Yamaha Bravo Parts Overview

When it comes to maintaining and enhancing your vehicle’s performance, a comprehensive grasp of its individual components is essential. This section aims to provide a detailed exploration of the various elements that make up the machinery, allowing enthusiasts and owners to navigate their maintenance and repairs more effectively.

Having a clear visual representation of each component not only aids in identifying parts but also facilitates smoother troubleshooting and replacement processes. This knowledge empowers users to make informed decisions, ensuring that their vehicle remains in optimal condition for all adventures on the road.

Whether you’re a seasoned mechanic or a novice, understanding the layout and function of each part can significantly impact the overall experience. By familiarizing yourself with these crucial elements, you can enhance your proficiency in vehicle upkeep and enjoy the journey ahead.

This section provides an introduction to a well-known recreational vehicle, highlighting its essential components and features. Understanding the construction and functionality of this machine is crucial for enthusiasts and maintenance practitioners alike. The insights shared here will pave the way for further exploration of specific elements, ensuring a comprehensive grasp of the overall system.

- General Features and Specifications

- Engine Mechanism and Functionality

- Chassis Structure and Design

- Transmission System Overview

- Fuel Delivery and Ignition Components

- Suspension System Insights

- Braking Mechanisms and Safety Features

- Electrical System Components

- Cooling System Essentials

- Maintenance Tips for Longevity

- Common Issues and Troubleshooting Guide

Key Components of Yamaha Bravo

The essential elements of this snowmobile play a significant role in ensuring its performance and reliability. Understanding these components can help users appreciate how each part contributes to the overall functionality and operation of the vehicle.

One of the primary features is the engine assembly, which provides the necessary power for acceleration and maneuverability. The cooling system is vital in maintaining optimal temperatures during operation, preventing overheating and ensuring efficient performance.

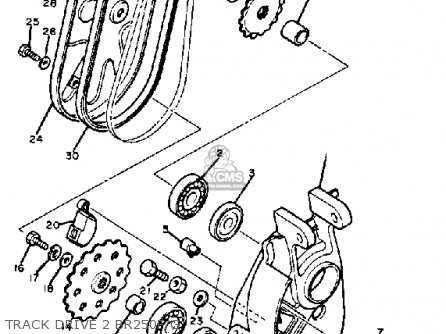

The chassis supports the entire structure and contributes to stability and handling, while the track system allows for smooth movement across various terrains. Additional elements such as the electrical system are crucial for starting the engine and powering accessories, enhancing the overall experience for the operator.

Each component works in harmony with others, creating a seamless driving experience and showcasing the engineering excellence behind this particular model.

