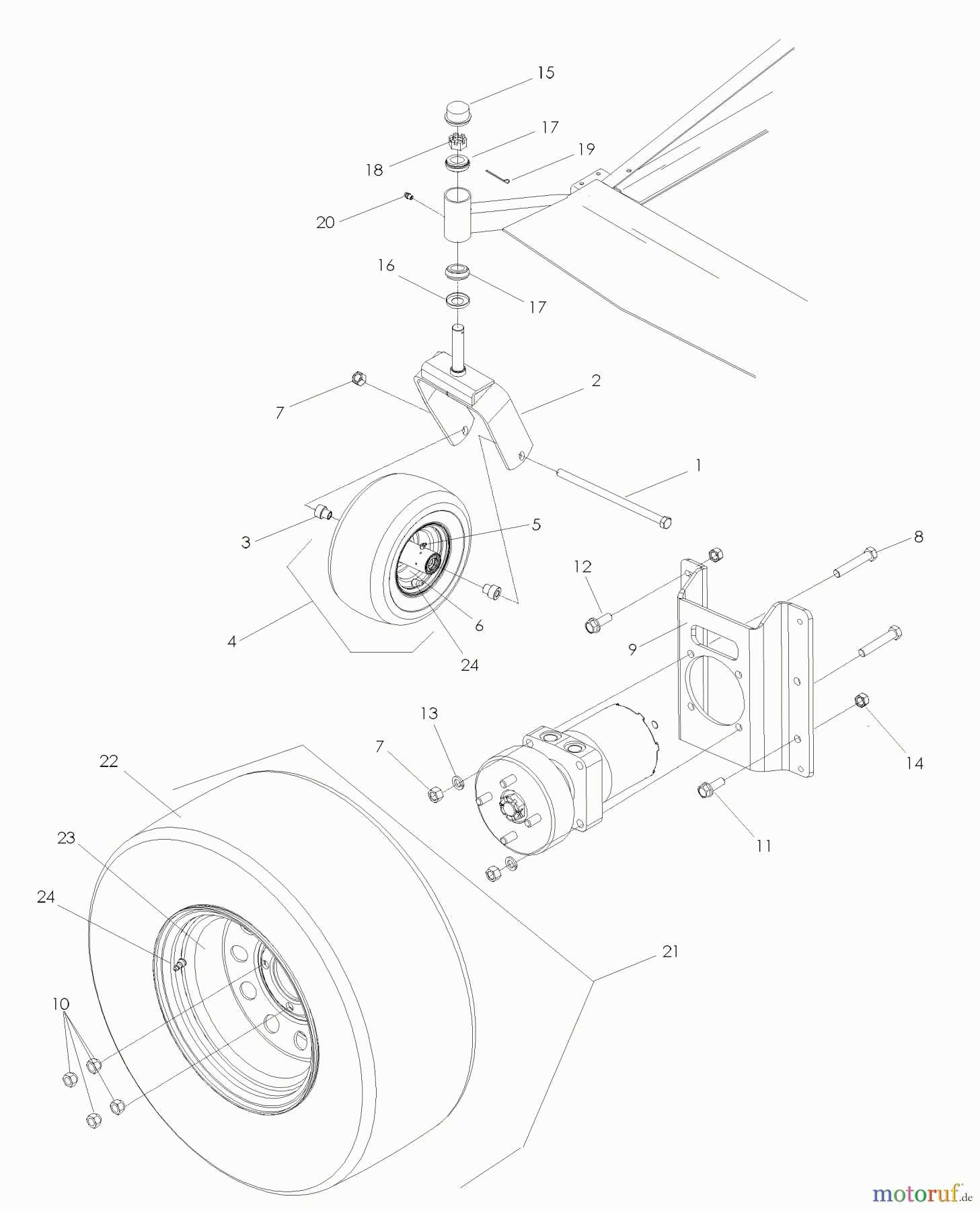

Z248f Parts Diagram Overview

When delving into the intricacies of mechanical systems, having a clear visual representation of each element can significantly enhance comprehension and maintenance. This knowledge is crucial for anyone involved in repair, assembly, or troubleshooting tasks. By familiarizing oneself with the arrangement and function of various components, one can streamline processes and improve efficiency.

Visual aids serve as indispensable tools in the realm of engineering. They provide a structured overview that helps users identify specific parts and their interrelationships. Such illustrations can transform complex machinery into a more digestible format, facilitating quicker learning and application of essential skills.

Whether you are a seasoned professional or a novice, mastering the layout of components fosters confidence and precision in handling machinery. A well-constructed visual representation not only clarifies the operational flow but also aids in diagnosing potential issues, making it an essential asset for effective management.

