Understanding the Jeep Wrangler Front Axle Parts Diagram

The intricacies of a vehicle’s suspension assembly play a crucial role in its performance and handling. A well-designed system not only enhances stability but also ensures a smooth ride across various terrains. Familiarity with the various elements involved can empower owners to make informed decisions regarding maintenance and upgrades.

In this section, we will delve into the specific components that constitute a key part of the suspension mechanism. Each component serves a distinct function, contributing to the overall efficacy of the vehicle. Recognizing these elements will provide insight into how they interact to deliver optimal performance under different driving conditions.

Additionally, understanding the configuration of these components can aid in troubleshooting common issues that may arise. Whether you’re an enthusiast looking to modify your ride or a casual driver aiming to enhance longevity, knowledge of these critical elements is invaluable. Let’s explore these foundational components and their roles in ensuring an exceptional driving experience.

Understanding Jeep Wrangler Axles

When exploring the world of off-road vehicles, it’s essential to grasp the fundamentals of the vehicle’s wheel drive system. The components responsible for transmitting power from the engine to the wheels play a crucial role in performance, stability, and handling on various terrains. A deep understanding of these elements can significantly enhance your ability to maintain and upgrade your vehicle.

In this section, we will delve into the key components and functions that define the wheel drive system. Here are some essential aspects to consider:

- Construction: The design often includes a sturdy structure, ensuring resilience against rough conditions.

- Functionality: These components work together to provide torque, enabling effective traction and control.

- Types: There are various configurations available, each offering distinct advantages depending on the intended use.

Furthermore, maintenance is crucial for optimal performance. Regular inspections can help identify wear and tear, ensuring reliability in challenging environments. Key maintenance practices include:

- Regular fluid checks to ensure lubrication efficiency.

- Visual inspections for signs of damage or corrosion.

- Replacement of worn components to prevent further issues.

Understanding these aspects will empower you to make informed decisions regarding upgrades and repairs, ultimately enhancing your driving experience in rugged landscapes.

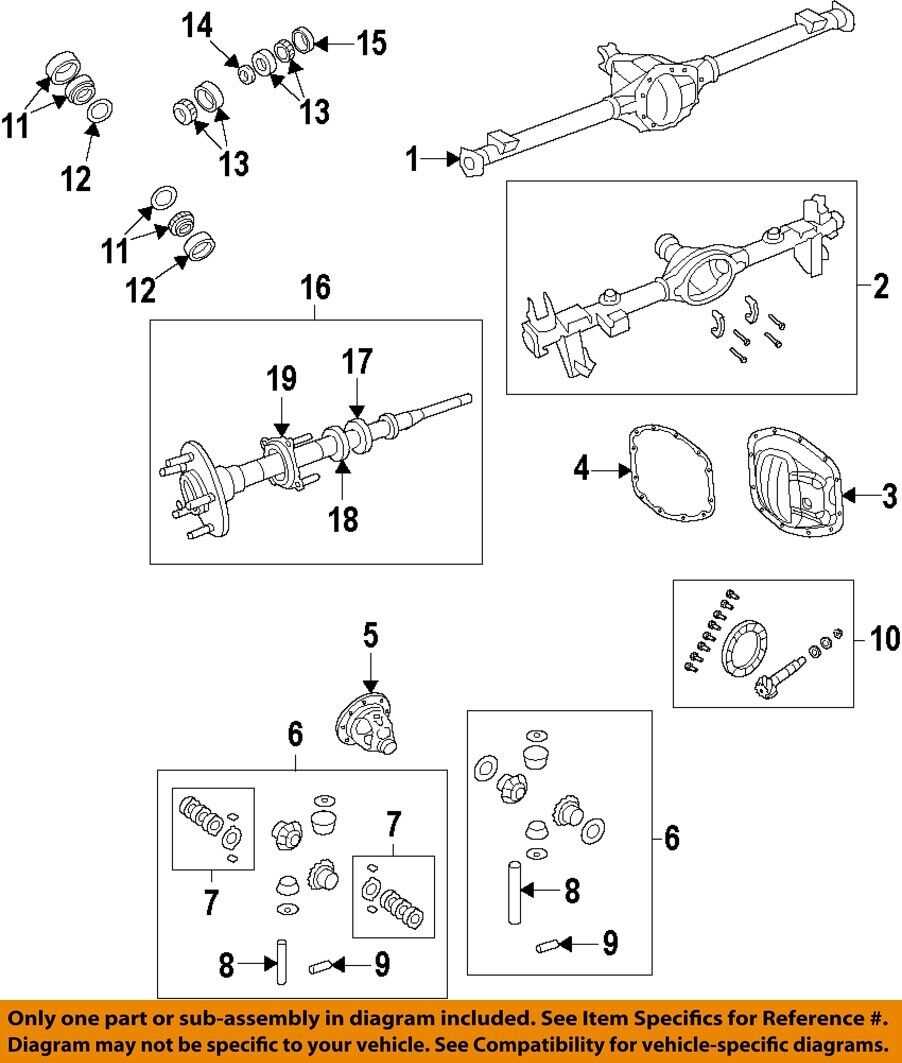

Key Components of Front Axle

The front assembly of a vehicle plays a crucial role in its overall functionality and performance. This intricate system is comprised of various elements that work together to ensure stability, handling, and power delivery to the wheels. Understanding these essential components can enhance maintenance efforts and improve vehicle longevity.

