2007 Honda Ridgeline Parts Diagram Overview

When working on a vehicle, it’s essential to have a clear understanding of its various components and their arrangement. This knowledge helps in identifying and replacing individual pieces, ensuring the vehicle operates efficiently and safely. A comprehensive overview of how each part connects and interacts is crucial for any repair or maintenance work.

Detailed visual guides are often used to simplify this process. They provide a clear representation of the vehicle’s structure, making it easier to pinpoint specific sections that require attention. Such illustrations are invaluable for both professional mechanics and DIY enthusiasts looking to perform repairs without difficulty.

Having an organized reference allows for a systematic approach to fixing issues, ensuring that every component is correctly handled. Whether you’re replacing worn-out elements or upgrading parts, a visual reference helps streamline the process and improves accuracy during repairs.

Overview of 2007 Honda Ridgeline Parts

The vehicle’s overall performance depends heavily on the various components that make up its structure. These elements are carefully engineered to ensure both reliability and durability in challenging driving conditions. Understanding how each part contributes to the vehicle’s functionality is essential for maintaining its optimal performance over time.

Key Elements of the Vehicle’s Construction

Each section of the vehicle plays a crucial role in its overall operation. From the engine to the suspension, each component is designed to work in harmony, allowing for a smooth and efficient driving experience. Whether it’s the drivetrain, the braking system, or the interior features, every aspect has been meticulously crafted to meet the demands of modern drivers.

Maintenance and Replacement Considerations

Regular inspection and timely replacement of worn-out elements help in preserving the vehicle’s efficiency. Whether replacing the engine components or suspension parts, attention to detail ensures that the vehicle continues to perform at its best.

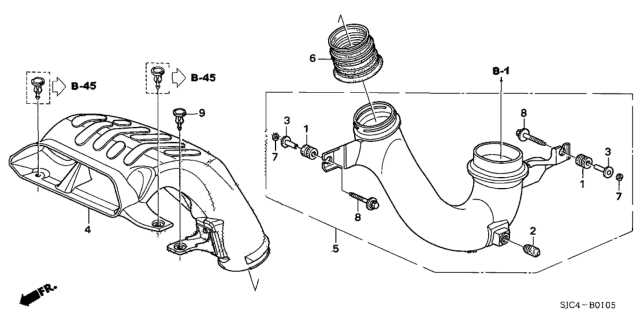

Understanding the Engine Components

Modern engines are composed of numerous elements that work in harmony to ensure smooth operation and optimal performance. These components play vital roles in controlling power generation, fuel combustion, and exhaust flow, all contributing to the vehicle’s efficiency and driving experience.

Each part within the engine has a specific function, whether it’s regulating the air-fuel mixture, managing the timing of combustion, or facilitating energy transfer to the transmission system. Together, they form an intricate system where precision and coordination are key.

The heart of the engine, the block, houses crucial components such as the pistons, crankshaft, and valves. These work together to convert fuel into mechanical energy, pushing the vehicle forward. Understanding how these parts interact can significantly enhance one’s knowledge of vehicle maintenance and troubleshooting.

Key Suspension and Steering Parts

The suspension and steering system plays a crucial role in providing stability, comfort, and control while driving. These components work together to absorb shocks, maintain wheel alignment, and ensure smooth handling on various terrains. Understanding the essential elements of these systems helps in maintaining the vehicle’s performance and safety.

Suspension components include springs, shock absorbers, and control arms, which work to minimize road impact and keep the vehicle steady. The steering system, on the other hand, consists of the steering wheel, linkages, and rack and pinion mechanisms, allowing precise control over direction and maneuverability.

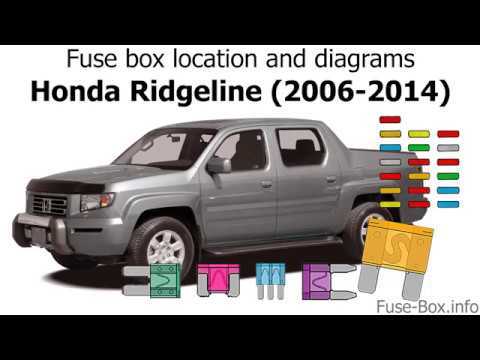

Electrical System and Wiring Diagram

The electrical system of a vehicle is crucial for its proper functioning, powering various components that control everything from lighting to internal electronics. A clear understanding of the wiring layout helps in troubleshooting and repairing faults within the system. Knowing how the circuits are interconnected is essential for maintaining performance and safety.

Key Components of the Electrical Network

Several critical elements make up the electrical framework, including the battery, alternator, fuses, relays, and wiring harnesses. These components work together to ensure the smooth operation of essential functions such as ignition, climate control, and infotainment systems.

| Component | Function |

|---|---|

| Battery | Stores and supplies electrical power to the system. |

| Alternator | Charges the battery while the engine is running. |

| Fuses | Protects the electrical circuits from overload. |

| Relays | Controls high-current circuits using low-power signals. |

| Wiring Harness | Organizes and directs electrical power to various components. |

Understanding the Circuit Connections

The connections between components are typically made through a network of wires that carry electrical signals and power. The wiring layout helps in tracing the path of each circuit, ensuring no power losses or short circuits occur. Proper knowledge of this network is vital when diagnosing issues related to lighting, battery charging, or electrical accessories.

