Understanding the Parts Diagram of Your Yard Machine Push Mower

Maintaining a pristine lawn requires not only dedication but also a thorough understanding of the tools involved. A comprehensive overview of essential equipment elements can significantly enhance your gardening experience. By familiarizing yourself with the various components, you’ll be better equipped to troubleshoot and optimize your lawn care routine.

Knowledge of each element plays a crucial role in ensuring efficiency and performance. This exploration will help you visualize how each part interacts within the overall framework of your gardening apparatus. With the right insights, you can address any challenges that may arise during your landscaping tasks.

Ultimately, having a clear representation of these components empowers you to make informed decisions about maintenance and repairs. Diving into the intricate details will lead to a deeper appreciation for the machinery that aids in cultivating your outdoor space.

Understanding Yard Machine Mowers

This section explores the intricacies of a specific type of lawn care equipment, highlighting its essential components and functionality. Knowing how each element contributes to overall performance can enhance the user experience and maintenance practices.

| Component | Description |

|---|---|

| Engine | Drives the equipment and powers the cutting mechanism. |

| Blade | Responsible for cutting grass efficiently and evenly. |

| Handle | Provides grip and control while operating the device. |

| Deck | Houses the blade and protects the internal components. |

| Wheels | Facilitate movement across various terrains. |

Importance of Proper Maintenance

Regular upkeep of equipment is essential to ensure its longevity and optimal performance. Neglecting maintenance can lead to decreased efficiency, increased wear and tear, and ultimately higher repair costs. Understanding the significance of this practice helps users to keep their tools functioning effectively and reliably.

Benefits of Consistent Care

- Enhanced Performance: Routine maintenance keeps the machinery operating smoothly, ensuring that tasks are completed efficiently.

- Extended Lifespan: Proper attention can significantly prolong the useful life of equipment, saving money in the long run.

- Safety: Regular inspections can prevent accidents and injuries caused by malfunctioning tools.

- Cost Efficiency: Timely maintenance can reduce the need for costly repairs by addressing minor issues before they escalate.

Key Maintenance Practices

- Regularly check and replace worn components.

- Clean equipment after each use to prevent buildup of debris.

- Inspect fuel and oil levels to ensure proper operation.

- Sharpen blades and other cutting tools to maintain efficiency.

