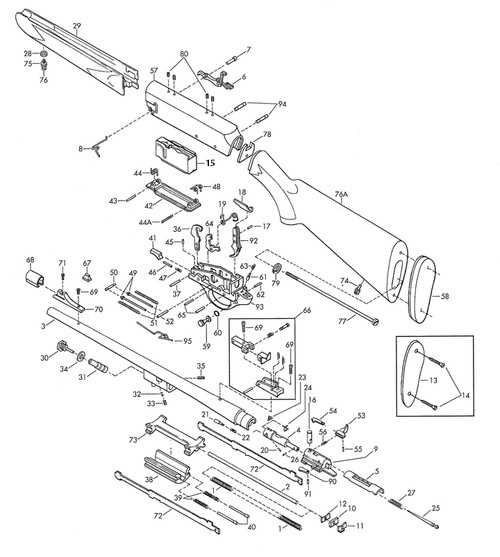

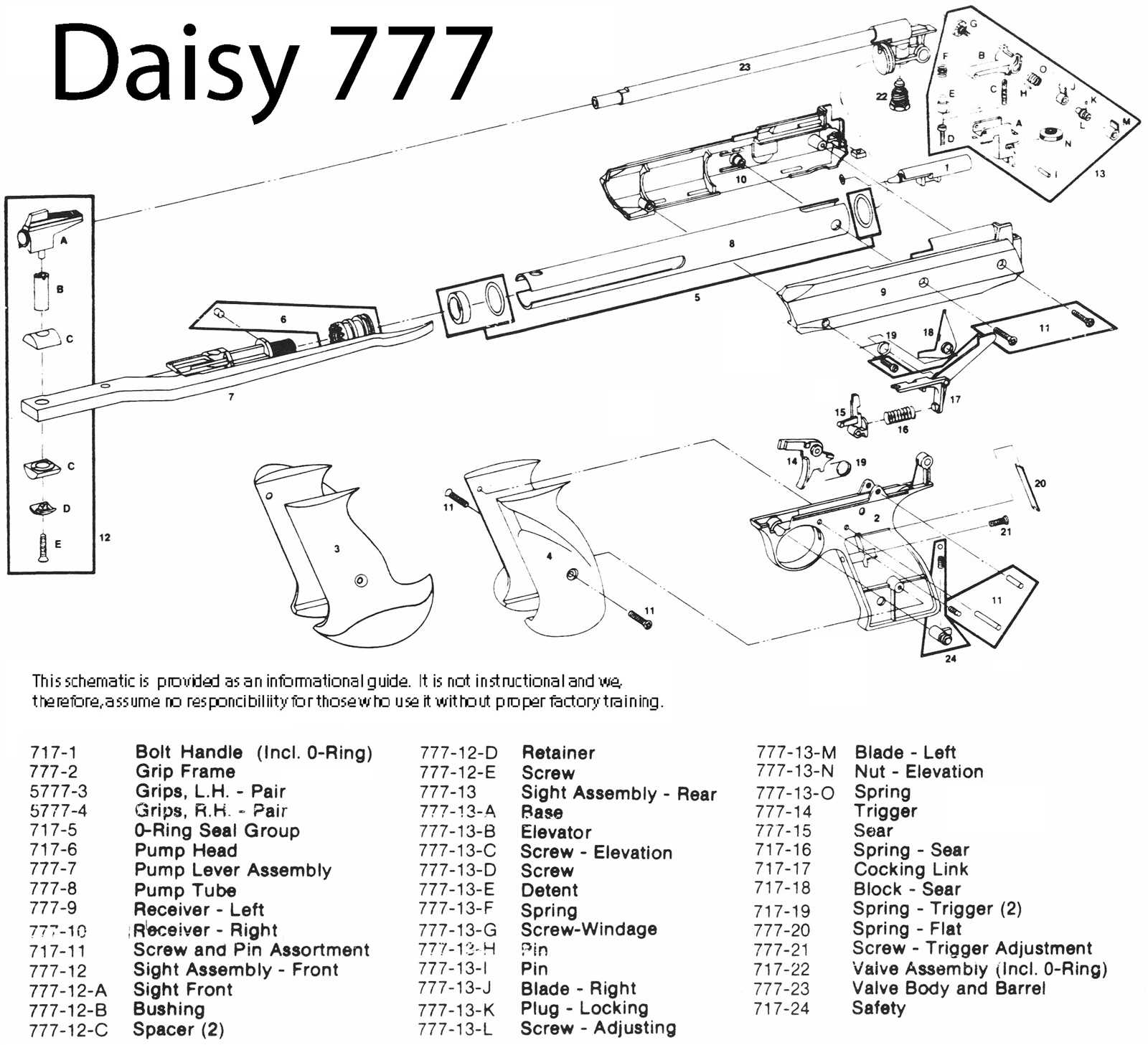

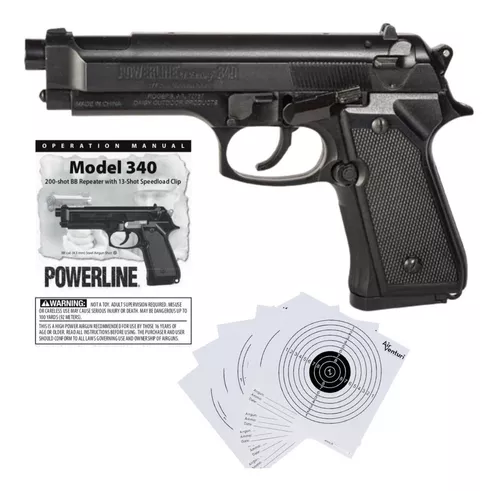

Daisy Powerline 340 Parts Breakdown and Assembly Guide

Air pistols have long been a popular choice for target practice and recreational shooting, providing both enthusiasts and beginners with an accessible way to enjoy marksmanship. When maintaining or repairing one of these models, it’s essential to have a clear understanding of how its internal mechanisms are structured. This guide will help clarify the primary components that allow the air pistol to function effectively.

From the trigger mechanism to the barrel, every element plays a crucial role in ensuring accuracy and power. Identifying the placement of these elements and how they interact can assist with troubleshooting or upgrading. Whether you’re an experienced user or new to air pistols, knowing the layout of key systems can significantly improve your experience.

In the following sections, we’ll break down the essential components and provide tips on how to recognize common issues and maintain your air pistol for optimal performance. By familiarizing yourself with the internal configuration, you’ll be better prepared to address any technical concerns and keep your equipment in top condition.

Overview of Key Components

In this section, we will explore the essential elements that make up this particular air-powered model. Understanding the role and structure of each component helps ensure efficient operation and proper maintenance. Each piece is designed to perform a specific function, contributing to the overall performance of the mechanism.

Trigger Mechanism: The trigger system is responsible for initiating the firing sequence. It is a critical part that must function smoothly to ensure the device operates correctly.

Compression System: This segment is responsible for generating the necessary force for launching projectiles. Ensuring that this part is maintained in good condition will lead to reliable performance.

Barrel Assembly: The barrel directs the trajectory, and its alignment is vital for accuracy. Regular cleaning and inspection of this part are recommended for optimal results.

Key Internal Mechanisms Breakdown

Understanding the intricate workings of this mechanical device requires a closer look at the essential internal components. Each of these parts works in harmony to ensure proper functionality, and by analyzing them, we can gain a better grasp of how the entire system operates.

