Comprehensive Guide to Yamaha Tiller Handle Parts Diagram

In the world of marine equipment, mastering the intricacies of control systems is essential for ensuring smooth navigation and optimal performance. Every element of these systems plays a crucial role in functionality and user experience.

Familiarity with the various components allows operators to make informed decisions regarding maintenance and upgrades. By examining the specific functions and connections between each segment, users can enhance their knowledge and skills.

To delve into the ultimate guide for these steering systems, it’s important to explore each individual piece and its significance. This exploration not only aids in troubleshooting but also enriches the overall understanding of maritime technology.

Understanding Yamaha Tiller Handle Components

This section aims to explore the various elements involved in the operation and functionality of steering systems for watercraft. Each component plays a vital role in ensuring smooth maneuverability and responsiveness, making it crucial to understand their interactions.

| Component | Description |

|---|---|

| Grip | The part that provides control and comfort to the operator. |

| Control Lever | Allows the user to adjust speed and direction with precision. |

| Connecting Rod | Links the steering mechanism to the propulsion system for effective steering. |

| Mounting Bracket | Secures the entire assembly to the vessel, ensuring stability during use. |

| Throttle Cable | Transmits the user’s input to regulate engine power. |

Importance of Proper Tiller Maintenance

Common Issues with Tiller Handles

When operating equipment that involves a steering mechanism, several typical problems can arise, affecting functionality and user experience. Understanding these issues can help in maintaining performance and ensuring safety during operation.

Worn Components: One of the most frequent challenges involves the degradation of various components due to regular use. Over time, parts may lose their integrity, leading to a decrease in responsiveness and control.

Loose Connections: Another common concern is the loosening of connections, which can result in instability. This can make steering difficult and may lead to unexpected movements, posing a risk to the operator.

Corrosion: Exposure to moisture and environmental elements can lead to corrosion, affecting metal parts. This deterioration not only hampers functionality but can also necessitate costly repairs or replacements.

Alignment Issues: Misalignment of components can lead to uneven handling. This can make maneuvering cumbersome and impact the overall efficiency of the equipment.

Grip Problems: The grip surface may wear down or become slippery, reducing comfort and control. Ensuring a secure grip is essential for safe operation, and addressing this issue promptly can prevent accidents.

By identifying and addressing these common concerns, operators can enhance the longevity and reliability of their steering mechanisms, ensuring a smoother and safer experience.

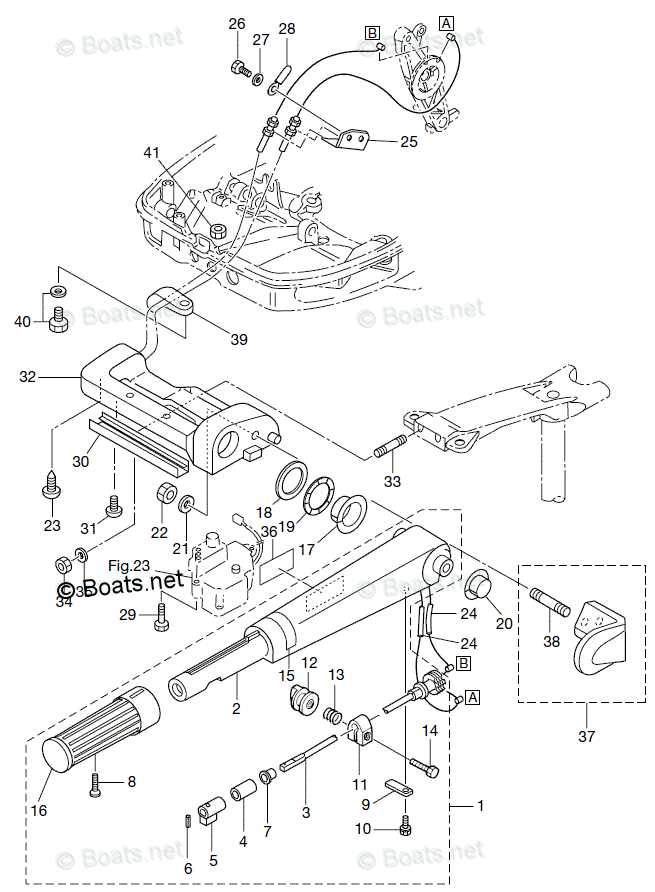

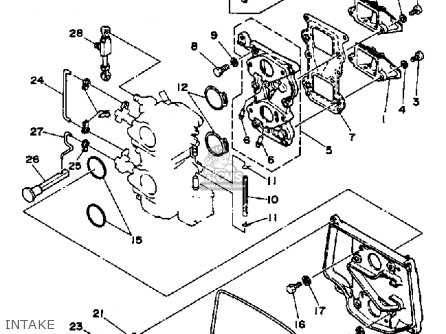

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of individual elements, their arrangement, and how they interact within a larger system. By familiarizing yourself with these visuals, you can streamline the process of identifying and sourcing necessary items.

Begin by identifying the legend, which explains the symbols and numbering used in the illustration. This will help you comprehend the various elements depicted. Next, examine the layout to see how parts are organized; often, they are grouped by function or assembly sequence, making it easier to locate specific items. Pay attention to any accompanying notes or instructions, as they may offer valuable insights regarding installation or troubleshooting.