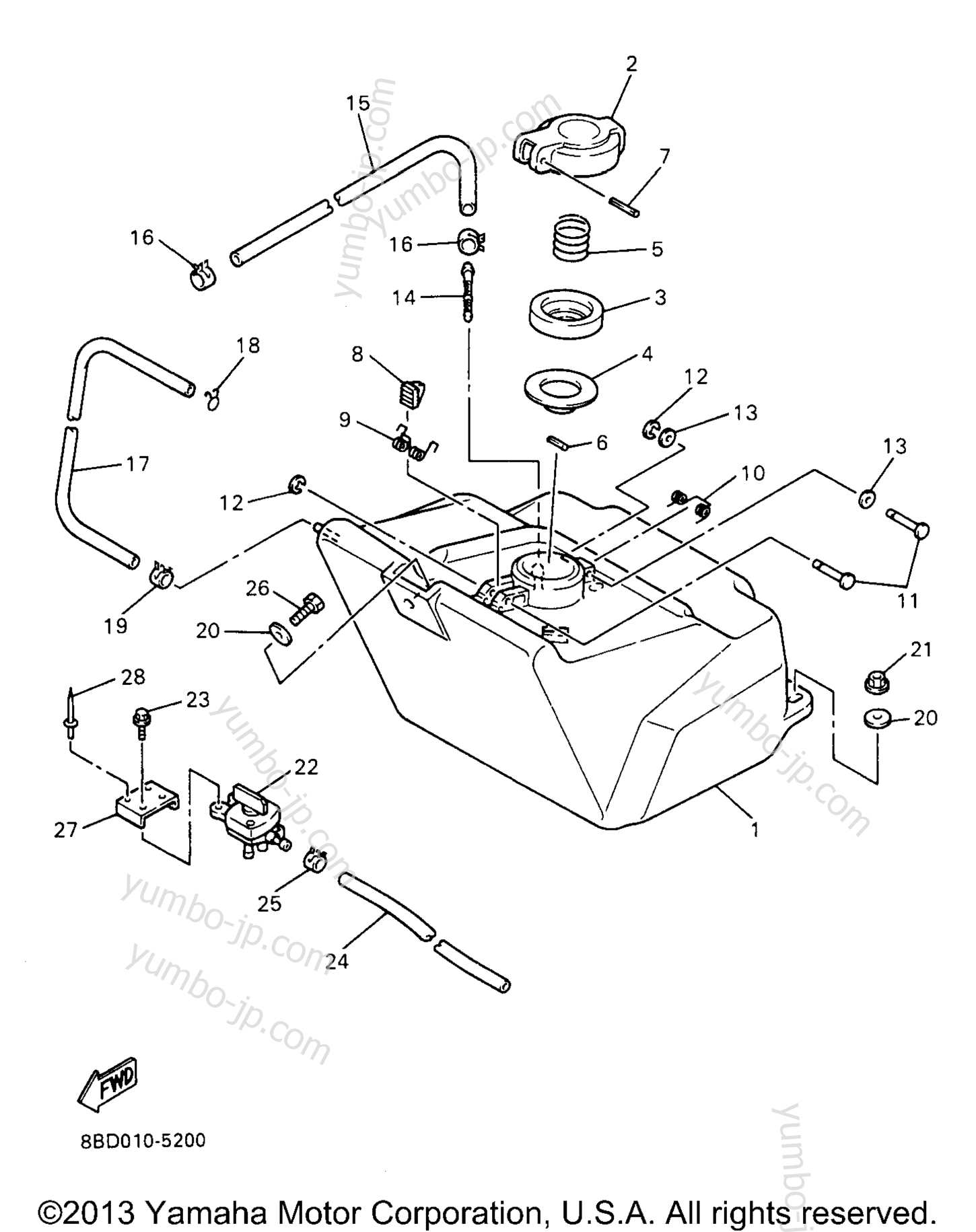

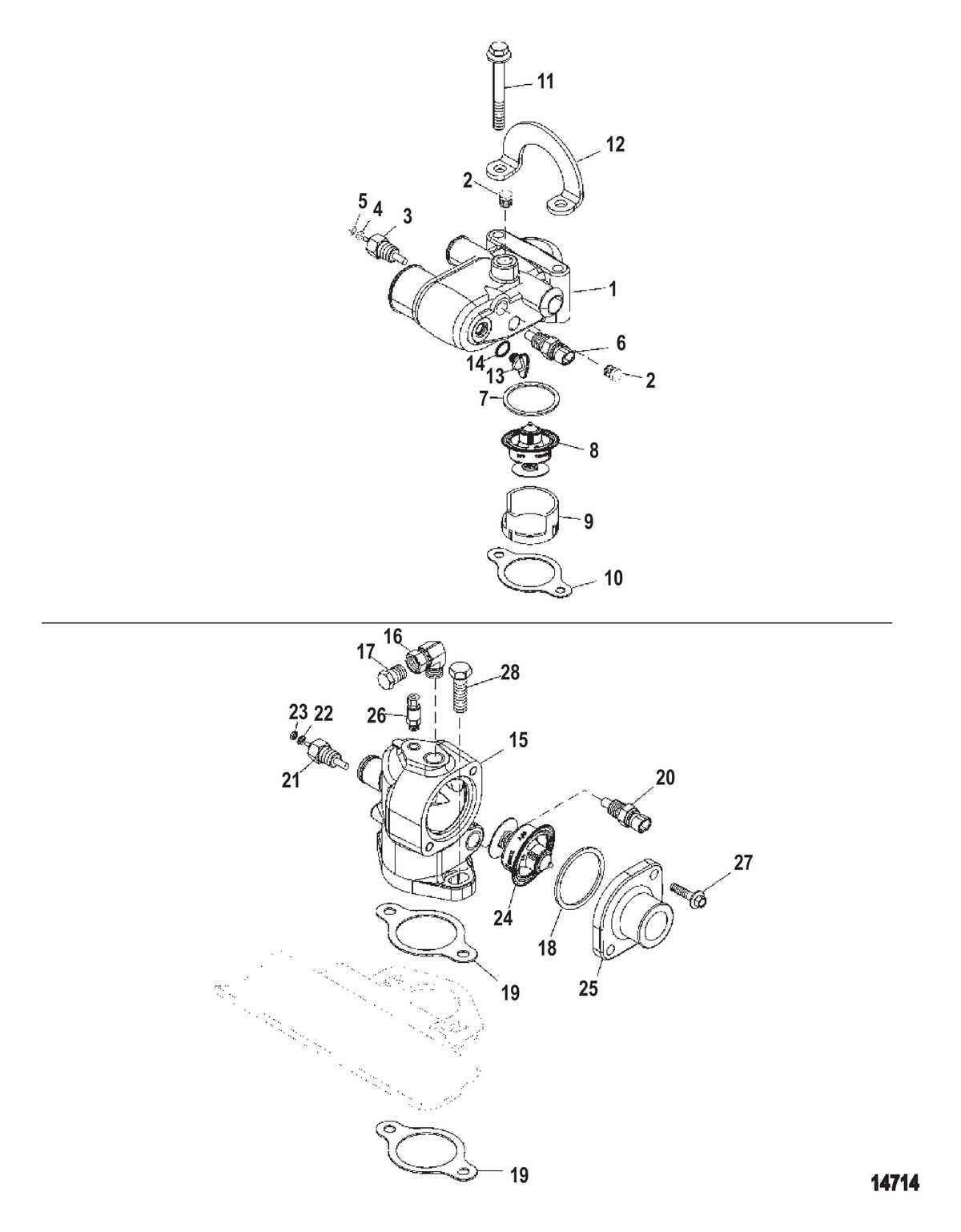

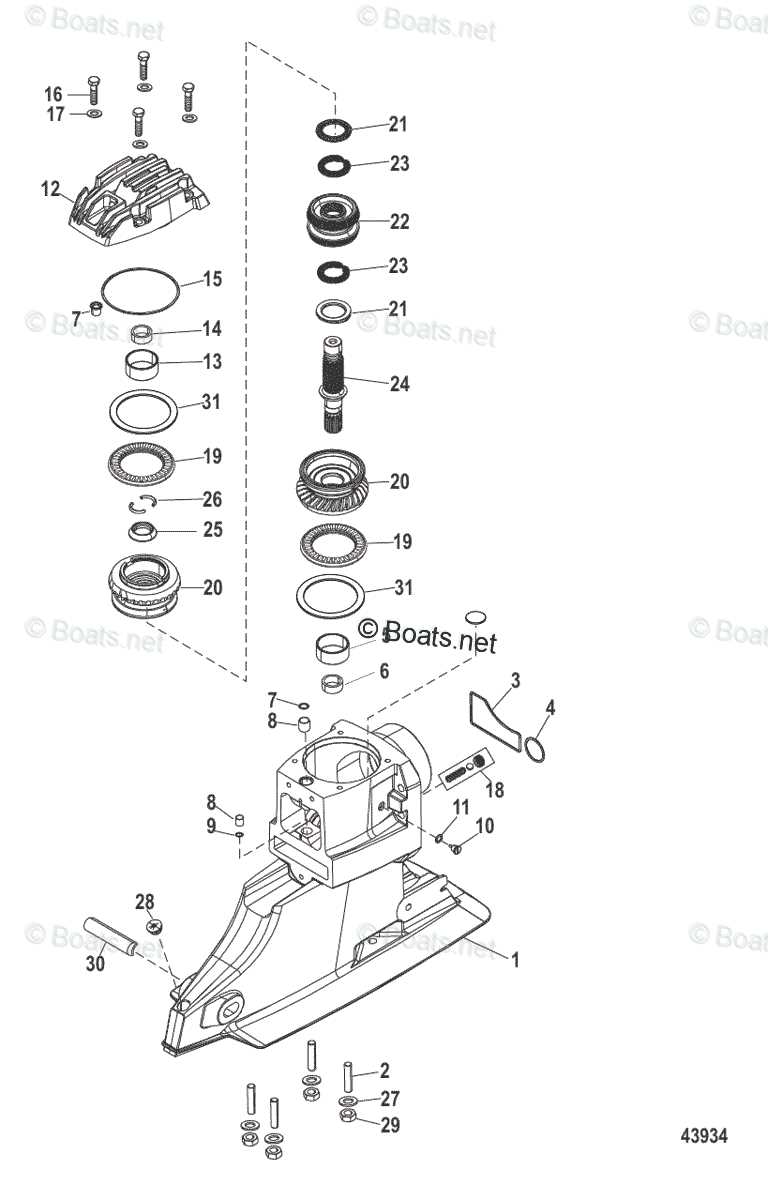

Understanding the Parts Diagram

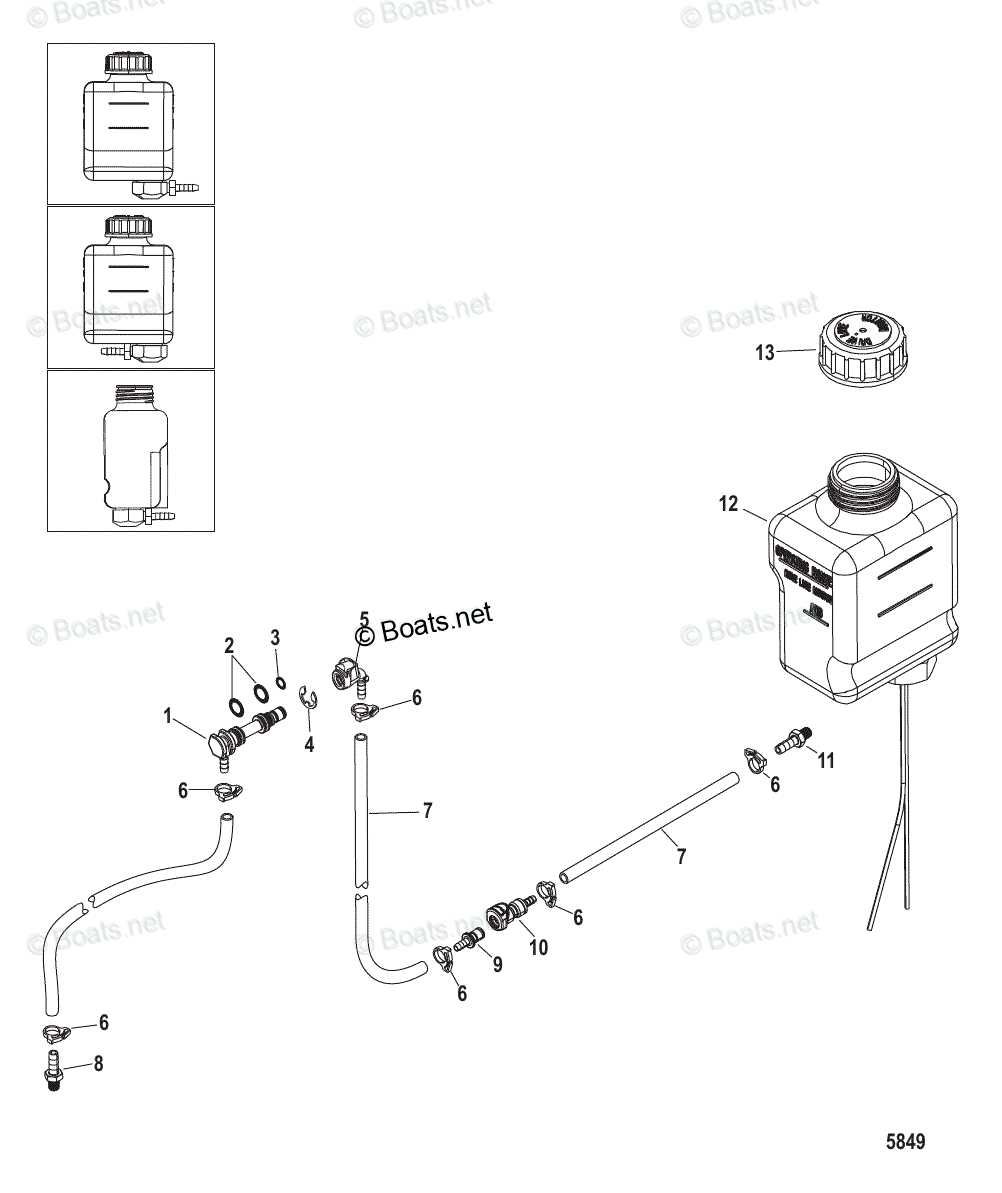

The visual representation of components is essential for comprehending the assembly and functionality of any machinery. Such illustrations serve as a valuable guide, helping users identify each element’s role within the overall structure. By familiarizing oneself with these representations, one can enhance maintenance practices and facilitate repairs.

