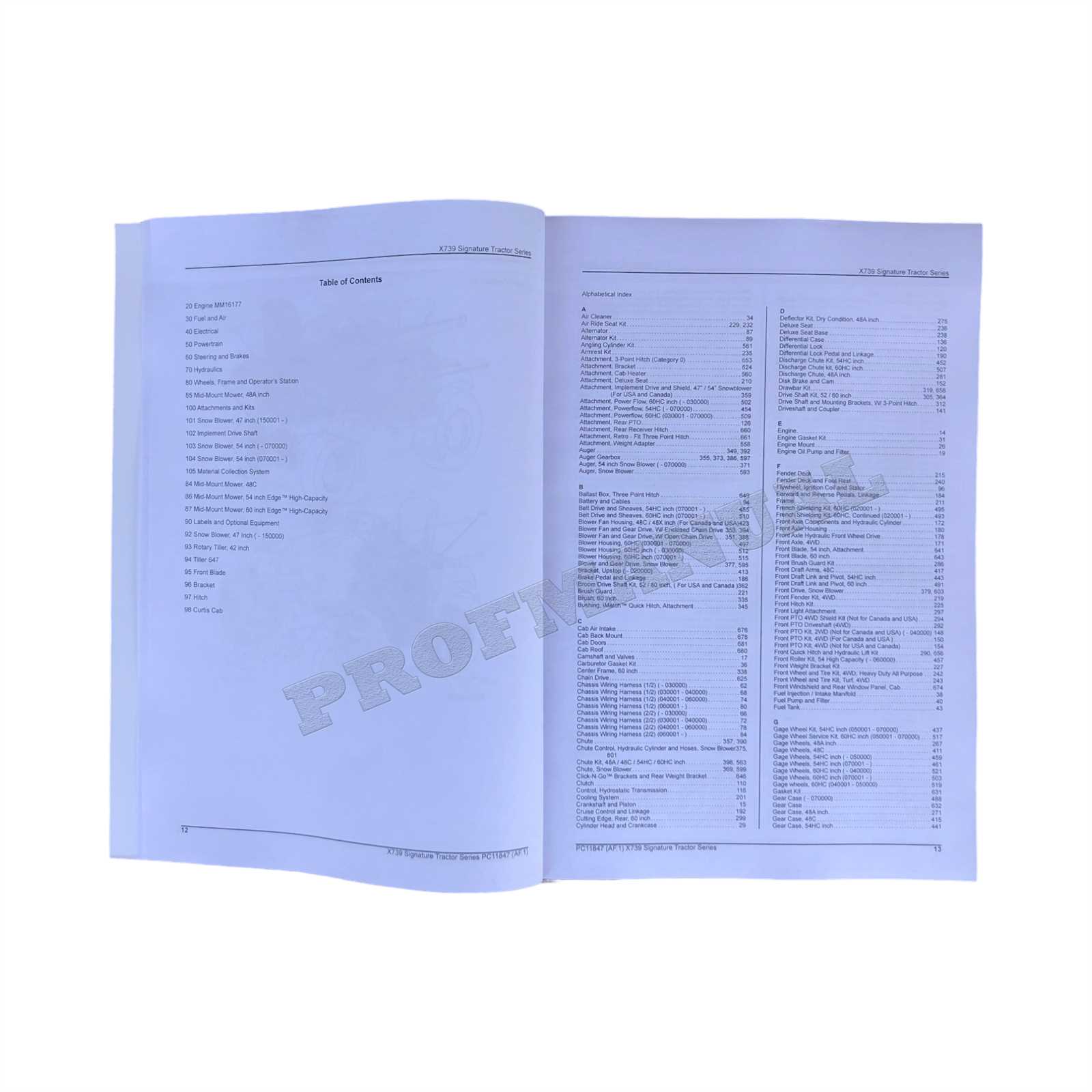

Complete Parts Diagram for John Deere X739

In the realm of agricultural machinery, a comprehensive grasp of individual elements and their arrangements is crucial for optimal performance. Each piece plays a significant role, contributing to the overall functionality of the equipment. Recognizing how these components interact can enhance maintenance and repair efforts, ultimately extending the lifespan of the machine.