Lastly, cross-reference the diagram with a list of components, ensuring you have all necessary items for your project. This methodical approach will enhance your ability to navigate through the visual information, ultimately leading to more efficient repairs and maintenance.

Identifying Key Tiller Parts

Understanding the essential components of a steering mechanism is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall functionality and user experience. By familiarizing yourself with these key elements, you can ensure effective operation and troubleshooting.

Essential Components

The primary elements include the grip, which offers control, and the shaft, connecting the grip to the main body. Additionally, the mounting brackets secure the assembly in place, while various connectors facilitate smooth movement. Recognizing these components can help you navigate repairs and upgrades.

Maintenance Tips

Regular inspection of these crucial parts can prevent wear and tear. Ensure that all connections are tight and that the grip remains comfortable for extended use. Keeping these components in good condition will enhance the longevity and efficiency of your equipment.

Replacement Parts for Yamaha Tiller

When maintaining outdoor equipment, ensuring the availability of essential components is crucial for optimal performance. The longevity and efficiency of your machinery often depend on the quality of its individual elements. Understanding which pieces may require replacement and where to find them can make all the difference in sustaining your tools over time.

Common components that may need to be replaced include grips, levers, and control mechanisms. Over time, wear and tear can affect their functionality, leading to decreased performance. Regular inspections can help identify any signs of damage or deterioration, allowing for timely replacements.

Numerous retailers offer high-quality alternatives for these essential elements, ensuring compatibility and reliability. When selecting replacements, it’s important to choose reputable suppliers to guarantee the longevity and performance of your machinery. Additionally, consulting user manuals can provide guidance on specifications and installation processes, making the replacement experience more efficient.

Tools Needed for Tiller Repairs

Ensuring the longevity and efficiency of your agricultural equipment requires the right set of tools. Proper maintenance and repairs can prevent costly replacements and downtime. This section outlines essential implements that will aid in your repair endeavors.

Essential Tools

- Wrenches and Socket Sets: Necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are crucial for various screws.

- Pliers: Useful for gripping, twisting, and cutting wire or small components.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Replacement Parts: Stock essential components that are prone to wear and tear.

Safety Equipment

- Gloves: Protect hands from sharp edges and chemicals.

- Safety Goggles: Shield eyes from debris and potential hazards.

- Hearing Protection: Especially important when working with loud machinery.

By equipping yourself with these tools, you can effectively tackle repairs and maintenance tasks, ensuring your equipment remains in optimal condition.

Step-by-Step Repair Process

This section provides a detailed guide for performing maintenance on your equipment. Following these steps carefully will ensure that you restore functionality effectively and efficiently.

Preparation

- Gather necessary tools: pliers, screwdrivers, and any specialized instruments required for disassembly.

- Ensure you have all replacement components on hand, as per the schematic.

- Review the operational manual to familiarize yourself with the assembly layout.

- Set up a clean and organized workspace to keep track of small pieces.

Disassembly

- Begin by removing any outer coverings or casings to expose the internal mechanisms.

- Carefully detach the components using the appropriate tools, ensuring you do not damage any fittings.

- Keep track of screws and small parts by placing them in labeled containers.

- Document the order of disassembly, either through photos or notes, for easier reassembly.

Safety Tips for Tiller Handling

Ensuring safety while operating equipment is crucial for both the user and those nearby. Proper practices can prevent accidents and enhance the overall experience.

- Always wear appropriate protective gear, including gloves and sturdy footwear.

- Before starting, inspect the machinery for any damage or loose components.

- Read the user manual thoroughly to understand the functionality and features.

- Maintain a safe distance from others while operating the equipment.

- Keep hands and feet clear of moving parts to avoid injury.

By following these guidelines, you can ensure a safer working environment and maximize efficiency.

Where to Buy Tiller Parts

Finding the right components for your gardening equipment can significantly enhance its performance and longevity. There are various options available to acquire the necessary items, ensuring you maintain your machinery efficiently.

Online Retailers

Many websites specialize in offering a wide selection of replacement items. These platforms often provide detailed descriptions and customer reviews, making it easier to select the appropriate components for your machinery.

Local Stores

Visiting nearby hardware or specialty shops can be beneficial. These locations typically carry essential items and allow you to consult with knowledgeable staff who can assist in identifying the correct components for your needs.

FAQs About Tiller Handle Maintenance

Maintaining the control mechanism of your aquatic vehicle is crucial for optimal performance and longevity. Regular upkeep not only enhances functionality but also ensures safety while navigating. Below are some common inquiries regarding the maintenance of these essential components.

1. How often should I inspect the steering mechanism?

Regular inspections are recommended at least once every season. However, if you frequently use your equipment in harsh conditions, more frequent checks are advisable.

2. What are the signs that maintenance is needed?

Look for signs of wear such as unusual noises, resistance during operation, or visible damage to the components. Any irregularities should prompt immediate attention.

3. What tools do I need for routine maintenance?

Basic tools such as screwdrivers, wrenches, and lubricants are typically sufficient for regular upkeep. A comprehensive toolkit can help address various issues as they arise.

4. Can I perform maintenance myself, or should I hire a professional?

Many maintenance tasks can be performed by enthusiasts with basic mechanical skills. However, for complex repairs or if you’re unsure, consulting a professional is recommended.

5. What type of lubricant is best for moving parts?

Using a marine-grade lubricant is ideal, as it is specifically formulated to withstand the conditions encountered in aquatic environments, providing optimal protection.