These detailed graphics typically categorize the various elements into logical sections, enabling quick reference and easier navigation. Understanding these classifications is crucial for effective troubleshooting and assembly, ensuring that each piece fits seamlessly into the larger system.

| Component | Description |

|---|---|

| Engine | The core unit responsible for generating power. |

| Transmission | Transmits power from the engine to the wheels. |

| Chassis | The framework that supports all other components. |

| Fuel System | Delivers fuel to the engine for combustion. |

Maintenance Tips for Yamaha Bravo

Regular upkeep is essential to ensure optimal performance and longevity of your snow vehicle. Following specific guidelines helps maintain functionality, enhances safety, and minimizes unexpected repairs. Here are some fundamental practices to consider for effective maintenance.

Routine Inspections

Conduct frequent evaluations of the vehicle’s key components. This includes checking the brakes, lights, and engine systems. Addressing any irregularities promptly can prevent larger issues from developing.

Fluid Levels and Condition

Monitoring and maintaining proper fluid levels is crucial. Ensure that engine oil, coolant, and fuel are at recommended levels and are in good condition. Regularly change fluids as per the manufacturer’s recommendations to keep the vehicle operating smoothly.

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Brakes | Every ride | Check for wear and functionality |

| Oil | Every 500 miles | Change if dirty or low |

| Filters | Every season | Replace as necessary |

| Lights | Every ride | Test functionality |

Common Issues and Solutions

Understanding typical challenges faced by users of specific machines can greatly enhance maintenance and performance. By identifying common problems and their remedies, owners can ensure optimal functionality and longevity of their equipment.

Here are some frequent issues and their respective solutions:

- Starting Difficulties:

- Check the fuel level and quality; old or contaminated fuel may cause issues.

- Inspect the battery for charge and corrosion; a weak battery can prevent starting.

- Examine the ignition system for faults, including spark plug condition.

- Unusual Noises:

- Identify any loose components that may need tightening or replacement.

- Listen for abnormal sounds from the engine, indicating potential mechanical failure.

- Regularly lubricate moving parts to minimize friction and noise.

- Overheating:

- Ensure proper coolant levels and check for leaks in the cooling system.

- Clean air filters to maintain airflow and prevent overheating.

- Verify that the radiator is functioning effectively, without blockages.

- Performance Issues:

- Regularly service the air and fuel filters to improve efficiency.

- Monitor tire pressure and condition to ensure proper traction and handling.

- Inspect belts and hoses for wear, replacing them as necessary.

How to Interpret the Diagram

Understanding a schematic representation can greatly enhance your ability to navigate through the components of a mechanical system. This visual guide serves as a map, illustrating the relationship between various elements, their functions, and how they interact within the overall framework.

Begin with Familiarization: Take time to familiarize yourself with the key symbols and notations used in the illustration. Each symbol corresponds to a specific part, and understanding these will allow you to identify components accurately.

Follow the Flow: Trace the connections represented in the visual. Notice how different elements are linked and how the flow of operation is depicted. This can provide insight into the sequence of actions and the dependencies among parts.

Consult the Legend: If available, refer to the accompanying legend or key. This section typically explains the meaning of various symbols and colors, aiding in a clearer interpretation of the illustration.

Focus on Groupings: Components are often organized into clusters that indicate functionality. Pay attention to these groupings as they can help you understand the system’s overall operation and maintenance needs.

Practice Makes Perfect: The more you study such visual representations, the more intuitive your understanding will become. Regular practice will enhance your ability to quickly interpret and utilize these resources effectively.

Ordering Replacement Parts

When it comes to maintaining and repairing your vehicle, obtaining suitable components is crucial for optimal performance and longevity. Ensuring you have the right items can save time and prevent potential issues down the line. This section will guide you through the process of acquiring the necessary replacements effectively.

Here are some steps to consider when placing an order:

- Identify the Needed Component: Accurately determine which item requires replacement. Refer to your vehicle’s documentation or consult a professional if unsure.

- Research Suppliers: Look for reputable retailers or online shops that specialize in automotive supplies. Verify their reliability through customer reviews and ratings.

- Check Availability: Ensure that the specific component you need is in stock. It’s advisable to confirm the estimated delivery time as well.

- Compare Prices: Before finalizing your order, compare prices across different vendors to ensure you’re getting the best deal.

- Review Return Policies: Familiarize yourself with the return and exchange policies of the supplier in case the item does not meet your expectations.

By following these steps, you can streamline the process of obtaining replacement components, ensuring your vehicle remains in top condition.