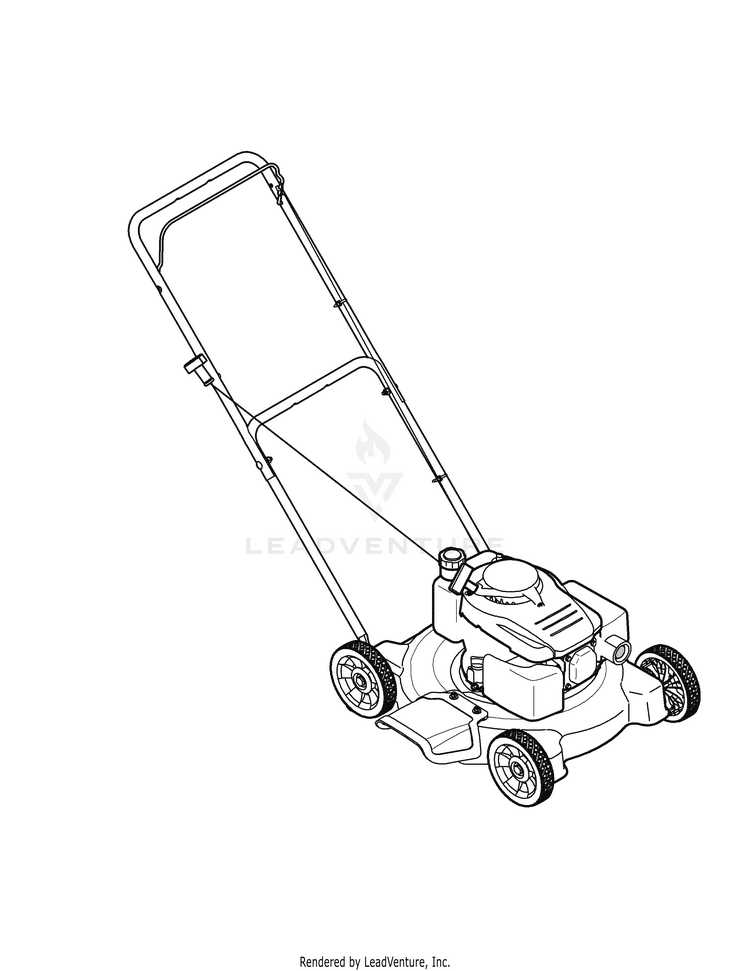

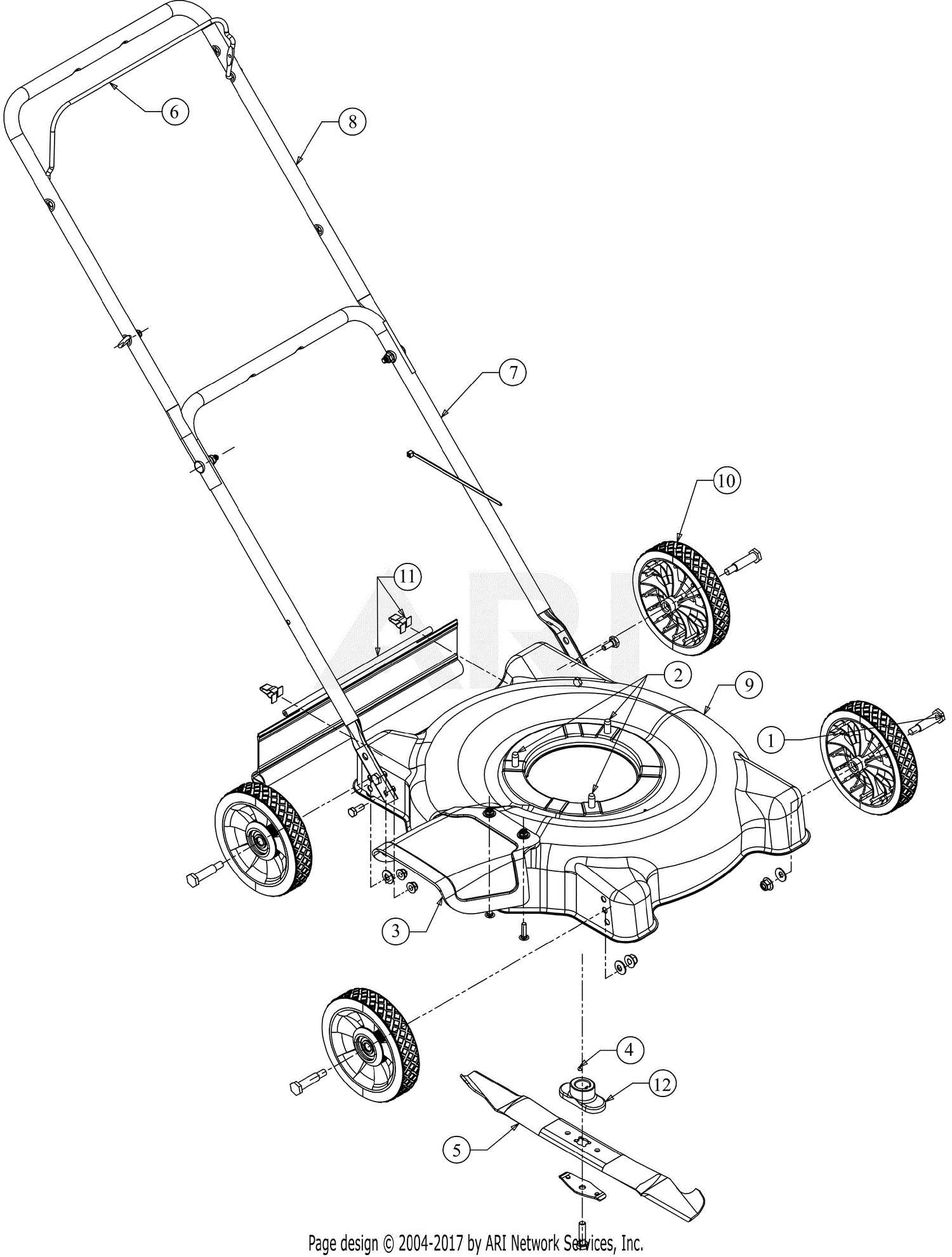

Key Components of Push Mowers

Understanding the essential elements of lawn care equipment is crucial for maintenance and efficient operation. Each component plays a significant role in the overall functionality, contributing to the effectiveness and longevity of the apparatus. By familiarizing oneself with these parts, users can ensure better performance and easier troubleshooting.

The cutting system is one of the primary features, typically consisting of blades that rotate at high speeds to achieve a clean cut. The engine or motor powers this mechanism, providing the necessary force to maneuver the device across various terrains. Additionally, the frame supports all components and offers stability during use.

The wheels and handles enhance maneuverability, allowing for easy navigation around obstacles. A collection system may be included to gather clippings, ensuring a tidy finish after trimming. Furthermore, the height adjustment mechanism is vital for achieving the desired grass length, adapting to different lawn conditions.