Brake System Breakdown

The braking mechanism of any vehicle is a critical safety feature that ensures proper stopping power. Understanding the components and their functions can help maintain the vehicle’s braking performance. A well-functioning system relies on a series of interconnected parts working in unison to bring the vehicle to a halt when necessary.

Brake pads are the most prominent wear items in the braking system. They press against the brake rotors to create the friction necessary for deceleration. Over time, they lose effectiveness and must be replaced to ensure optimal performance.

The rotors, also known as brake discs, are another key element. These metal components provide a surface for the brake pads to apply pressure. Warped or grooved rotors can reduce braking efficiency, leading to vibrations or noise during braking.

Another important part of the system is the caliper, which houses the brake pads and is responsible for pushing them against the rotors. The hydraulic pressure from the master cylinder allows the caliper to function correctly.

Additionally, brake fluid plays an essential role in the overall braking process. It transmits the pressure from the brake pedal to the calipers, allowing the vehicle to stop. Regular checks and changes of brake fluid are necessary to avoid corrosion or air bubbles, which can compromise braking ability.

Maintaining all these components is vital for ensuring safety on the road. Regular inspections can prevent costly repairs and ensure the system’s reliability.

Transmission and Drivetrain Details

The transmission and drivetrain play a crucial role in ensuring the smooth and efficient transfer of power from the engine to the wheels. These components are designed to deliver the necessary torque and control to enhance performance and handling under various driving conditions.

Transmission Overview

The transmission system is responsible for shifting gears, adjusting power output, and enabling the vehicle to operate effectively at different speeds. It consists of several key elements:

- Gearbox: A set of gears that control the vehicle’s speed and torque.

- Clutch: A mechanism that engages and disengages the engine from the drivetrain.

- Shift Linkage: A system that allows the driver to select the appropriate gear.

Drivetrain Components

The drivetrain is a collection of parts that transmit the engine’s power to the wheels. It ensures that the vehicle moves forward or backward, depending on the driver’s commands:

- Driveshaft: A long shaft that transmits torque from the transmission to the wheels.

- Differential: A device that allows wheels on the same axle to rotate at different speeds, crucial for turning.

- Axles: The shafts that connect the wheels to the differential, enabling them to rotate.

Fuel System and Tank Components

The fuel system is essential for storing and delivering fuel to the engine efficiently. It includes various components that work together to ensure proper fuel flow, optimal combustion, and engine performance. These elements are designed to manage fuel delivery under different conditions and to maintain safety throughout the vehicle’s operation.

Fuel Tank

The fuel tank serves as the primary storage for fuel. It is typically made from durable materials to withstand various environmental factors and impacts. The tank is equipped with a cap and seal to prevent fuel vapor leaks and maintain pressure within the system. Additionally, it is designed to allow easy refueling and ensures a tight fit with the fuel lines.

Fuel Pump and Fuel Lines

The fuel pump is responsible for transferring fuel from the tank to the engine. It operates under pressure to push fuel through the lines, ensuring consistent flow. Fuel lines are designed to handle this pressurized delivery while maintaining safety by preventing leaks or degradation from exposure to heat and chemicals.

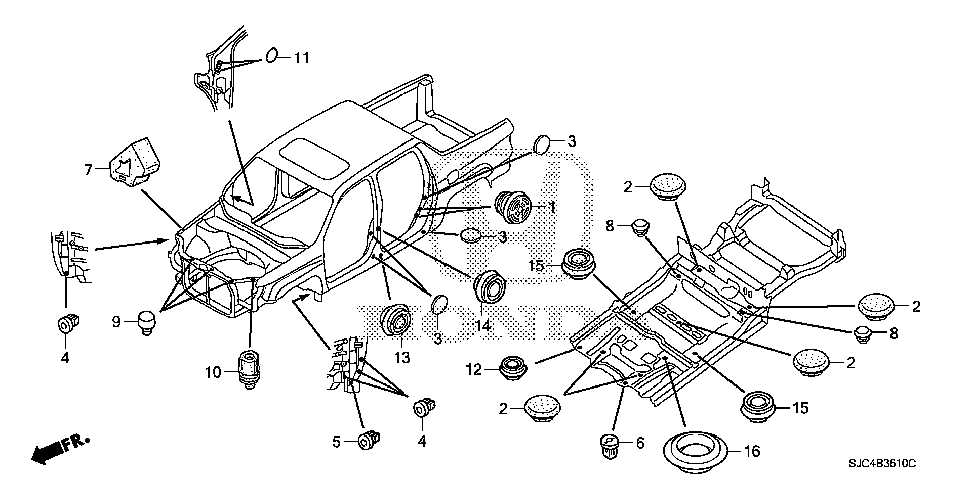

Interior and Exterior Body Parts

The vehicle’s body consists of both internal and external components that play a vital role in its functionality, safety, and appearance. These elements include various structures and elements that enhance comfort, support, and overall protection while driving. The integration of these pieces ensures durability and seamless performance under different driving conditions.

