Whirlpool WTW4616FW2 Parts Diagram Overview

In this guide, we will explore the internal structure of a well-known home appliance model. By diving into the detailed layout, you’ll gain insight into how different mechanisms work together to ensure efficient operation. The following sections will provide a clear and comprehensive look at the essential elements that keep the machine running smoothly.

Each section of the device is carefully crafted to perform a specific function. Understanding the placement and role of these elements can help with maintenance and troubleshooting. This overview will walk you through the arrangement and purpose of various crucial sections, offering a deeper understanding of their interactions.

For anyone looking to perform repairs or simply learn more about how their equipment operates, this breakdown will provide valuable information. From minor adjustments to more complex fixes, k

Overview of Whirlpool WTW4616FW2 Components

This section provides an outline of the various elements that work together to ensure the efficient operation of the appliance. Each part plays a specific role, contributing to the overall functionality and reliability of the unit.

Main Mechanical Elements

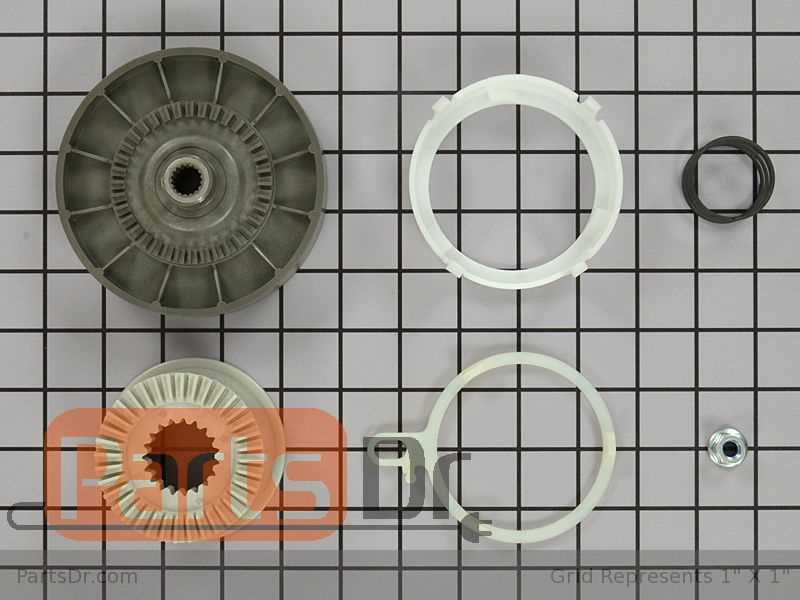

The system includes several core mechanisms that drive its performance. These include the motor, responsible for powering the movement, and various gears that manage the rotation and cycles. A belt connects the motor to other essential moving parts, ensuring smooth operation during every cycle.

Control and Monitoring Units

Alongside mechanical components, electronic units are crucial for regulating the functions. A central control board oversees the operations, processing user inputs and managi

Understanding the Drum Mechanism

The drum system plays a crucial role in the overall operation, ensuring effective and efficient handling of materials during the cycle. This section delves into the mechanics behind how the drum functions, allowing for proper distribution and movement within the system. By exploring these elements, we can better understand the importance of its design and operation.

Structure and Design

The drum’s design is engineered to balance durability with gentle handling of the contents. Made of sturdy materials, it rotates smoothly, aided by internal mechanisms that help create a consistent motion. The structural design prevents excessive wear while ensuring that the contents inside are treated carefully, avoiding damage during the cycle.

Movement and Functionality

The movement of the drum is controlled by a motor and a set of belts, ensuring a steady and reliable rotation. Proper alignment of these components

Water Inlet System Explained

The water inlet system in a washing appliance is responsible for managing the flow of water into the machine. It ensures that the correct amount of water enters the drum at the right pressure and temperature for effective cleaning. Understanding how this system operates can help in diagnosing potential issues with water flow and preventing further complications.

- Inlet Valves: These valves regulate the flow of water from the household supply into the machine. They open and close based on the machine’s requirements during the washing cycle.

- Temperature Control: The system allows for the mixing of hot and cold water to achieve the desired temperature for different fabric types and wash programs.

