Understanding the Wheel Hub Parts Diagram for Better Maintenance

The intricate assembly that facilitates the smooth movement of a vehicle involves numerous essential elements working in harmony. These components play a critical role in ensuring stability and control while navigating various terrains. A thorough comprehension of this assembly is vital for anyone seeking to maintain or enhance their vehicle’s performance.

In this section, we will explore the various components involved in the rotational mechanism, focusing on their functions and interrelationships. Understanding how these elements interact will provide valuable insights into the overall mechanics, enhancing your ability to diagnose issues and optimize vehicle efficiency.

We will delve into the individual pieces that constitute this system, highlighting their significance and the roles they play in promoting safe and effective transportation. By familiarizing yourself with these components, you will gain a deeper appreciation for the engineering marvels that underpin modern vehicles.

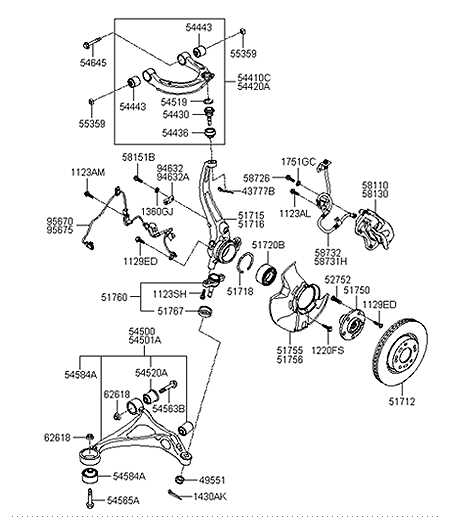

Understanding Wheel Hub Components

This section explores the essential elements that contribute to the functionality and safety of your vehicle’s wheel assembly. Each component plays a critical role in ensuring smooth operation and effective load distribution.

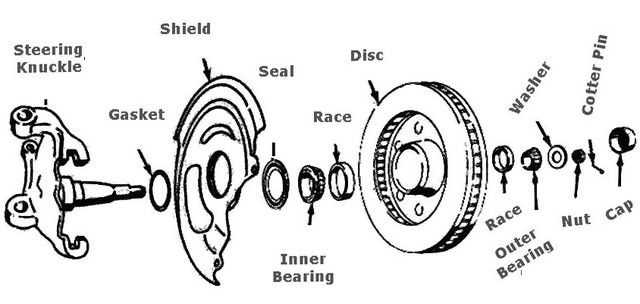

- Bearing: Facilitates rotation and minimizes friction.

- Spindle: Provides support and stability for the entire structure.

- Flange: Connects to the brake system and aids in secure fitting.

- Seals: Protect internal elements from debris and moisture.

- Nut: Fastens components together for secure attachment.

Understanding these elements allows for better maintenance and awareness of your vehicle’s performance.

Basic Functions of Wheel Hubs

The components that connect the tires to the suspension system play a crucial role in ensuring smooth operation and stability of the vehicle. These essential elements facilitate movement, provide support, and contribute to overall safety on the road.

Support and Stability

One primary function of these components is to support the weight of the vehicle. They help maintain proper alignment, ensuring that the tires remain in contact with the road, which is vital for handling and performance.

Rotation and Motion

Additionally, these structures enable smooth rotation of the tires, allowing for efficient motion. They are designed to minimize friction, enhancing performance and extending the lifespan of both the tires and the suspension system.

Common Types of Wheel Hubs

Understanding the various types of assemblies that connect the wheel to the vehicle is essential for maintenance and performance. Each configuration serves a specific function, impacting handling and safety.

- Standard Assembly: Typically found in most vehicles, designed for basic functionality and durability.

- Performance Assembly: Engineered for high-speed applications, offering enhanced handling and responsiveness.

- Heavy-Duty Assembly: Built to withstand significant loads, ideal for trucks and commercial vehicles.

- Adaptive Assembly: Features advanced technology for variable driving conditions, enhancing traction and control.

Each type plays a crucial role in the overall dynamics of the vehicle, ensuring safe and efficient operation on the road.

