Explore the Yamaha F250 Parts Diagram for Ultimate Clarity

Exploring the intricate world of marine machinery reveals a complex web of elements, each playing a crucial role in the overall functionality of the system. Grasping how these components interact with one another is essential for both maintenance and enhancement of performance. A clear visualization of these parts can significantly aid in troubleshooting and repairs.

In this section, we will delve into a comprehensive representation that outlines the various elements involved in this specific model. By examining the configuration and relationships among these components, users can gain a deeper understanding of the assembly and its operational mechanisms. This knowledge is invaluable for anyone looking to ensure longevity and efficiency in their marine experience.

Whether you’re a seasoned professional or a novice enthusiast, familiarizing yourself with the layout of these crucial components will empower you to make informed decisions. Armed with this information, you can approach maintenance tasks with confidence and tackle challenges as they arise.

Understanding Yamaha F250 Parts Diagram

Comprehending the components of marine engines is essential for effective maintenance and repairs. Familiarity with the layout and function of each element enhances both performance and longevity. This section explores the intricacies involved in interpreting these visual representations, providing clarity on each segment.

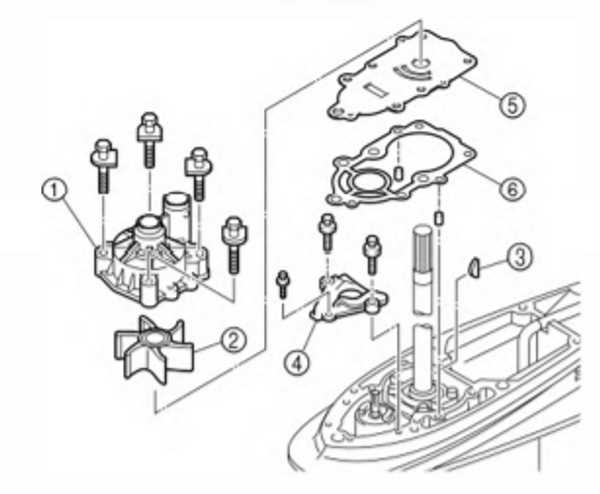

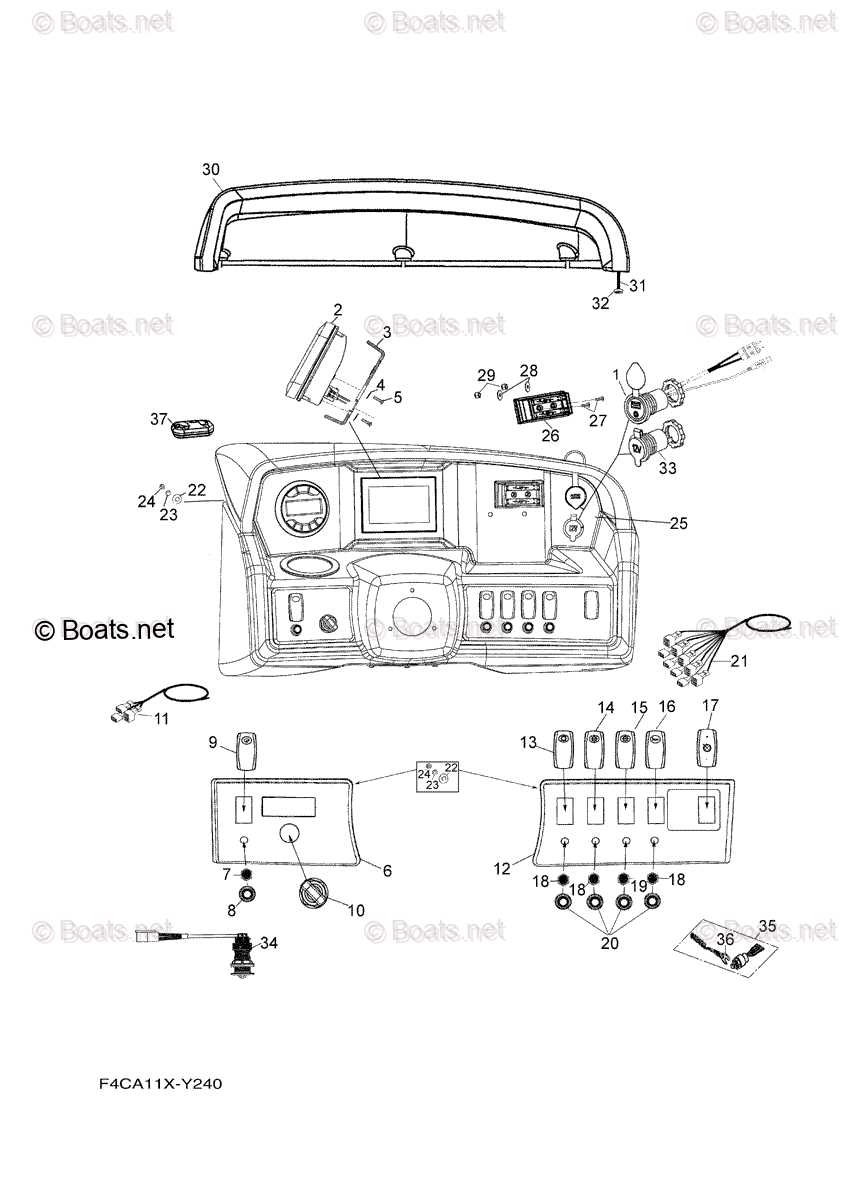

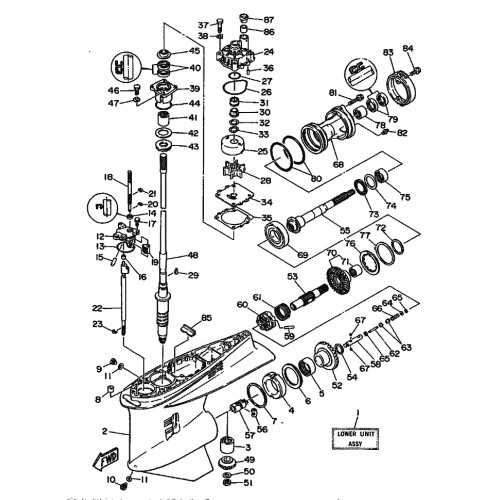

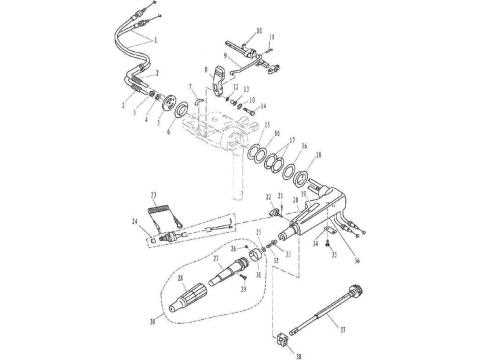

Importance of Visual Representation

Visual guides serve as invaluable tools, allowing users to identify individual pieces and their specific roles within the engine assembly. By simplifying complex structures, these illustrations enable quicker diagnosis of issues and facilitate efficient repairs.

Key Components Overview

| Component | Description |

|---|---|

| Powerhead | Core unit housing critical mechanical parts. |

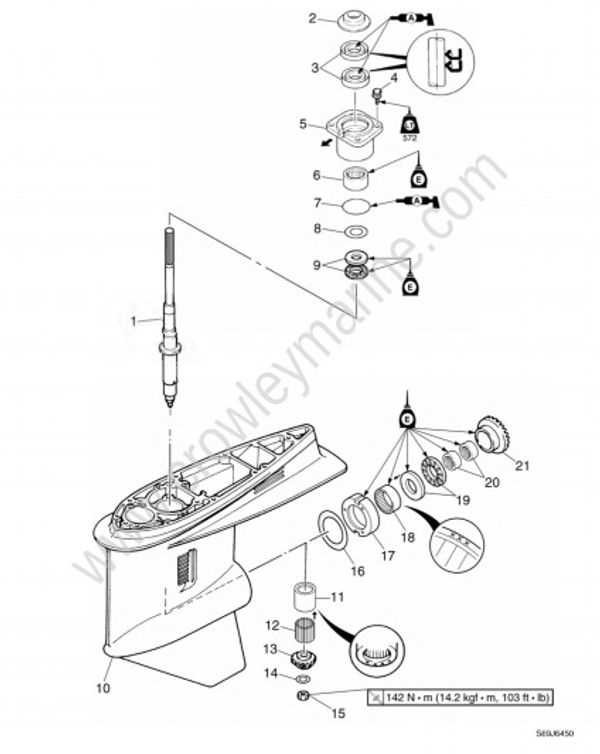

| Lower Unit | Contains gears and driveshaft for propulsion. |

| Fuel System | Ensures proper mixture and delivery of fuel. |

| Cooling System | Regulates temperature to prevent overheating. |

Key Components of Yamaha F250 Engine

The performance of any marine power unit hinges on its essential elements, which work in harmony to ensure efficiency and reliability. Understanding these core components is crucial for optimal maintenance and performance enhancement.

