Comprehensive Guide to Husqvarna ST 230P Parts Diagram

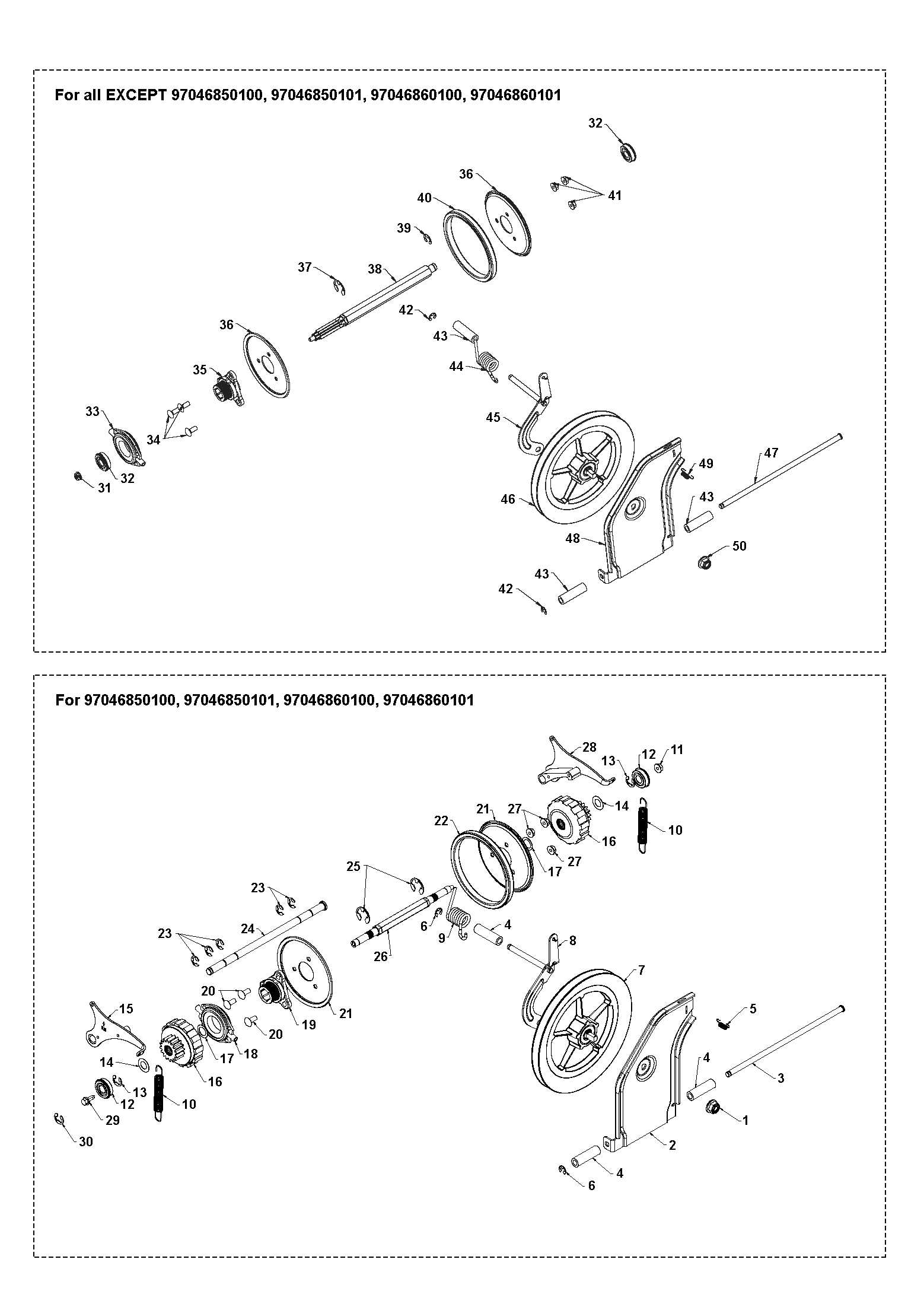

When it comes to maintaining outdoor machinery, having a clear visual representation of its components is essential. This section aims to provide a comprehensive overview of how various elements fit together, enhancing your understanding of the equipment’s functionality.

