Understanding the Expobar Office Lever Parts Diagram

In the intricate world of espresso preparation, the functionality of various components plays a crucial role in achieving the perfect brew. Each mechanism is designed to work harmoniously, contributing to the overall efficiency and quality of the coffee-making process. A comprehensive exploration of these elements unveils the artistry behind espresso craftsmanship.

For enthusiasts and professionals alike, grasping the layout and operation of these components is essential. This knowledge not only enhances the brewing experience but also aids in troubleshooting and maintenance. A well-structured overview illuminates how each section interacts within the espresso machine, revealing the synergy that defines exceptional coffee.

By delving into the specifics, one can appreciate the sophistication of design and engineering involved. The relationships between various sections are not merely functional; they reflect a commitment to quality and precision. Understanding this intricate system fosters a deeper connection to the art of coffee making, encouraging mastery over every cup produced.

Understanding Expobar Office Lever Parts

Comprehending the components of your brewing machine is crucial for effective maintenance and optimal performance. Each element plays a specific role in ensuring that your beverage preparation experience is seamless and satisfying.

Key Components

- Group Head: Essential for water distribution.

- Boiler: Maintains the necessary temperature for extraction.

- Pump: Provides the pressure required for brewing.

- Portafilter: Holds the coffee grounds during extraction.

- Steam Wand: Used for frothing milk and creating microfoam.

Maintenance Tips

- Regularly clean the group head to prevent coffee buildup.

- Check the boiler pressure to ensure it operates within the ideal range.

- Inspect the pump for any signs of wear or leaks.

- Clean the steam wand after each use to avoid milk residue.

- Replace any worn gaskets or seals promptly to maintain efficiency.

Components of the Lever Mechanism

The mechanism that facilitates the brewing process consists of various essential elements that work in harmony to produce high-quality coffee. Each component plays a critical role in ensuring the proper functioning and efficiency of the system.

| Component Name | Description |

|---|---|

| Arm | The primary element that is manually operated, allowing the user to control the pressure applied during extraction. |

| Piston | A cylindrical part that moves within a chamber to generate pressure, essential for forcing water through coffee grounds. |

| Spring | A component that provides resistance, returning the arm to its original position after use and ensuring consistent pressure application. |

| Group Head | The area where the coffee grounds are placed and where water is forced through during the brewing process. |

| Seal | A vital component that prevents leaks and ensures a tight fit between moving parts, maintaining the necessary pressure. |

Benefits of Lever Espresso Machines

Manual espresso makers offer a unique approach to crafting coffee, allowing enthusiasts to experience the full spectrum of flavor and aroma. These machines rely on user skill and technique, creating a more engaging brewing process that can yield exceptional results. The hands-on nature not only enhances the brewing experience but also fosters a deeper connection to the art of coffee making.

One of the primary advantages of these machines is the level of control they provide. Baristas can adjust variables such as pressure and extraction time, leading to a personalized cup of coffee tailored to individual preferences. This precision is often difficult to achieve with automatic models, which can restrict creativity.

Additionally, the build quality of these devices is typically robust, often featuring materials that enhance durability and longevity. This commitment to craftsmanship means that users can rely on their machine for years, making it a worthy investment for serious coffee lovers.

Lastly, the aesthetic appeal of manual espresso machines adds to their charm. Many models boast a classic design that can complement any kitchen decor, serving as both a functional tool and a striking centerpiece.

| Benefit | Description |

|---|---|

| Control | Allows for precise adjustments in brewing variables. |

| Durability | Typically constructed from high-quality materials for longevity. |

| Aesthetic Appeal | Offers a classic design that enhances kitchen decor. |

| Engagement | Encourages a deeper connection to the coffee-making process. |

How to Identify Each Part

Understanding the components of a machine is essential for efficient operation and maintenance. Each element plays a crucial role in the overall functionality, and recognizing them can significantly enhance your ability to troubleshoot and repair. This section will guide you through identifying the various segments, ensuring you have a clear grasp of their functions.

Visual Identification

Start by examining the exterior of the device. Look for distinct shapes and sizes that can help you distinguish each component. Take note of any markings or labels that might provide additional information regarding the specific role of each segment. Photographs can also be useful; having a visual reference allows for easier recognition.

Functionality Recognition

Understanding how each element operates is equally important. For instance, components that control flow, pressure, or temperature can often be identified by their placement and connections. Referencing a manual or schematic can aid in this identification, helping you to correlate the physical characteristics with their intended functions.

Common Issues with Expobar Parts

When it comes to espresso machines, various components can face challenges that affect performance. Understanding these common problems is crucial for maintaining efficiency and ensuring a satisfying brewing experience.

Frequent Malfunctions

Several issues can arise with critical machine components, leading to subpar results. Regular inspections and timely replacements can mitigate these concerns and prolong the lifespan of the equipment.