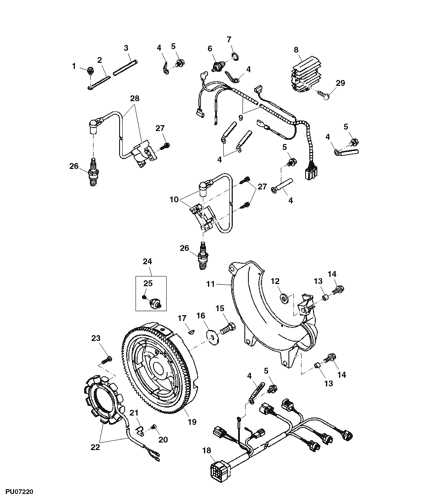

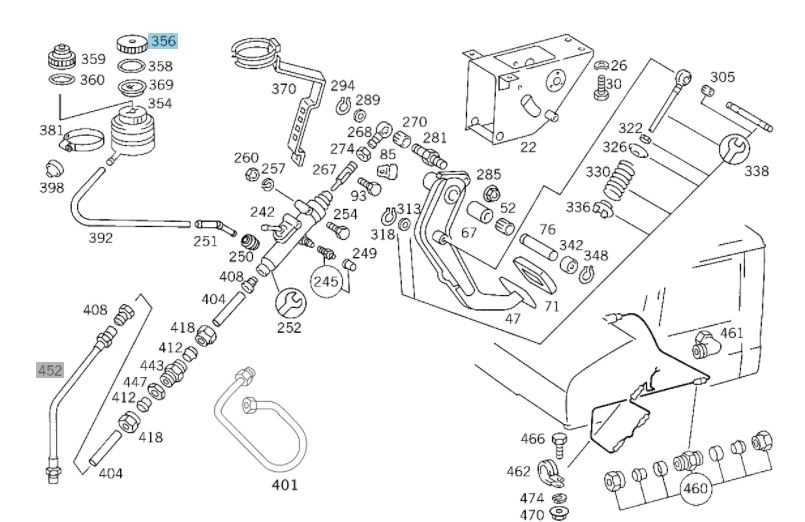

Visual representations of these elements provide invaluable insights into the assembly and operation of the machinery. By examining these illustrations, operators and technicians can pinpoint specific parts, facilitating troubleshooting and upgrades. This understanding fosters a deeper connection to the equipment, empowering users to make informed decisions regarding care and enhancement.

Whether for routine maintenance or complex repairs, being familiar with the intricate layout of components allows for a more efficient workflow. Engaging with these visuals helps demystify the machinery, making it accessible even to those who may not be specialists. As a result, a solid knowledge base about these essential elements can lead to improved performance and greater satisfaction in using the equipment.

Understanding John Deere X739 Parts

Gaining insight into the various components of your equipment is essential for effective maintenance and operation. Familiarity with each element not only enhances performance but also ensures longevity. This section delves into the intricate details of the machine’s structure, offering a comprehensive look at its essential elements.

Key Components

- Engine: The powerhouse that drives the machine.

- Transmission: Essential for transferring power efficiently.

- Chassis: The framework that supports all other elements.

- Steering System: Critical for maneuverability and control.

- Electrical System: Powers various functionalities and features.

Maintenance Tips

- Regularly inspect the engine for signs of wear.

- Check fluid levels and replace them as necessary.

- Ensure all connections in the electrical system are secure.

- Clean the chassis to prevent rust and damage.

- Consult the manual for specific maintenance schedules.

Overview of X739 Model Features

This section provides an insight into the notable characteristics of a premium lawn care machine designed for efficiency and versatility. It highlights the features that contribute to its exceptional performance in various gardening tasks.

- Powerful Engine: Equipped with a robust engine that delivers reliable performance, ensuring that the machine can tackle tough mowing conditions with ease.

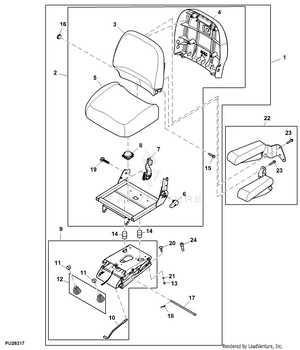

- Comfortable Operation: Designed with user comfort in mind, it offers an ergonomic seat and intuitive controls for a smooth and enjoyable experience.