By exploring the intricate arrangement of parts, you will gain insight into their roles and how they contribute to the overall performance. Whether you are a seasoned user or a newcomer, familiarizing yourself with these details is crucial for effective upkeep and troubleshooting.

Furthermore, having access to a detailed illustration can empower you to make informed decisions regarding repairs and replacements. This ultimate guide serves as a valuable resource to delve into the specifics, ensuring your machinery operates smoothly for years to come.

Understanding Husqvarna ST 230P Components

Grasping the intricacies of essential elements in outdoor power equipment is vital for maintenance and efficiency. Each component plays a significant role in ensuring optimal performance and longevity. This section delves into the key features that make up this particular model, shedding light on their functions and interconnections.

Key Components

- Engine: The powerhouse that drives the entire unit.

- Auger: Essential for breaking up snow and facilitating movement.

- Impeller: Aids in propelling snow away from the chute.

- Chassis: The framework providing stability and support.

- Controls: User interface for operating various functions.

Functionality Overview

Understanding how each element interacts enhances the user experience and maintenance practices. Regular inspections can prevent potential issues, ensuring that the equipment remains in peak condition throughout its usage.

Importance of Parts Diagrams

Understanding how mechanical components fit together is crucial for maintaining and repairing equipment. Visual references allow for quick identification of elements, making assembly or replacement far more efficient. These schematics serve as a guide, simplifying tasks and reducing errors during repairs or installations.

- Helps locate specific components easily

- Provides a clear overview of the system layout

- Minimizes the risk of incorrect assembly

- Saves time during troubleshooting and repairs

By offering detailed visual breakdowns, these resources ensure precision and accuracy when working with machinery, contributing to overall longevity and performance.

Common Issues with ST 230P Parts

When operating this equipment, various challenges can arise that affect its efficiency and performance. Understanding frequent malfunctions is crucial to ensuring smooth operation and preventing breakdowns.

Wear and Tear of Key Components

Due to frequent use, certain elements tend to wear out more quickly, especially those subjected to constant friction or force. It’s essential to regularly inspect and replace these elements to avoid operational delays.

- Belts may loosen or snap after extensive use.

- Auger-related mechanisms may get jammed due to debris buildup.

- Shear pins often break under pressure to protect other components.

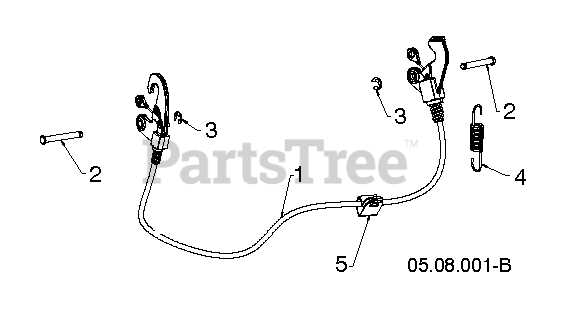

Electrical and Mechanical Failures

Electrical connections and mechanical linkages are prone to occasional failure. These issues can cause the system to stop functioning, leading to downtime and costly repairs if not promptly addressed.

- Loose wires or damaged connectors may interrupt electrical flow.

- Mechanical controls can become unresponsive due to frozen or stiff cables.