Understanding Z248f Parts Diagram

Grasping the intricacies of mechanical schematics is crucial for effective maintenance and troubleshooting. These visual representations serve as blueprints, detailing the individual components and their relationships within a system. By familiarizing oneself with these illustrations, users can better comprehend the assembly and functionality of various elements.

Here are some key aspects to consider when analyzing these visual aids:

- Component Identification: Each part is labeled for easy recognition, allowing for swift location and understanding of its role.

- Relationships: Understanding how each piece interacts with others is essential for diagnosing issues or planning repairs.

- Assembly Order: Many schematics provide insights into the order of assembly, which is vital for correct installation or reassembly.

To effectively utilize these illustrations, follow these steps:

- Examine the legend or key, if available, to familiarize yourself with symbols and labels.

- Trace the flow or connections between components to understand their interactions.

- Refer to additional resources or manuals for comprehensive explanations of complex parts.

Mastering these visual tools enhances both the efficiency of repairs and the overall understanding of the system’s architecture.

Key Components of Z248f

This section focuses on the essential elements that contribute to the overall functionality and performance of the machinery. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring that the system operates smoothly and efficiently.

| Component | Description |

|---|---|

| Engine | The powerhouse responsible for converting fuel into mechanical energy, driving the entire system. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, allowing for speed variation and torque adjustments. |

| Cooling System | Prevents overheating by circulating coolant through the engine and other critical components. |

| Fuel System | Delivers fuel to the engine while maintaining the correct mixture for optimal combustion. |

| Electrical System | Supplies power to various components and systems, ensuring reliable operation of lights, ignition, and other electrical devices. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for anyone involved in maintenance or assembly. These illustrations serve as a guide, highlighting individual elements and their relationships within a larger system. By mastering the skill of interpreting these visuals, users can efficiently identify and source necessary items, ensuring smooth operation and repair processes.

When approaching these illustrations, it is essential to familiarize oneself with the various symbols and annotations commonly used. Each element typically has a corresponding number or code that refers to a specific listing or catalog. This connection allows for quick reference and accurate ordering, saving time and effort in maintenance tasks.

| Symbol/Code | Description |

|---|---|

| 1 | Main component |

| 2 | Connector |

| 3 | Fastener |

| 4 | Support element |

In addition to recognizing symbols, paying attention to the layout is vital. Often, elements are arranged logically, reflecting their assembly sequence or functional relationship. This spatial awareness aids in comprehending how each piece integrates into the whole, which is especially beneficial during troubleshooting or reassembly.

Finally, it is advisable to consult the accompanying documentation or catalogs that provide detailed descriptions of each item represented. This information not only enhances understanding but also ensures that replacements are precise, maintaining the integrity of the system.

Common Issues in Z248f Parts

In the realm of machinery and equipment, various components can encounter challenges that affect overall performance. Understanding these frequent problems can aid in effective troubleshooting and maintenance. This section delves into typical concerns that arise with these specific elements, highlighting their implications and potential solutions.

Wear and Tear

Degradation over time is a common phenomenon, especially in high-usage environments. Factors such as friction, exposure to elements, and operational stress contribute to this issue. Regular inspection and timely replacement can mitigate the risks associated with compromised functionality.

Compatibility Issues

Another prevalent challenge involves incompatibility between different components. Utilizing mismatched elements can lead to inefficient operation or even damage. Ensuring that each part is suited for its intended role is crucial for maintaining system integrity and performance.

Maintenance Tips for Z248f Users

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also helps prevent unexpected breakdowns. By following a few simple practices, you can keep your machine running smoothly and effectively.

Here are some key maintenance suggestions to consider:

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Weekly | Ensure that the oil level is within the recommended range to prevent engine wear. |

| Inspect Filters | Monthly | Clean or replace air and fuel filters as needed to maintain proper airflow and fuel delivery. |

| Tire Pressure Check | Bi-weekly | Monitor tire pressure to ensure optimal traction and prevent uneven wear. |

| Clean Exterior | As needed | Remove debris and dirt buildup to protect surfaces and maintain appearance. |

| Sharpen Blades | Seasonally | Keep cutting blades sharp for efficient performance and a clean cut. |

By adhering to these guidelines, you can significantly extend the lifespan of your machinery and enhance its functionality. Regular attention to these details will pay off in performance and reliability over time.

Where to Find Replacement Parts

Locating components for maintenance or repair can often feel overwhelming, especially when dealing with complex machinery. However, there are numerous reliable sources that can simplify the process. Understanding where to look and what to consider can save time and ensure you get quality items for your needs.

Authorized Dealers

One of the most trustworthy places to find the necessary components is through authorized dealers. These retailers often provide original items that meet the manufacturer’s specifications. Additionally, purchasing from them ensures that you receive the correct part for your specific model, minimizing the risk of compatibility issues.

