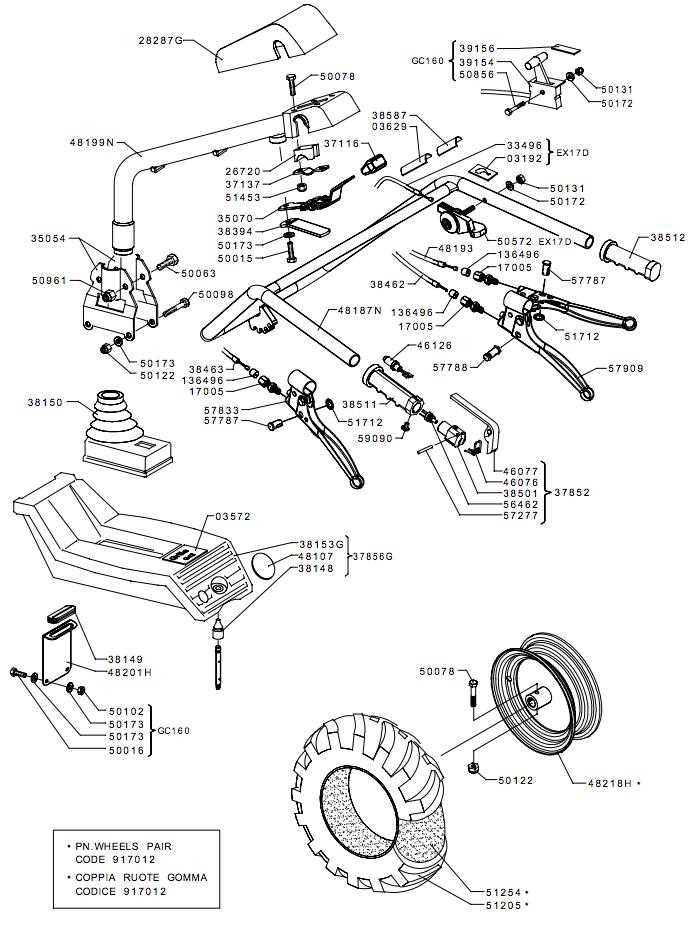

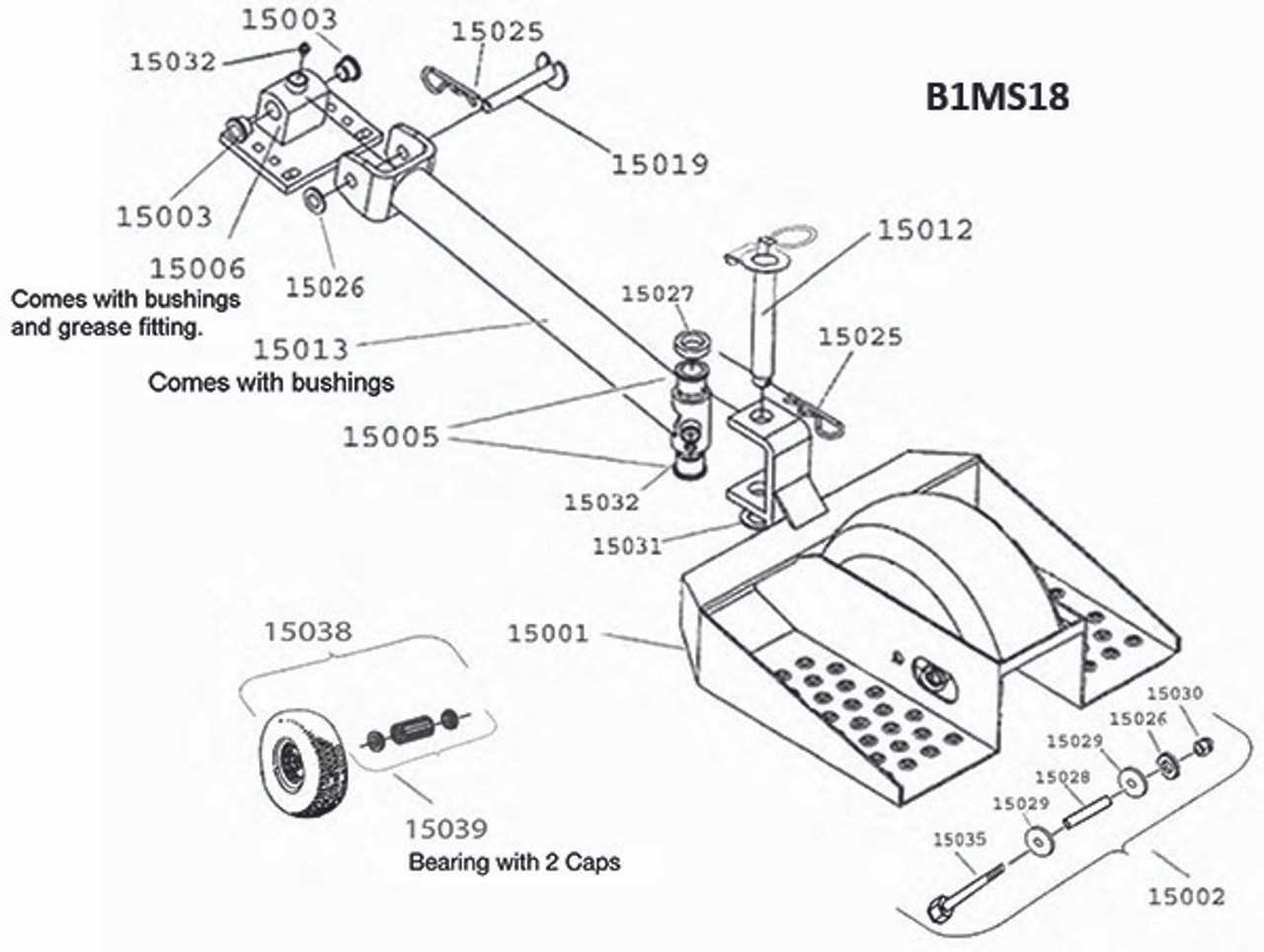

Identifying Key Parts on Diagrams

Understanding the layout and components illustrated in schematics is crucial for effective maintenance and repair. These visual representations provide valuable insights into the organization and functionality of various elements, allowing users to troubleshoot issues efficiently and carry out necessary replacements or adjustments.

Recognizing Essential Elements

Every illustration typically features a set of fundamental components, each serving a specific role. Familiarity with these crucial elements enhances the ability to interpret the overall system, enabling a clearer understanding of how each piece interacts within the assembly.

Utilizing Labels and Symbols

Diagrams often employ distinct labels and symbols to convey information about the various components. Paying attention to these annotations is essential, as they guide users in identifying not only the parts but also their connections and operational significance within the system.

Maintenance Tips for Wheel Horse Parts

Proper upkeep of your machinery components is essential for ensuring optimal performance and longevity. Regular inspections and timely maintenance can prevent unexpected breakdowns and costly repairs. Below are some practical suggestions for maintaining your equipment effectively.

1. Regular Cleaning: Keeping your machinery clean is vital. Remove dirt, debris, and grass clippings from various components to prevent rust and wear. Use a soft brush or compressed air to reach tight spots.

2. Lubrication: Ensure that all moving elements are adequately lubricated. This reduces friction and minimizes wear. Check the manufacturer’s recommendations for the appropriate type of lubricant to use.

3. Check for Wear: Periodically inspect all components for signs of wear or damage. Look for cracks, frayed belts, or loose fittings. Early detection can save time and money.

4. Battery Care: If your equipment includes a battery, check its charge regularly and clean the terminals to prevent corrosion. Ensure that it is securely mounted to avoid vibration damage.

5. Follow the Manual: Always refer to the owner’s manual for specific maintenance guidelines and schedules. Each machine has unique requirements, and adhering to them can prolong its life.

Common Issues and Solutions