Main Elements

- Differential: A crucial component that allows for the distribution of power to the wheels while accommodating differences in wheel speed during turns.

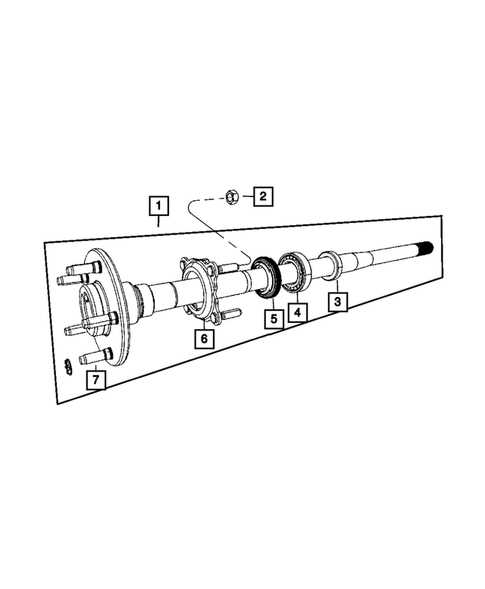

- Hub Assembly: Houses the wheel bearings and is integral for connecting the wheels to the vehicle, allowing for smooth rotation.

- Spindle: Connects the wheel hub to the suspension system, enabling steering and support for the weight of the vehicle.

- Control Arms: Link the chassis to the wheels, providing stability and facilitating vertical movement of the suspension.

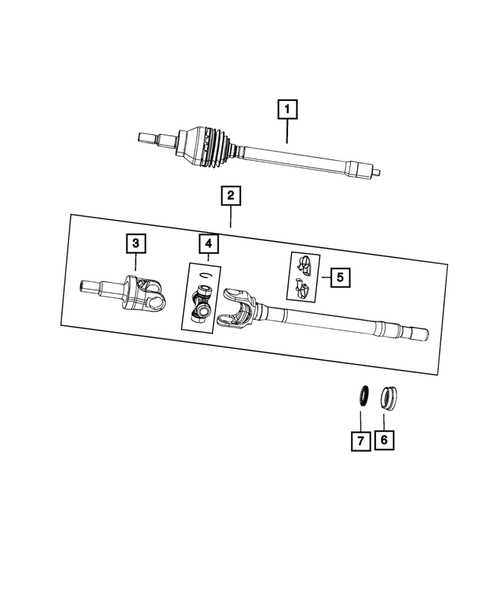

- CV Joints: Allow for flexible movement and torque transfer from the transmission to the wheels, accommodating the suspension’s travel.

Supporting Structures

- Steering Knuckle: Connects the spindle to the control arms, playing a vital role in steering precision.

- Drag Link: Transmits motion from the steering gear to the wheels, influencing steering responsiveness.

- Track Bar: Stabilizes the axle, ensuring proper alignment and reducing lateral movement during driving.

- Ball Joints: Allow for movement between the control arms and steering knuckles, providing flexibility and maintaining alignment.

Familiarity with these fundamental components can empower vehicle owners to make informed decisions about maintenance and upgrades, ensuring optimal performance and safety on the road.

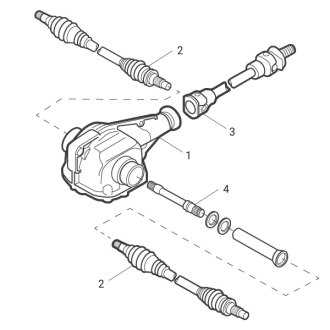

Functions of Each Axle Part

The components of a vehicle’s drive system play a crucial role in ensuring optimal performance and stability. Each element is designed with specific functions that contribute to the overall efficiency of the machine, allowing for smooth navigation over various terrains.

Main Elements and Their Roles

- Center Differential: This mechanism allows for variations in wheel speed between the left and right sides, enabling the vehicle to navigate turns without losing traction.

- Drive Shafts: These components transmit power from the engine to the wheels, ensuring that the vehicle moves forward efficiently.

- Hub Assemblies: Housing the wheel bearings, these units support the wheels and allow for smooth rotation during movement.

- Gear Sets: These mechanical assemblies alter the torque and speed transmitted to the wheels, providing the necessary power for different driving conditions.