Each of these elements works in concert, and understanding their function can lead to improved care practices and increased efficiency in maintaining green spaces.

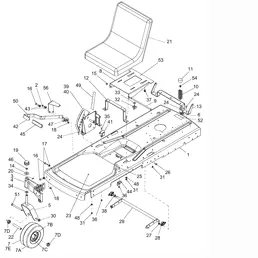

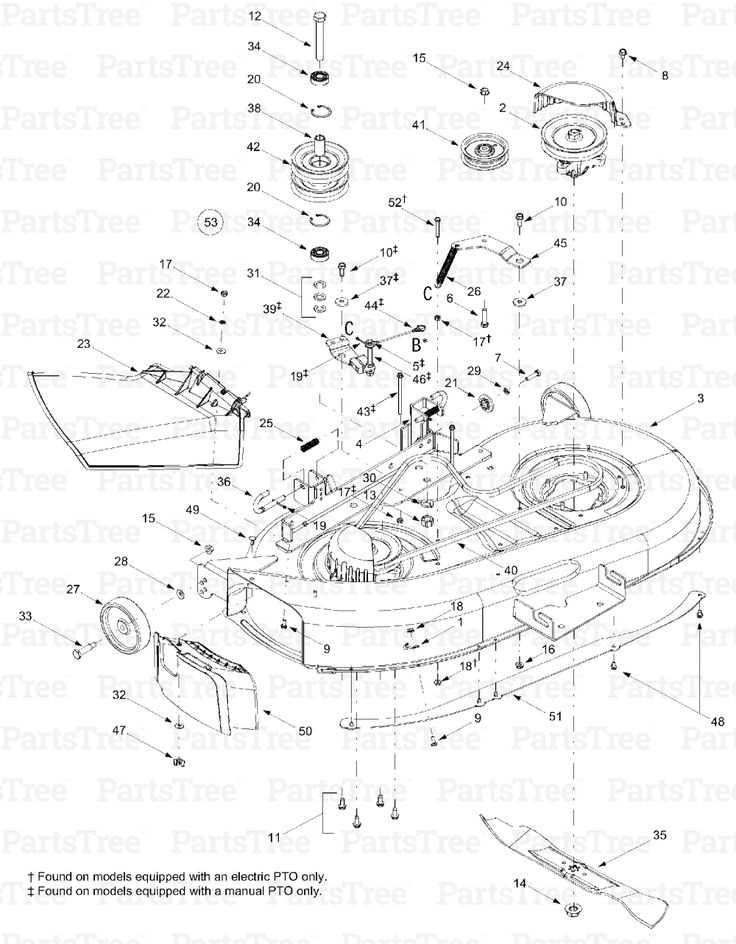

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations offer a detailed overview of various elements, enabling users to identify and procure the correct items. Here’s how to approach them:

- Familiarize Yourself with Symbols:

- Learn the common icons used to denote specific components.

- Recognize the color codes and lines indicating different functions.

- Locate the Legend:

- Find the key that explains the symbols and numbers.

- This helps in understanding the layout and relationships between components.

- Identify Key Sections:

- Look for clusters that represent functional areas or systems.

- Note how parts connect and interact within these sections.

- Cross-Reference with Manuals:

- Use your owner’s manual for additional context and instructions.

- This can clarify complex arrangements and offer repair guidance.

By mastering these techniques, you’ll be equipped to navigate any component representation with confidence and precision.

Common Issues with Push Mowers

Maintaining a well-functioning lawn care tool is essential for achieving a pristine yard. However, various complications can arise that hinder performance, leading to frustration. Understanding these common problems can help users diagnose and resolve issues efficiently.

Frequent Problems

Several factors can contribute to subpar operation. Below is a list of typical challenges faced by owners:

| Issue | Description |

|---|---|

| Difficulty Starting | Often caused by stale fuel or a faulty spark plug. |

| Uneven Cutting | This may occur due to dull blades or uneven tire pressure. |

| Overheating | Can result from excessive use without proper cooling breaks. |

Preventive Measures

Regular maintenance, such as sharpening blades and changing oil, can significantly reduce these issues. By staying proactive, users can ensure their equipment operates smoothly and efficiently.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right tools is crucial for efficient repairs and upkeep. A well-equipped toolkit not only simplifies the process but also enhances the quality of the work performed. Understanding which instruments are essential can save time and ensure optimal performance.

Basic Tools

Every repair enthusiast should have a selection of basic instruments at their disposal. Wrenches, screwdrivers, and pliers are fundamental for loosening or tightening components. Additionally, a socket set can significantly speed up tasks that require multiple sizes of fasteners. Investing in high-quality hand tools ensures longevity and reliability.

