Understanding Yamaha Outboard Lower Unit Parts Diagram

The intricacies of marine propulsion systems can often be daunting, yet they are essential for optimal performance and reliability. A clear visual representation of key elements can greatly enhance one’s comprehension of these mechanical wonders.

By exploring a detailed schematic, one can uncover the ultimate functions of each component, gaining insights into how they work together seamlessly. This knowledge not only aids in maintenance but also empowers enthusiasts to address potential issues before they escalate.

In this section, we will delve into the various segments of marine engines, highlighting their roles and interactions. Understanding these components is crucial for anyone looking to ensure the longevity and efficiency of their vessel.

Understanding Yamaha Outboard Lower Units

Exploring the intricacies of marine propulsion systems can greatly enhance your boating experience. These essential components play a crucial role in transferring power from the engine to the propeller, ensuring optimal performance and efficiency on the water. Understanding their structure and functionality allows for better maintenance and troubleshooting.

Key Components

Within these assemblies, several vital elements work in unison. Gear sets facilitate speed variations, while seals protect internal mechanisms from water ingress. Regular inspections of these components can prevent costly repairs and extend the lifespan of the entire system.

Maintenance Tips

Routine care is paramount for sustained performance. Regular oil changes and inspection for wear can prevent malfunctions. Familiarity with the assembly can empower you to identify issues early, ensuring a smooth and enjoyable boating experience.

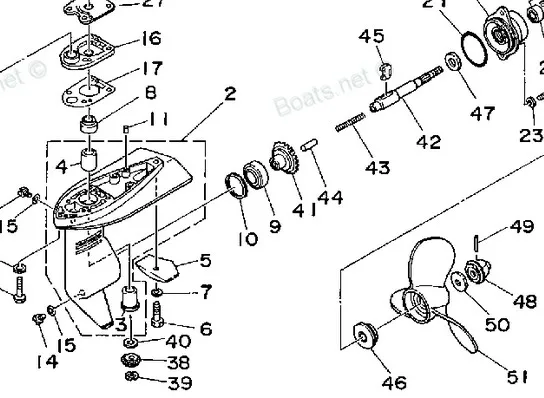

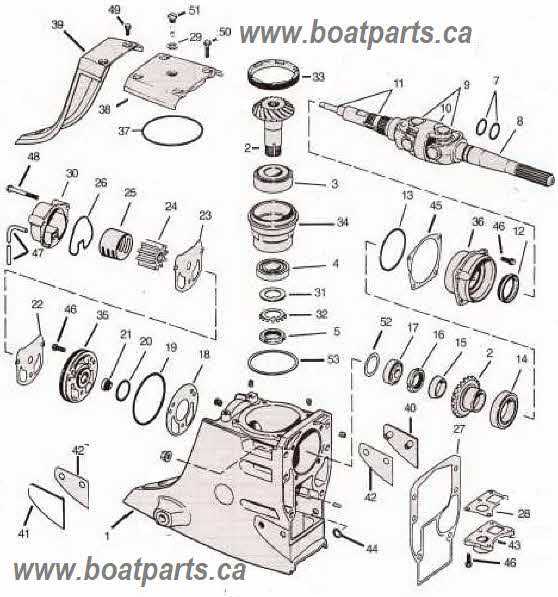

Essential Components of Lower Units

Understanding the key elements of marine propulsion systems is vital for maintenance and repair. These crucial components work together to ensure efficient operation and reliability in various watercraft. Familiarity with their functions and arrangements can significantly enhance performance and longevity.

- Gearcase: This housing protects the gears and other internal mechanisms, ensuring smooth operation and reducing wear.

- Propeller Shaft: A critical component that transfers power from the engine to the propeller, allowing for effective thrust generation.

- Pinion Gear: This gear interacts with the drive gear to facilitate the rotation necessary for propulsion.

- Drive Gear: Paired with the pinion gear, it plays a vital role in adjusting the torque and speed delivered to the propeller.

- Water Pump: Essential for cooling, this pump circulates water through the system to prevent overheating.

- Shift Mechanism: This allows the operator to change gears, ensuring smooth transitions and control during navigation.

- Seals and Bearings: These elements minimize friction and prevent leakage, contributing to overall efficiency and durability.

Each of these components serves a specific purpose, working in harmony to provide reliable functionality. Regular inspection and maintenance of these elements are crucial for optimal performance and to avoid costly repairs.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to maintain and repair equipment. These illustrations provide a detailed overview of the various elements involved, enabling you to identify each piece and its function within the assembly. Mastering the skill of interpreting these visuals is essential for anyone looking to effectively manage mechanical systems.

Begin by familiarizing yourself with the layout, noting the arrangement and connections between elements. Often, numbers or letters are used to label individual components, which correspond to a list detailing their specifications. Pay close attention to any legends or notes, as they often clarify the purpose of each section and indicate important assembly details.