- Knuckles: Acting as pivot points, these parts connect the steering mechanism to the suspension, allowing for effective handling and maneuverability.

Importance of Proper Functioning

Each element must operate seamlessly to ensure reliable performance. Regular maintenance and timely replacement of worn-out components are essential to maintain the vehicle’s handling and safety. Understanding the function of these parts helps in diagnosing issues and improving overall driving experience.

Common Issues with Front Axles

Mechanical components that facilitate motion can experience various complications over time. Understanding these frequent issues can aid in their identification and resolution, ensuring a smoother ride and enhanced performance. Below are some of the prevalent problems encountered with these essential systems.

Wear and Tear

One of the most common challenges is the gradual degradation of components due to prolonged use. This can manifest in several ways:

- Worn bearings leading to excessive play

- Deterioration of seals, causing leaks

- Damaged shafts affecting overall alignment

Alignment Issues

Misalignment can result from impacts or incorrect adjustments. Symptoms may include:

- Uneven tire wear

- Difficulty steering or tracking straight

- Unusual noises during operation

Regular inspections and maintenance can mitigate these concerns, prolonging the lifespan of the crucial mechanical systems.

Upgrading Jeep Wrangler Axle Parts

Enhancing the performance of your vehicle’s undercarriage components can significantly improve its handling and durability. By investing in high-quality upgrades, you can boost the overall functionality and resilience of your off-road machine. This section explores various options available for elevating your vehicle’s lower assembly.

When considering enhancements, it’s essential to evaluate the following aspects:

- Material Quality: Upgrading to stronger materials can prevent premature wear and enhance longevity.

- Gear Ratios: Modifying gear ratios can improve torque and traction, providing better control in rugged environments.

- Lubrication Systems: Improved lubrication can reduce friction, ensuring smoother operation and extending component life.

Below are some popular enhancements to consider:

- Heavy-Duty Differentials: Opting for reinforced differentials can handle increased loads and provide better power distribution.

- Upgraded Spindles: Enhanced spindles improve strength and stability, crucial for handling rough terrains.

- Performance Shafts: Investing in high-performance shafts can deliver superior power transfer and durability.

- High-Clearance Suspension: Adjusting the suspension setup can increase ground clearance, allowing for more aggressive off-road capability.

Ultimately, the choice of upgrades will depend on your specific driving needs and conditions. By carefully selecting enhancements, you can optimize your vehicle’s performance, making it more capable of tackling any challenge on and off the road.

Comparison of Axle Types

When evaluating different types of driveline systems, it is essential to understand their unique characteristics and functionalities. Various configurations offer distinct advantages, affecting performance, durability, and handling capabilities. By exploring the differences among these configurations, one can make informed decisions based on specific needs and applications.

The solid assembly, often found in off-road applications, provides exceptional strength and stability. Its rigid structure allows for better load distribution and enhanced traction on uneven surfaces. Conversely, the independent variety offers improved ride quality and maneuverability, making it a popular choice for on-road vehicles. This design reduces body roll and enhances comfort, particularly during cornering.

Another configuration worth mentioning is the semi-floating design, which strikes a balance between robustness and flexibility. This type is commonly used in light to medium-duty applications, providing sufficient support while allowing for some movement. Each design has its own set of trade-offs, which can significantly influence the overall performance and reliability of the vehicle.

Maintenance Tips for Front Axles

Proper care and attention to critical components of your vehicle’s drivetrain are essential for ensuring optimal performance and longevity. Regular inspection and maintenance can prevent unexpected failures and costly repairs. By following a few straightforward guidelines, you can keep these essential elements functioning smoothly.

1. Regular Inspections: Consistently examine the key elements for signs of wear or damage. Look for any leaks, unusual noises, or abnormal vibrations while driving. Early detection can save you time and money.

2. Lubrication: Ensure that all necessary joints and bearings are well-lubricated to reduce friction and prevent premature wear. Use the appropriate grease or oil as specified in your vehicle’s manual.

3. Alignment Checks: Maintaining proper alignment is crucial for even wear and tear. Misalignment can lead to handling issues and further complications. Consider having it checked at regular intervals.

4. Tire Maintenance: Keep an eye on tire pressure and tread depth. Uneven wear can affect the entire drivetrain system. Rotate your tires regularly to promote even wear.

5. Addressing Noise: If you hear any clunking or grinding sounds, it may indicate a problem within the assembly. Do not ignore these noises; investigate promptly to avoid more severe damage.

6. Replace Worn Components: Be proactive about replacing any worn or damaged components before they fail. This includes seals, bearings, and any other crucial elements that may degrade over time.

By adhering to these maintenance tips, you can ensure that your vehicle operates smoothly and efficiently, extending its lifespan and enhancing your driving experience.