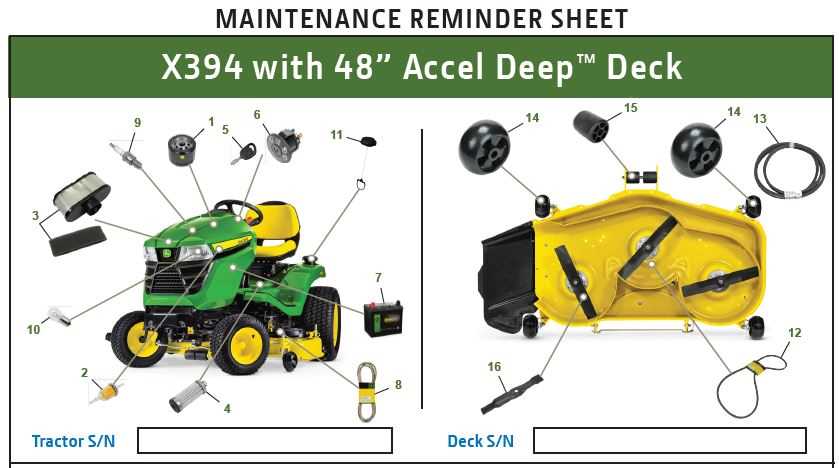

- Advanced Cutting System: Features a sophisticated cutting mechanism that provides precise and uniform grass trimming, promoting a healthy lawn.

- Versatile Attachments: Compatible with a variety of tools and accessories, allowing for year-round functionality beyond just mowing.

- Durability: Built with high-quality materials to withstand the rigors of outdoor use, ensuring longevity and reliable service.

- Easy Maintenance: Engineered for straightforward upkeep, simplifying the process of servicing and enhancing longevity.

The combination of these attributes makes this model a valuable asset for homeowners and professional landscapers alike, providing the necessary tools to maintain a pristine outdoor space.

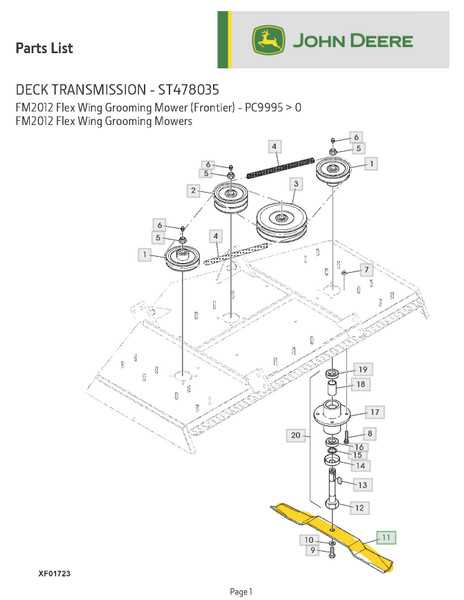

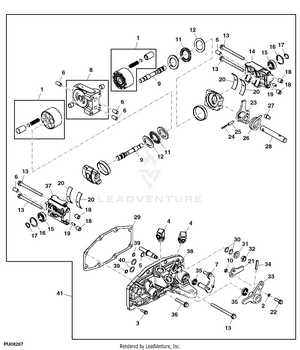

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations play a significant role in achieving this clarity, enabling users to identify components and their relationships within the system.

Such illustrations offer numerous advantages, including:

- Enhanced Clarity: Visual aids simplify complex systems, making it easier to grasp the layout and function of each element.

- Efficient Troubleshooting: With clear visuals, identifying issues becomes quicker, leading to faster resolution of problems.

- Improved Communication: These representations facilitate better discussions among technicians and users, ensuring everyone is on the same page.

- Accurate Ordering: Knowing the specific components needed helps in obtaining the right replacements without errors.

- Streamlined Assembly: When putting parts together, visual guides can significantly reduce assembly time and prevent mistakes.

In summary, detailed illustrations are invaluable tools for anyone working with machinery, providing clarity, efficiency, and accuracy throughout the maintenance process.

Key Components of X739 Machinery

This section delves into the essential elements that make up this specific model, highlighting their functions and importance in overall performance. Understanding these components allows for better maintenance and enhances the longevity of the machinery.

Core Functional Parts

Among the primary elements, the engine plays a pivotal role, providing the necessary power for operation. Coupled with the transmission system, it ensures smooth movement and optimal efficiency. Additionally, the cutting deck is critical for achieving precise lawn care.