- Trigger System: This mechanism initiates the action, setting off a chain reaction within the device. Its precise engagement is crucial for smooth operation.

- Firing Mechanism: The core of the system, this part is responsible for delivering the intended function. It works by transferring energy efficiently through various moving parts.

- Chamber: This section is where the primary action occurs, housing essential elements that work together to produce the desired outcome.

- Spring Assembly: A tightly coiled spring provides the necessary tension, releasing energy when activated to power the mechanism.

- Barrel Alignment: Ensures that the internal components are correctly positioned to guide the operation accurately.

Each of these key mechanisms plays a pivotal role, working in unison to maintain the overall efficiency and reliability of the device.

Trigger System and Its Role

The mechanism that initiates the firing process plays a crucial role in the overall functionality of any shooting device. It serves as the critical component that connects the user’s action to the release of the internal forces, allowing for the projectile to be propelled forward. Understanding how this system operates provides key insights into the inner workings of the device.

Key Functions: The trigger not only controls the timing of the shot but also ensures that safety measures are upheld, preventing accidental discharge. The smooth operation of this mechanism is vital for precision and reliability during use.

Operational Dynamics: When the user applies pressure, the internal components work together to release the stored energy, resulting in the desired outcome. Any misalignment or malfunction in this process can severely impact performance, making it essential for the trigger system to be well-maintained and properly aligned.

Understanding the Barrel Assembly

The barrel assembly is a crucial component in any device that operates through projectile propulsion. It plays a central role in directing and stabilizing the movement of the projectile, ensuring accuracy and consistency in operation. Its structure typically includes a chamber where the projectile is loaded, and a long cylindrical part that guides it toward its target.