Moreover, consider the scale and orientation presented in the image. Understanding these aspects will help you visualize how parts fit together in reality. Practice regularly by analyzing different illustrations to enhance your proficiency. This knowledge not only aids in troubleshooting but also empowers you to make informed decisions during maintenance tasks.

Common Issues in Lower Units

Understanding the frequent challenges that arise in propulsion systems is crucial for maintaining optimal performance. These issues can stem from various factors, including wear and tear, environmental conditions, and improper maintenance practices.

Seal Failures

One of the most prevalent problems involves the breakdown of seals. Over time, exposure to saltwater and debris can lead to leaks, compromising the integrity of the entire assembly. Regular inspections and timely replacements are essential to prevent further damage.

Gearbox Malfunctions

Gearbox failures often result from inadequate lubrication or misalignment. This can lead to grinding noises or a complete loss of functionality. It is vital to monitor oil levels and conduct routine checks to ensure proper operation and longevity.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of marine machinery requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of critical components. By following a systematic routine, users can avoid costly repairs and ensure safe and enjoyable outings on the water.

Regular Inspections

Conduct frequent examinations of key elements to identify wear and tear early. Check seals, fasteners, and connecting points for any signs of corrosion or damage. Pay attention to fluid levels and quality, replacing them as necessary to maintain optimal operation. These small actions can prevent larger issues down the line.

Proper Cleaning and Storage

After each use, thoroughly rinse the machinery to remove salt, dirt, and debris that can cause deterioration. Store the equipment in a dry, sheltered area to protect it from environmental factors. Covering the machinery can also help prevent dust accumulation and exposure to moisture, which are detrimental to long-term functionality.

Tools Required for Repairs

When it comes to performing maintenance on marine propulsion systems, having the right tools is essential for ensuring efficiency and accuracy. A well-equipped toolkit not only simplifies the repair process but also helps prevent potential damage to the components involved.

Basic Hand Tools: A set of standard hand tools, including wrenches, pliers, and screwdrivers, is fundamental. These tools are necessary for loosening and tightening bolts, as well as for manipulating various fixtures and fittings.

Specialized Equipment: Depending on the specific tasks at hand, certain specialized instruments may be required. For instance, torque wrenches are crucial for applying the correct amount of pressure when securing fasteners, while alignment tools ensure that components are positioned accurately.

Diagnostic Tools: In modern propulsion systems, having access to diagnostic devices is increasingly important. These tools help in troubleshooting issues by providing real-time data on performance and functionality, enabling effective problem-solving.

Safety Gear: Lastly, do not overlook the importance of safety equipment. Gloves, goggles, and protective clothing are vital for safeguarding against potential hazards during repairs.

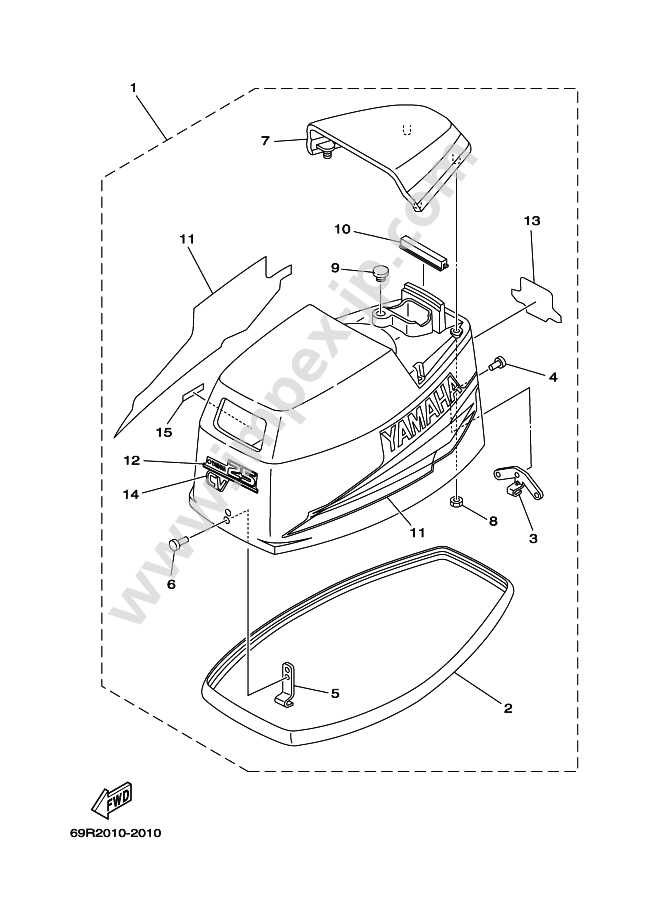

Identifying Parts by Model Year

Understanding the components of a marine propulsion system can be crucial for maintenance and repair. Each manufacturing year may introduce changes in design and specifications, making it essential to recognize the variations across different models. This knowledge aids in ensuring compatibility and optimal performance when replacing or upgrading elements of the system.

