Comprehensive Honda GX100 Parts Diagram Guide

The intricate world of small engine mechanics relies heavily on a comprehensive understanding of individual components and their interrelations. A well-structured visual representation can significantly enhance the efficiency of repairs and maintenance, enabling enthusiasts and professionals alike to navigate complex systems with ease. Such resources serve as vital guides, clarifying the placement and function of each element.

In this section, we delve into the essential framework that underpins these compact power sources. By examining the arrangement of various sections, one can gain insights into how each part contributes to the overall functionality. This knowledge not only streamlines the repair process but also fosters a deeper appreciation for engineering ingenuity.

Utilizing a detailed visual reference empowers users to identify specific components quickly, troubleshoot issues effectively, and execute maintenance tasks proficiently. This approach not only minimizes downtime but also ensures optimal performance, reflecting the significance of thorough understanding in the realm of small engines.

Understanding the Honda GX100 Engine

This section explores the intricacies of a popular small engine widely utilized in various applications. With its compact design and reliable performance, this power unit has gained a reputation for efficiency and durability. Understanding its components and functionality can enhance maintenance practices and overall performance.

The engine features a simple yet effective structure, comprising several key elements that work together harmoniously. Familiarity with these components can aid in troubleshooting common issues and ensuring optimal operation.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel combustion into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Carburetor | Mixes air and fuel for combustion. |

| Ignition System | Ignites the air-fuel mixture for combustion. |

Regular maintenance of these parts is crucial for longevity and performance. Understanding each component’s role aids in effective servicing and enhances the engine’s reliability in various applications.

Key Components of the GX100

This section explores the essential elements of a small engine that significantly contribute to its performance and efficiency. Understanding these components is crucial for maintenance, troubleshooting, and enhancing the overall functionality of the machine.

Engine Block and Cylinder

The core structure houses the combustion chamber and plays a vital role in the engine’s power generation. The cylinder is designed to facilitate optimal airflow and fuel combustion, ensuring maximum output and efficiency.

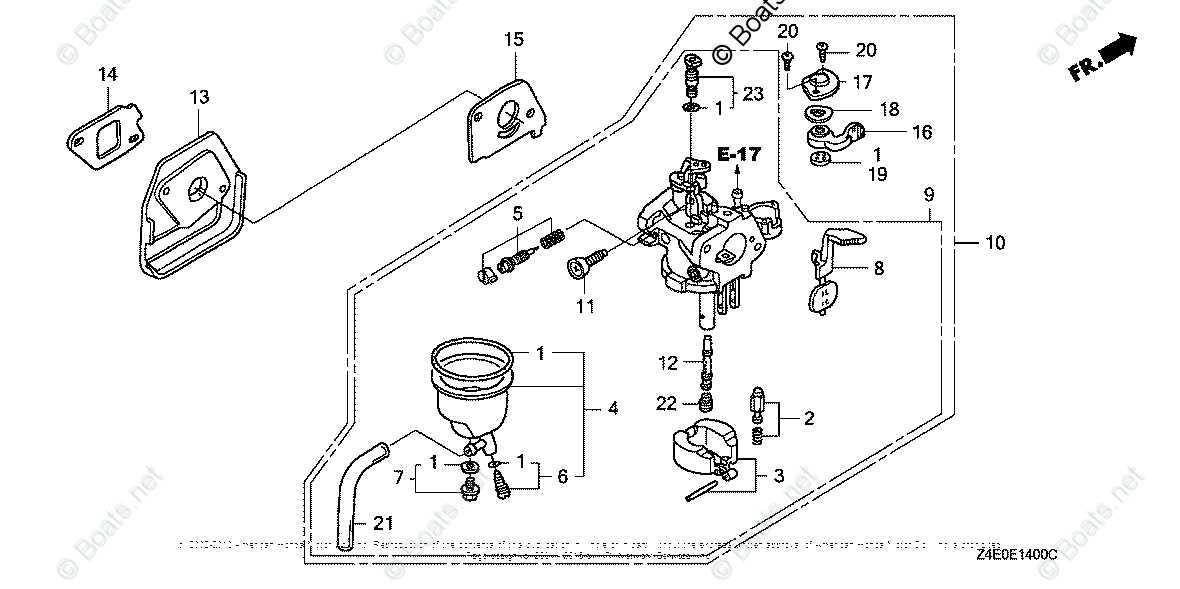

Fuel System

This system includes the fuel tank, carburetor, and lines that transport the fuel to the combustion chamber. Proper functioning of the fuel system is essential for maintaining the right mixture of air and fuel, which directly affects engine performance.