Key Functions of the Barrel

The primary function of the barrel is to provide a path for the projectile to travel through, maintaining its trajectory. The interior of the barrel is often designed to reduce friction and allow the projectile to move smoothly. This precision in design is essential for ensuring that the projectile maintains speed and direction.

Importance of Maintenance

Regular maintenance of the barrel assembly is vital for optimal performance. Over time, debris or wear can impact the smooth operation, affecting both accuracy and reliability. Keeping the assembly clean and inspecting it for signs of wear can extend the life of the device and ensure safe operation.

Exploring the Spring and Piston Function

In many mechanical systems, the combination of a spring and piston plays a crucial role in generating and regulating motion. These components work together in a process that involves compression and expansion, converting stored energy into mechanical action. Understanding their interaction is key to comprehending how forces are managed and transferred within the system.

The spring is responsible for storing potential energy when compressed, while the piston acts as a driver that converts this stored energy into kinetic movement. Together, they form a dynamic system that ensures consistent operation, depending on the design and pressure applied.

| Component | Function |

|---|---|

| Spring | Stores and releases energy through compression and expansion. |

| Piston | Converts stored energy into mechanical movement, driving the system forward. |

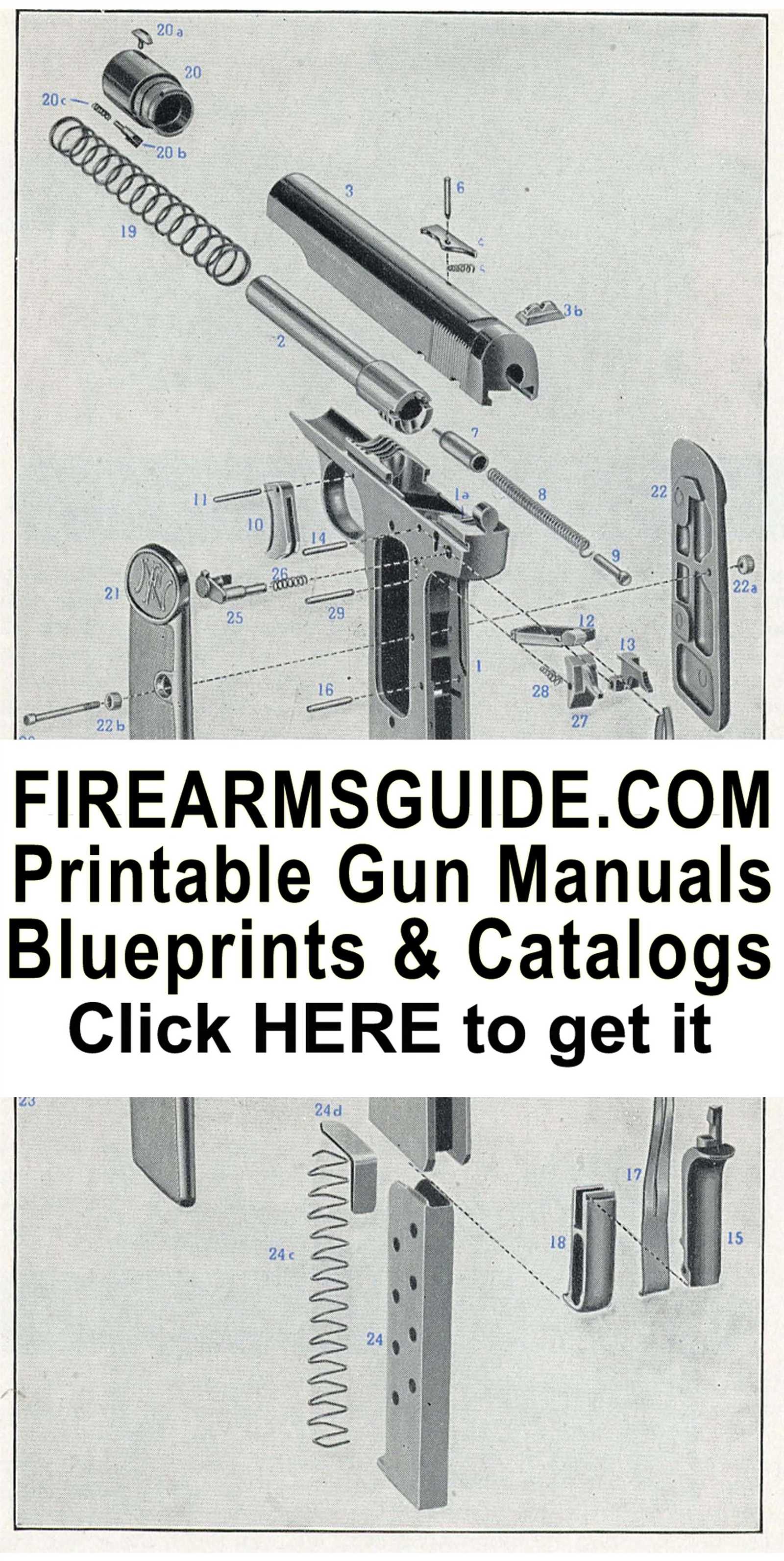

Magazine and Ammunition Loading System

The mechanism responsible for loading and storing projectiles plays a crucial role in the functionality of any air-powered shooting device. This system ensures that ammunition is efficiently fed into the firing chamber, ready for use. Understanding its components and operation is essential for maintaining smooth performance during use.

Key Components

- Loading chamber

- Spring or mechanical drive

- Feeding mechanism

- Sealing components

Loading Process

- Placing the ammunition into the loading chamber.

- The spring or mechanical drive activates to push the rounds into position.

- Feeding mechanism directs each round into the firing chamber when required.

- Once the round is loaded, the device is ready to fire.

Handle and Grip: Structure and Design

The handle and grip of a shooting instrument are crucial for ensuring comfort, control, and accuracy. Their design is carefully crafted to provide users with a firm and stable hold, allowing for better handling and overall performance. The materials used and the ergonomics of the grip play significant roles in reducing strain during extended use while enhancing the user’s precision and comfort level.

The structure of the handle is typically designed with attention to durability and ease of use. It often includes ergonomic features such as textured surfaces or contours to fit the natural curvature of the hand. This ensures a more secure and comfortable hold, which is essential for minimizing hand fatigue and enhancing performance.