Supporting Systems

Auxiliary systems such as the fuel system and electrical components contribute to the machinery’s functionality. These systems are designed to support the main operations, ensuring reliability and ease of use.

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Transmission | Facilitates movement and speed control |

| Cutting Deck | Ensures effective lawn cutting |

| Fuel System | Delivers fuel to the engine |

| Electrical Components | Supports ignition and lighting |

Finding Replacement Parts Easily

Locating the right components for your equipment can often feel daunting, but with the right approach, it becomes a straightforward task. Understanding how to access the necessary information and resources is essential for maintaining your machinery effectively.

Utilizing Online Resources

- Search for manufacturer websites that provide detailed information on components.

- Join forums and community groups dedicated to equipment maintenance for insights and recommendations.

- Explore online marketplaces that specialize in equipment parts, offering user-friendly search options.

Consulting Manuals and Guides

- Refer to the operator’s manual for specific details about your machine’s components.

- Look for technical service guides that outline part numbers and specifications.

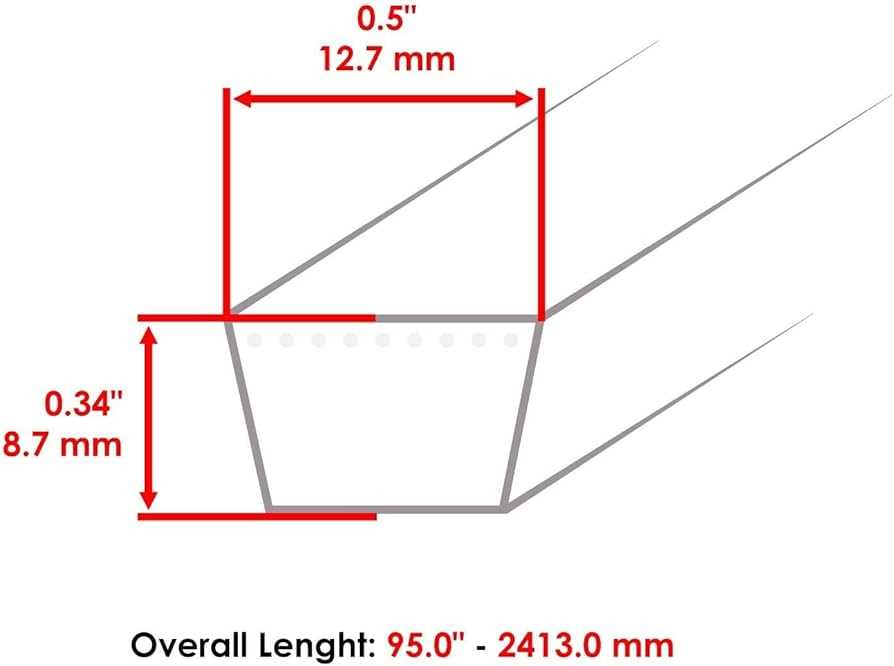

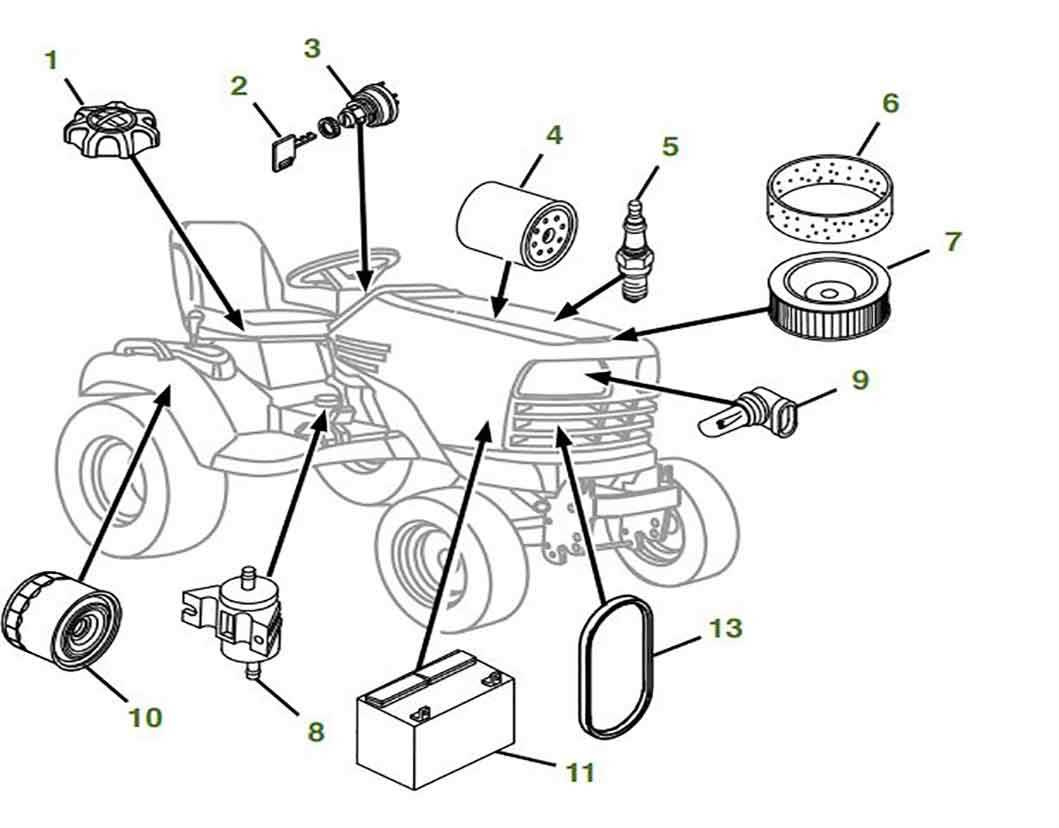