Typical Component Failures

| Component | Common Issue | Solution |

|---|---|---|

| Pressure Gauge | Inaccurate readings | Calibrate or replace |

| Steam Wand | Weak steam output | Check for blockages |

| Group Head | Uneven extraction | Clean and descale |

| Water Pump | Noisy operation | Inspect for wear and replace |

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for ensuring the durability and optimal performance of your equipment. By following a few straightforward guidelines, you can significantly extend its lifespan and maintain its efficiency over time.

- Regular Cleaning: Clean components regularly to prevent the buildup of residue and mineral deposits. Use appropriate cleaning agents to ensure surfaces remain intact.

- Check Seals and Gaskets: Inspect seals and gaskets frequently for wear and tear. Replace them as necessary to avoid leaks and maintain pressure.

- Lubrication: Apply lubricant to moving parts as recommended by the manufacturer. This helps reduce friction and prevents premature wear.

- Water Quality: Use filtered water to minimize scale buildup. Hard water can significantly affect performance and longevity.

- Routine Inspections: Schedule regular inspections to identify potential issues before they escalate. Look for signs of wear or malfunction.

Implementing these practices can lead to a noticeable improvement in reliability and overall functionality, allowing you to enjoy your equipment for years to come.

Replacing Worn-Out Components

Over time, certain elements within a machine may become fatigued or degraded, impacting overall performance. Recognizing these signs is crucial for maintaining functionality and ensuring longevity. Addressing these issues promptly can prevent further damage and enhance efficiency.

Identifying worn-out components is the first step. Look for any unusual noises, leaks, or inconsistent operation, which may indicate a need for replacement. Regular inspections will help in early detection, allowing for timely intervention.

Once the components are identified, removal and replacement should be approached systematically. Refer to the manufacturer’s guidelines for specific procedures, as improper handling can lead to additional complications. Use high-quality replacements to guarantee optimal performance.

Finally, testing the machine after replacements is essential. Ensure everything operates smoothly and efficiently, allowing you to delve deeper into any remaining issues if necessary. This attention to detail will ultimately result in a more reliable and effective machine.