The grip is often molded or coated with materials that offer a non-slip surface, allowing for better control even under challenging conditions. The choice of material can vary, with rubberized coatings or synthetic compounds being popular for their durability and comfort. Additionally, some designs feature customizable elements to suit different hand sizes and preferences.

External Parts and Their Maintenance

The external components of a device play a crucial role in its overall performance and longevity. Proper care and attention to these elements ensure the functionality and extend the lifespan of the system. Regular inspection and maintenance are essential to keep everything in optimal working condition, preventing premature wear and tear. Below, we will explore the key external elements that require care and how to maintain them effectively.

Key Components to Maintain

- Frame and Housing: Protects internal mechanisms from damage and dust.

- Trigger Mechanism: Responsible for initiating action; it should be cleaned and checked regularly.

- Grip and Handles: Ensure comfort and stability during use. Regularly inspect for cracks or wear.

- Barrel: Often subjected to stress and friction; periodic cleaning ensures smooth operation.

- Sights: Provide aiming accuracy; maintain cleanliness for clear vision.

Maintenance Tips

- Regularly inspect the external elements for signs of damage or wear.

- Use a soft cloth to clean the frame and housing to avoid scratches.

- Lubricate moving parts such as triggers and mechanisms to prevent friction-related issues.

- Ensure grips and handles remain free of dirt or moisture to preserve their functionality.

- Check sights for alignment and adjust as needed for precision targeting.

Sights and Aiming Mechanism Explained

Accurate targeting is essential for achieving precise shots, and understanding the components that assist in aligning a projectile with a target plays a key role. These elements, designed to guide the shooter, ensure that every shot is aimed correctly. The aiming mechanism consists of different parts, each working together to improve accuracy and consistency in shooting.

The primary components involved in aiming include:

- Rear Sight: Positioned at the back, this part helps in adjusting the view for various distances. It allows for fine-tuning the shot based on the target’s range.

- Front Sight: Located near the muzzle, the front sight provides a clear point of reference to align with the target. Its design can vary for better visibility.

- Adjustment Knobs: These allow users to modify the rear sight for windage and elevation, ensuring more accurate shots under varying conditions.

- Trigger Mechanism: A smooth and consistent trigger mechanism ensures the shot is released with precision after proper alignment.

Each of these components plays a crucial role in enhancing shooting accuracy, making it easier to align sights with the target. The proper use of these aiming elements ensures that the shooter maintains control and focus, leading to effective results.

