Comprehensive Guide to John Deere LT190 Parts Diagram

Exploring the intricacies of agricultural machinery is essential for anyone involved in the maintenance and operation of these vital tools. A thorough comprehension of each component’s role not only enhances efficiency but also extends the lifespan of the equipment. This guide delves into the essential elements of a popular lawn tractor model, providing valuable insights for both novice and experienced users.

In the realm of outdoor power equipment, familiarity with individual parts allows for better troubleshooting and repair. Knowing how various sections interact contributes to smoother operation and can significantly reduce downtime. Whether you’re a homeowner managing a lawn or a professional landscaper, understanding the layout and function of these components is indispensable.

This resource aims to simplify the complexities of machinery assembly, offering a clear representation of each part’s placement and significance. With a detailed overview, operators can confidently approach maintenance tasks, ensuring their equipment remains in optimal condition for years to come.

Understanding John Deere LT190 Components

Exploring the elements of a well-engineered lawn care machine reveals a complex interplay of parts that work together to ensure optimal performance. Each component plays a vital role in the functionality and efficiency of the equipment, contributing to a seamless mowing experience.

Key Elements of the Machinery

- Engine: The powerhouse that drives the entire system, providing the necessary torque and power.

- Transmission: Responsible for transferring energy from the engine to the wheels, allowing for smooth movement.

- Chassis: The framework that supports all components, ensuring stability and durability during operation.

- Deck: The cutting mechanism that determines the height and quality of the cut.

- Wheels: Essential for mobility, designed to navigate various terrains efficiently.

Importance of Maintenance

Regular upkeep of these components is crucial for prolonging the lifespan of the machine. Proper care ensures:

- Optimal performance during use.

- Reduced risk of breakdowns.

- Enhanced safety for the operator.

- Improved fuel efficiency.

Understanding each element’s function not only helps in effective maintenance but also enhances the overall user experience, ensuring that the machinery remains a reliable tool for lawn care.

Overview of LT190 Specifications

This section provides a comprehensive look at the key characteristics and features of a popular lawn care machine. Understanding these specifications is crucial for optimal operation and maintenance, ensuring efficiency and longevity.

Engine and Performance

- Type: Air-cooled, four-stroke engine

- Power Output: Typically around 17.5 horsepower

- Displacement: Approximately 500cc

- Transmission: Automatic, variable speed

Dimensions and Weight

- Overall Length: About 66 inches

- Overall Width: Approximately 42 inches

- Height: Roughly 44 inches

- Weight: Close to 400 pounds

These specifications contribute to the machine’s effectiveness in managing various lawn care tasks, making it a reliable choice for homeowners and professionals alike.

Common Issues with LT190 Parts

When maintaining lawn care equipment, various challenges may arise related to components and their functionality. Understanding these common problems can help users identify issues early and ensure optimal performance. Below are some prevalent concerns encountered with these types of machinery.

| Issue | Description | Potential Solutions |

|---|---|---|

| Engine Not Starting | This can be caused by a dead battery, faulty ignition system, or fuel supply issues. | Check battery connections, inspect the ignition coil, and ensure the fuel lines are clear. |

| Uneven Cutting | Typically results from dull blades, improper tire pressure, or uneven deck height. | Sharpen or replace blades, check tire pressure, and adjust the cutting deck. |

| Excessive Vibration | Vibrations may indicate unbalanced blades or worn-out bearings. | Inspect and balance blades, and replace any damaged bearings. |

| Overheating | This can stem from blocked cooling fins or low oil levels. | Clean the cooling fins and ensure proper oil levels are maintained. |

