Comprehensive Guide to John Deere 652R Parts Diagram

In the realm of heavy equipment, comprehending the intricate structure and functionality of various elements is vital for ensuring optimal performance. Familiarity with these components allows operators and technicians to maintain, troubleshoot, and repair their machines effectively. This knowledge not only enhances operational efficiency but also extends the lifespan of the machinery.

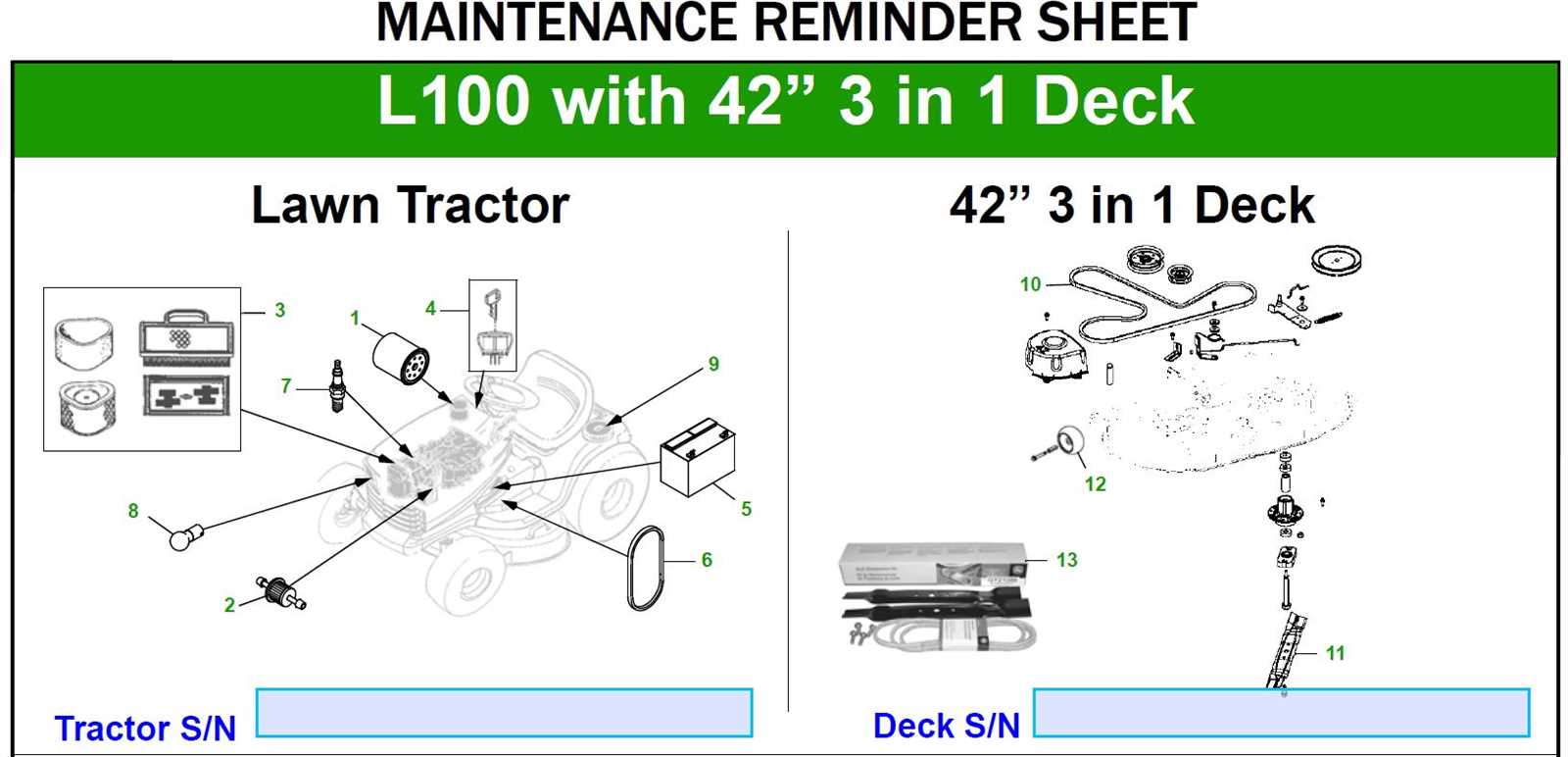

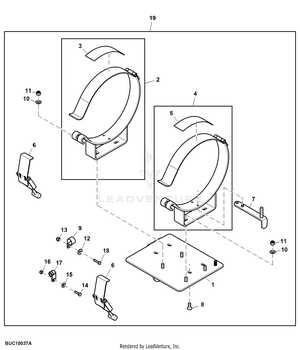

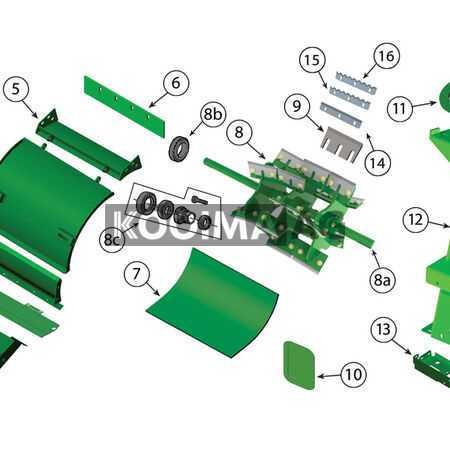

Illustrations that detail the arrangement and interconnection of these essential elements serve as invaluable resources. By providing a visual representation, they simplify the process of identifying specific parts and understanding their roles within the larger system. Such clarity is crucial for anyone involved in the upkeep and operation of complex machinery.

Whether you are a seasoned technician or a new operator, mastering the specifics of these diagrams can significantly impact your ability to manage equipment effectively. Empowering yourself with this information paves the way for successful maintenance practices, minimizing downtime and maximizing productivity.

Understanding John Deere 652R Parts

Grasping the components of any machinery is essential for optimal performance and maintenance. Knowing the individual elements that contribute to functionality can significantly enhance the user experience and prolong the life of the equipment. This section delves into the intricacies of one such model, emphasizing the importance of familiarizing oneself with its key features and components.

Key Components

- Engine: The powerhouse of the machinery, responsible for generating the required energy.

- Transmission: Facilitates smooth gear shifts and power transfer to the wheels.

- Hydraulic System: Controls various movements and functions, providing necessary force.

- Chassis: The framework that supports all other components, ensuring structural integrity.

- Electrical System: Powers essential features such as lights, ignition, and sensors.

Maintenance Tips

- Regularly check fluid levels to ensure efficient operation.

- Inspect belts and hoses for wear and tear, replacing them as necessary.

- Keep filters clean to prevent clogging and maintain performance.

- Schedule periodic servicing to address potential issues early.

- Refer to the equipment manual for specific guidance on maintenance practices.

Understanding these components and maintenance tips will empower users to manage their equipment effectively, ensuring longevity and reliable performance.

Overview of the 652R Model