- Use visual aids such as schematics to better understand where each component fits.

By leveraging these strategies, you can streamline the process of finding and acquiring the necessary components to keep your equipment running smoothly.

Common Issues with X739 Parts

When dealing with machinery, it is not uncommon to encounter various challenges related to individual components. Understanding these common concerns can significantly enhance maintenance efforts and prolong the lifespan of the equipment. Below are some frequent issues users may experience with their machines.

Frequent Component Failures

Several elements tend to experience wear and tear over time. Key areas of focus include:

- Belts: Prone to fraying and cracking, requiring regular inspections.

- Blades: Dullness can lead to inefficient cutting, necessitating frequent sharpening or replacement.

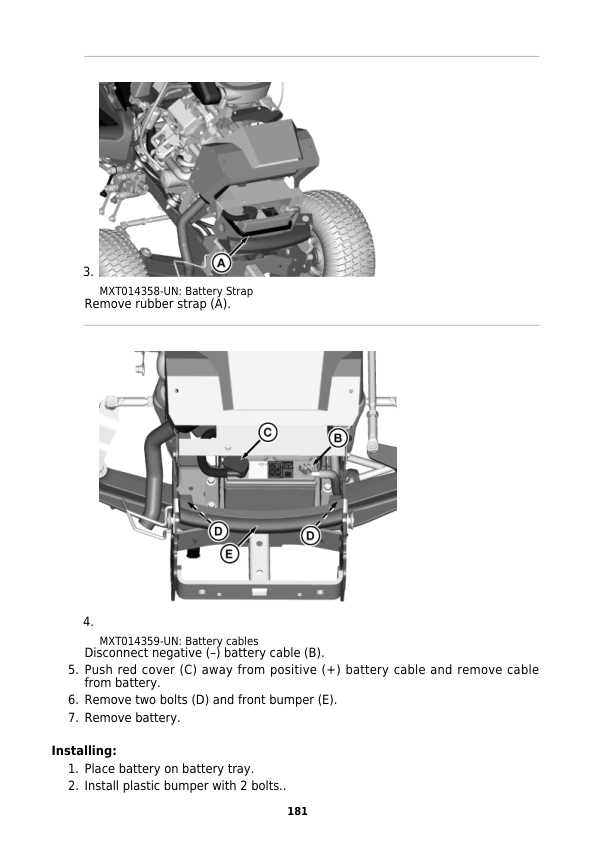

- Battery: Short lifespan or failure can result in starting issues.

Performance Issues

Another aspect to consider is how certain components can affect overall functionality:

- Transmission: Slipping or lagging can indicate internal wear.

- Fuel System: Clogs in filters or lines can lead to power loss.

- Electrical Connections: Corrosion can disrupt functionality, causing intermittent operation.

By being aware of these prevalent issues, operators can take proactive steps to ensure efficient and reliable performance from their equipment.