Online Marketplaces

The internet has opened up a wealth of options for sourcing components. Online marketplaces offer a vast selection, often at competitive prices. It is crucial to check seller ratings and reviews to ensure reliability. Furthermore, many websites provide user-friendly search tools to help narrow down options based on the exact specifications you need.

Comparing Z248f with Similar Models

When evaluating various machinery options, it is essential to analyze how a specific model stacks up against its competitors in terms of performance, reliability, and features. Understanding the differences and similarities can provide valuable insights for potential buyers, helping them make informed decisions tailored to their needs.

Performance Metrics

In comparing different machines, performance metrics such as power output, speed, and efficiency play a critical role. Some models may excel in fuel efficiency while others offer superior power for demanding tasks. Identifying the strengths of each variant can guide users toward the most suitable choice based on their operational requirements.

Features and Usability

Feature sets vary widely among similar machines, affecting usability and adaptability for various applications. Some models may include advanced technological integrations, making them easier to operate or more efficient in specific contexts. Evaluating these features can highlight which machine best aligns with user preferences and operational needs.

Benefits of Using Official Diagrams

Utilizing authorized illustrations can significantly enhance the efficiency and accuracy of maintenance and repair tasks. These visual representations provide precise details, ensuring that individuals can easily identify components and understand their interactions within a system. Accessing reliable resources streamlines the troubleshooting process and reduces the likelihood of errors, making it an invaluable practice for both professionals and enthusiasts.

Moreover, official illustrations often come with comprehensive guidelines that are tailored to specific models, which can lead to better decision-making when it comes to repairs and replacements. This can save both time and resources, ultimately leading to increased satisfaction with the service provided.

| Benefits | Description |

|---|---|

| Accuracy | Ensures that users have the correct information for identification and assembly. |

| Time-saving | Reduces the time spent on locating and understanding components. |

| Reduced Errors | Lowers the chances of mistakes during maintenance and repair. |

| Comprehensive Guidance | Provides detailed instructions that facilitate effective troubleshooting. |

| Enhanced Understanding | Improves overall comprehension of how different parts function together. |

Tools Needed for Z248f Repairs

Effective maintenance and repair of machinery require a specific set of instruments. Having the right tools not only enhances efficiency but also ensures that the work is completed to a high standard. Below is a list of essential equipment that can assist in performing repairs effectively.

- Wrenches: A variety of sizes is crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips head are necessary for different screw types.

- Pliers: Useful for gripping and twisting wires or components.

- Socket Set: Provides versatility for different nut and bolt sizes.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: Essential for diagnosing electrical issues and measuring voltage.

In addition to the basic tools, some specialized equipment may also be required:

- Diagnostic Software: Helps in troubleshooting complex problems.

- Oil Filter Wrench: Makes changing filters easier and more efficient.

- Grease Gun: Necessary for lubrication of moving parts.

- Inspection Mirror: Assists in viewing hard-to-reach areas.

By ensuring that these tools are available, the repair process can be streamlined, making it easier to maintain optimal functionality.

Upgrading Z248f: What to Consider

When enhancing the performance and functionality of your machinery, careful planning is essential. Evaluating various components and their compatibility is crucial to ensure a seamless upgrade process. The following aspects should be taken into account to achieve optimal results.

Performance Goals

Before proceeding, define your objectives. Consider the following:

- Desired power output

- Improved fuel efficiency

- Enhanced durability and lifespan

Compatibility and Integration

Ensuring that new components work well with existing systems is vital. Focus on:

- Identifying compatible upgrades

- Reviewing manufacturer specifications

- Consulting with experts or user communities

Taking these factors into account will guide you toward making informed decisions, ultimately leading to a more effective and efficient machine operation.

Expert Insights on Z248f Performance

In the realm of machinery, understanding the intricate dynamics that influence operational efficiency is paramount. Professionals often emphasize the significance of components working harmoniously to achieve optimal functionality. Insights from experts shed light on various aspects that contribute to performance enhancement and longevity of the equipment in question.

Key Factors Influencing Efficiency

Several critical elements play a role in maximizing output. Maintenance practices are fundamental; regular checks and timely replacements of worn-out components can prevent costly downtimes. Additionally, the selection of high-quality materials significantly impacts the overall durability and reliability of the system. Calibration is another crucial factor; ensuring that all settings are precise enhances performance and reduces the risk of failure during operation.

Innovative Upgrades and Adaptations

As technology advances, incorporating innovative upgrades can lead to substantial improvements. Many experts advocate for the integration of modern technologies that streamline processes and boost efficiency. Adapting to new methodologies not only increases productivity but also ensures that the equipment remains competitive in a rapidly evolving market. Continuous education and training for operators are equally important, as skilled personnel are essential for leveraging these advancements effectively.