In any mechanical system, certain challenges may arise that can affect performance and reliability. Understanding these common complications and their corresponding remedies is essential for maintaining optimal functionality. This section addresses frequent concerns encountered by users, offering effective strategies for resolution.

Frequent Complications

Users often report issues related to operational inefficiencies, wear and tear, or component failures. Identifying the specific source of these problems can significantly aid in implementing the right solutions. Below are some prevalent complications along with suggested remedies.

| Issue | Description | Solution |

|---|---|---|

| Loss of Power | Reduced efficiency or inability to perform tasks. | Check fuel levels and ensure all connections are secure. |

| Unusual Noises | Strange sounds during operation, indicating possible internal issues. | Inspect components for wear and replace any damaged parts. |

| Difficulty Starting | Issues with ignition or power supply. | Examine the battery and starter system for faults. |

Preventive Measures

Regular maintenance can prevent many issues from arising. Ensuring that all components are in good working order and performing routine checks can extend the lifespan of the equipment. Adhering to a consistent upkeep schedule will help mitigate potential complications and enhance overall efficiency.

Parts Replacement and Upgrades

Maintaining and enhancing the functionality of your machinery requires attention to various components. Regularly evaluating and updating these elements can lead to improved performance and extended lifespan. This section will explore the essential considerations and steps involved in the replacement and enhancement of various components.

Before initiating any changes, it is crucial to assess the condition of existing elements. This involves:

- Conducting thorough inspections to identify wear and tear.

- Researching compatible alternatives for upgraded components.

- Ensuring all necessary tools and resources are available before starting the process.

When replacing any component, consider the following steps:

- Remove the damaged or outdated part with care to prevent any further issues.

- Compare new and old components to confirm compatibility.

- Install the new piece, following manufacturer instructions to ensure proper fit and function.

- Test the system to verify successful installation and functionality.

In addition to basic replacements, exploring upgrades can significantly enhance the efficiency and capabilities of your machinery. Potential enhancements include:

- Installing more advanced components designed for higher performance.