Identifying OEM vs. Aftermarket Parts

When maintaining or upgrading a vehicle, understanding the distinction between original equipment and alternative components is crucial. This knowledge can significantly impact the performance, durability, and overall experience of ownership. The choice between these options often involves considerations of quality, cost, and compatibility.

Original Equipment Manufacturer (OEM) Components

OEM components are produced by the same manufacturer that created the original parts for the vehicle. These items are designed to meet the same specifications and standards as those initially installed. They typically offer reliability and are often backed by a warranty, ensuring a certain level of quality and performance.

Aftermarket Components

Aftermarket components, on the other hand, are produced by third-party manufacturers. These items can vary widely in terms of quality and price, offering consumers a broader range of options. While some aftermarket options may provide superior performance or additional features, others may lack the same level of reliability as their OEM counterparts.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | Typically high, meets original specifications | Varies widely, can be high or low |

| Price | Generally more expensive | Can be less expensive, but varies |

| Warranty | Often includes warranty | May or may not include warranty |

| Availability | Limited to manufacturer’s supply | Widely available from multiple sources |

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is essential for ensuring effective and efficient work. Proper tools not only facilitate the repair process but also contribute to safety and precision.

Essential Tools

- Wrenches: Various sizes are crucial for loosening or tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different screws.

- Socket Set: Ideal for accessing hard-to-reach fasteners.

- Pliers: Useful for gripping, bending, and cutting wires or small components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

Additional Equipment

- Diagnostic Tools: Help identify issues with the machinery.

- Work Light: Provides adequate illumination for detailed tasks.

- Toolbox: Keeps all instruments organized and easily accessible.

- Protective Gear: Safety glasses and gloves are vital for personal protection.

Step-by-Step Repair Guide

This section provides a comprehensive approach to conducting repairs on your vehicle. By following a structured process, you can efficiently address common issues, ensuring optimal performance and longevity.

Here is a simplified guide to assist you:

- Preparation:

- Gather necessary tools and materials.

- Ensure a clean and well-lit workspace.

- Review any relevant manuals or guides.

- Diagnosis:

- Identify the specific problem or symptoms.

- Check for any error codes if applicable.

- Perform a visual inspection of components.

- Disassembly:

- Carefully remove any outer covers or panels.

- Document the order of disassembly for reassembly.

- Keep track of all screws and small parts.

- Repair or Replacement:

- Assess whether components need repair or replacement.

- Follow specific instructions for replacing faulty parts.

- Utilize appropriate lubricants or adhesives as needed.

- Reassembly:

- Carefully reassemble all components in reverse order.

- Ensure all fasteners are tightened to specifications.

- Check for any leftover parts that may have been missed.

- Testing:

- Start the vehicle and monitor for any irregularities.

- Test all functionalities to confirm repairs were successful.

- Document any further issues for future reference.

By following these steps, you can effectively manage repairs and maintain the functionality of your vehicle.

Safety Precautions During Maintenance

When conducting maintenance on any machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the tasks but also ensure the longevity and functionality of the equipment being serviced.

Here are some essential safety measures to consider:

- Wear Protective Gear: Always use appropriate safety equipment, such as gloves, goggles, and masks, to shield yourself from potential hazards.

- Ensure Adequate Ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes and dust particles.

- Disconnect Power Sources: Before starting any maintenance, make sure to disconnect all power sources to eliminate the risk of accidental activation.

- Use Proper Tools: Utilize the correct tools for the job to prevent injuries and damage to the machinery.

- Keep Workspace Organized: Maintain a clean and organized work area to reduce the chances of accidents and ensure efficient workflow.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s instructions and recommendations to ensure safe and effective maintenance.

By following these precautions, individuals can create a safer environment during maintenance activities, leading to better outcomes and reduced risks.

Resources for Further Assistance

When seeking guidance and support for your mechanical components, numerous resources are available to enhance your understanding and troubleshooting skills. Whether you are looking for detailed guides, community forums, or expert advice, tapping into these avenues can provide valuable insights and assistance.

Online Communities

Engaging with online forums and communities can be incredibly beneficial. These platforms allow enthusiasts and experts to share their experiences, solutions, and tips. Participating in discussions can help you resolve specific issues and connect with individuals who share similar interests.

Technical Manuals and Guides

Accessing comprehensive manuals and guides can provide in-depth information about your equipment. These documents often contain diagrams, maintenance tips, and troubleshooting steps that can assist you in various tasks. Ensure to utilize these resources to gain a thorough understanding of your machinery.