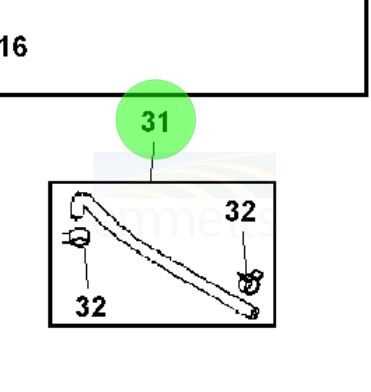

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair of machinery. These visual aids provide a detailed representation of various elements, helping users identify and source the necessary items. Grasping how to interpret these visuals can significantly streamline your repair processes.

Key Elements of Illustrations

Component illustrations typically include several vital features. Familiarizing yourself with these elements will enhance your ability to utilize them effectively:

| Element | Description |

|---|---|

| Labeling | Each part is usually assigned a unique identifier or code that corresponds to a list of components. |

| Legend | A key that explains symbols, lines, and shading used in the illustration to convey specific meanings. |

| References | Numerical or alphabetical markers linking parts to their respective descriptions in an accompanying manual or catalog. |

Tips for Effective Reading

To maximize your comprehension of these illustrations, consider the following strategies:

- Always begin with the legend to understand the symbols used.

- Take note of the identifiers for each component, as these will guide you when sourcing replacements.

- Cross-reference with the accompanying documentation to clarify any uncertainties.

Essential Tools for Maintenance

Proper upkeep of your equipment is vital for ensuring longevity and optimal performance. Having the right tools on hand can make all the difference, allowing for efficient servicing and quick repairs. This section highlights key instruments that every operator should consider for effective maintenance routines.

Basic Hand Tools

Starting with the fundamentals, a selection of hand tools is indispensable. Wrenches, screwdrivers, and pliers should be part of every toolkit. These tools facilitate easy adjustments and replacements, ensuring that components are secured and functioning as intended. It’s advisable to keep a variety of sizes to accommodate different fasteners.

Diagnostic Equipment

In addition to hand tools, diagnostic equipment is crucial for identifying issues before they escalate. Tools such as multimeters and pressure gauges can provide valuable insights into the condition of your machinery. Regular checks with these instruments can help prevent unexpected breakdowns and extend the life of your equipment.

Where to Buy Authentic Parts

Finding genuine components for your machinery is crucial for ensuring optimal performance and longevity. Whether you’re a professional landscaper or a dedicated hobbyist, sourcing high-quality replacements can make all the difference in your equipment’s efficiency. Authentic products not only guarantee compatibility but also enhance reliability, ultimately saving you time and money in the long run.

Official Retailers

One of the best places to purchase genuine components is through authorized dealers. These retailers often carry a comprehensive selection of items tailored to specific models, ensuring you receive exactly what you need. Additionally, they provide expert advice and support, helping you choose the right parts for your equipment.

Online Marketplaces

Numerous reputable online platforms specialize in high-quality components. When using these sites, it is essential to verify the authenticity of the products. Look for sellers with positive reviews and ensure that they offer return policies, as this can provide peace of mind when making a purchase. Always prioritize vendors known for their commitment to quality and customer satisfaction.

Comparing Aftermarket and OEM Options

When it comes to sourcing components for machinery, understanding the differences between original and alternative suppliers is crucial. Each option has its advantages and potential drawbacks, influencing both performance and budget. This section delves into the key factors to consider when deciding which type of component best suits your needs.

Quality and Performance

Original components are often engineered specifically for a particular machine, ensuring compatibility and reliability. These parts typically come with warranties that guarantee their performance. On the other hand, alternatives may vary in quality, as they can be produced by different manufacturers with varying standards. While some aftermarket options can match or even exceed the quality of originals, it is essential to research the supplier’s reputation and product reviews.

Cost Considerations

One of the most significant differences between original and alternative components is the price. Original equipment tends to be more expensive due to brand recognition and the assurance of quality. In contrast, aftermarket options often present a more affordable solution, appealing to those looking to save on maintenance costs. However, it is important to weigh the initial savings against the potential need for replacements or repairs down the line.

In summary, the choice between original and alternative components hinges on balancing quality, performance, and cost. Making an informed decision can lead to better maintenance outcomes and extended machinery life.