- Ignition systems

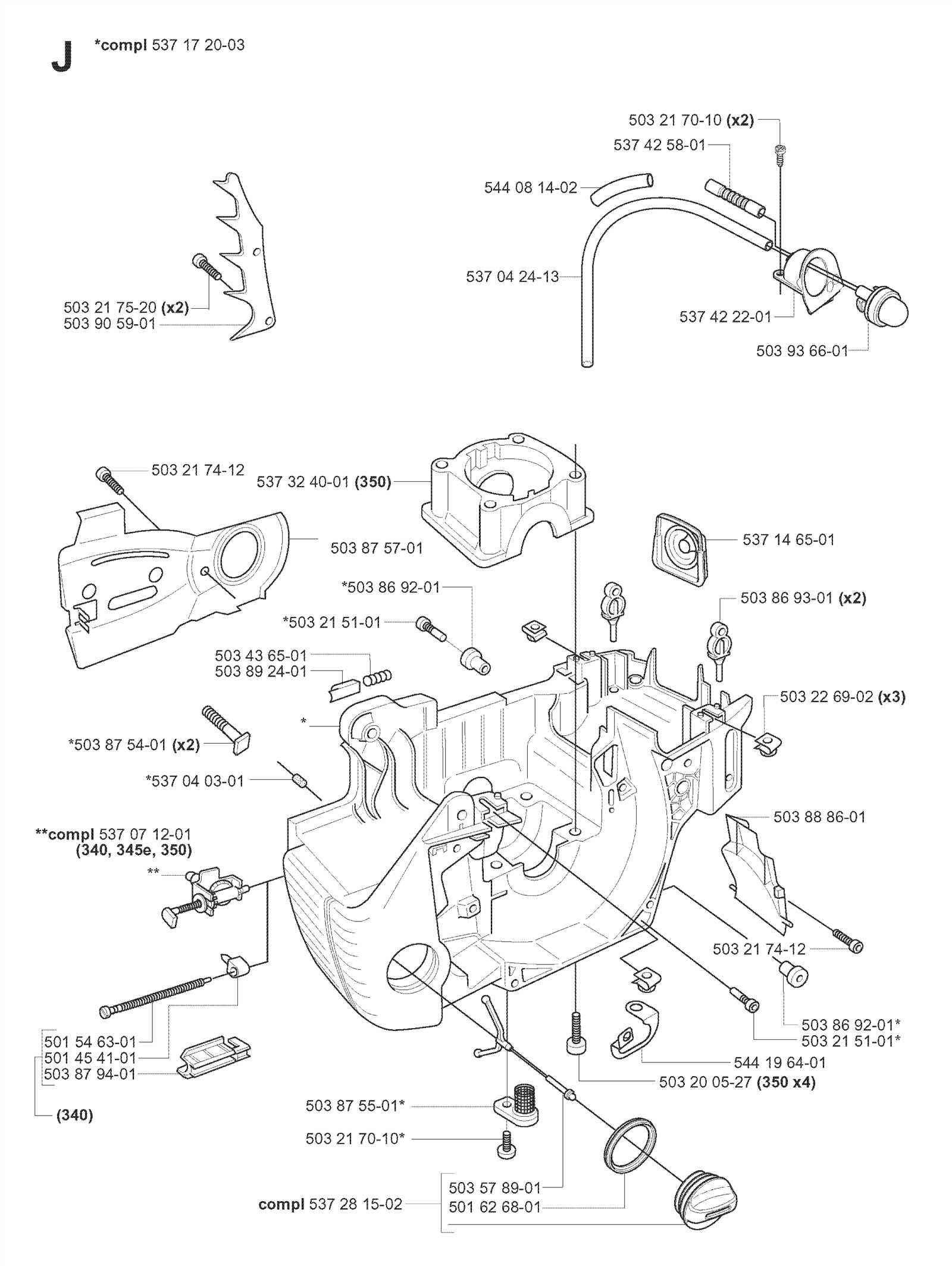

How to Read a Parts Diagram

Understanding component schematics can be essential when it comes to maintaining or repairing equipment. These visual layouts break down complex assemblies into individual elements, making it easier to identify specific components and how they fit together. Learning how to interpret these schematics will help you quickly locate what you need.

To make sense of the layout, follow these steps:

- Start by identifying the overall structure or machine in the schematic. This usually serves as a reference for where each component belongs.

- Look for numbered labels or codes next to each element. These correspond to a list, often located beside or below the diagram, that details the components.

- Use the list to match each number with its corresponding item description. This will typically include the item name, its function, and sometimes its size or model number.

- Pay attention to any arrows, lines, or dotted paths. These indicate how different elements connect or interact with each other, guiding you through the assembly process.

Breaking do

Essential Tools for Maintenance

Maintaining outdoor equipment requires a selection of tools that ensure efficient and timely care. With the right instruments at hand, routine upkeep becomes more manageable, allowing for the longevity and reliability of your machine.