The 652R model stands out in its category, known for its robust performance and efficiency in various agricultural tasks. Designed to meet the demands of modern farming, it combines advanced technology with user-friendly features, making it a favorite among operators.

This model is engineered for versatility, suitable for a range of applications, from mowing to landscaping. Its powerful engine ensures optimal productivity, while ergonomic controls enhance comfort during prolonged use. The durable construction guarantees reliability in diverse working conditions.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for efficient operation |

| Cutting Width | Generous width for quicker mowing |

| Weight | Optimized weight for stability and traction |

| Operator Comfort | Ergonomic design with intuitive controls |

| Durability | Robust materials for long-lasting use |

Overall, this model exemplifies a perfect blend of performance and user-centric design, catering to the needs of professionals in the field.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of complex machinery. These illustrations provide detailed insights into the arrangement and functionality of various elements, making them invaluable for both professionals and enthusiasts alike.

Enhancing Maintenance Efficiency

Clear visual guides enable technicians to quickly identify and locate specific components. This streamlines repair processes, reduces downtime, and minimizes the risk of errors during maintenance tasks. When each element is clearly marked, it becomes easier to ensure that the right actions are taken, ultimately enhancing overall efficiency.

Facilitating Knowledge Transfer

Such visual aids serve as excellent educational tools. They allow individuals to familiarize themselves with intricate systems, promoting a deeper understanding of how everything works together. By studying these representations, new operators can gain confidence and skills necessary for effective machine management.

Main Components of the 652R

This section highlights the essential elements that contribute to the efficient operation of the machine. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The heart of the machinery, providing the necessary power for various tasks.

- Transmission: This system is responsible for transferring power from the engine to the wheels, ensuring smooth operation.

- Chassis: The structural framework that supports all other components and provides stability during operation.

- Hydraulic System: Essential for powering attachments and enhancing maneuverability, allowing for a range of functions.

- Electrical System: Controls various features and provides the necessary power for lights, indicators, and other electronic components.

Each of these parts plays a vital role in the overall functionality and efficiency of the machine, making it important for operators to be familiar with their functions and maintenance needs.