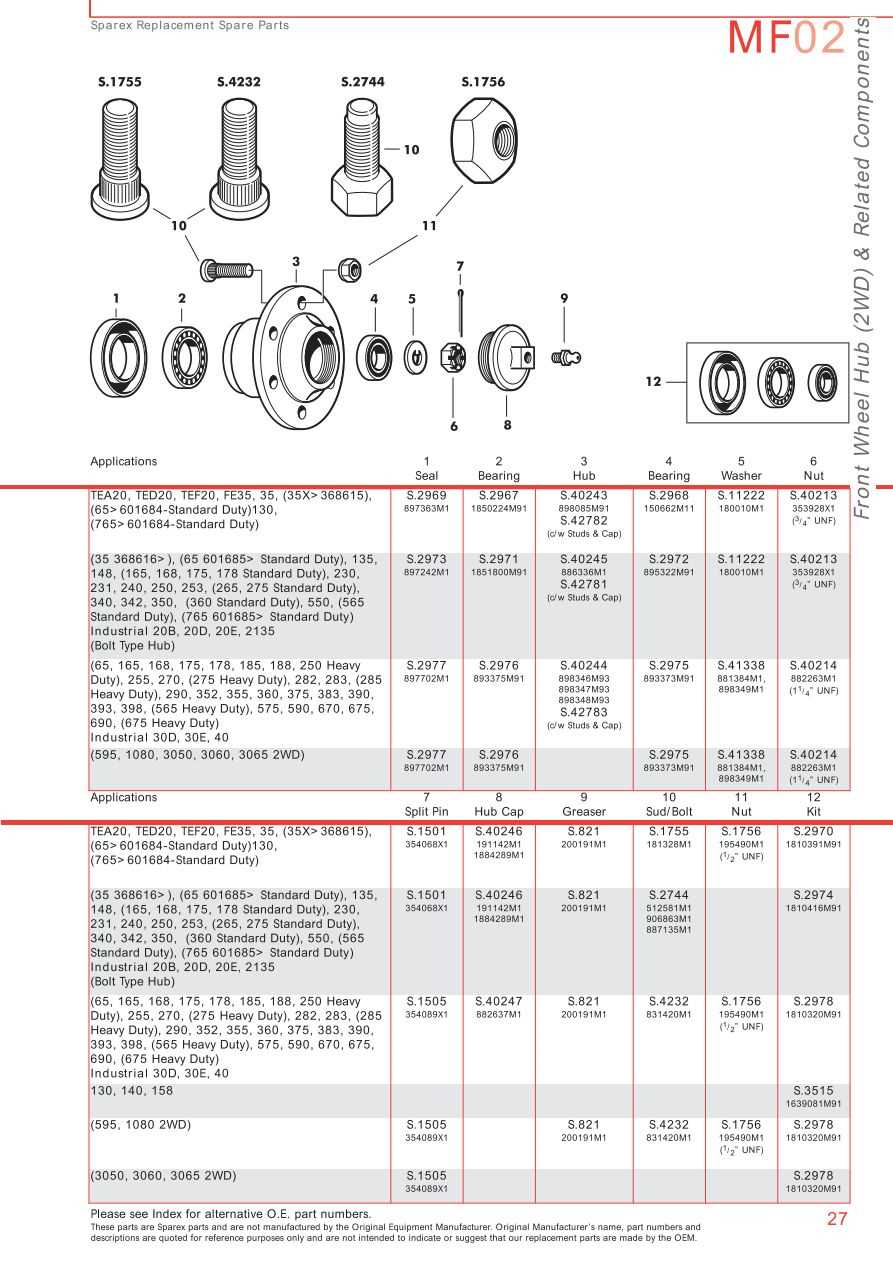

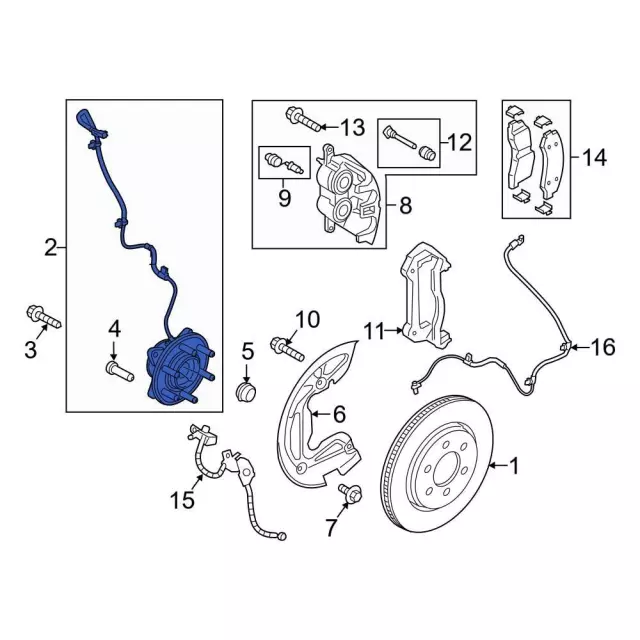

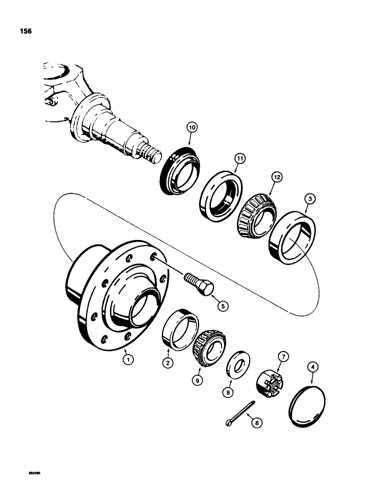

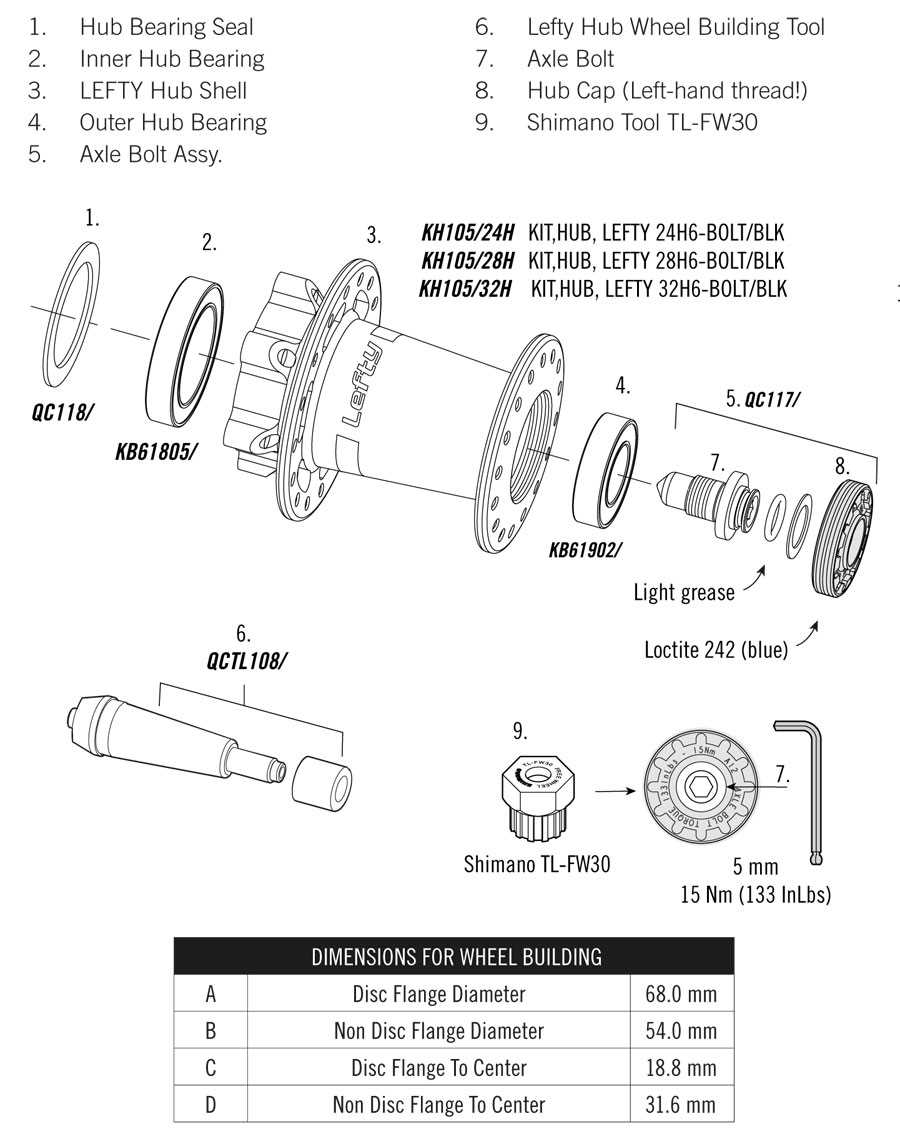

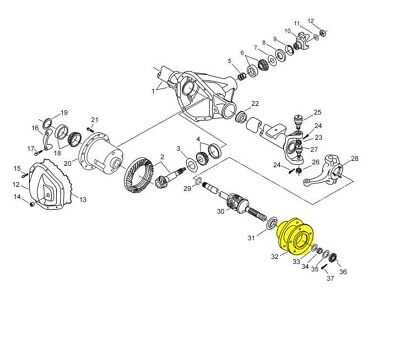