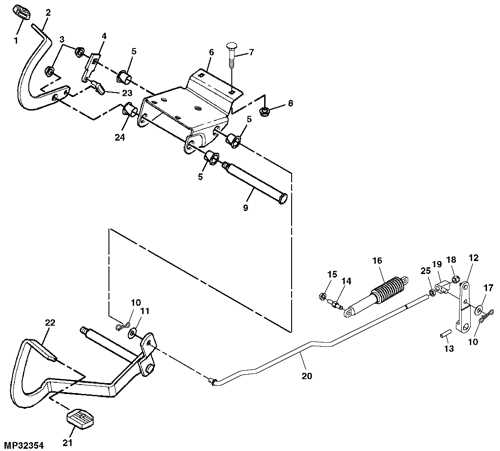

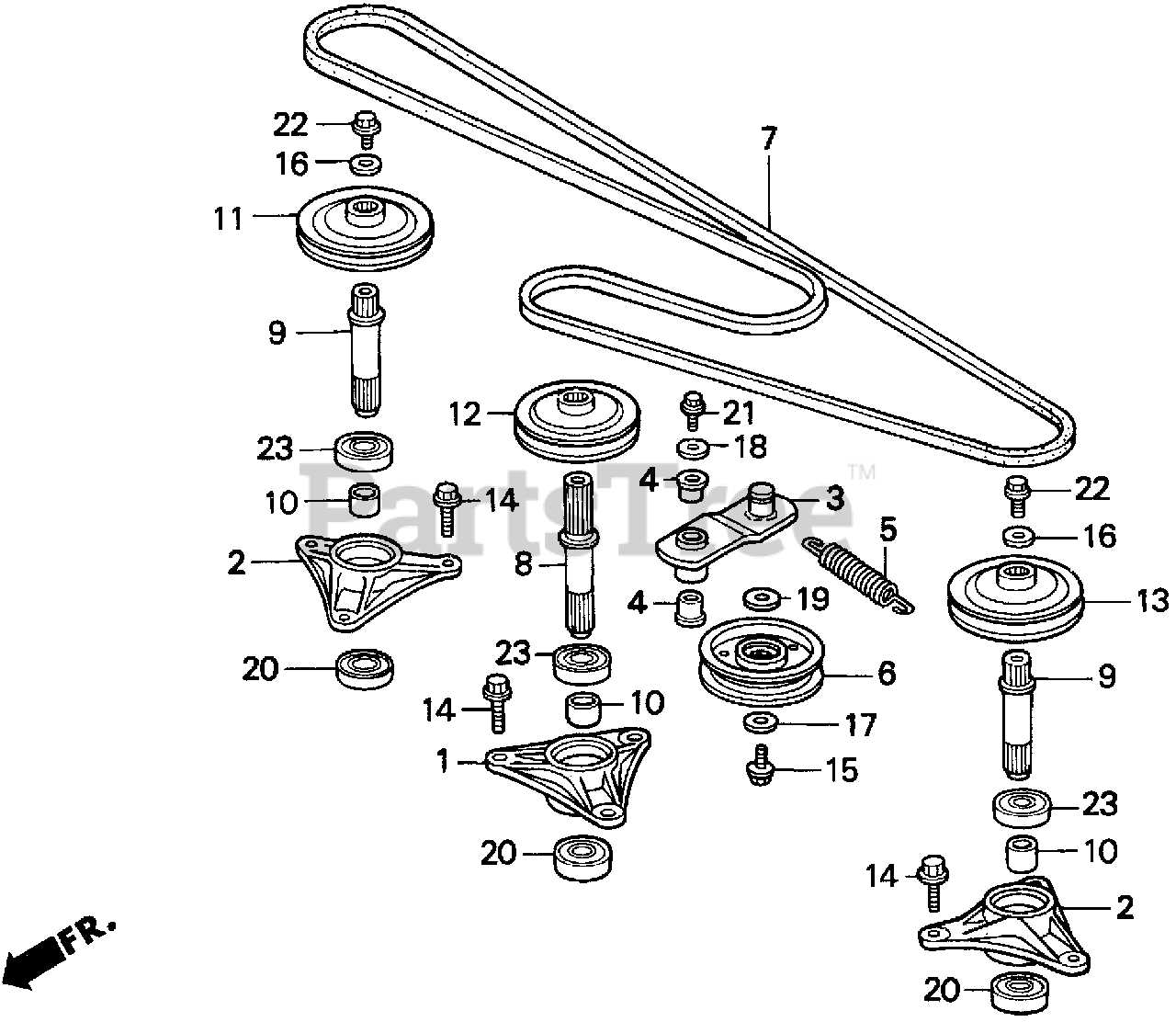

Importance of Accurate Parts Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair of machinery. These visuals serve as a roadmap, guiding users through complex systems and ensuring that each component is correctly identified and understood. When mechanics and operators have access to reliable schematics, they can efficiently locate and replace elements, minimizing downtime and enhancing productivity.

