Exploring the Husqvarna 240 Parts Diagram for Ultimate Clarity

The intricate assembly of a cutting tool is crucial for its optimal performance and longevity. Each element plays a vital role in ensuring that the equipment functions smoothly, making it essential for users to familiarize themselves with its structure. This knowledge not only aids in maintenance but also enhances overall efficiency during operation.

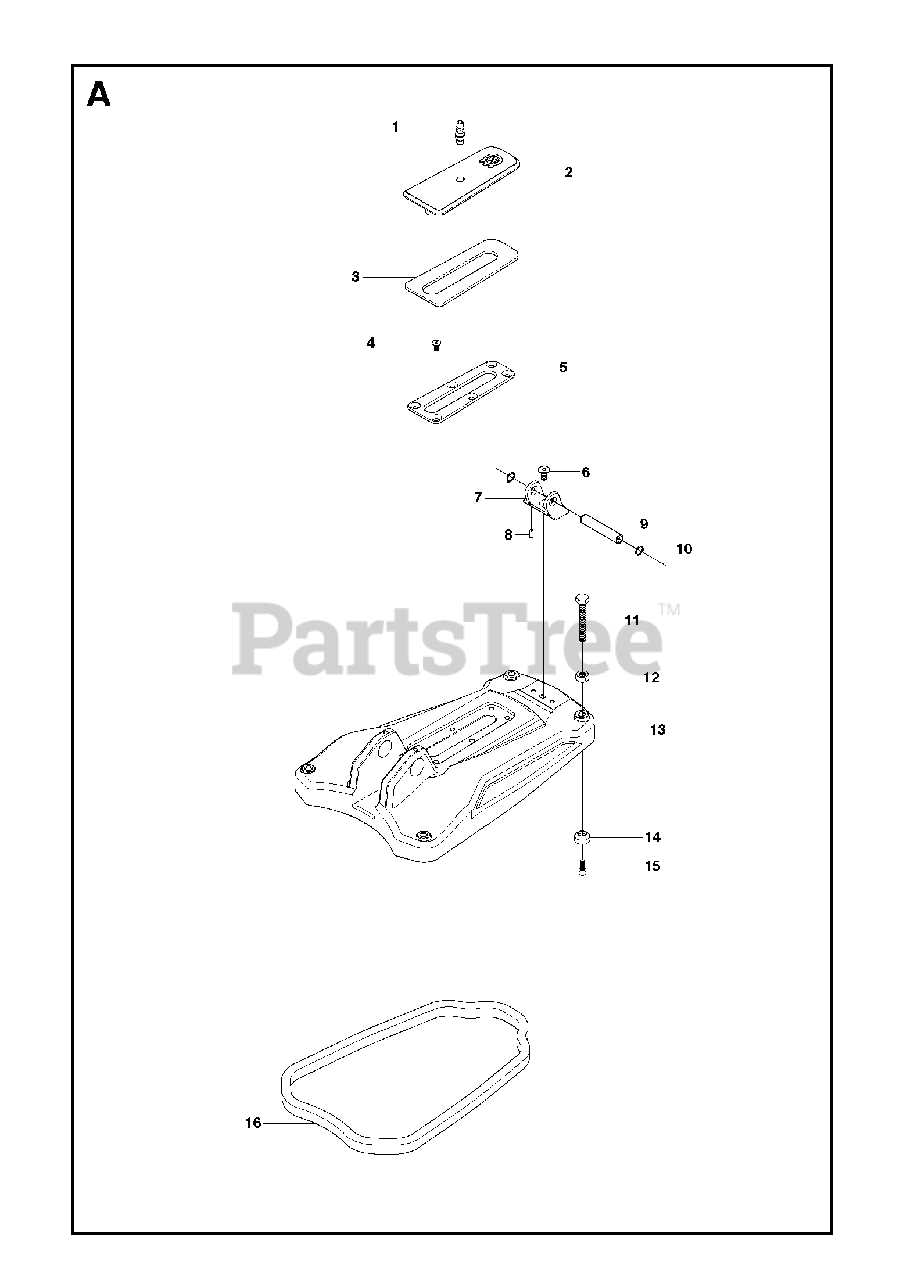

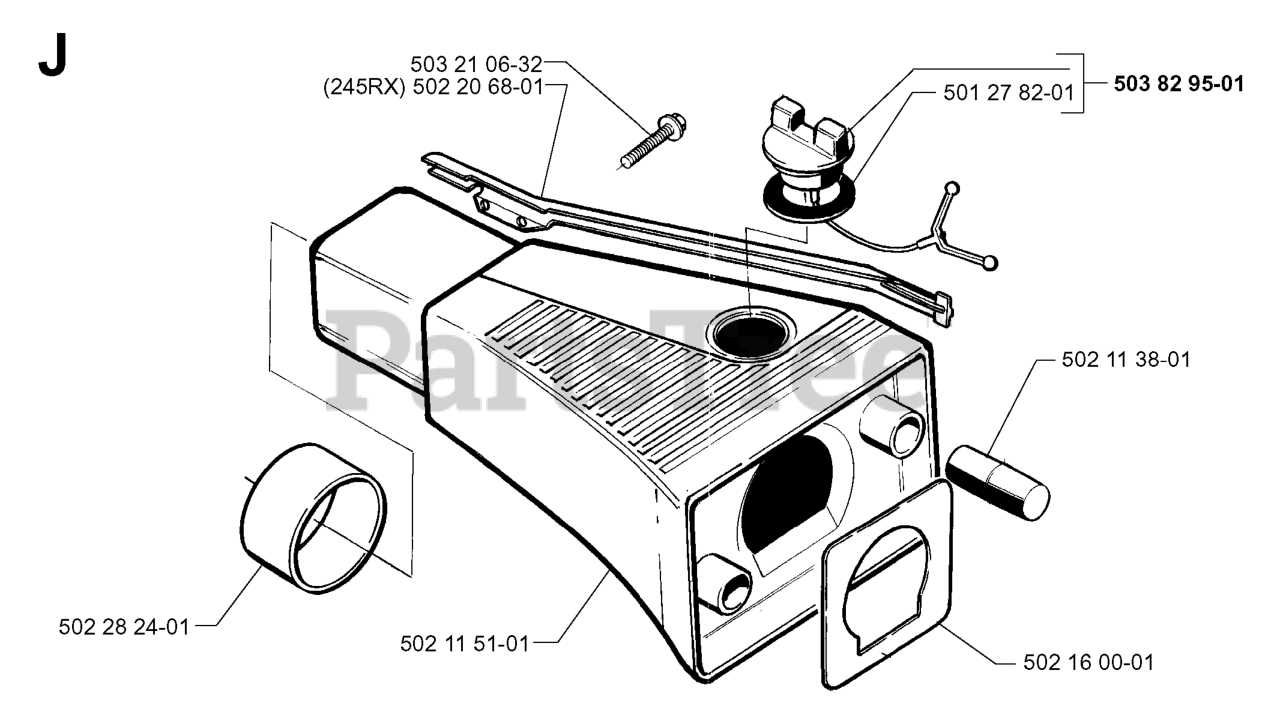

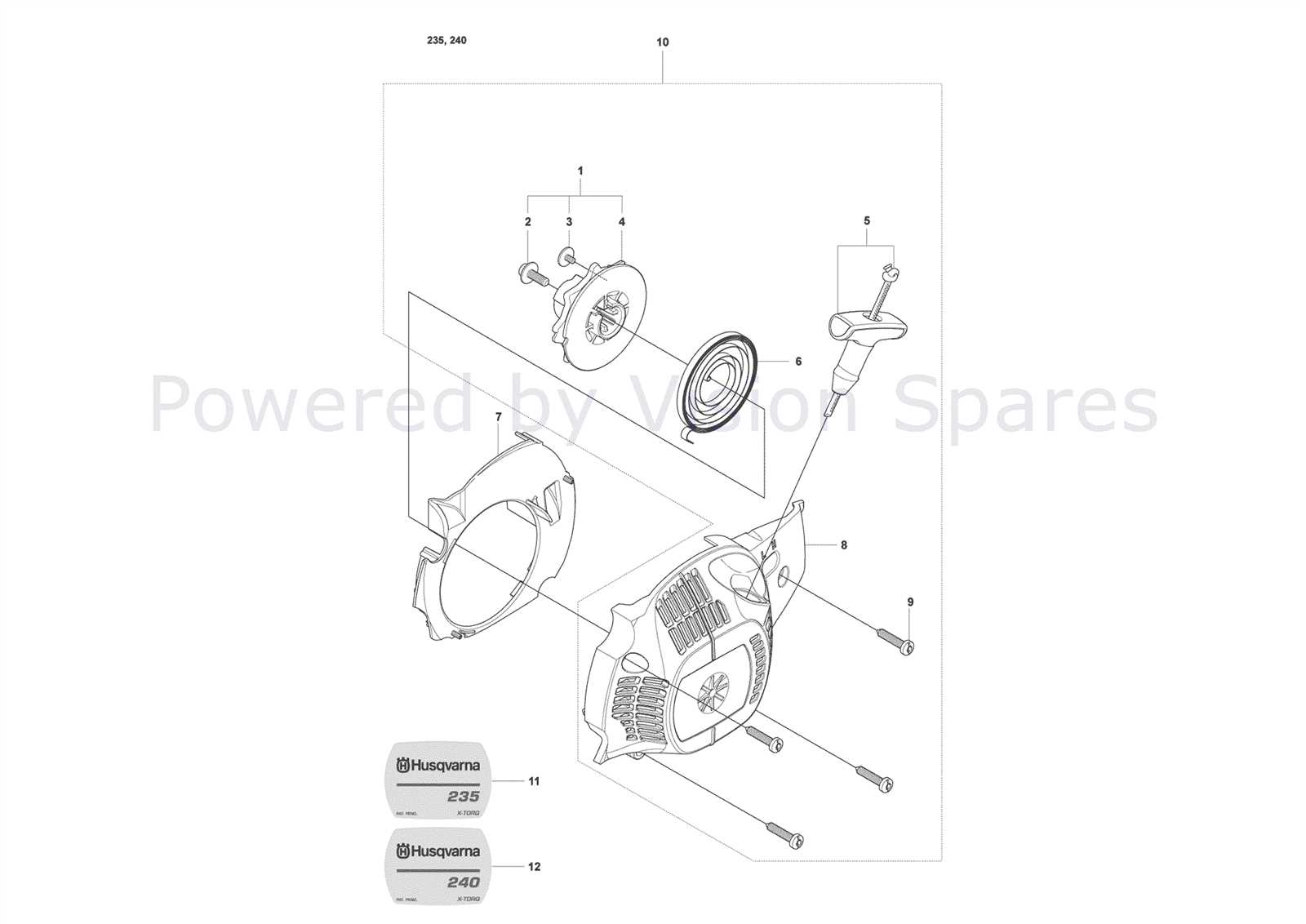