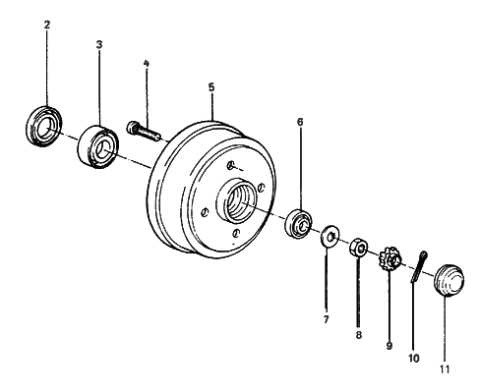

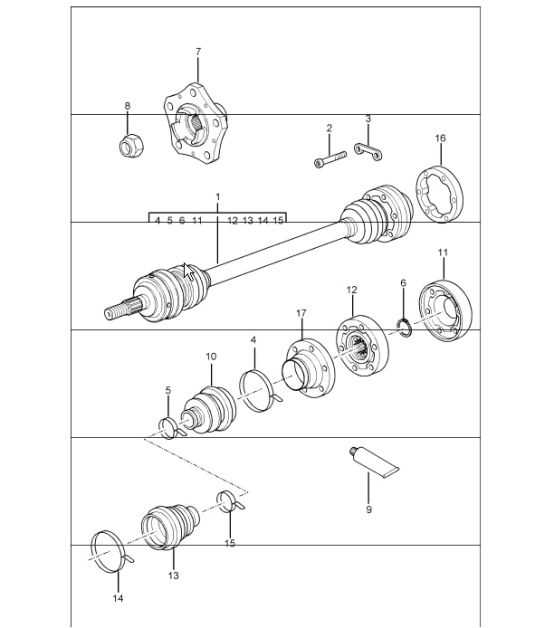

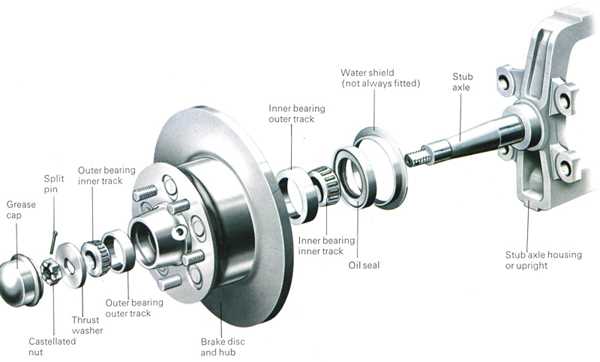

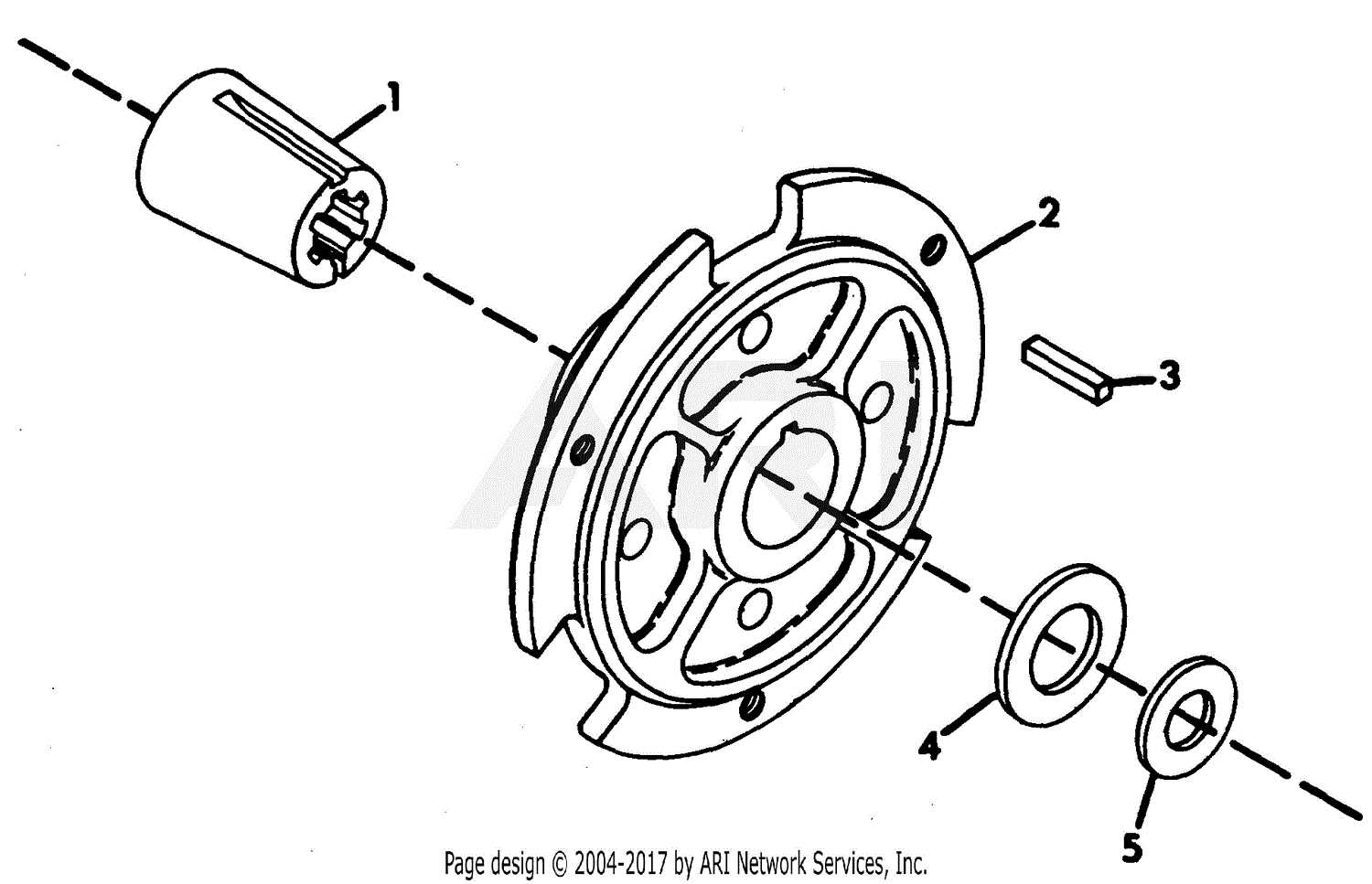

Essential Parts of a Wheel Hub

The components that make up the assembly which connects the axle to the rim play a crucial role in the overall functionality of a vehicle. These elements work in harmony to ensure smooth rotation, stability, and effective load distribution. Understanding these critical elements can enhance both maintenance practices and overall vehicle performance.