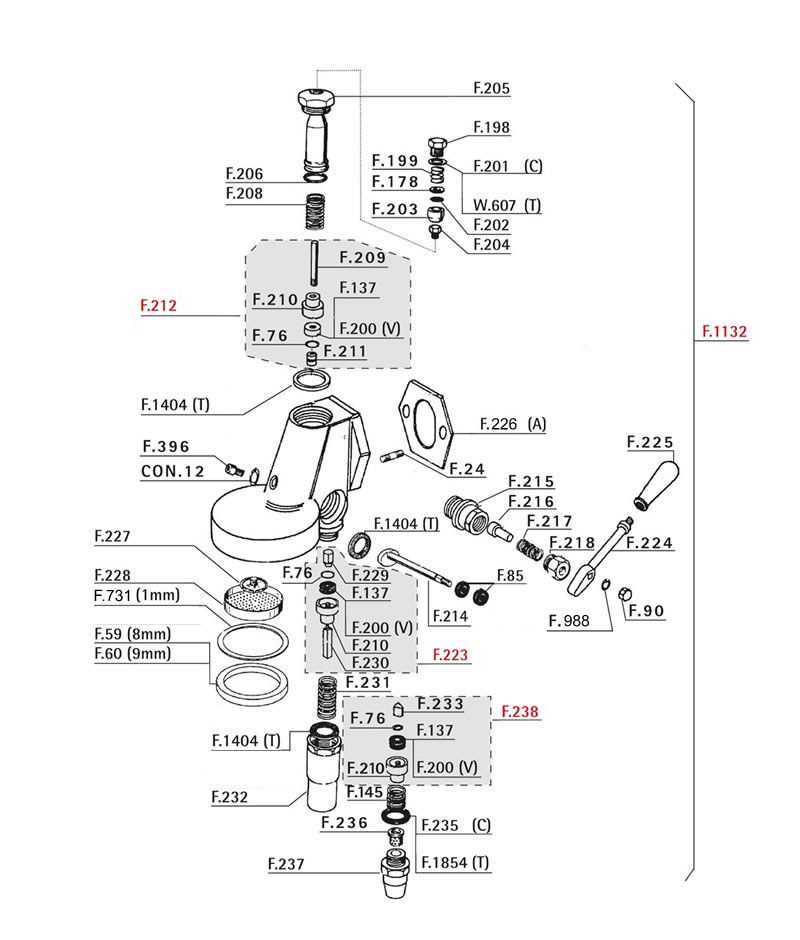

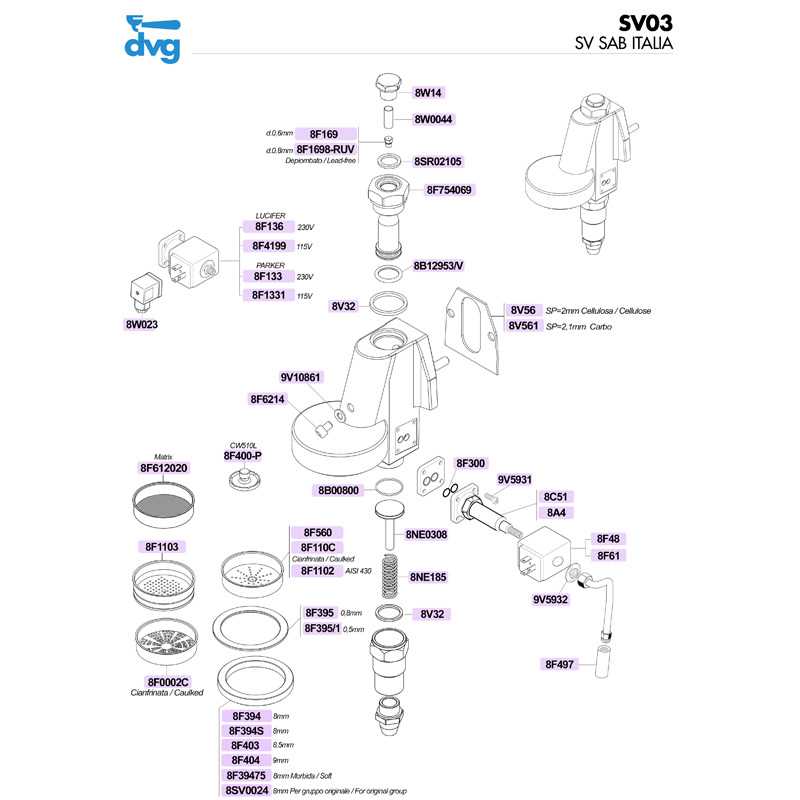

Diagrams: Visualizing the Assembly

Effective visualization of complex structures enhances understanding and simplifies the assembly process. By employing illustrative representations, users can grasp the relationship between components and their arrangement, making it easier to identify and address potential issues during setup or maintenance.

Benefits of Visual Aids

Utilizing graphical representations not only aids in comprehension but also serves as a valuable reference during assembly. These visuals can clarify the steps involved, highlight critical connections, and ensure that every element is correctly positioned for optimal functionality.

Creating Effective Visual Representations

To produce informative illustrations, it’s essential to focus on clarity and detail. Each component should be accurately depicted, accompanied by labels and annotations that explain its function. This approach fosters a deeper understanding of the overall mechanism and empowers users to tackle the assembly confidently.

Comparing Models in the Series

When evaluating different models within a particular lineup, it’s essential to understand the nuances that set each apart. Variations in design, functionality, and user experience can significantly impact performance and overall satisfaction. This analysis delves into key differences and similarities among the offerings, providing a clearer perspective for potential users.

Key Features

- Design Elements: Different models may showcase unique aesthetics, impacting the overall ambiance of the workspace.

- Functionality: Variances in operation and ease of use can cater to diverse preferences, whether for casual or professional settings.

- Size and Capacity: Dimensions and output capabilities can influence the choice based on available space and intended usage.

Performance Metrics

- Brewing Temperature: Some variants offer more precise temperature control, crucial for brewing quality.

- Speed of Operation: The efficiency of each model can vary, affecting overall workflow.

- Durability: Materials and construction quality can lead to differences in longevity and maintenance needs.

By examining these aspects, users can make informed decisions that align with their specific requirements and preferences, ensuring optimal satisfaction from their chosen model.

Upgrading Parts for Better Performance

Enhancing the components of your espresso machine can significantly elevate its functionality and efficiency. By investing in superior elements, users can experience improved extraction quality and consistency, ultimately leading to a more satisfying brew experience.

Benefits of High-Quality Components

Utilizing upgraded components ensures not only durability but also a refined taste profile. Premium materials can reduce wear and tear, resulting in fewer maintenance issues over time.

Recommended Upgrades

| Component | Upgrade Option | Benefit |

|---|---|---|

| Group Head | Brass or Stainless Steel | Improved heat retention |

| Steam Wand | Upgraded Design | Better frothing capability |

| Gaskets | High-Temperature Silicone | Longer lifespan and seal |

Where to Find Replacement Parts

Locating suitable components for your coffee machine can seem daunting, but there are several reliable avenues to explore. Whether you’re in need of a specific item for maintenance or an upgrade, understanding where to source these essential elements is crucial for keeping your equipment in top shape.

Start by checking with authorized dealers and distributors. They often carry a comprehensive selection of components that meet manufacturer specifications, ensuring compatibility and quality. Online retailers are another excellent option, offering a wide array of choices and often competitive pricing. Be sure to verify the credibility of the website and read reviews to avoid counterfeit products.

Local repair shops can also be valuable resources. Many technicians have access to a network of suppliers and can assist you in finding the right items. Additionally, specialty stores focusing on brewing equipment frequently stock necessary supplies and can provide expert advice on your search.

Lastly, consider joining online forums or communities dedicated to coffee enthusiasts. Members often share insights and recommendations for sourcing items, and you might even find second-hand options that are still in good condition. By exploring these avenues, you can efficiently locate the components you need to maintain or enhance your brewing experience.