- Pressure Management: A pressure sensor monitors the water level

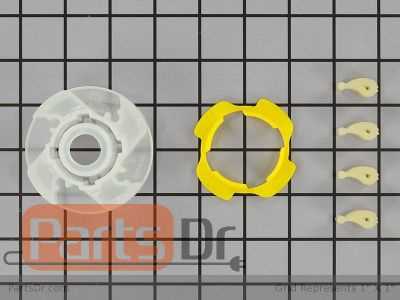

How the Agitator Functions

The agitator plays a crucial role in washing by creating movement within the laundry load, which helps to thoroughly clean the fabric. Its design ensures that clothes are lifted and rotated effectively, aiding in the removal of dirt and stains. This component works by utilizing various motions to enhance the overall washing process.

Agitator Mechanism

At the core of the agitator’s functionality is a set of rotations and shifts, which move the clothes through the water and detergent. These movements ensure even distribution of cleaning agents while also preventing clothes from tangling. The back-and-forth action generates friction between fabrics, which is essential for breaking down grime.

Benefits of the Agitator

This mechanism is especially beneficial for handling large or heavily soiled loads. It ensures a balanced wash cycle by continu

Control Panel Layout and Features

The control panel of this model is designed to provide easy access to all the essential functions and settings. It offers a user-friendly interface that allows for intuitive operation, ensuring that all available options are easily identifiable and accessible.

Buttons and Knobs: The layout includes multiple buttons and knobs, each assigned to a specific function. These components are strategically arranged to simplify the process of selecting the desired mode or adjusting the settings according to individual preferences.

Cycle Selection: A central feature of the panel is the ability to choose from various operational cycles. Each cycle is clearly labeled, offering a range of options to handle different types of tasks effectively.

Indicator Lights: Additionally, indicator lights are integrated into the design to provide real-time feedback on the machine’s status. These visual cues help the us

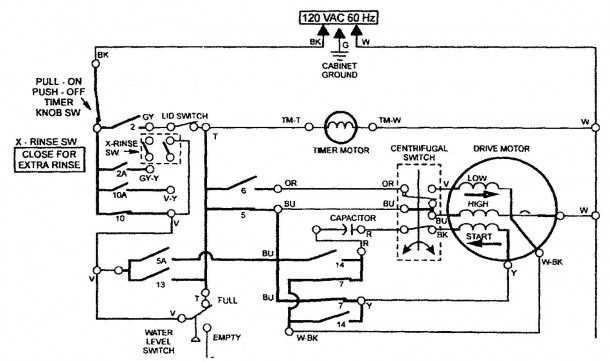

Identifying the Lid Switch Assembly

The lid switch assembly plays a crucial role in the operation of a washing machine. It serves as a safety mechanism that ensures the appliance functions only when the lid is closed. Understanding its components and how to locate them can greatly assist in troubleshooting issues related to machine performance.

Key Features of the Lid Switch Assembly

- Functionality: This assembly prevents the washing machine from running when the lid is open, ensuring safety during operation.

- Location: Typically situated beneath the lid or on the top of the cabinet, it can be accessed by removing the lid or the control panel.

- Components: It generally consists of the switch itself, a mounting bracket, and wiring harnesses that connect to the main control board.

Common Issues and Signs of Malfunction

- Machine does not start or stops mid-cycle, indicating a potential failure of the assembly.

- Erratic behavior during cycles, such as the drum moving without the lid being closed.

- Visible damage to the switch or wires, which can be inspected upon access.

By familiarizing oneself with the lid switch assembly and its functions, users can effectively diagnose problems and take appropriate actions to ensure proper machine operation.

Drive Motor and Its Role

The drive motor serves as a crucial component in the functionality of laundry appliances, facilitating the necessary movements for efficient cleaning. It transforms electrical energy into mechanical energy, allowing the machine to perform various cycles, such as washing and spinning.

Key functions of the drive motor include:

- Enabling the rotation of the drum, which is essential for agitating and cleaning garments.

- Providing variable speeds to accommodate different washing modes, ensuring optimal performance for various fabric types.

