Understanding the Powerhouse PH3100RI Parts Diagram

Every intricate machine relies on a multitude of elements that work in harmony to achieve optimal performance. Gaining insights into the layout and functionality of these individual components is essential for efficient maintenance and troubleshooting. Whether you are a seasoned technician or a curious owner, familiarity with the structure can enhance your experience.

In this section, we will explore the various segments that contribute to the overall functionality of your device. By breaking down the assembly into its key pieces, you will be better equipped to recognize the purpose of each part and its role in the system. This knowledge can ultimately aid in prolonging the lifespan of your machinery.

Understanding the intricacies of your equipment not only empowers you to perform routine checks but also prepares you to address potential issues swiftly. As we delve into the details, you will discover how each component interacts, paving the way for a deeper appreciation of your machine’s design and engineering.

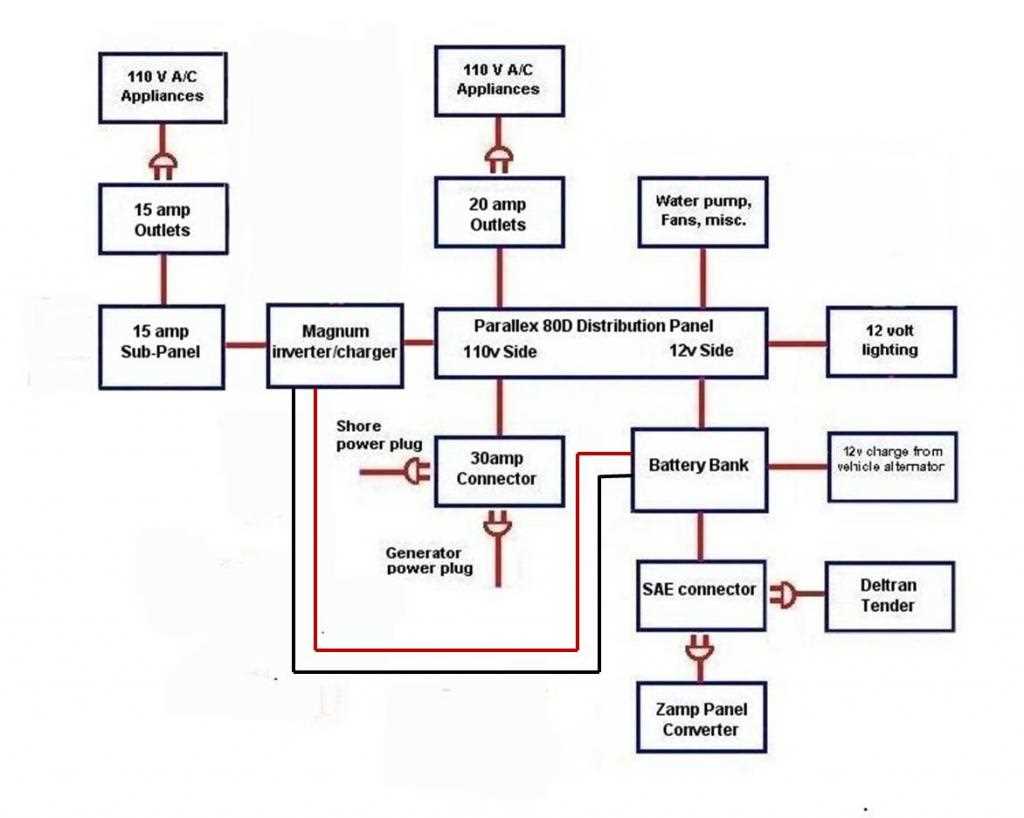

Understanding Powerhouse PH3100RI Components

Grasping the essential elements of a generator is crucial for both operation and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the machine. A thorough understanding can enhance performance and extend longevity.

| Component | Function |

|---|---|

| Engine | Generates power through combustion. |

| Alternator | Converts mechanical energy into electrical energy. |

| Fuel Tank | Stores the fuel needed for operation. |

| Control Panel | Monitors and regulates the generator’s operation. |

| Exhaust System | Discharges gases produced during combustion. |

Importance of Parts Diagrams

Understanding the layout and components of any machine is crucial for effective maintenance and repair. Visual representations help users quickly identify elements, enhancing both knowledge and efficiency.

- Facilitates accurate identification of components

- Streamlines troubleshooting processes

- Enhances communication among technicians

- Serves as a valuable reference for assembly and disassembly

These illustrations ultimately support users in maintaining the longevity and performance of their equipment.

Common Issues with Generators

Generators are essential tools for providing electricity in various situations, yet they can experience several common problems that affect their performance. Understanding these issues can help users troubleshoot effectively and maintain their devices for optimal functionality.