- Integrating additional features that provide better usability or improved results.

- Utilizing aftermarket options that may offer superior quality or technology.

Ultimately, being proactive in the upkeep and enhancement of these vital components can lead to a more reliable and effective operation.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. Genuine items ensure compatibility and reliability, offering peace of mind for users. Below are several effective methods for sourcing these essential elements.

Authorized Dealers

One of the most reliable ways to obtain original components is through authorized dealerships. These establishments often carry a full range of products that meet the manufacturer’s standards.

- Visit the manufacturer’s official website for a list of certified dealers.

- Contact local dealers to inquire about their inventory and availability.

- Check for warranties and return policies to ensure your purchase is protected.

Online Marketplaces

Numerous online platforms specialize in selling genuine items. These websites often provide detailed descriptions and specifications to help you make informed decisions.

- Search for reputable e-commerce websites known for their quality and service.

- Read customer reviews to gauge the reliability of the seller.

- Utilize search filters to narrow down options based on compatibility and features.

Importance of Accurate Diagrams

Precise illustrations are crucial for understanding complex systems. They serve as vital tools that enable users to visualize components and their relationships effectively. Without clear representations, it becomes challenging to assemble, maintain, or repair machinery. Accurate schematics not only enhance comprehension but also facilitate efficient troubleshooting.

Enhancing Clarity and Understanding

When dealing with intricate machinery, well-crafted representations provide clarity. They break down complicated mechanisms into digestible sections, allowing users to grasp how each element functions within the whole. This understanding is essential for proper operation and maintenance, reducing the risk of errors that could lead to malfunction.

Streamlining Maintenance and Repairs

Accurate representations play a significant role in the upkeep of equipment. Technicians rely on these visual aids to identify specific elements needing attention or replacement. With precise schematics, they can swiftly locate issues, ensuring timely repairs and minimizing downtime. Ultimately, this leads to enhanced performance and longevity of the equipment.

History of Wheel Horse Models

The evolution of these iconic garden machines reflects a blend of innovation and practicality, catering to the diverse needs of landowners and gardeners. Over the decades, numerous models have emerged, each representing advancements in technology and design aimed at enhancing efficiency in landscaping and agriculture.

Initially introduced in the mid-20th century, these machines quickly gained popularity due to their robust construction and versatility. Early designs were characterized by simplicity, making them accessible to a broad audience. As demand grew, manufacturers responded by incorporating advanced features that catered to more specialized tasks.

Throughout the years, several notable models have left their mark, showcasing a range of capabilities from basic mowing to more complex landscaping tasks. Each model not only serves a practical purpose but also embodies the changing trends in gardening technology. The rich history of these machines illustrates a commitment to quality and user satisfaction, ensuring their place in the hearts of enthusiasts and professionals alike.

Community Resources for Enthusiasts

Engaging with a vibrant community can greatly enhance the experience for those passionate about their hobbies. Access to shared knowledge, resources, and support is invaluable for individuals looking to deepen their understanding and skills. Here, we explore various avenues that enthusiasts can tap into for information, networking, and assistance.

Online Forums and Discussion Groups

Participating in online platforms allows enthusiasts to connect with like-minded individuals. These spaces are excellent for exchanging tips, seeking advice, and sharing personal experiences. Some notable options include:

- Dedicated online communities on social media platforms

- Specialized forums with categorized topics

- Subreddits focused on specific interests

Local Clubs and Meetups

Finding local organizations can provide a more hands-on experience. Members often gather for events, workshops, and discussions, fostering a sense of camaraderie. Benefits of joining these groups include:

- Networking opportunities with local enthusiasts

- Access to tools and equipment

- Participation in organized activities and competitions

Future of Wheel Horse Equipment

The landscape of outdoor machinery continues to evolve, driven by advancements in technology and changing consumer preferences. As enthusiasts and professionals seek more efficient, versatile, and sustainable solutions, the future of this category of equipment appears promising. Innovations in design, functionality, and performance are poised to reshape how users engage with their tools and implements.

Technological Advancements

Emerging technologies are set to play a crucial role in enhancing the efficiency and usability of outdoor machinery. Key areas of focus include:

- Smart Connectivity: Integration of IoT (Internet of Things) will enable users to monitor and control their equipment remotely, optimizing operations.

- Battery Technology: Improved energy storage solutions will facilitate longer usage times and quicker charging, contributing to sustainability.

- Automated Features: Automation in operation will reduce manual labor and enhance precision, making tasks easier and more efficient.

Environmental Considerations

As environmental awareness grows, the industry is shifting towards more sustainable practices. Future designs may incorporate:

- Eco-Friendly Materials: Utilizing recyclable and sustainable materials in manufacturing to minimize environmental impact.

- Emission Reductions: Developing engines and systems that produce fewer emissions to align with global sustainability goals.

- Energy Efficiency: Enhancing the energy efficiency of machinery to lower operational costs and reduce waste.