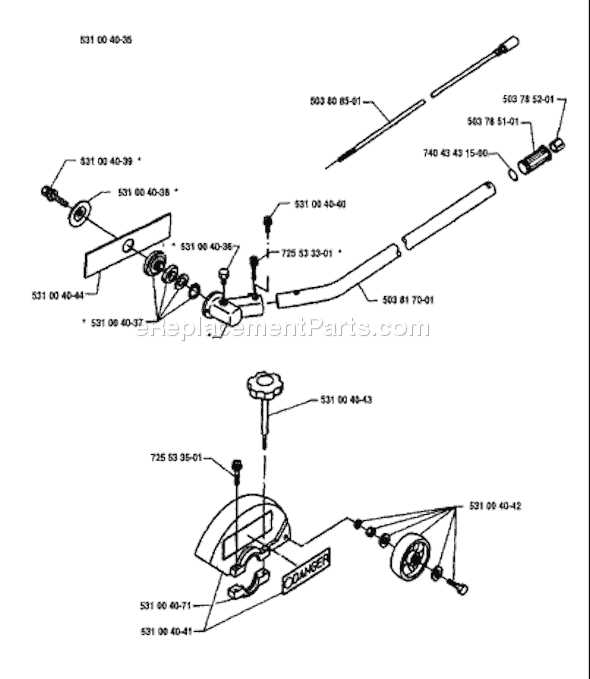

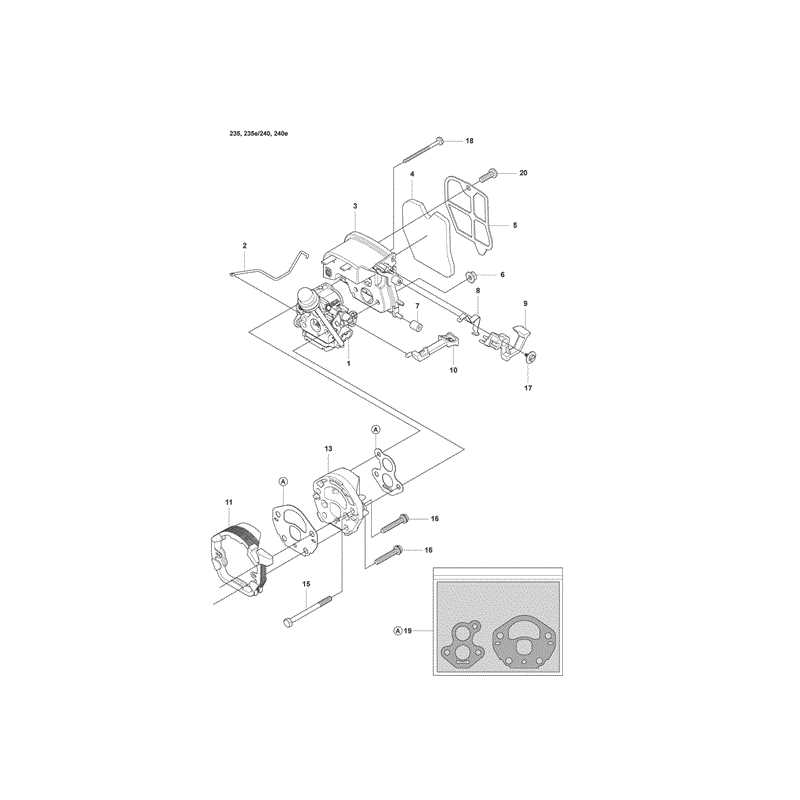

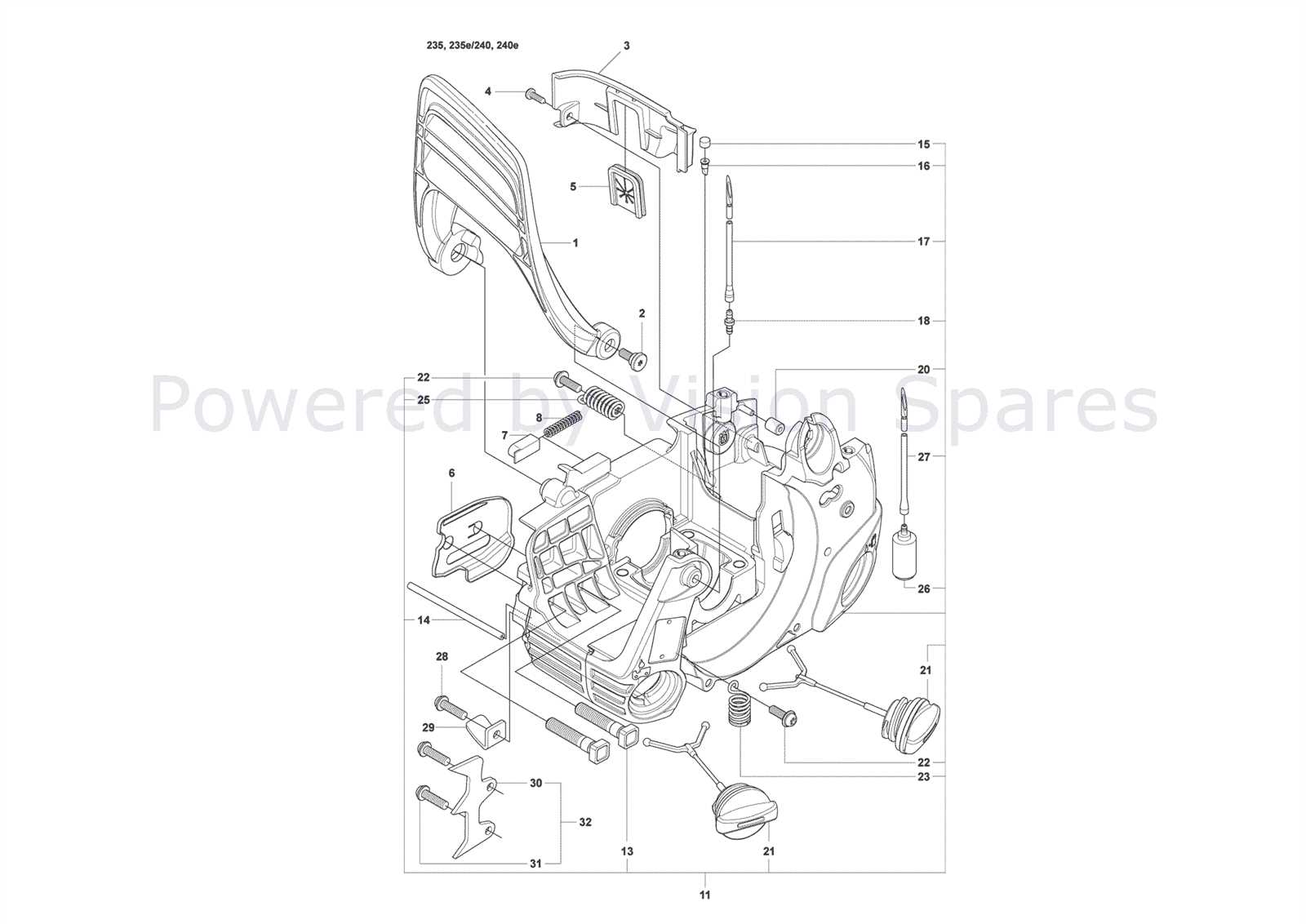

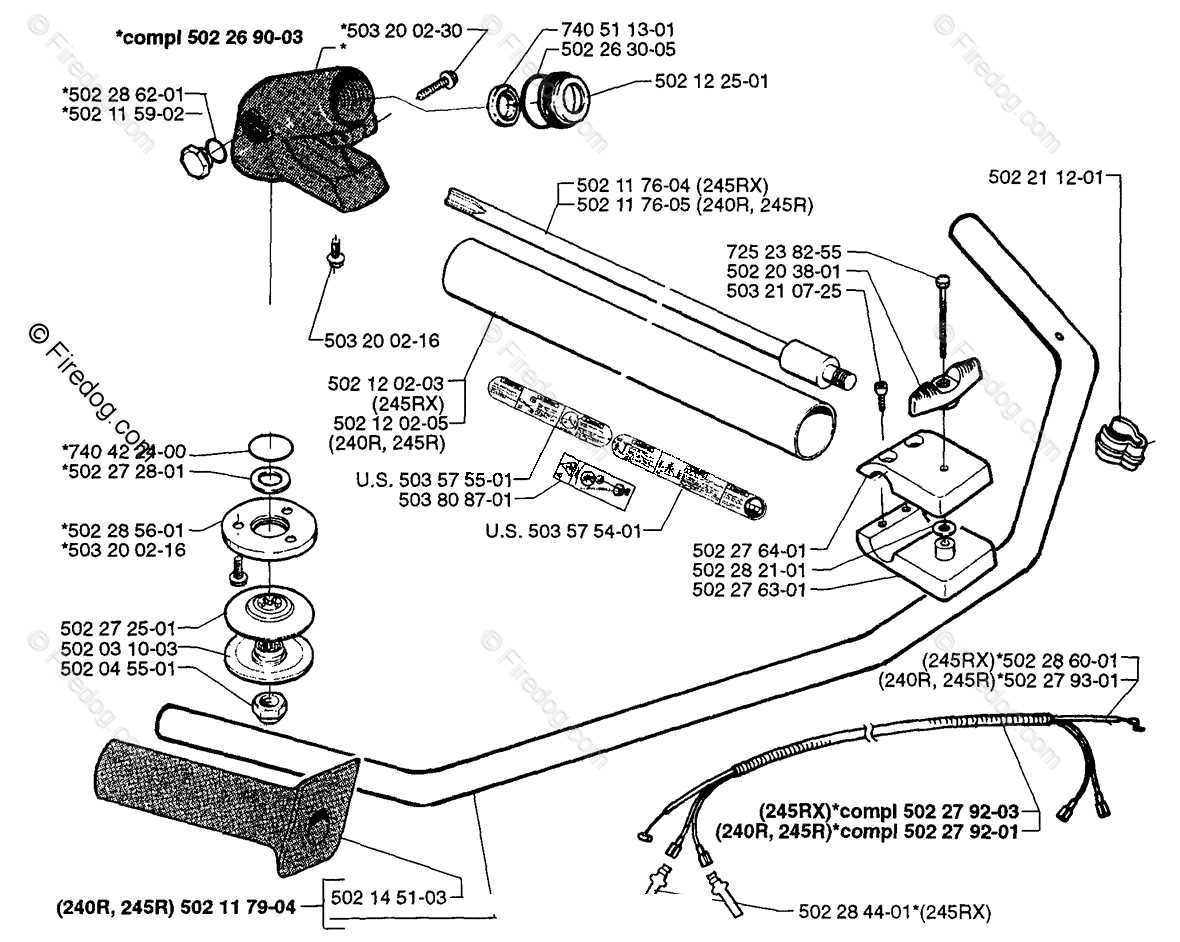

To navigate the complexities of your machine, a detailed visual representation can be incredibly beneficial. Such an illustration provides clarity on the arrangement and connection of each individual segment, allowing users to identify specific components and their functions effortlessly. By grasping these details, operators can make informed decisions when it comes to repairs and upgrades.