How to Diagnose Axle Problems

Identifying issues within the drivetrain system is essential for maintaining vehicle performance and safety. Common symptoms can manifest as unusual noises, vibrations, or handling difficulties. A systematic approach to diagnosis can help pinpoint the source of these concerns and ensure timely repairs.

Signs of Trouble

- Unusual Noises: Listen for clunking, grinding, or clicking sounds when turning or accelerating.

- Vibrations: Pay attention to any abnormal shaking felt in the steering wheel or throughout the vehicle.

- Handling Issues: Notice if the vehicle pulls to one side or exhibits difficulty in steering response.

Diagnostic Steps

- Inspect for Leaks: Check for any fluid leaks underneath the vehicle, which may indicate a seal or gasket failure.

- Visual Examination: Look for damaged components, such as worn boots, cracked housings, or misaligned assemblies.

- Road Test: Take the vehicle for a test drive to replicate symptoms and determine when they occur.

- Check Alignment: Ensure that the wheel alignment is correct, as misalignment can exacerbate handling problems.

- Consult a Professional: If issues persist, seek assistance from a qualified technician for a thorough evaluation.

Installation Guide for Axle Components

This section provides a comprehensive overview of the installation process for essential components of the vehicle’s suspension system. Proper assembly is crucial for ensuring optimal performance, durability, and safety. Following this guide will help you navigate the complexities of the installation, allowing for a smoother and more efficient procedure.

Preparation is key before starting the installation. Gather all necessary tools and components to avoid interruptions during the process. Ensure that you have a clean workspace and proper lighting to facilitate your work. It is also advisable to review the manufacturer’s instructions to familiarize yourself with specific requirements for your vehicle model.

Begin by removing any existing components carefully. Utilize appropriate tools to disassemble parts without causing damage. Keep track of all fasteners and hardware, as they will be needed during reassembly. Once the old components are removed, inspect the surrounding areas for any signs of wear or damage, addressing any issues before proceeding.

Next, install the new components according to the specifications provided. Follow the sequence recommended by the manufacturer to ensure a proper fit and function. It is crucial to secure all fasteners to the specified torque settings to maintain integrity and safety during operation.

After installation, perform a thorough inspection of the entire assembly. Check for any loose connections and ensure that everything is aligned correctly. It is also beneficial to take the vehicle for a test drive, monitoring for any unusual noises or behaviors, which could indicate a need for further adjustment.

Regular maintenance of these components is vital for long-term performance. Establish a schedule for inspections and adjustments to ensure that everything remains in optimal condition.

Tools Needed for Axle Repairs

Performing maintenance or repairs on a vehicle’s suspension and drive components requires the right equipment to ensure efficiency and safety. Having a well-prepared toolkit can significantly streamline the repair process, allowing for a smoother experience and optimal results.

- Wrenches: A variety of sizes, including both standard and metric, are essential for loosening and tightening bolts.

- Socket Set: A comprehensive socket set with extensions will help reach difficult areas and provide greater torque.

- Jack and Jack Stands: A reliable hydraulic jack, along with sturdy jack stands, is crucial for lifting the vehicle securely.

- Pry Bars: Useful for separating components that may be stuck together due to corrosion or wear.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Breaker Bar: Provides extra leverage for loosening stubborn fasteners.

- Impact Gun: Speeds up the process of removing and installing bolts, especially those that are rusted or corroded.

- Cleaning Supplies: Degreasers and brushes help clean components and surfaces before assembly.

- Safety Gear: Always wear gloves, goggles, and protective clothing to ensure personal safety during repairs.

Having these essential tools at your disposal will enhance your ability to effectively perform necessary repairs, leading to improved vehicle performance and longevity.

Expert Advice on Axle Performance

Understanding the functionality and reliability of your vehicle’s drivetrain components is essential for optimal performance. Proper maintenance and selection of quality components can significantly enhance the efficiency and durability of these critical systems. Below, we share key insights and recommendations for maximizing performance.

Key Considerations for Optimal Functionality

- Quality of Components: Always opt for high-grade materials when replacing or upgrading any drivetrain components. This ensures longevity and reliability.

- Regular Inspections: Conduct routine checks for wear and tear. Identifying issues early can prevent more extensive damage and costly repairs.

- Lubrication: Keep all moving elements properly lubricated to reduce friction and heat buildup, which can lead to premature failure.

Upgrading for Enhanced Performance

- Choose the Right Ratio: Selecting the appropriate gear ratio can enhance torque delivery and fuel efficiency, especially in demanding driving conditions.

- Consider Heavy-Duty Options: If you frequently navigate challenging terrains, investing in heavy-duty alternatives can provide added strength and resilience.

- Consult with Experts: Engage with professionals who can offer tailored advice based on your vehicle’s specific needs and your driving habits.

By following these guidelines, you can ensure that your vehicle operates at its best, providing you with a reliable and enjoyable driving experience.