Below are some frequent challenges encountered with these machines, along with potential solutions:

| Issue | Description | Solution |

|---|---|---|

| Starting Difficulties | The generator fails to start or struggles to turn over. | Check the fuel level, battery charge, and ensure the choke is properly set. |

| Fuel Leaks | Fuel is leaking from the unit, which can pose safety hazards. | Inspect fuel lines and connections for damage, and replace any worn components. |

| Overheating | The generator becomes excessively hot during operation. | Ensure proper ventilation, check for low oil levels, and clean the air filter. |

| Electrical Output Issues | The unit does not provide the expected power output. | Inspect the circuit breaker and connections; test for load imbalances. |

| Noise Levels | Excessive noise is emitted during operation. | Check for loose parts and consider using soundproofing solutions. |

By being aware of these typical issues, users can take proactive steps to ensure their generators operate smoothly and efficiently, enhancing their reliability when needed most.

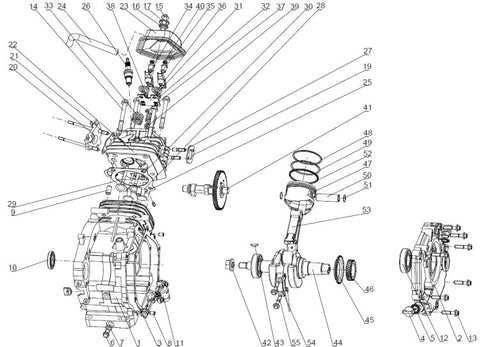

Identifying Key Parts in PH3100RI

Understanding the essential components of any machinery is crucial for effective operation and maintenance. By recognizing these elements, users can enhance their experience and ensure longevity. This section will explore the primary features and their functions in the specified model.

Main Components

- Engine: The powerhouse that drives the entire unit.

- Fuel Tank: Stores the energy source needed for operation.

- Control Panel: Interface for managing settings and monitoring performance.

- Chassis: Provides structural support and stability.

- Exhaust System: Manages emissions and noise output.

Understanding Their Functions

Each component plays a vital role:

- The engine converts fuel into mechanical energy.

- The fuel tank ensures a continuous supply for efficiency.

- The control panel allows for easy adjustments and monitoring.

- The chassis supports all parts, enhancing durability.

- The exhaust system reduces environmental impact.

Maintenance Tips for Optimal Performance

To ensure the highest efficiency and longevity of your equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also prevents unexpected breakdowns and costly repairs. Implementing a routine check-up can lead to a smoother operation and better results.

| Task | Frequency | Description |

|---|---|---|

| Clean Air Filters | Every Month | Inspect and clean or replace air filters to maintain airflow and efficiency. |

| Check Fuel Levels | Weekly | Regularly monitor fuel levels to avoid running out during use. |

| Inspect Hoses and Connections | Monthly | Look for cracks or wear in hoses and ensure all connections are secure. |

| Change Oil | Every 50 Hours | Replace oil to keep the engine running smoothly and prevent buildup of debris. |

| Test Safety Features | Before Each Use | Ensure all safety mechanisms are functioning properly for safe operation. |

By adhering to these guidelines, users can maximize performance and reliability, ensuring the equipment operates at its best for years to come.

How to Troubleshoot Generator Problems

Generators can encounter various issues that hinder their performance. Understanding how to identify and resolve these problems is essential for ensuring reliable operation. This guide provides a systematic approach to diagnosing common generator faults.

Follow these steps to troubleshoot effectively:

- Check Fuel Supply:

- Ensure there is enough fuel in the tank.

- Inspect for any blockages in fuel lines.

- Inspect the Battery:

- Verify the battery charge level.

- Check for corrosion on terminals.

- Examine Electrical Connections:

- Look for loose or damaged wires.

- Ensure proper grounding of the generator.

- Monitor Engine Performance:

- Listen for unusual noises during operation.

- Check for smoke or unusual emissions.

- Review Maintenance Records:

- Ensure regular servicing is up to date.

- Replace worn-out parts as needed.

By following these troubleshooting steps, you can effectively identify and rectify issues, enhancing the overall performance of your generator.