Ultimately, understanding the assembly of your equipment empowers you to tackle any issues that may arise. Whether it’s for routine maintenance or troubleshooting, having access to a comprehensive reference can streamline your efforts, ensuring that your tool remains in top-notch condition for years to come.

Understanding Husqvarna 240 Components

Exploring the intricate elements of a specific tool reveals the importance of each component in ensuring optimal performance and longevity. A comprehensive grasp of these individual parts allows users to maintain their equipment effectively, addressing potential issues before they escalate.

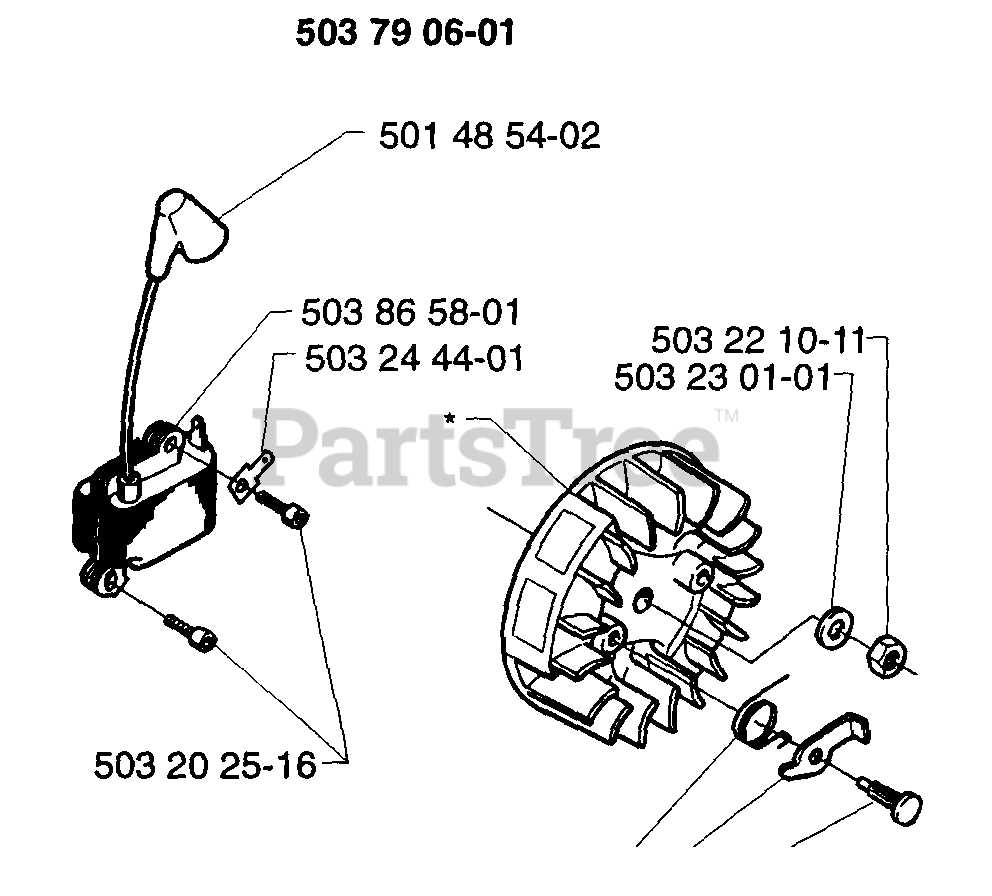

Key components play crucial roles in the overall functionality. From the engine assembly to the cutting mechanism, each element must work in harmony to achieve the desired results. Familiarity with these components enables users to identify and troubleshoot common problems swiftly.

Moreover, understanding the interplay between various elements aids in selecting appropriate replacements when needed. Knowing the specifications and functions of each part empowers users to make informed decisions and enhances their overall experience.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations serve as a guide, helping users identify each element and understand its function within the overall system. This clarity enhances efficiency and accuracy when performing repairs or replacements, ensuring that every piece is correctly handled.

Furthermore, these visual aids assist in simplifying complex mechanical structures. By breaking down assemblies into individual components, they enable users to visualize the interconnections and workflows, fostering a deeper understanding of the equipment. This can be particularly beneficial for those who may not have extensive technical training.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Illustrations provide a clear view of all components, reducing confusion during repairs. |

| Time Efficiency | Quick identification of parts allows for faster troubleshooting and maintenance. |

| Improved Learning | Visual tools aid in the understanding of complex systems, promoting better knowledge retention. |

| Reduced Errors | Clear guidance minimizes the risk of mistakes during assembly or disassembly. |

Common Issues with Husqvarna 240

When operating a popular chainsaw model, users often encounter several recurring challenges that can affect performance and reliability. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