Enhanced Understanding

Clear and detailed visuals foster a deeper comprehension of how various components interact within a system. This knowledge empowers technicians to troubleshoot issues more effectively, leading to quicker resolutions and less guesswork. Moreover, a well-structured illustration can highlight the importance of each part, allowing users to appreciate the overall design and functionality of the equipment.

Reduction of Errors

Accurate schematics significantly reduce the likelihood of mistakes during repairs. By providing precise information on assembly and disassembly, these guides help prevent misalignment or incorrect installations that could result in costly damages. As a result, having reliable visuals not only saves time but also enhances the longevity of the equipment, ultimately contributing to better performance and reliability.

Where to Find LT190 Parts Diagrams

Locating detailed illustrations for specific machinery components can greatly enhance repair and maintenance efforts. These visuals serve as essential tools for understanding assembly and disassembly processes, ensuring accuracy during replacement tasks. There are several reliable resources available to help enthusiasts and professionals access these invaluable resources.

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | The official site often provides comprehensive resources, including manuals and schematics, for various models. |

| Online Retailers | Many online stores specialize in selling parts and may also offer links to relevant illustrations and manuals. |

| Forums and Community Groups | Online communities can be a great place to ask for assistance or find shared resources from other users. |

| Local Dealerships | Visiting or contacting nearby dealerships can provide access to physical or digital copies of required schematics. |

Step-by-Step Parts Replacement Guide

This section provides a comprehensive approach to replacing components of your machinery effectively. Following a structured process can ensure optimal performance and longevity of your equipment. Here, you’ll find a systematic method to identify, remove, and install various elements with ease.

Preparation Steps

Before diving into the replacement process, ensure you have the necessary tools and new components ready. Here’s a brief checklist:

| Item | Purpose |

|---|---|

| Wrench Set | To remove and tighten bolts |

| Screwdriver | For handling screws |

| Replacement Component | New part for installation |

| Safety Gear | To ensure personal safety |

Replacement Process

Follow these steps for efficient replacement:

- Disconnect the power source to prevent any accidents.

- Carefully remove any covers or shields that may obstruct access to the component.

- Identify the faulty part and take note of its connections and positioning.

- Remove the damaged item by unscrewing or unbolting it from its position.

- Install the new part by reversing the removal process, ensuring all connections are secure.

- Reattach any covers or shields that were removed.

- Reconnect the power source and perform a test to ensure everything functions properly.

How to Identify Genuine John Deere Parts

Ensuring the authenticity of components for machinery is essential for maintaining performance and longevity. Genuine products are specifically designed to meet the exact specifications of your equipment, thereby enhancing its functionality and reliability. Recognizing these original items can save you from potential issues associated with counterfeit alternatives.

One of the primary indicators of authenticity is the packaging. Official items typically come in distinctive, branded packaging that includes detailed information about the product. Look for holograms or seals that indicate quality assurance. Additionally, cross-referencing the serial numbers and part codes with the manufacturer’s database can confirm legitimacy.

Another aspect to consider is the price point. If an offer seems too good to be true, it likely is. Original items are usually priced consistently across authorized retailers. When purchasing, always opt for reputable suppliers to ensure you are acquiring the right components.

Lastly, seek advice from experienced technicians or enthusiasts within your community. Their insights can guide you in recognizing genuine offerings and avoiding inferior substitutes. By following these guidelines, you can confidently source the right components for your machinery.

LT190 Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires a thoughtful approach to upkeep and care. By following a systematic maintenance routine, you can prevent potential issues and enhance performance over time. Regular checks and timely interventions are key to achieving optimal functionality and reliability.

Regular Inspections: Conduct routine examinations of your machinery to identify any signs of wear or damage. Pay close attention to critical components, such as belts and blades, to ensure they remain in good condition.

Keep it Clean: Debris and dirt accumulation can lead to performance issues. Regularly clean the exterior and interior, focusing on air filters and cooling systems to maintain airflow and prevent overheating.

Oil Changes: Change the oil at recommended intervals to keep the engine running smoothly. Fresh oil lubricates parts effectively and reduces friction, which is essential for long-term operation.