Importance of a Parts Diagram

Understanding the components of a machine is crucial for effective maintenance and repair. A visual representation of these elements aids users in identifying each part’s role and how they interact within the system. This knowledge not only streamlines the repair process but also enhances overall efficiency.

Benefits of Visual Representations

- Facilitates quick identification of components

- Reduces the likelihood of errors during assembly or disassembly

- Enhances understanding of complex systems

Applications in Maintenance and Repair

- Improves troubleshooting by highlighting potential failure points

- Guides technicians through the repair process with clarity

- Assists in ordering the correct replacements for faulty items

Incorporating visual guides into maintenance routines ultimately leads to more informed decisions and prolonged equipment lifespan.

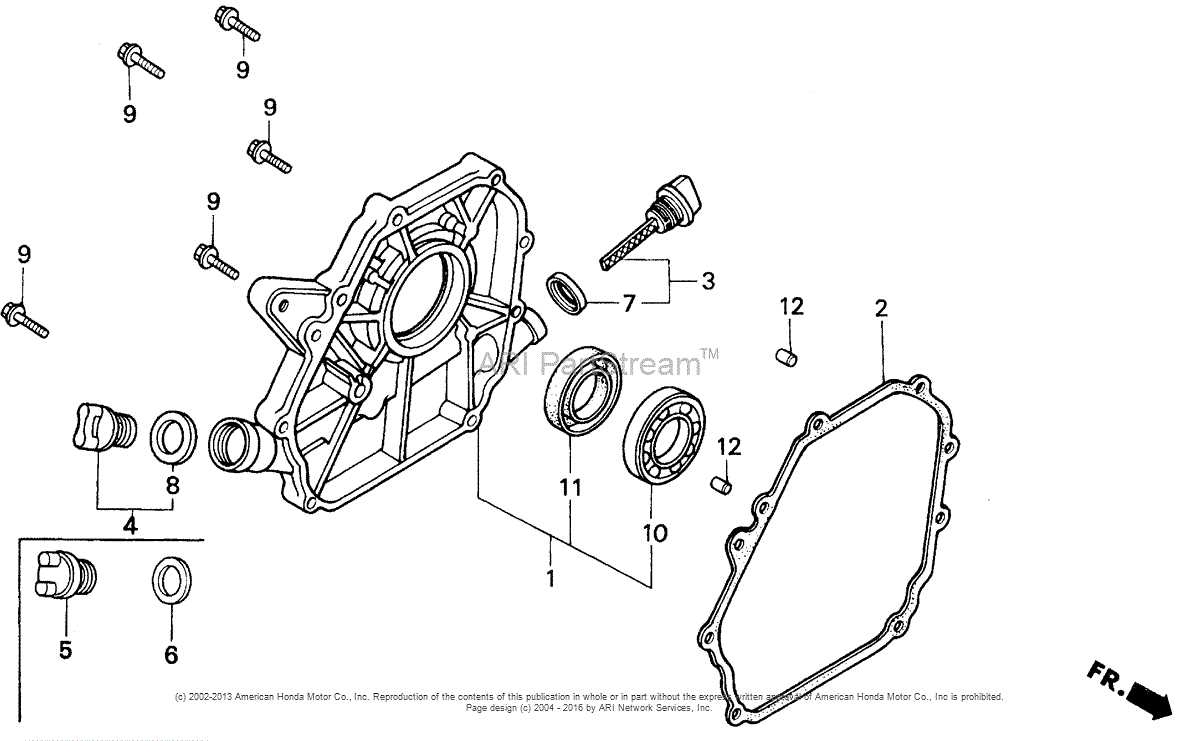

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as valuable guides, showcasing various elements and their relationships within a system. By familiarizing yourself with the layout and symbols used, you can streamline the process of identifying and sourcing necessary components.

To begin, it’s crucial to recognize the different sections of the illustration. Components are typically labeled with numbers or letters, which correspond to a list of parts. This correlation allows for easy reference when ordering or replacing items. Below is a breakdown of common features you might encounter:

| Feature | Description |

|---|---|

| Labels | Each component is usually marked with a unique identifier. |

| Legend | A key that explains symbols used in the illustration. |

| Exploded View | A detailed representation showing how parts fit together. |

| Orientation | Indications of how components are positioned in relation to one another. |

By taking the time to study these features, you can enhance your understanding and ensure that repairs are performed accurately. Mastering the art of reading these illustrations is a valuable skill for anyone involved in maintenance tasks.