Engine Troubles

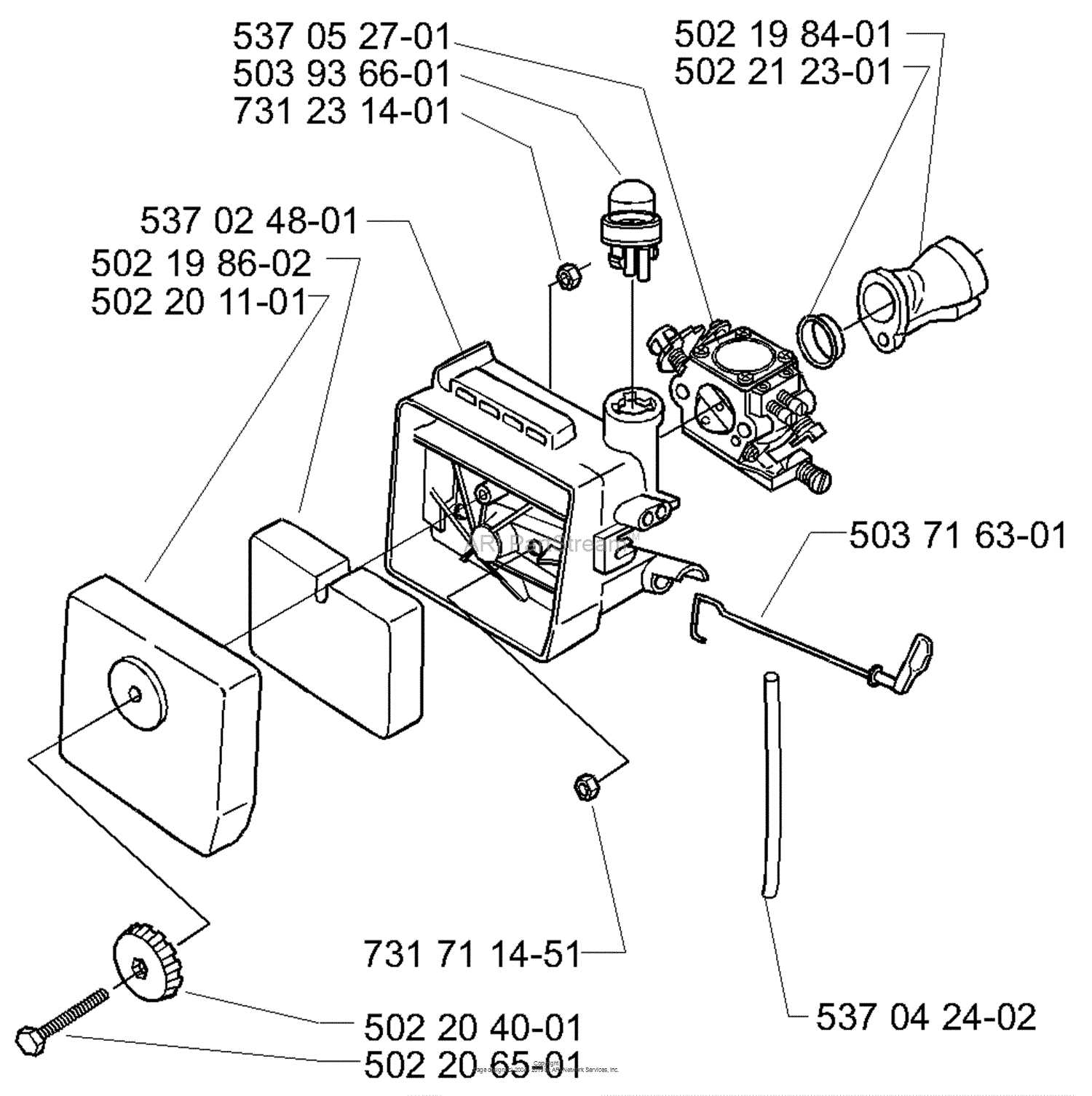

One frequent issue is related to engine performance. Users may notice difficulties in starting or inconsistent idling. This can often be attributed to fuel quality, air filter blockages, or ignition system failures. Regular maintenance and timely replacement of filters can mitigate these issues.

Chain and Bar Concerns

Another area where problems arise is with the cutting components. Chains can become dull or damaged, leading to inefficient cutting and increased strain on the engine. Additionally, bar wear can occur if lubrication is inadequate. Ensuring proper maintenance and using the correct tension for the chain are essential for longevity and effectiveness.

Addressing these common challenges will enhance the performance and lifespan of your equipment, ensuring it remains a reliable tool for various tasks.