Exterior Components

Exterior components are designed to withstand environmental factors and contribute to the vehicle’s overall aesthetic appeal. These parts include the outer shell, the protective surfaces, and the elements that impact aerodynamics and visibility.

| Component | Function |

|---|---|

| Front Bumper | Protects the front of the vehicle during collisions and enhances the vehicle’s appearance. |

| Side Mirrors | Provide visibility for the driver and improve safety on the road. |

| Headlights | Illuminate the road ahead, ensuring visibility in low-light conditions. |

| Grille | Allows air to flow to the engine, helping to regulate temperature. |

Interior Components

The interior of the vehicle is designed to offer comfort and convenience to its occupants. This includes various fittings and fixtures that enhance the driving experience while ensuring safety and comfort during extended use.

| Component | Function |

|---|---|

| Dashboard | Displays important vehicle information and controls critical functions. |

| Seats | Provide support and comfort for passengers and drivers during travel. |

| Steering Wheel | Allows the driver to control the direction of the vehicle. |

| Air Conditioning System | Maintains comfortable cabin temperature and improves air quality. |

Honda Ridgeline Cooling System Diagram

The cooling mechanism in a vehicle plays a crucial role in regulating engine temperature, ensuring optimal performance. It is designed to prevent overheating by circulating coolant through various components, dissipating excess heat and maintaining a safe operating range. Understanding the layout of this system is essential for anyone looking to maintain or troubleshoot their vehicle’s engine performance.

Components of the Cooling Mechanism

At the heart of the cooling system is the radiator, which works in conjunction with the thermostat, water pump, and hoses. The radiator expels heat from the coolant, while the water pump circulates it throughout the engine and other key areas. The thermostat regulates the coolant flow based on temperature, ensuring the engine stays within an optimal range.

Functionality and Flow

The flow of coolant through the system is crucial for heat regulation. Coolant is drawn from the radiator, circulated through the engine, and then returned to the radiator to be cooled again. This process is continuous, helping to maintain the engine at its ideal operating temperature during both city driving and high-speed conditions.

Maintenance Parts for the 2007 Model

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. Maintaining the key components of your ride helps avoid unexpected issues and keeps it running smoothly. Here’s an overview of the essential elements you need to focus on for routine maintenance.

Essential Components for Care

To maintain efficiency and extend the life of your vehicle, certain components should be replaced or inspected periodically. These include items that play crucial roles in performance, safety, and comfort.

| Component | Recommended Maintenance Interval | Notes |

|---|---|---|

| Air Filter | Every 12,000 to 15,000 miles | Replace more frequently in dusty environments. |

| Brake Pads | Every 30,000 to 50,000 miles | Inspect regularly for wear. |

| Oil and Filter | Every 5,000 to 7,500 miles | Use recommended oil type for better engine protection. |

| Timing Belt | Every 60,000 to 100,000 miles | Failure can lead to serious engine damage. |

Detailed Diagram of Honda Ridgeline Tires

Understanding the components and structure of vehicle wheels is essential for proper maintenance and performance. A comprehensive breakdown of these elements ensures optimal function, safety, and longevity of your vehicle’s tires. Each part plays a crucial role in supporting the vehicle’s weight, providing traction, and absorbing shocks from the road.

| Component | Description |

|---|---|

| Tread | The rubber part of the tire that makes contact with the road, designed to provide grip and traction. |

| Sidewall | The vertical part of the tire that connects the tread to the rim, helping to absorb shocks and maintain tire integrity. |

| Bead | The inner edge of the tire that sits against the rim, ensuring the tire stays securely in place. |

| Rim | The metal component that holds the tire in place and supports the overall wheel structure. |

| Valve Stem | A small component that allows air to be added or removed from the tire, playing a key role in maintaining tire pressure. |

Commonly Replaced Parts in Ridgeline

Throughout the vehicle’s lifespan, certain components are more prone to wear and require replacement. These items are essential for maintaining the performance, safety, and overall functionality of the vehicle. Regular maintenance helps extend the life of these components, but some may need attention sooner than others due to various driving conditions and environmental factors.

Brake pads are one of the most frequently replaced elements, as they wear down over time with regular use. Depending on the driving habits and road conditions, they might need to be replaced more often to ensure optimal stopping power.

Suspension components such as shocks and struts also undergo significant stress and can degrade, affecting ride quality and handling. Replacing these parts helps maintain comfort and control, especially when driving on rough or uneven surfaces.

The battery is another critical component that often requires replacement after several years of use. Environmental factors, such as extreme temperatures, can shorten its lifespan, causing it to fail unexpectedly.

Finally, filters–air, oil, and cabin filters–need regular attention to ensure proper engine performance and air quality inside the vehicle. Keeping these components in good condition contributes to the overall efficiency of the vehicle.