Essential Elements

Each part plays a significant role in the overall functioning of the engine. From the fuel system to the ignition components, these elements contribute to the unit’s power output and durability.

| Component | Description |

|---|---|

| Fuel Pump | Delivers fuel to the combustion chamber for efficient ignition. |

| Ignition System | Responsible for igniting the fuel-air mixture at the optimal time. |

| Cooling System | Maintains the engine temperature to prevent overheating. |

| Lubrication System | Ensures smooth operation by reducing friction between moving parts. |

Impact on Performance

Understanding these crucial components allows for better troubleshooting and ensures that the engine operates at its ultimate potential, providing reliability and longevity on the water.

Importance of Parts Diagrams for Maintenance

Understanding the intricate components of machinery is crucial for effective upkeep and repair. Visual representations serve as invaluable resources, enabling technicians and enthusiasts to identify, locate, and manage various elements efficiently. This knowledge ultimately enhances performance and prolongs the lifespan of the equipment.

Enhanced Troubleshooting

Having a clear visual reference aids in diagnosing issues swiftly. When problems arise, knowing the layout of components allows for quicker identification of potential faults, leading to timely resolutions.

Efficient Repair Process

Clear illustrations streamline the repair process by providing detailed insights into the assembly and disassembly of parts. This clarity minimizes errors and reduces the time spent on maintenance tasks.

| Benefit | Description |

|---|---|

| Quick Identification | Visual aids help in easily locating components during maintenance. |

| Improved Accuracy | Clear instructions reduce the risk of mistakes during repairs. |

| Time Efficiency | Streamlined processes save time in diagnosing and fixing issues. |

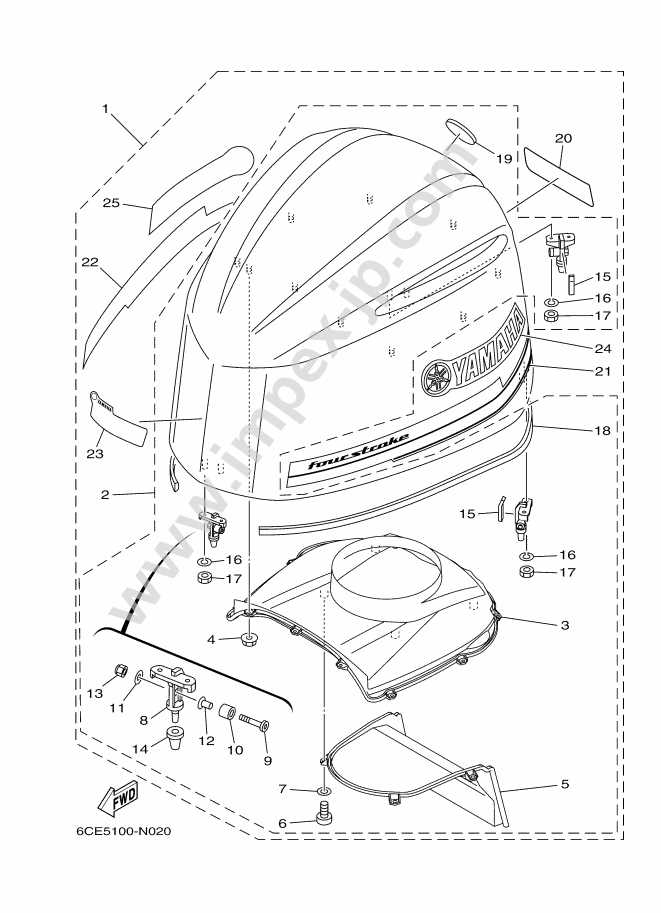

How to Read Yamaha F250 Schematics

Understanding technical illustrations for marine engines can be essential for maintenance and repairs. These schematics provide a visual representation of components, helping you identify parts and their relationships. Mastering the ability to read these documents can significantly enhance your efficiency in troubleshooting and servicing your engine.