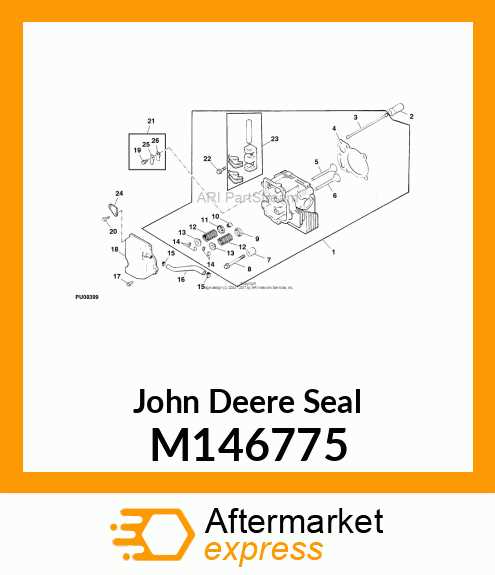

Finding the Right Replacement Parts

When it comes to maintaining and repairing heavy machinery, ensuring that you acquire the correct components is crucial for optimal performance. Properly fitting replacements not only enhance the functionality of the equipment but also prolong its lifespan. Understanding where to look and how to identify the right items can save time and prevent costly errors.

Research and Identification

Begin by gathering all necessary information about your machine. This includes model numbers, specifications, and any relevant manuals. Utilizing these resources will aid in accurately identifying the components you need. Online databases and manufacturer websites often provide comprehensive details that can guide you in your search.

Quality and Compatibility

Once you have pinpointed the required components, focus on sourcing high-quality options. Opting for OEM (Original Equipment Manufacturer) items typically ensures better compatibility and reliability. However, aftermarket alternatives can also be viable if they meet strict quality standards. Always check reviews and ratings to ensure you’re making an informed decision.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the performance and longevity of machinery. These high-quality elements are specifically designed to fit perfectly and function optimally within the systems for which they were created.

Reliability is a primary benefit of opting for original components. These items undergo rigorous testing and adhere to strict manufacturing standards, ensuring they can withstand the demands of heavy use. When you choose authentic parts, you minimize the risk of failures that can lead to costly downtime.

Another significant advantage is compatibility. OEM components are engineered to integrate seamlessly with existing systems, which reduces the likelihood of compatibility issues. This precise fit not only improves performance but also enhances the overall efficiency of the equipment.

Furthermore, using original components can provide warranty protection. Many manufacturers offer warranties on their machinery, which often require the use of OEM elements. By adhering to these guidelines, operators can safeguard their investments and ensure they remain protected against unexpected repairs.

Lastly, choosing authentic components can result in better resale value. Equipment maintained with original parts tends to retain its value longer, appealing to potential buyers who recognize the benefits of using high-quality materials.

In conclusion, selecting original equipment manufacturer components is a wise decision that leads to enhanced reliability, compatibility, warranty protection, and better resale value, ultimately ensuring the longevity and efficiency of your machinery.

Common Issues and Solutions

In the realm of machinery, users often encounter a variety of challenges that can affect performance and efficiency. Recognizing these common problems and understanding their solutions is essential for maintaining optimal functionality. This section will explore frequent issues, providing insights and remedies to enhance equipment reliability.

Frequent Mechanical Failures

One prevalent issue involves mechanical breakdowns, which can stem from wear and tear or insufficient maintenance. Regularly inspecting components such as belts and bearings can prevent unexpected failures. Solution: Establish a routine maintenance schedule that includes lubrication and part replacement as needed. This proactive approach can significantly extend the lifespan of the machinery.

Electrical System Malfunctions

Another common concern relates to electrical systems, where faults can lead to erratic performance or complete shutdowns. Issues may arise from loose connections or faulty wiring. Solution: Conduct regular electrical checks to ensure all connections are secure and free from corrosion. Additionally, replacing any damaged wiring promptly can prevent further complications.

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone involved in maintenance or repair tasks. These illustrations serve as valuable guides, helping users identify various elements and their relationships within a system. By familiarizing yourself with the layout and symbols used, you can streamline your work and enhance efficiency.

1. Familiarize Yourself with Symbols: Each illustration typically employs specific symbols and notations to represent various items. Take time to learn what each symbol signifies, as this knowledge is crucial for accurate interpretation.

2. Identify the Key Sections: Most visual guides are divided into sections, each corresponding to different areas of the machinery. Understanding how these sections relate to one another will aid in locating the components you need.

3. Refer to the Legend: Many visuals include a legend or key that explains the symbols and color codes used. Always refer to this guide, as it provides essential information for deciphering the content accurately.

4. Trace Connections: Follow the lines that indicate connections between elements. This will help you understand how each component interacts with others, which is vital for troubleshooting and repairs.

5. Make Notes: As you study the visual representation, consider jotting down notes or highlighting key areas. This will reinforce your understanding and serve as a quick reference during practical applications.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the lifespan of any machinery. By following a structured maintenance routine, operators can ensure optimal performance and reduce the likelihood of unexpected breakdowns.

- Regular Inspections: Schedule routine checks to identify wear and tear early. Pay attention to critical components.

- Fluid Management: Change oils and fluids as recommended. Clean filters and check fluid levels consistently.