How to Use the Diagram Effectively

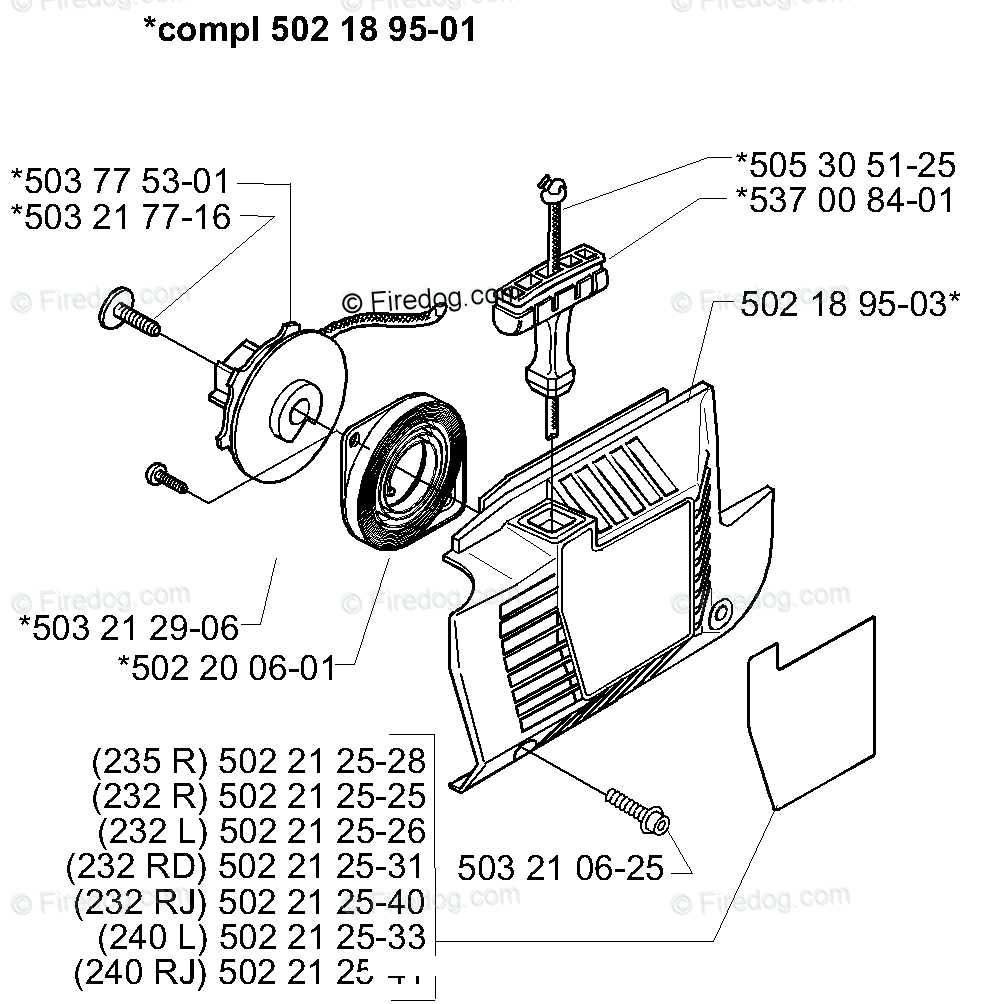

Understanding how to navigate a visual reference for components can significantly enhance your repair or maintenance experience. By familiarizing yourself with the layout and symbols, you can quickly identify and source the necessary items, making the process more efficient and less stressful.

Familiarize Yourself with the Layout

Start by examining the overall structure of the visual guide. Note how the elements are organized and categorized. This will help you locate specific sections with ease, ultimately saving time when you need to refer back to it during repairs.

Cross-Reference with Manuals

Use the visual guide alongside your user manual or service instructions. This cross-referencing allows for a more comprehensive understanding, ensuring that you are aware of any specific installation techniques or safety precautions associated with the components.

Identifying Replacement Parts

When it comes to maintaining your equipment, recognizing the essential components is crucial for effective repairs and replacements. Understanding how each piece contributes to overall functionality can enhance performance and extend the lifespan of your machine.

Begin by consulting the user manual, which often includes detailed information about various components and their specifications. This resource will guide you in pinpointing the necessary items based on your specific model and its requirements.

Additionally, utilizing online resources or forums dedicated to similar machinery can provide insights from fellow users. These platforms often share experiences and recommendations that can assist in identifying the correct replacements.

Ultimately, having a clear understanding of the individual elements will streamline the process, making it easier to find and acquire what you need for successful maintenance.

Maintenance Tips for Husqvarna 240

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential issues that could arise from neglect. Following a consistent maintenance routine will help you get the most out of your machine.

Routine Inspections

Conduct regular inspections to check for any signs of wear or damage. Pay attention to the cutting elements, air filters, and fuel systems. Ensuring that these components are in good condition will prevent unexpected breakdowns and maintain high performance levels.

Cleaning and Lubrication

Regular cleaning is crucial for maintaining functionality. Remove debris and dirt from the equipment after each use. Additionally, applying appropriate lubricants to moving parts will reduce friction and wear, promoting smooth operation and extending the lifespan of your tool.

Finding Genuine Parts Online

Locating authentic components for your machinery online can be a straightforward process if approached with care. The key is to ensure that the sources you choose are reliable and specialize in high-quality replacements. By doing so, you can maintain the performance and longevity of your equipment while avoiding the pitfalls of counterfeit alternatives.

Identifying Trustworthy Retailers

Start by researching reputable vendors that are known for their commitment to quality. Look for customer reviews and ratings, as these can provide valuable insights into their service and product reliability. Additionally, official websites often have lists of authorized dealers, ensuring that you are purchasing genuine items.

Utilizing Online Marketplaces

While online marketplaces can offer convenience, exercise caution. Always verify the seller’s credentials and check for guarantees that confirm the authenticity of the components. Secure transactions and return policies are also crucial to ensure a smooth purchasing experience.