Key Components

The central piece of this assembly is often the bearing, which allows for smooth movement and reduces friction. Alongside it, the outer casing provides structural integrity, protecting internal mechanisms from dirt and debris. Fasteners secure the entire setup, ensuring that everything stays in place under various driving conditions.

Additional Elements

Seals are vital in preventing contaminants from entering the system, thereby prolonging the lifespan of the assembly. Furthermore, spacers and washers assist in maintaining proper alignment and spacing, contributing to the efficient operation of the entire unit. Together, these components create a reliable foundation for vehicle dynamics.

How Wheel Hubs Affect Performance

The components that facilitate the connection between the axle and the rims play a crucial role in vehicle dynamics. Their design and material influence not only the longevity of the assembly but also the overall driving experience. Understanding how these elements interact can lead to improved handling, efficiency, and safety on the road.

First and foremost, the quality of these elements directly impacts the rotational dynamics of the vehicle. Lightweight materials can enhance acceleration and braking efficiency, allowing for a more responsive driving experience. Conversely, heavier assemblies may hinder performance, leading to increased fuel consumption and slower response times.

Furthermore, proper alignment and smooth operation of these components reduce friction and wear, contributing to better tire longevity and improved grip. A well-engineered design minimizes vibration and noise, enhancing comfort for passengers while maintaining control during sharp turns and sudden maneuvers.

Ultimately, investing in high-quality options can yield significant benefits in terms of both performance and safety. By ensuring that these crucial connections are well-maintained and designed, drivers can enjoy a smoother, more controlled ride in various driving conditions.

Signs of Wheel Hub Failure

Identifying issues with the central components of your vehicle’s rotating assemblies is crucial for ensuring safety and performance. When these critical elements begin to fail, several noticeable symptoms may arise, alerting you to potential problems that require immediate attention.

Unusual Noises: One of the first indicators of trouble is often a distinct sound emanating from the area of the tires. A grinding, growling, or clicking noise during movement can suggest that internal mechanisms are wearing down or that bearings are becoming damaged.

Vibration: If you experience abnormal vibrations in the steering wheel or throughout the chassis while driving, this could signal that something is amiss with the rotating assemblies. These vibrations may intensify as speed increases, making them particularly concerning.

Uneven Tire Wear: An inspection of tire conditions may reveal uneven or excessive wear patterns. This can occur when the alignment is off due to issues with the central rotating elements, leading to premature tire degradation.

Play in the Wheel: Excessive movement when shaking the wheel can indicate that the connections are loosening or failing. This play may compromise the stability of the vehicle and should be addressed promptly.

Warning Lights: Modern vehicles are equipped with systems that can detect anomalies. If warning lights related to traction or stability control activate, it may be an indication of underlying issues with the essential components responsible for maintaining proper function.

Recognizing these signs early can help prevent more severe complications and ensure a safer driving experience. Regular inspections and maintenance are key to avoiding failure in these critical systems.

Tools for Wheel Hub Inspection

Ensuring the functionality and safety of rotational assemblies requires specific equipment and techniques. Proper tools facilitate thorough evaluations, allowing for the identification of wear and potential failures that could compromise performance.

Essential Equipment

Calipers are vital for measuring clearances and tolerances accurately. They help assess the condition of components, ensuring they meet necessary specifications. Additionally, torque wrenches ensure that fasteners are secured to the appropriate specifications, preventing over-tightening or loosening.

Diagnostic Instruments

Utilizing vibration analysis tools can reveal underlying issues not visible to the naked eye. These devices help detect anomalies in operation that might indicate wear or imbalance. Furthermore, bearing pullers are crucial for safely removing elements without causing damage, allowing for a comprehensive inspection.

Step-by-Step Hub Replacement Guide

This guide provides a comprehensive approach to replacing essential components that support vehicle movement. Following these steps will ensure a smooth and efficient process, enhancing overall performance.

Tools and Materials Needed

- Jack and jack stands

- Socket set

- Wrench set

- Lubricant

- New assembly

Replacement Process

- Begin by safely lifting the vehicle and securing it with jack stands.