- Lubrication: Apply grease to moving parts regularly to minimize friction and prevent premature wear.

- Cleanliness: Keep the equipment clean to avoid dirt accumulation that can lead to corrosion and mechanical issues.

- Storage Practices: Store the machinery in a sheltered location to protect it from harsh weather and environmental factors.

By implementing these strategies, operators can significantly enhance the durability and efficiency of their equipment, ensuring it remains reliable over time.

Tools Needed for Repairs

When it comes to maintaining machinery, having the right tools is essential for ensuring efficient and effective repairs. A well-equipped toolkit can make the difference between a smooth repair process and a frustrating experience. Understanding which instruments to gather beforehand can save time and enhance the overall quality of work.

Essential Instruments

Key tools for any repair job typically include wrenches, sockets, and screwdrivers. Wrenches come in various sizes and types, enabling the technician to loosen or tighten nuts and bolts effectively. Socket sets provide versatility, allowing access to fasteners in tight spaces. Screwdrivers, both flat and Phillips, are indispensable for securing components and accessing intricate parts.

Specialized Equipment

In addition to basic tools, specialized equipment may be necessary for certain repairs. Torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing potential damage. Diagnostic tools, such as multimeters, can help identify electrical issues, while hydraulic jacks and stands assist in safely lifting heavy machinery for maintenance work.

Where to Purchase 652R Parts

Finding reliable components for your machinery is crucial for maintaining optimal performance and longevity. There are several avenues to explore when seeking quality replacements that ensure your equipment operates smoothly and efficiently.

Authorized Dealers: One of the most dependable sources for obtaining components is through authorized retailers. They often provide original parts and accessories, ensuring compatibility and reliability. Additionally, these dealers can offer expert advice and support for installation and maintenance.

Online Marketplaces: The internet has revolutionized the purchasing process, allowing for easy access to numerous online platforms. Websites specializing in equipment supplies frequently feature a wide variety of components, often at competitive prices. Be sure to check seller ratings and reviews to ensure the credibility of the supplier.

Local Repair Shops: Many local repair shops not only provide services but also sell components. Establishing a relationship with a nearby mechanic can be beneficial, as they can recommend specific parts tailored to your needs and may offer installation services as well.

Second-Hand Options: For those on a budget, exploring second-hand markets can yield valuable finds. Websites and local classifieds often list used components at reduced prices. While this option may require more diligence in assessing quality, it can lead to significant savings.

Regardless of the chosen avenue, ensuring that you select quality components is essential for the upkeep and efficiency of your machinery.

Upgrading Components for Better Performance

Enhancing the functionality of your machinery can lead to significant improvements in efficiency and output. By focusing on key elements that affect performance, operators can ensure their equipment operates at its best. This approach not only maximizes productivity but also prolongs the lifespan of the equipment.

Key Areas for Improvement

Identifying which components to upgrade is crucial. Common focus areas include the engine, hydraulic systems, and drive mechanisms. Investing in high-quality parts can lead to enhanced power delivery, improved responsiveness, and better fuel efficiency. Furthermore, regular assessments can help pinpoint worn or outdated components that may hinder overall performance.

Benefits of Upgrading

Upgrading critical components can result in noticeable benefits. Enhanced durability and reduced maintenance costs are just the beginning. Operators often experience smoother operations and increased reliability, allowing for uninterrupted workflows. Additionally, modern parts may offer advanced features that contribute to better control and precision during use.

Frequently Asked Questions About 652R

This section addresses common inquiries regarding the model, providing clarity on various aspects. Whether you are a new user or seeking to deepen your understanding, these questions aim to assist you in navigating the essential features and functionalities.

What are the key features of this model?

The model is known for its robust design and user-friendly interface, which includes advanced technology for enhanced performance and efficiency. Key attributes often highlighted include its powerful engine, excellent maneuverability, and ease of maintenance.

How do I identify the components for maintenance?

To effectively identify the necessary components, refer to the manufacturer’s guide or consult online resources that provide detailed illustrations. Familiarizing yourself with the layout can streamline the maintenance process.

Where can I find replacement parts?

Replacement components can typically be sourced from authorized dealers or online retailers specializing in machinery accessories. It is advisable to ensure that any replacements meet the quality standards outlined in the user manual.

Are there any common issues to be aware of?

Users often report a few recurring challenges, such as performance inconsistencies or wear on specific components. Regular maintenance and timely inspections can mitigate these issues effectively.

What is the warranty policy?

The warranty coverage usually encompasses manufacturing defects and may vary by region. It’s recommended to review the warranty terms provided at the time of purchase for comprehensive details.

How can I enhance the longevity of my equipment?

To prolong the lifespan of your machinery, adhere to routine maintenance schedules, use quality fuels, and ensure proper storage. Following these practices can lead to optimal performance and durability over time.