Tire Maintenance: Check tire pressure regularly and inspect for any signs of damage. Properly inflated tires ensure better traction and handling, contributing to a safer and more efficient experience.

Battery Care: Inspect battery terminals for corrosion and ensure connections are secure. A well-maintained battery is crucial for reliable starts and overall performance.

Seasonal Preparations: Before extreme weather changes, perform a thorough check-up. This includes inspecting fluid levels and ensuring that all systems are ready to handle varying conditions.

By adhering to these maintenance tips, you can significantly enhance the durability and performance of your equipment, allowing it to serve you effectively for years to come.

Comparing LT190 to Similar Models

When evaluating a particular lawn tractor, it is essential to consider how it stacks up against comparable machines in its class. This analysis provides insights into design, functionality, and overall performance, helping potential buyers make informed choices. By examining various attributes such as engine power, cutting width, and ease of maintenance, one can determine which model best suits their needs.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power (HP) | 20 | 22 | 18 |

| Cutting Width (inches) | 42 | 48 | 40 |

| Transmission Type | Automatic | Hydrostatic | Manual |

| Fuel Capacity (gallons) | 2.5 | 3.0 | 2.0 |

| Weight (lbs) | 450 | 475 | 430 |

By comparing specifications and features, potential users can discern differences that may affect performance and suitability for specific tasks. Whether it’s for residential lawns or larger properties, understanding these comparisons will guide buyers toward the right choice for their gardening needs.

Popular Aftermarket Parts for LT190

When maintaining and upgrading a well-loved lawn tractor, enthusiasts often seek alternatives that enhance performance and durability. The availability of aftermarket components provides users with a variety of options, catering to different needs and preferences. These substitutes can often deliver comparable, if not superior, functionality compared to original items.

High-Quality Blades

One of the most sought-after enhancements involves the cutting blades. Quality replacement blades not only improve the efficiency of grass cutting but also ensure a cleaner finish. Users often opt for mulching blades that finely chop grass, returning nutrients to the soil and promoting healthy growth.

Enhanced Air Filters

Another critical upgrade is the air filtration system. Performance air filters are designed to improve airflow and engine efficiency, resulting in better fuel economy and overall power. Opting for a high-efficiency filter can lead to noticeable improvements in the tractor’s performance, particularly during prolonged use.

By considering these popular alternatives, owners can maximize their machine’s potential while enjoying enhanced reliability and performance.

Cost Factors for LT190 Replacement Parts

When it comes to maintaining machinery, understanding the various elements that influence the expenses associated with acquiring components is crucial. Several factors contribute to the overall cost, which can vary significantly based on the type of item required, the source of procurement, and the specific model involved.

Key Influencers on Pricing

Several aspects play a role in determining the financial outlay for replacement items. These include brand reputation, material quality, and whether the components are original or aftermarket. Additionally, geographical location and market demand can also impact pricing structures.

Cost Comparison Table

| Type | Price Range | Quality Level |

|---|---|---|

| OEM | $50 – $200 | High |

| Aftermarket | $30 – $150 | Variable |

| Used | $10 – $100 | Variable |

By evaluating these factors, owners can make informed decisions that balance cost and performance effectively, ensuring their machinery remains operational without unnecessary expenditure.

Resources for LT190 Owners and Technicians

Maintaining and repairing outdoor equipment requires access to reliable resources and information. For owners and technicians, having comprehensive materials can enhance understanding, streamline repairs, and ensure optimal performance. This section aims to provide valuable resources that will aid in servicing and troubleshooting.

Manuals and Documentation

Official manuals are essential for understanding the specifications and maintenance schedules of your equipment. They provide detailed information on operation, maintenance procedures, and troubleshooting steps. Additionally, digital resources can often be found online for easy access and reference.

| Resource Type | Description | Access Link |

|---|---|---|

| User Manual | Comprehensive guide for operation and care. | Download here |

| Service Manual | In-depth information for repair and maintenance. | Download here |

| Parts Catalog | Listing of available components and accessories. | Download here |

Online Communities and Forums

Engaging with fellow owners and professionals can provide insights and solutions to common issues. Online forums and social media groups dedicated to outdoor equipment often share tips, troubleshooting advice, and experiences that can be invaluable for both new and seasoned users.