- Remove the wheel to access the assembly.

- Unscrew the fastening elements connecting the component to the assembly.

- Carefully detach the old unit from its position.

- Install the new component, ensuring a secure fit.

- Reattach the wheel and lower the vehicle back to the ground.

- Test for functionality by taking a short drive.

Importance of Proper Lubrication

Effective lubrication is crucial for the smooth operation and longevity of any mechanical assembly. It minimizes friction and wear, ensuring components function harmoniously and efficiently over time.

Benefits of Adequate Lubrication

- Reduces friction and heat buildup.

- Prevents corrosion and rust formation.

- Enhances performance and responsiveness.

- Extends the lifespan of machinery.

Consequences of Neglecting Lubrication

- Increased wear and tear on moving components.

- Higher risk of mechanical failure.

- Decreased efficiency and productivity.

- Potential costly repairs and replacements.

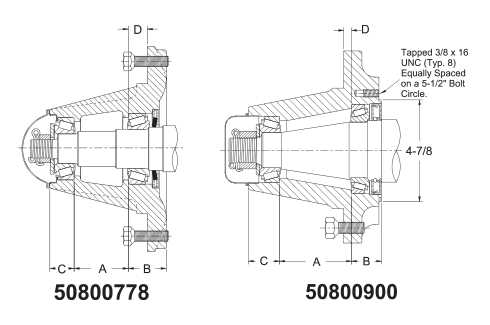

Differences in Hub Designs

Understanding the variations in design elements can greatly enhance the efficiency and performance of vehicles. These differences often stem from engineering choices made to optimize strength, weight, and functionality. By examining these characteristics, one can appreciate how they influence overall performance and user experience.

Types of Designs

There are several distinctive configurations that cater to specific applications. Each style presents unique advantages, tailored for various driving conditions and requirements.

| Design Type | Advantages | Applications |

|---|---|---|

| Conventional | Cost-effective, easy maintenance | Standard vehicles |

| Multi-piece | Customization, lightweight | Performance vehicles |

| Integrated | Reduced weight, increased strength | Luxury vehicles |

Material Choices

The selection of materials also plays a critical role in determining durability and performance. Different substances can alter weight distribution and resistance to wear, affecting longevity and efficiency.

Wheel Hub Maintenance Tips

Proper care of your vehicle’s central components is essential for longevity and optimal performance. Regular checks can prevent issues and enhance safety on the road. Here are key strategies to ensure these crucial elements remain in excellent condition.

Routine Inspections

Conducting regular examinations can help identify wear and tear before it escalates. Look for signs of damage or unusual noises during driving, which may indicate underlying problems.

Lubrication and Cleaning

Keeping these components clean and well-lubricated is vital. Dirt and debris can cause friction, leading to premature wear. Make sure to use appropriate lubricants and clean surfaces thoroughly during maintenance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 3 months | Check for cracks and wear |

| Cleaning | Every 6 months | Use mild detergents |

| Lubrication | Annually | Use manufacturer-recommended grease |

Future Trends in Hub Technology

The evolution of rotational assemblies is poised to transform the landscape of transportation and machinery. Innovations are expected to enhance efficiency, durability, and overall performance, leading to significant advancements in various industries. As technology progresses, the focus will shift towards integrating smart features and sustainable materials.

Smart Integration will play a crucial role in the future of these components. Sensors and connectivity will allow for real-time monitoring, providing data on wear and performance. This capability will facilitate predictive maintenance, reducing downtime and improving safety.

Another trend is the use of advanced materials. The shift towards lightweight and eco-friendly substances will not only enhance strength but also contribute to lower energy consumption. This change aligns with global sustainability goals, as manufacturers seek to minimize their environmental impact.

Additionally, modular designs are gaining traction. This approach allows for easier upgrades and replacements, promoting longevity and adaptability. By simplifying maintenance processes, industries can ensure optimal performance over time.

In summary, the future of rotational assemblies is bright, driven by technological innovations and a commitment to sustainability. As these trends unfold, they will redefine efficiency and performance standards across various applications.