Common Issues with GX100 Parts

When it comes to small engines, several common challenges can arise that affect their performance and longevity. Understanding these issues is crucial for proper maintenance and troubleshooting, ensuring that the machinery operates smoothly and efficiently. From wear and tear to improper assembly, various factors can contribute to these problems.

Wear and Tear: Over time, components can degrade due to regular usage. This often manifests as reduced efficiency or difficulty starting the engine. Regular inspections are necessary to identify worn parts before they lead to more significant failures.

Fuel Issues: Contaminated or stale fuel can lead to poor performance. It’s essential to use clean, fresh fuel to prevent clogging in the system, which can cause starting difficulties or erratic operation.

Overheating: Inadequate cooling can result in excessive heat buildup. This might stem from blocked air filters or insufficient oil levels. Monitoring temperature and ensuring proper airflow can help mitigate this risk.

Assembly Errors: Incorrect assembly during maintenance can lead to misalignments or component failures. Always refer to service manuals and ensure that all parts are installed correctly to avoid operational issues.

Vibration Damage: Excessive vibrations can loosen screws and components over time. Regular checks are advisable to ensure that everything remains securely fastened, preventing potential breakdowns during operation.

Addressing these common challenges proactively can lead to enhanced performance and reliability, extending the life of the equipment and reducing the likelihood of costly repairs.

Finding Genuine Honda Parts

When it comes to maintaining and repairing outdoor power equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure compatibility and reliability, ultimately enhancing the overall efficiency of your machinery.

Benefits of Using Authentic Components

- Durability: Genuine components are manufactured to strict quality standards, ensuring they withstand the rigors of use.

- Performance: Using authentic items guarantees that your equipment operates as intended, minimizing the risk of malfunctions.

- Warranty Protection: Many manufacturers offer warranties on their equipment, which may be voided if non-genuine parts are used.

How to Identify Authentic Components

- Check Packaging: Authentic items usually come in branded packaging with clear labeling.

- Verify Serial Numbers: Manufacturers often include serial numbers that can be checked against their databases.

- Purchase from Reputable Sources: Always buy from authorized dealers or trusted retailers to ensure authenticity.

DIY Maintenance Tips for GX100

Regular upkeep of your small engine can significantly enhance its performance and longevity. Engaging in simple maintenance tasks not only ensures efficient operation but also prevents potential issues that could arise from neglect. Below are essential tips to keep your machine in top condition.

| Task | Frequency | Tips |

|---|---|---|

| Change Oil | Every 50 hours of use | Use the recommended oil type and check the level regularly. |

| Check Air Filter | Every 25 hours of use | Clean or replace if it’s dirty to ensure proper airflow. |

| Inspect Spark Plug | Every 100 hours of use | Clean or replace to maintain efficient ignition. |

| Clean Fuel System | Every season | Use fresh fuel and consider adding a stabilizer. |

| Examine Belts and Hoses | Every 50 hours of use | Look for wear and tear; replace if necessary. |

By following these maintenance guidelines, you can ensure that your engine remains reliable and performs at its best for years to come. Regular attention to these areas will help you avoid costly repairs and extend the life of your equipment.

Replacing Worn Parts Efficiently

Maintaining optimal performance of machinery requires timely replacement of components that have degraded over time. Efficiently identifying and substituting these items not only prolongs the lifespan of the equipment but also enhances its functionality. A systematic approach can significantly reduce downtime and improve overall productivity.

To ensure a smooth replacement process, consider the following steps:

| Step | Description |

|---|---|

| 1 | Inspect regularly for signs of wear, such as unusual noises or decreased efficiency. |

| 2 | Refer to the manufacturer’s specifications to identify the correct dimensions and compatibility of the replacement components. |

| 3 | Gather all necessary tools and materials before beginning the replacement process to streamline the workflow. |

| 4 | Follow a step-by-step guide for disassembly and assembly to prevent damage to surrounding components. |

| 5 | Conduct a test run after the replacement to ensure everything operates as intended. |

By adhering to these steps, one can ensure a hassle-free replacement process that minimizes disruption and maximizes efficiency in operations.

Aftermarket vs. OEM Components

When it comes to replacement parts for machinery, two main categories emerge: those produced by the original manufacturer and alternatives from third-party suppliers. Each option has its advantages and drawbacks, influencing the decision-making process for consumers and professionals alike.