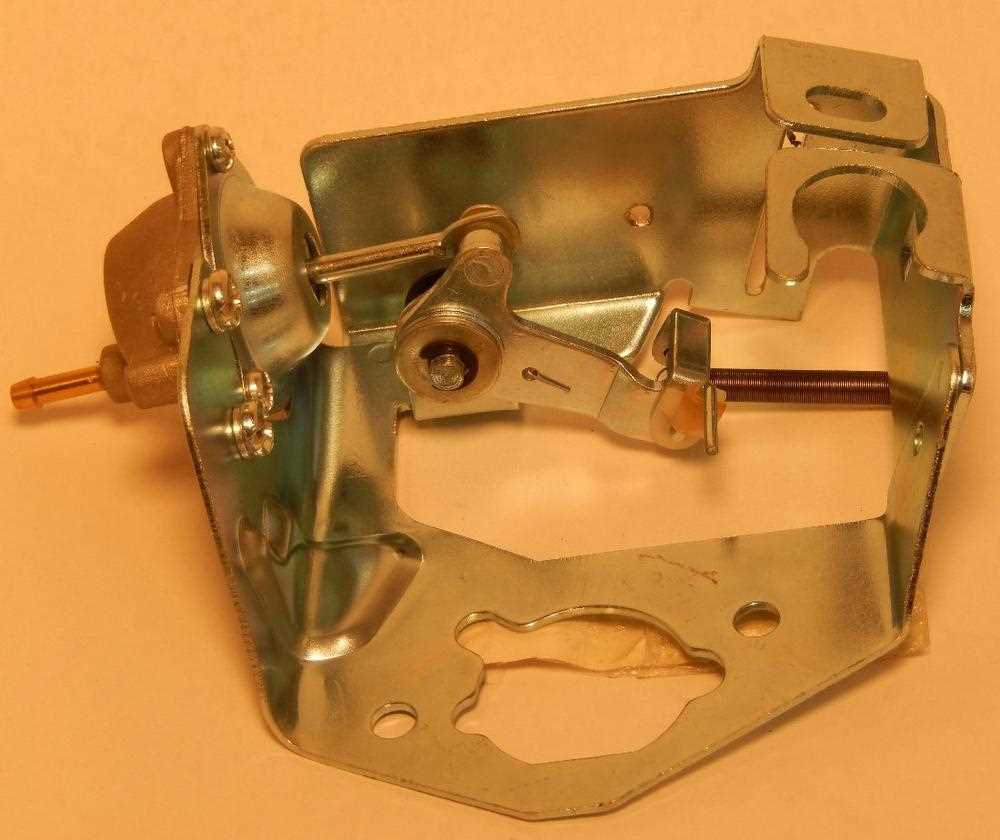

Replacing Worn-Out Components Safely

Maintaining equipment involves the careful replacement of deteriorated elements to ensure optimal performance and safety. Proper techniques and precautions are essential for a successful and secure process.

Before beginning the replacement, follow these guidelines:

- Always disconnect the power source to prevent accidental activation.

- Use appropriate personal protective equipment (PPE) to safeguard against hazards.

- Refer to the manufacturer’s manual for specific instructions related to the equipment.

During the replacement process:

- Carefully remove the damaged parts, taking note of their placement.

- Clean the area to remove debris and ensure a proper fit for new components.

- Install the new elements securely, following the manufacturer’s specifications.

After completing the task:

- Double-check all connections and fittings for safety.

- Reconnect the power source and perform a test run to ensure functionality.

- Regularly monitor the equipment to identify any further issues early.

Where to Find Quality Replacement Parts

When searching for high-quality components to restore equipment, it’s essential to know the right places to look. Quality replacements not only ensure longevity but also enhance performance. Here are some reliable sources:

- Authorized Dealers: These retailers offer genuine items, ensuring compatibility and durability.

- Online Marketplaces: Websites like Amazon and eBay feature a wide selection, often with user reviews to guide your choice.

- Local Hardware Stores: Visiting nearby shops can provide immediate access to necessary components, along with knowledgeable staff assistance.

- Specialty Stores: Some businesses focus specifically on equipment needs, providing tailored solutions.

Utilizing these resources can lead you to the ultimate quality components for your repair needs.

Step-by-Step Assembly Instructions

This section provides clear and concise guidance for assembling your unit efficiently and effectively. Following these instructions will ensure that all components fit together seamlessly, leading to optimal performance.

Before you begin, gather all necessary tools and components. Review the following steps carefully to achieve a successful assembly:

| Step | Action |

|---|---|

| 1 | Lay out all parts on a clean, flat surface to ensure everything is accessible. |

| 2 | Begin with the base unit and securely attach the initial components according to the specified guidelines. |

| 3 | As you proceed, make sure to tighten all screws and fasteners to maintain stability. |

| 4 | Once the main structure is complete, connect any additional accessories as outlined in the manual. |

| 5 | Double-check all connections and ensure that everything is aligned properly before finalizing. |

By adhering to these straightforward steps, you will successfully assemble your device, setting the stage for ultimate functionality.

Comparing PH3100RI with Other Models

This section explores the key differences and similarities between a specific generator model and its competitors in the market. By analyzing various features, performance metrics, and user experiences, we can gain valuable insights into which model best suits diverse needs.

- Power Output: Different models offer varying wattage, affecting suitability for specific tasks.

- Fuel Efficiency: Some generators consume less fuel while delivering similar power, leading to cost savings.

- Portability: Weight and design influence ease of transport, especially for outdoor use.

- Noise Levels: Assessing decibel ratings helps determine operational quietness.

By evaluating these aspects, potential buyers can make informed decisions that align with their requirements and preferences.

FAQs About Powerhouse Generators

This section addresses common inquiries related to portable energy solutions, helping users understand their features, maintenance, and operation.

What should I consider when choosing a generator?

When selecting a generator, evaluate factors such as power output, fuel type, run time, and noise levels. Understanding your energy needs is essential for making the right choice.

How do I maintain my generator?

Regular upkeep includes checking the oil level, replacing air filters, and ensuring proper fuel storage. Routine maintenance extends the lifespan and efficiency of your unit.