Identifying Components

Start by familiarizing yourself with the symbols used in these illustrations. Each component is represented by a unique icon, often accompanied by labels that indicate their function. Carefully examining the legend will help you decode these symbols, making it easier to locate specific elements such as valves, pumps, and electrical connections.

Understanding Connections

Pay attention to the lines that connect various components. These lines often represent electrical wiring or fluid pathways, providing insight into how different parts interact. Tracing these connections will give you a clearer understanding of the overall system, aiding in identifying potential issues during diagnostics and repairs.

Common Issues and Replacement Parts

In the realm of marine engines, understanding prevalent problems and their corresponding solutions is crucial for maintaining optimal performance. Regular maintenance can help identify these issues early, ensuring a smooth sailing experience and prolonging the lifespan of your vessel.

Frequent Problems

Engine overheating, fuel inefficiency, and electrical failures are typical concerns that can arise. Recognizing the signs early can save time and reduce repair costs, making it essential for boat owners to stay vigilant.

Necessary Components for Replacement

When addressing these challenges, certain components are commonly replaced. Cooling systems, fuel injectors, and ignition parts often require attention. Having these essential items on hand can facilitate quick repairs, keeping your marine adventure uninterrupted.

Where to Find Genuine Yamaha Parts

When it comes to maintaining your watercraft, ensuring that you use authentic components is crucial for optimal performance and longevity. High-quality replacements are available through various trusted sources, ensuring that you can find exactly what you need to keep your vessel running smoothly.

Authorized Dealers

One of the most reliable ways to acquire genuine components is through authorized dealerships. These establishments are directly linked to the manufacturer and offer a comprehensive selection of authentic items. Their staff are knowledgeable and can assist you in finding the correct components for your specific model.

Online Retailers

Another excellent option is reputable online retailers specializing in marine equipment. Many of these platforms offer a wide range of authentic replacements, often at competitive prices. Ensure that the site has a solid reputation and offers customer reviews to help you make an informed decision.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance both performance and longevity of machinery. These elements are specifically designed to meet the exact specifications required, ensuring optimal compatibility and reliability.

Quality Assurance

OEM components are manufactured under strict quality control standards, leading to a higher level of consistency and durability. This ensures:

- Longer lifespan compared to aftermarket options

- Reduced risk of malfunction or failure

- Enhanced performance and efficiency

Warranty Protection

Using original components often helps maintain warranties on the equipment. Benefits include:

- Coverage for repairs and replacements

- Increased resale value due to maintained integrity

- Peace of mind knowing the equipment is protected

Exploring Aftermarket Options for F250

When it comes to enhancing performance and reliability, many enthusiasts turn to alternative solutions that extend beyond the original manufacturer offerings. These options often provide an ideal blend of affordability and quality, allowing users to customize their experience to meet specific needs.

Benefits of Aftermarket Alternatives

One of the primary advantages of aftermarket selections is the potential for improved performance. Upgrades such as high-efficiency components can enhance power and fuel efficiency. Additionally, the variety of choices available enables users to find products that align perfectly with their individual preferences.

Choosing Quality and Compatibility

While exploring alternatives, it is crucial to prioritize both quality and compatibility. Researching reputable brands and reading user reviews can guide buyers towards reliable options. Ensuring that components are specifically designed for seamless integration will ultimately lead to a more satisfying experience.

Essential Tools for Parts Replacement

Replacing components in machinery requires a specific set of instruments to ensure a smooth and efficient process. The right tools not only facilitate the task but also help in preventing damage to the equipment and ensuring safety during maintenance. Understanding which instruments are necessary can significantly streamline the replacement procedure and enhance overall performance.

Basic Instruments

Every technician should have a basic toolkit that includes wrenches, screwdrivers, and pliers. These are fundamental for loosening and tightening various fasteners. Additionally, a ratchet set can be invaluable for reaching tight spaces, while torque wrenches ensure that connections are made with the correct tension, preventing future issues.

Specialized Equipment

For more intricate tasks, specialized equipment may be necessary. Socket sets are crucial for removing stubborn bolts, while cutting tools can assist in precise modifications. A multimeter is essential for electrical diagnostics, helping to identify issues that may not be immediately visible. Ensuring access to these specialized instruments can make complex repairs more manageable and effective.

Step-by-Step Guide to Disassembly

Disassembling complex machinery requires careful attention to detail and a systematic approach. By following a structured process, you can ensure that each component is removed safely and efficiently, minimizing the risk of damage or loss. This guide provides a clear sequence to facilitate the disassembly of your equipment.