Benefits of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. Engaging in routine care not only enhances efficiency but also prevents unexpected breakdowns, ultimately saving time and resources.

| Benefit | Description |

|---|---|

| Increased Longevity | Regular maintenance extends the lifespan of equipment by addressing wear and tear early. |

| Improved Performance | Well-maintained machines operate more smoothly and effectively, leading to better results. |

| Cost Savings | Preventative care reduces the likelihood of costly repairs and replacements over time. |

| Enhanced Safety | Regular checks help identify potential hazards, ensuring a safer working environment. |

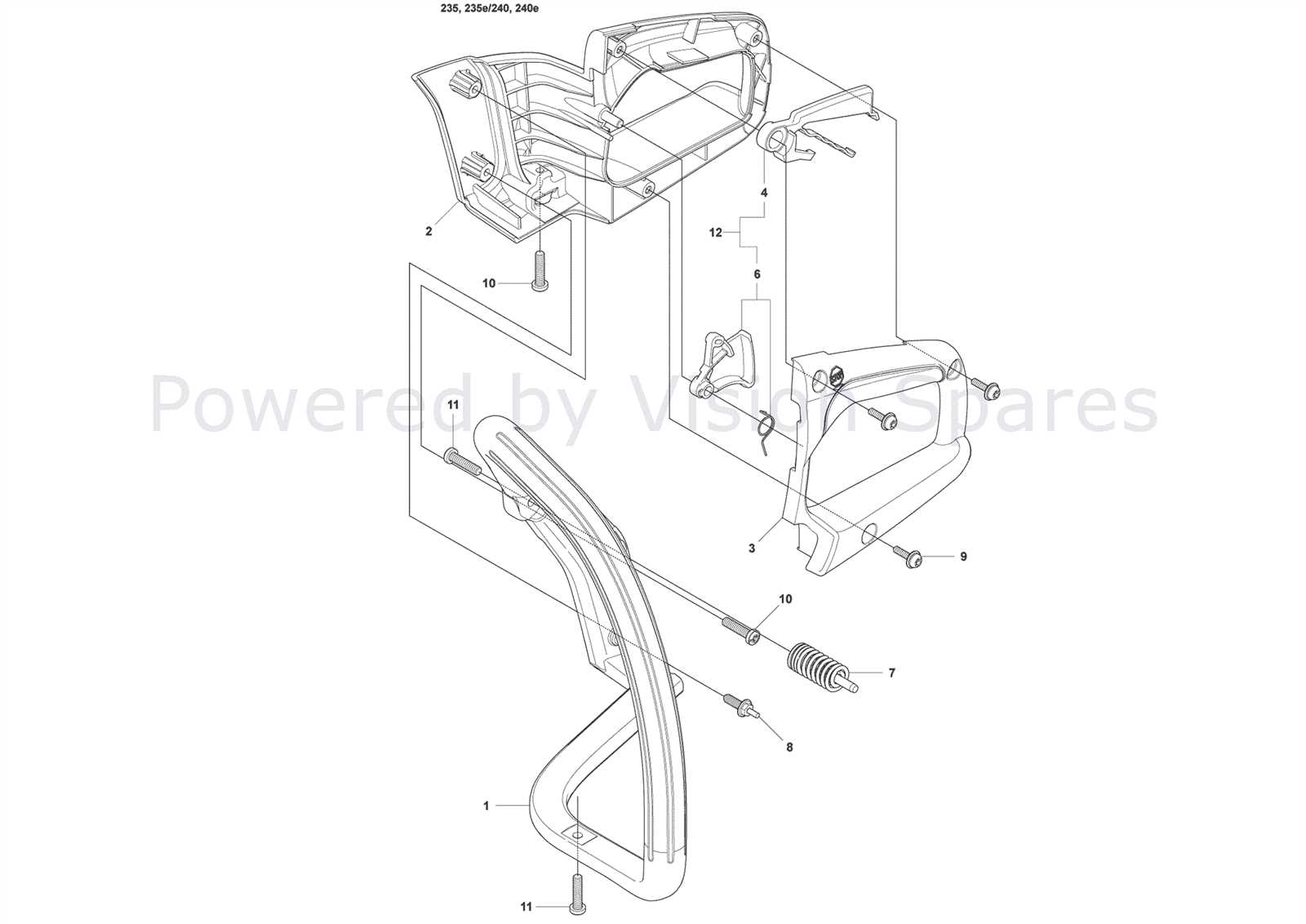

Assembly and Disassembly Instructions

Understanding the process of assembling and disassembling equipment is crucial for effective maintenance and repair. This section provides a clear guide on how to safely and efficiently take apart and put together components, ensuring optimal performance and longevity.

Disassembly Process

Begin by preparing your workspace, ensuring that all necessary tools are within reach. Safety first: always wear protective gear, such as gloves and goggles. Start by removing any external parts that may obstruct access to internal components. Carefully document each step, taking notes or photos, as this will aid in the reassembly process. Use appropriate tools to avoid damaging screws or fittings.

Assembly Process

Once disassembled, inspect all parts for wear or damage before beginning reassembly. Start by aligning components as per the manufacturer’s specifications. Take your time: ensuring each part fits correctly is essential for proper function. Secure all screws and fittings, double-checking each connection for stability. Finally, perform a thorough inspection to confirm that everything is assembled correctly before testing the equipment.

Upgrading Your Husqvarna Chainsaw

Enhancing your saw can significantly improve performance, efficiency, and longevity. With various components available, you can optimize your equipment for better cutting power and user comfort. This guide explores essential upgrades to take your tool to the next level.

Key Upgrades to Consider

- Bar and Chain: Upgrading to a high-quality bar and chain can reduce cutting resistance and improve speed.

- Air Filter: A premium air filter enhances airflow, ensuring your engine runs smoothly.

- Fuel System: Upgrading the fuel line and carburetor can lead to better fuel efficiency and performance.

Benefits of Upgrading

- Increased Cutting Efficiency

- Enhanced Engine Longevity

- Improved User Safety and Comfort

By carefully selecting components for enhancement, you can achieve the ultimate performance from your equipment while ensuring it meets your specific needs.