Tips for DIY Repairs

Engaging in self-repair can be a rewarding experience, offering both cost savings and the satisfaction of completing a project. However, it’s essential to approach these tasks with preparation and care to ensure success and safety. Here are some useful tips to help you navigate your repair journey.

- Gather the Right Tools: Ensure you have the necessary tools before starting. A well-equipped toolbox can make the process smoother.

- Consult the Manual: Always refer to the equipment’s manual for guidance on assembly and maintenance. This can provide valuable insights and troubleshooting steps.

- Take Notes: Document each step of the disassembly and repair process. This will help you remember the order and placement of components.

- Work in a Clean Space: A tidy workspace minimizes the risk of losing small parts and makes it easier to focus on the task.

Before you start, ensure that you have all necessary materials and parts on hand to avoid interruptions. Here are a few more strategies to consider:

- Safety First: Always wear appropriate safety gear, including gloves and goggles, to protect yourself from injuries.

- Test Your Work: After completing repairs, always test the equipment to ensure everything is functioning properly before returning it to use.

- Seek Help When Needed: If you encounter difficulties, don’t hesitate to ask for assistance or consult online forums for advice.

By following these guidelines, you can enhance your repair skills and confidence, making each project a successful endeavor.

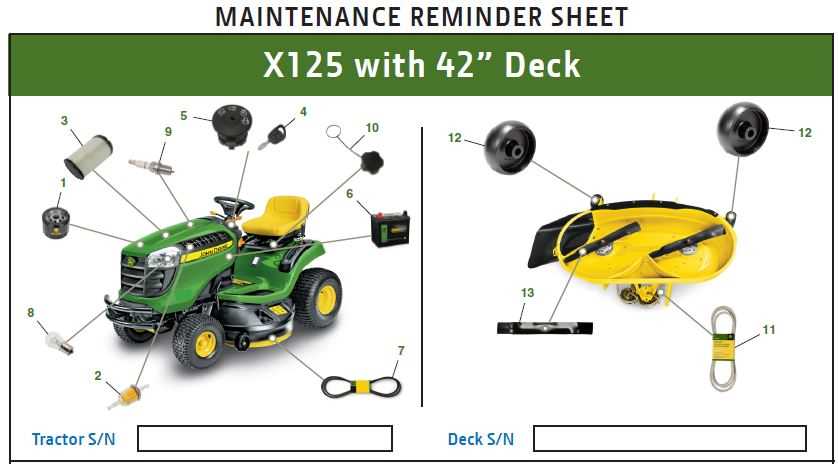

Maintenance Schedule for X739

A consistent upkeep routine is essential for ensuring optimal performance and longevity of your machinery. By adhering to a structured maintenance plan, operators can prevent potential issues and maintain efficient operation throughout the seasons. This section outlines key tasks and timelines to follow for effective care.

Daily Maintenance Tasks

Every day, before starting the equipment, operators should perform a visual inspection. Check for any leaks, ensure that all safety features are functioning, and examine the condition of the tires. Additionally, it’s advisable to clean the exterior to prevent dirt buildup and protect components.

Seasonal Maintenance Activities

During each season, specific maintenance actions should be carried out to prepare the machinery for varying operational demands. Spring is the ideal time to change oil and filters, while Fall requires thorough cleaning and lubrication of moving parts. Regularly inspecting belts and cables is crucial, and replacing worn components promptly can save time and expenses.

By adhering to this schedule, you can ensure the reliability and efficiency of your equipment, enabling smooth operations year-round.

Upgrades and Customization Ideas

Enhancing the functionality and aesthetics of your outdoor machinery can significantly improve performance and efficiency. Whether you’re looking to boost power, increase comfort, or add unique features, there are numerous options to consider that cater to both practical needs and personal style.

Performance Enhancements

To maximize efficiency, consider upgrading the engine components for improved power output. Replacing the air filter with a high-flow variant can enhance airflow, resulting in better combustion and performance. Additionally, exploring options for exhaust systems can provide a more robust sound while reducing back pressure, allowing the engine to breathe more freely.

Personalized Features

Customization is key for those looking to tailor their machinery to specific tasks or preferences. Adding accessories like a premium seat with extra cushioning can improve comfort during long hours of use. Furthermore, implementing LED lighting kits can enhance visibility and safety during nighttime operations. Don’t overlook aesthetic upgrades, such as custom paint jobs or decals, to give your equipment a unique flair that stands out.