Advantages of OEM Components

- Designed specifically for compatibility, ensuring optimal performance.

- Often backed by a warranty, providing peace of mind.

- Maintains the integrity of the equipment, preserving its resale value.

Benefits of Aftermarket Alternatives

- Typically more affordable, offering cost savings for consumers.

- A wide range of options available, allowing for customization.

- Can sometimes feature enhanced performance characteristics or materials.

Ultimately, the choice between original and alternative components depends on factors such as budget, required performance, and long-term plans for the equipment.

Resources for GX100 Owners

Owning a small engine can be a rewarding experience, especially when you have access to the right tools and information. Whether you’re looking to maintain, repair, or enhance your equipment, having reliable resources at your fingertips is essential. This section provides valuable insights and links to help you make informed decisions regarding your machinery.

Online Forums and Communities: Engaging with fellow enthusiasts can provide you with tips, tricks, and support. Various online platforms host discussions where users share their experiences, troubleshooting advice, and modifications. Participating in these communities can enhance your understanding and keep you informed about the latest trends.

Instructional Videos: Visual aids are incredibly beneficial when learning about engine upkeep. Numerous channels offer step-by-step guides on maintenance and repairs. Watching these tutorials can make complex tasks more manageable and boost your confidence in handling your equipment.

Manufacturer Manuals: Always refer to the official manual for your engine. It contains crucial information about specifications, maintenance schedules, and troubleshooting steps. Keeping this document handy will ensure you have the necessary guidance for effective care.

Parts Suppliers: When repairs are needed, knowing reliable suppliers is vital. Many online retailers specialize in engine components, offering a wide range of options at competitive prices. Always check for quality and compatibility to ensure optimal performance.

Local Workshops: Don’t underestimate the value of local expertise. Workshops in your area can provide personalized service and advice. Building a relationship with a trusted mechanic can be incredibly beneficial for long-term maintenance.

Utilizing these resources will empower you to keep your engine running smoothly and efficiently, enhancing your overall experience as an owner.

Using Parts Diagrams for Repairs

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations provide a clear overview of the various elements involved, helping technicians and DIY enthusiasts understand how each piece fits together and functions. By utilizing these resources, users can streamline their repair processes and ensure that they address issues effectively.

Here are some key benefits of using these visual aids:

- Enhanced Understanding: They offer a simplified view of complex assemblies, making it easier to identify individual components.

- Efficient Troubleshooting: Users can quickly locate potential problem areas by referencing specific parts.

- Accurate Reassembly: Detailed illustrations guide users in reassembling units correctly after maintenance.

To make the most of these resources, consider the following steps:

- Identify the Issue: Start by diagnosing the problem accurately to determine which components may require attention.

- Consult the Visuals: Reference the illustrations to find the exact parts that relate to your issue.

- Gather Necessary Tools: Prepare all required tools and replacement items before starting the repair.

- Follow the Guide: Use the visual aids to guide your repair process step by step, ensuring each component is addressed.

- Test the Equipment: After completing the repairs, test the machinery to confirm that everything is functioning properly.

By integrating these visual tools into your repair strategy, you can enhance your efficiency and effectiveness, resulting in more successful outcomes.

Benefits of Regular Maintenance Practices

Implementing consistent upkeep procedures for equipment and machinery offers numerous advantages that extend their lifespan and enhance performance. Regular attention not only ensures operational efficiency but also contributes to safety and reliability.

- Improved Performance: Regular checks and servicing can lead to optimal functionality, ensuring that machines operate at their best.

- Increased Lifespan: Routine maintenance helps prevent wear and tear, ultimately prolonging the life of the equipment.

- Cost Efficiency: By addressing minor issues before they escalate, maintenance can reduce the likelihood of costly repairs and replacements.

- Enhanced Safety: Regular inspections can identify potential hazards, reducing the risk of accidents and ensuring a safer working environment.

- Environmental Impact: Well-maintained equipment typically operates more efficiently, leading to lower emissions and reduced energy consumption.

Establishing a schedule for maintenance not only safeguards investments but also fosters a culture of responsibility and care within an organization.

- Set a regular maintenance schedule.

- Document all maintenance activities.

- Train personnel on proper handling and upkeep procedures.

By prioritizing these practices, one can ensure long-term reliability and effectiveness of machinery, leading to smoother operations overall.