- Enhancing energy efficiency by adjusting power consumption based on the selected cycle.

The effectiveness of the drive motor is pivotal for achieving desired washing outcomes, making it an integral part of the appliance’s design. Proper maintenance and occasional checks can prolong its lifespan, ultimately ensuring consistent performance over time.

Examining the Suspension System

The suspension system plays a crucial role in maintaining the balance and stability of the appliance during operation. Its primary function is to absorb vibrations and prevent excessive movement, ensuring that the unit remains stable while performing its tasks. A well-functioning suspension mechanism contributes significantly to the overall efficiency and longevity of the machine.

Components of the Suspension Mechanism

This system consists of several key components that work together to provide optimal support and stability. Each part is designed to absorb shocks and minimize the impact of motion, which can affect the performance of the appliance.

Component Description Springs These provide the necessary tension and flexibility to absorb shocks and vibrations during operation. Shock Absorbers These dampen the vibrations produced by the appliance, enhancing stability and performance. Mounting Brackets These secure the suspension components in place, ensuring proper alignment and function. Importance of Maintenance

Regular maintenance of the suspension system is essential to prevent wear and tear, which can lead to operational issues. Checking for signs of damage or fatigue in the components can help ensure that the appliance functions smoothly and efficiently for years to come.

Pump and Drainage System Overview

The pump and drainage mechanism plays a crucial role in maintaining the efficiency of any washing apparatus. This system is responsible for removing excess water from the drum after a wash cycle, ensuring that the laundry is effectively cleaned and prepared for drying. Understanding its components and functionality is essential for troubleshooting and maintenance.

Components of the System: The assembly typically consists of a motor-driven pump, drainage hoses, and various valves. Each component works in unison to facilitate the smooth expulsion of water. The pump creates the necessary pressure to move water through the hoses, while the valves regulate the flow and prevent backflow.

Functionality: When a wash cycle concludes, the control unit activates the pump, initiating the drainage process. Water is drawn from the drum and pushed through the drainage hoses, leading to a designated outlet. This operation is vital for avoiding overflow and ensuring optimal washing performance.

Regular inspection and maintenance of the pump and drainage components are recommended to prevent clogs and operational issues. Proper functioning of this system enhances the overall longevity and reliability of the appliance.

How to Replace the Drive Belt

Replacing the drive belt in your washing machine is an essential maintenance task that ensures smooth operation. A worn or damaged belt can lead to inefficient washing and increased noise levels. This guide will walk you through the steps to replace the drive belt effectively.

Before starting, gather the necessary tools, including a screwdriver, pliers, and a new drive belt compatible with your appliance. Ensure the machine is unplugged to prevent any electrical hazards during the replacement process.

Step Description 1 Remove the back panel of the appliance by unscrewing the screws to access the inner components. 2 Locate the old drive belt; it may be loose or snapped. Carefully detach it from the motor and drum pulleys. 3 Take the new drive belt and position it around the drum pulley first, followed by the motor pulley. 4 Ensure the belt is aligned properly and has the correct tension by manually rotating the drum to check for any obstructions. 5 Reattach the back panel securely and plug the machine back in to test its functionality. Following these steps will help you successfully replace the drive belt, restoring the machine’s performance and extending its lifespan.

Safety Precautions for Part Replacement

When undertaking the task of replacing components in any appliance, it is crucial to prioritize safety to prevent accidents and ensure effective repairs. Adhering to proper safety guidelines can significantly reduce the risk of injury and damage during the replacement process.

Preparation and Environment

Before beginning the replacement, ensure that the working area is clean and organized. Clear away any unnecessary tools or materials that may pose a tripping hazard. Additionally, it’s important to disconnect the appliance from its power source to avoid electrical shock. Using gloves can also protect your hands from sharp edges or potential contaminants.

Using the Right Tools

Utilizing the correct tools for the task at hand is essential for both efficiency and safety. Ensure that all tools are in good condition and suitable for the specific job. Improvised tools can lead to accidents or ineffective repairs, so it is wise to invest in quality equipment that will help facilitate the replacement process.