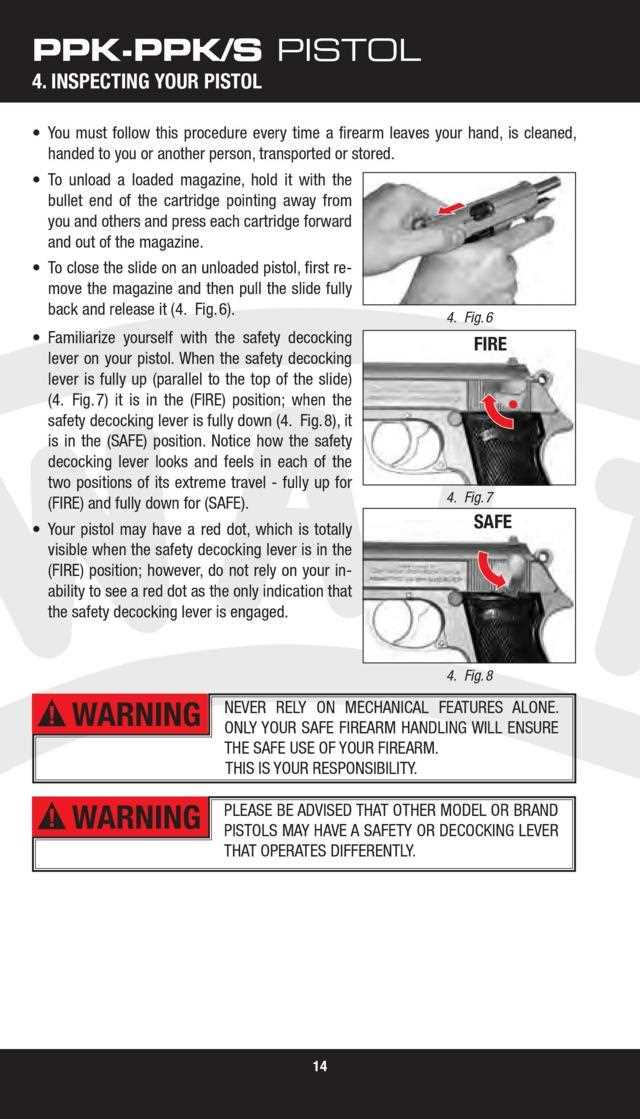

Safety Features and Controls Layout

Understanding the layout of safety mechanisms and control systems is essential for the proper and secure operation of any device. The key elements in this system are designed to provide both convenience and protection, ensuring that users can easily navigate and operate the unit with minimal risk.

The safety features are strategically positioned for quick access, allowing users to activate or deactivate them as needed. These controls are designed to enhance the overall user experience while maintaining high levels of security during operation.

- Trigger Safety Mechanism: A key component that prevents accidental activation, providing an extra layer of protection when handling the device.

- Safety Lock: Positioned to secure the unit in a non-operational state, avoiding any unintended use when not in active operation.

- Comfortable Grip: Designed to reduce the risk of slips, ensuring a firm and safe hold during use, even in challenging conditions.

- Clear Indicators: Visual signals guide users to easily understand when the system is in a safe or active mode.

- Adjustable Settings: Controls that allow users to modify the operational parameters while maintaining safety protocols.

Each control and safety feature is intuitively placed, giving users a seamless interaction with the device while keeping safety as the top priority.

Troubleshooting Common Parts Failures

Understanding common component malfunctions is crucial for restoring functionality to your device. Identifying the root cause of issues early on can save time and prevent unnecessary replacements. This section outlines some typical failures that might occur, along with tips to diagnose and resolve them effectively.

- Power Supply Failures: One of the most frequent issues, often caused by a broken connection or internal short circuit. Ensure the connections are secure and check for any visible signs of wear.

- Trigger Mechanism Problems: If the device does not respond when activated, the internal trigger mechanism might be jammed or damaged. Inspect the mechanism for obstructions or broken parts.

- Spring or Pneumatic Failures: These components are essential for the operation of the system. Over time, they may lose tension or suffer from mechanical wear. Check for any loss of spring tension or leaks in pneumatic systems.

- Ammunition Feed Issues: Inconsistent or failed feeding could result from misalignment or damage to the feeding mechanism. Examine the feed path and look for debris or broken components.

- Sealing or Gasket Failures: Leaks often arise from damaged seals. Inspect any rubber or plastic seals for cracks, and replace them if necessary to maintain proper pressure.

Regular maintenance and quick troubleshooting can extend the lifespan of your device, preventing further damage and improving overall performance.