Specialized Equipment

For more intricate repairs, specialized equipment becomes necessary. A multimeter is invaluable for diagnosing electrical issues, while a fuel line wrench helps with maintenance of the fuel system. Furthermore, having a mechanic’s creeper allows for easier access to hard-to-reach areas, making the overall process smoother and more efficient.

Finding Replacement Parts Online

Locating suitable components for outdoor equipment can often feel overwhelming. However, the internet provides numerous avenues to simplify this process. By utilizing specific resources and tools, you can efficiently identify and acquire what you need without leaving your home.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often have catalogs and direct links to order components. |

| Online Retailers | Major e-commerce platforms provide a vast selection and competitive pricing. |

| Forums and Community Groups | Enthusiasts share advice and recommendations for reliable sources. |

| Parts Lookup Tools | Many websites offer search functions where you can input model numbers for exact matches. |

Step-by-Step Repair Guide

This section offers a comprehensive approach to tackling maintenance and fixing issues effectively. By following a structured method, you can ensure your equipment runs smoothly and lasts longer.

-

Identify the Issue:

- Observe any unusual sounds or performance drops.

- Check for visible damage or wear.

-

Gather Necessary Tools:

- Screwdrivers

- Wrenches

- Replacement components

-

Disassemble Carefully:

- Document each step for easy reassembly.

- Keep small parts organized in containers.

-

Inspect and Replace:

- Examine each component for wear.

- Swap out damaged parts with new ones.

-

Reassemble and Test:

- Follow your documentation to put everything back together.

- Run a test to ensure functionality.

By adhering to this guide, you can maintain optimal performance and prolong the life of your equipment.

Comparing Different Mower Models

When selecting a cutting tool, it’s essential to explore various options available in the market. Each type boasts unique features and capabilities tailored to different needs, making the choice crucial for optimal lawn care. Understanding the distinctions between models can enhance efficiency and performance.

Features to Consider

Key aspects to evaluate include engine power, cutting width, and ease of maneuverability. A robust engine ensures better performance on uneven terrains, while a wider cutting path can significantly reduce mowing time. Additionally, weight and design impact how easily the equipment can be handled.

Cost and Maintenance

Affordability is another vital consideration. Higher-priced models often offer advanced features and durability, but it’s important to weigh these against maintenance costs. Regular upkeep is necessary to prolong the lifespan of any equipment, making initial investment only one part of the overall equation.

Seasonal Maintenance Tips

Regular upkeep is essential for ensuring optimal performance throughout the year. By following a structured maintenance schedule, you can prolong the lifespan of your equipment and enhance its efficiency, making tasks easier and more enjoyable.

Spring Preparation

As the season shifts, it’s crucial to check and replace any worn components. Start by inspecting the blades for sharpness; dull blades can damage grass. Additionally, change the oil and clean air filters to promote better airflow and functionality. Keep an eye on belts and cables, ensuring they are in good condition.

Autumn Shutdown

Before winter sets in, take the time to winterize your gear. This includes thoroughly cleaning the exterior and draining any fuel to prevent corrosion. Consider storing the unit in a dry area to shield it from harsh conditions. Completing these steps will set you up for success when the new season arrives.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety should be the top priority. Proper precautions help prevent accidents and injuries while working on equipment. Familiarizing oneself with essential safety measures can lead to a smoother and more secure repair process.

Essential Safety Gear

Wearing appropriate protective equipment is crucial. This includes gloves, safety glasses, and sturdy footwear to safeguard against potential hazards.

Work Environment Safety

Maintain a clean and organized workspace to minimize risks. Ensure proper ventilation and avoid clutter to facilitate safe handling of tools and components.

| Precaution | Description |

|---|---|

| Protective Gear | Use gloves, goggles, and non-slip shoes. |

| Workspace Organization | Keep tools and parts neatly arranged. |

| Ventilation | Ensure adequate airflow in the work area. |

When to Seek Professional Help

Determining the right time to consult an expert can save both time and resources. While many issues can be tackled independently, certain situations demand specialized knowledge and experience. Recognizing these moments is crucial for maintaining optimal performance and safety.

It is advisable to consider professional assistance in the following circumstances:

| Situation | Reason for Professional Help |

|---|---|

| Persistent Operational Issues | If problems recur despite troubleshooting efforts, a professional can provide insights into underlying causes. |

| Complex Repairs | Tasks requiring advanced skills or tools are best left to specialists to avoid further complications. |

| Safety Concerns | When there is a risk of injury or damage, enlisting an expert ensures safe handling of the equipment. |

| Time Constraints | For those with limited time, hiring a professional can expedite the repair process. |

In summary, recognizing when to reach out for help can enhance the longevity and functionality of your equipment while ensuring safety and efficiency.