To accurately identify the necessary components, one should refer to the specific model year. Documentation and references often include detailed lists that highlight the distinctions in parts based on the production year. This can involve variations in size, shape, and functionality, which are critical for seamless integration into the existing framework.

Utilizing manufacturer resources and online databases can greatly assist in this identification process. Many platforms provide comprehensive information that includes diagrams and part numbers aligned with specific years. This enables users to make informed decisions and select the correct components without unnecessary complications.

Upgrading vs. Replacing Components

When considering the maintenance of marine machinery, two primary approaches often arise: enhancing existing elements or completely substituting them with new ones. Each strategy carries its own set of advantages and challenges, influencing both performance and cost. Understanding these differences is crucial for making informed decisions that can affect longevity and efficiency.

Upgrading typically involves improving or modifying existing components to boost their performance or extend their lifespan. This might include adding new technologies, improving materials, or enhancing designs. In contrast, replacing involves removing old components and installing brand-new ones, which can sometimes be necessary when parts are beyond repair or outdated.

| Criteria | Upgrading | Replacing |

|---|---|---|

| Cost | Generally lower; focuses on specific enhancements | Potentially higher; requires purchasing new components |

| Time | Often quicker; minor modifications can be done swiftly | Can be time-consuming; involves removing and installing |

| Performance | Improves specific functionalities | Restores full functionality, may offer better specs |

| Risk | Possible compatibility issues with older systems | Lower risk; new parts are designed to work together |

Ultimately, the decision between enhancing existing components and opting for new installations depends on the specific circumstances and goals. Evaluating factors such as budget, time constraints, and desired performance will guide the choice that best fits individual needs.

Where to Find OEM Parts

Locating original equipment manufacturer components is essential for maintaining the integrity and performance of your marine machinery. Whether you’re conducting repairs or upgrades, ensuring you have authentic items can significantly enhance reliability and longevity.

Authorized Dealers

Your first stop should be authorized dealerships that specialize in marine equipment. These vendors typically offer a comprehensive selection of genuine components and can provide expert advice on the specific needs of your vessel.

Online Retailers

Another convenient option is to explore reputable online retailers. Many websites specialize in marine supplies and often feature user-friendly navigation, allowing you to delve into specific categories and find the ultimate components for your needs.

Installation Process for New Parts

Replacing essential components is a critical task that ensures optimal performance and longevity of marine machinery. This section outlines the steps to effectively install new elements, focusing on accuracy and safety.

Before starting the installation, gather all necessary tools and components. A clean workspace will facilitate an efficient process and reduce the risk of losing small items.

| Step | Description |

|---|---|

| 1 | Disconnect the power supply to prevent any accidental activation. |

| 2 | Remove the old components carefully, taking note of their arrangement for reference. |

| 3 | Clean the area where the new elements will be installed, ensuring there is no debris. |

| 4 | Install the new components following the reference notes, ensuring a snug fit. |

| 5 | Reconnect the power supply and conduct a test to verify proper functionality. |

Following these steps will help ensure that the installation process is seamless and that the machinery operates efficiently.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions should be taken to create a secure work environment, which enhances both the effectiveness of the repair and the well-being of the individual performing it.

Before beginning any service, it is essential to familiarize oneself with the necessary safety guidelines and recommended practices. This includes using appropriate protective gear, maintaining a clean workspace, and being aware of potential hazards associated with the equipment.

| Safety Measure | Description |

|---|---|

| Protective Gear | Always wear safety goggles, gloves, and steel-toed boots to shield against potential injuries. |

| Clean Workspace | Keep the area tidy and free from unnecessary tools and materials to reduce trip hazards. |

| Tool Inspection | Regularly check tools for wear and damage to ensure they function properly and safely. |

| Proper Ventilation | Ensure adequate airflow to prevent the buildup of harmful fumes, especially when working with chemicals. |

| Emergency Procedures | Be familiar with first aid procedures and know the location of emergency equipment like fire extinguishers. |

By adhering to these essential safety measures, individuals can significantly reduce the risk of accidents and ensure a successful repair process. Taking the time to prioritize safety is an investment in both personal well-being and the longevity of the equipment being serviced.

Comparing Yamaha with Other Brands

When examining different manufacturers in the marine engine sector, various aspects come into play that influence consumer choices. Each brand offers distinct features, reliability, and performance levels that cater to diverse user needs.

One of the key factors that sets brands apart is their engineering philosophy. Some companies prioritize advanced technology, resulting in higher efficiency and speed, while others focus on simplicity and ease of maintenance. Understanding these differences helps buyers make informed decisions based on their specific requirements.

Additionally, customer service and support play significant roles in brand reputation. Brands that provide comprehensive support and readily available components tend to build stronger relationships with their clients. This aspect can be crucial when repairs or replacements are necessary.

Finally, price point is a significant consideration. While some brands may offer premium models at a higher cost, others provide more budget-friendly options without compromising on essential features. Evaluating the overall value of each option can lead to the ultimate choice that best fits one’s needs.