- Preparation:

- Gather necessary tools, including wrenches, screwdrivers, and pliers.

- Ensure the workspace is clean and well-lit.

- Have a container ready for small parts to avoid misplacement.

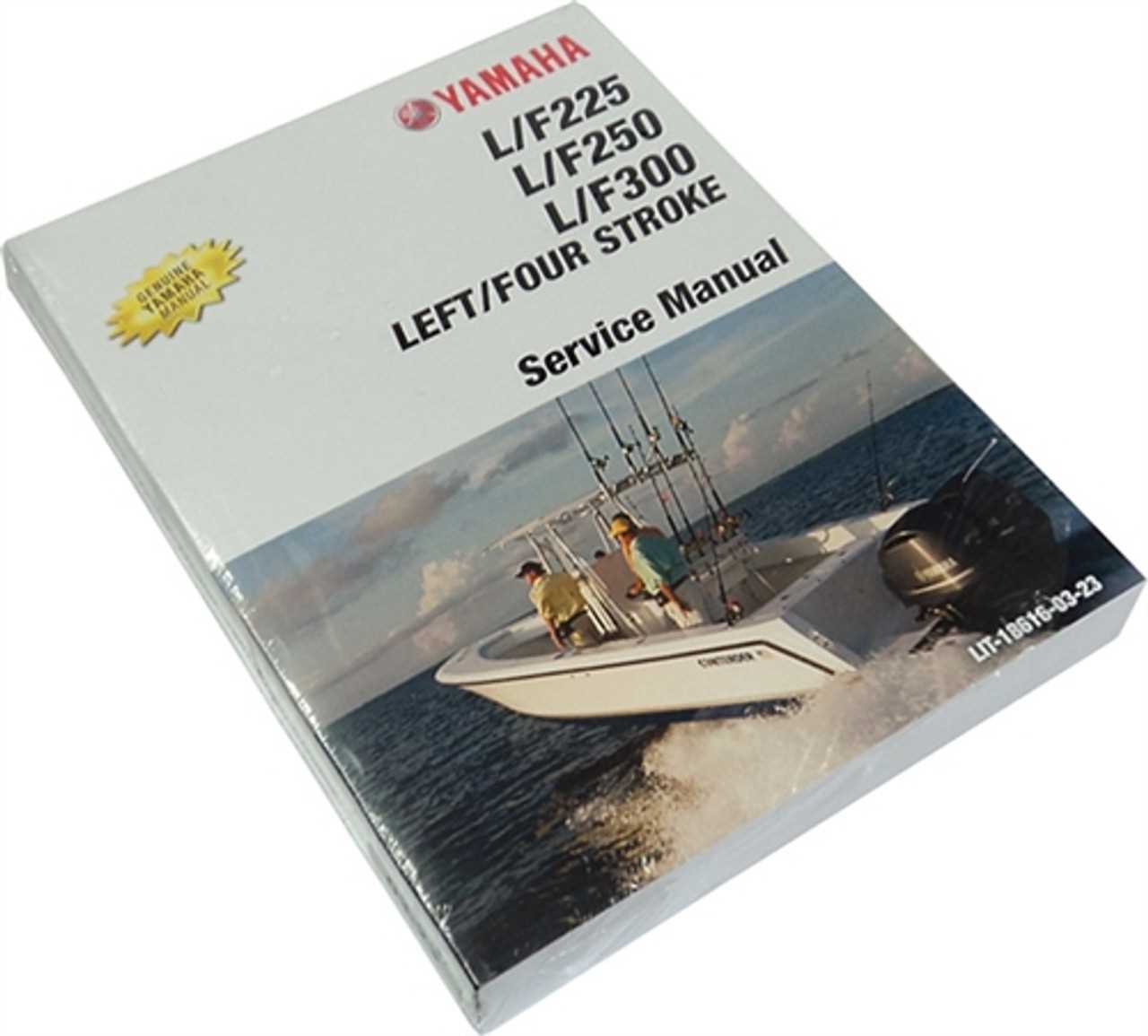

- Consult Documentation:

- Refer to the service manual for specific instructions and diagrams.

- Familiarize yourself with the layout and the order of assembly.

- Remove External Covers:

- Identify and unscrew any external covers or panels.

- Keep screws organized according to their respective locations.

- Disconnect Electrical Components:

- Carefully unplug any wiring harnesses or connectors.

- Label wires if necessary for easier reassembly.

- Take Out Major Components:

- Identify the major parts that need to be removed, such as the engine or transmission.

- Support heavy components properly to avoid strain or damage.

- Use appropriate lifting techniques or tools when necessary.

- Detach Smaller Assemblies:

- Remove smaller parts such as hoses, belts, and brackets in a logical sequence.

- Take notes or photographs to remember the placement of each component.

- Final Clean-Up:

- Inspect each part for wear or damage.

- Clean the workspace and tools after disassembly.

By adhering to this step-by-step approach, you can simplify the disassembly process and ensure that all components are handled with care, paving the way for effective maintenance or repairs.

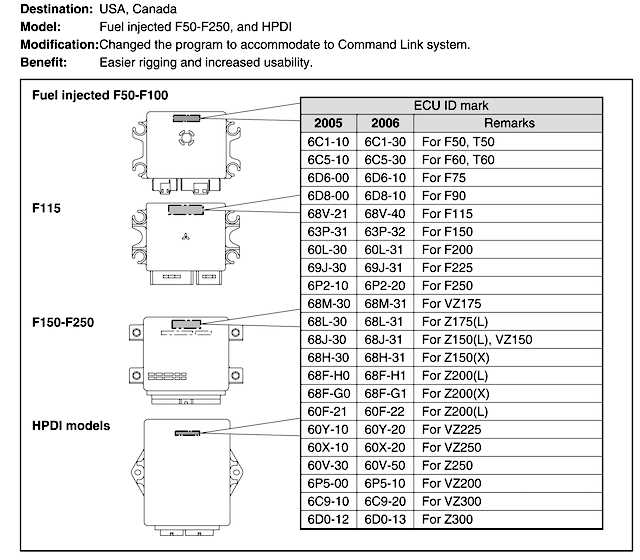

Identifying Parts by Model Number

Understanding the specific components of your vessel’s engine is crucial for maintenance and repairs. Each engine variant is associated with a unique identification code that helps in pinpointing the necessary elements for replacement or servicing. Recognizing these codes allows for efficient sourcing of the right items, ensuring optimal performance.

Why Model Numbers Matter

Model identification codes serve several important purposes:

- Precision: They provide exact specifications for compatible elements.

- Compatibility: Ensures the selected components fit seamlessly with your engine.

- Identification: Simplifies the process of locating items in catalogs or online.

How to Locate the Model Number

Finding the identification code can be straightforward if you know where to look. Follow these steps:

- Check the engine’s manual for the model identification section.

- Inspect the engine itself; often, the number is stamped on a metal plate.

- Look for documentation from previous maintenance or purchases that might include the model number.

By utilizing the model identification code effectively, you can ensure that you procure the correct components for your engine, enhancing its longevity and reliability.

Preventive Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. Implementing a routine maintenance plan can significantly enhance its lifespan and efficiency, preventing costly repairs and downtime.

Regular Inspections

- Conduct thorough visual checks to identify any signs of wear or damage.

- Inspect fluids for cleanliness and proper levels to ensure smooth operation.

- Examine all connections and components for signs of corrosion or loosening.

Scheduled Servicing

- Follow the manufacturer’s guidelines for regular service intervals.

- Replace filters and fluids as recommended to maintain peak performance.

- Lubricate moving parts to reduce friction and wear over time.

Resources for Yamaha F250 Owners

For enthusiasts and operators of marine engines, having access to the right resources can significantly enhance the ownership experience. This section provides a compilation of valuable tools and references to assist in maintenance, troubleshooting, and enhancing the performance of your outboard motor.

Here are some essential resources:

- Owner’s Manuals: Detailed guides offering insights into operation, maintenance schedules, and troubleshooting tips.

- Online Forums: Communities where owners share experiences, advice, and solutions to common issues.

- Technical Support: Manufacturer’s helplines and customer service for direct assistance with specific problems.

- Videos and Tutorials: Visual aids available on platforms like YouTube, covering everything from routine maintenance to advanced repairs.

- Specialized Retailers: Stores that focus on marine equipment, providing both components and expert advice.

- Service Workshops: Certified service centers that offer professional maintenance and repair services.

Utilizing these resources can help ensure the longevity and reliability of your vessel, allowing you to enjoy every moment on the water.