Basic Hand Tools

For regular servicing, a set of basic hand tools, including wrenches, screwdrivers, and pliers, is indispensable. These are needed to access various components, tighten bolts, and make quick adjustments. A well-organized toolkit can significantly reduce downtime and help in addressing minor issues on the spot.

Specialized Equipment

In addition to standard tools, certain tasks may require more specialized gear. A torque wrench is vital for ensuring precise tightening, while a set of gauges can help with fine-tuning key mechanisms. These specialized tools allow for a more thorough and accurate approach to maintenance, ensuring peak performance over time.

Finding Genuine Replacement Parts

When it comes to maintaining outdoor machinery, sourcing authentic components is crucial for ensuring durability and optimal performance. Whether you’re facing a minor repair or a more complex issue, selecting the right elements can significantly extend the lifespan of your equipment.

Authenticity and reliability are key factors to consider when choosing replacements. Verified suppliers and authorized retailers are essential in obtaining pieces that match original specifications, ensuring compatibility and seamless operation.

Moreover, identifying exact model details will aid in narrowing down the search for matching components. Always prioritize genuine options to avoid complications with installation or performance.

Assembly Tips for ST 230P

When putting together your snow-clearing equipment, following proper guidelines can ensure smooth operation and long-term reliability. Precise alignment of components, secure fittings, and careful attention to specific connections are key to achieving an efficient assembly process. Below are some practical recommendations that will guide you through each critical step.

Step Recommendation Handle Installation Ensure that the handle is tightly secured to avoid any looseness during operation. Double-check the fastening points for stability. Auger Attachment When attaching the auger, make sure it is aligned correctly with the housing. Lubricate moving parts to facilitate smooth operation. Engine Mounting Mount the engine carefully to avoid any misalignment. Tighten bolts in a cross pattern for even distribution of pressure. Control Panel Setup Ensure all cables are correctly routed and connected to their corresponding control mechanisms. Avoid sharp bends that could damage wires. Tire and Wheel Assembly Make sure the tires are properly inflated and the wheels are securely mounted. Regularly check for any signs of wear or damage. Comparing ST 230P to Other Models

When analyzing different options within the snow thrower lineup, it’s important to consider the various features and capabilities that distinguish each model. By understanding how these machines vary in performance, handling, and efficiency, one can make an informed decision based on specific needs and operational conditions.

Performance Differences

The performance levels across these machines differ primarily in terms of engine power, clearing width, and snow intake capacity. Some models are designed for lighter snowfall, offering smaller clearing widths and less powerful engines, while others are built for heavier tasks, featuring larger capacities and more robust mechanisms.

Handling and Maneuverability

Handling plays a crucial role in the ease of use, especially when operating in tight spaces or on uneven surfaces. Certain models offer enhanced maneuverability with features like power steering and adjustable handles, making them more user-friendly for a wide range of terrains and snow conditions.

Model Engine Power (HP) Clearing Width (inches) Special Features Where to Buy Husqvarna Parts

When it comes to maintaining or repairing essential outdoor equipment, finding the right replacement components is crucial. Whether it’s for regular maintenance or dealing with unexpected issues, reliable sources for acquiring specific items are necessary for ensuring the longevity of your machinery.

Authorized Retailers and Service Centers

The most reliable way to secure genuine replacement pieces is through certified retailers or service centers. These outlets not only offer a wide selection of original items but also ensure that you receive professional advice on compatibility and installation.

Online Marketplaces

For those who prefer the convenience of online shopping, there are numerous platforms offering a variety of components. Some websites specialize in outdoor machinery, providing detailed listings, customer reviews, and even technical support to help you make an informed decision.

Maintenance Checklist for Optimal Performance

Regular upkeep is essential to ensure your equipment continues to operate efficiently. By following a consistent maintenance schedule, you can extend the lifespan of the machine and reduce the likelihood of breakdowns. Below is a practical guide to key tasks that will help maintain peak performance.

Inspect Moving Components

Ensure all moving parts are free from debris and properly lubricated. Regularly check for signs of wear and tear, and replace any damaged elements immediately to prevent further issues. Maintaining clean and well-lubricated parts is critical to preserving the overall functionality.

Check Fluid Levels

It is important to frequently monitor fluid levels, including oil and any hydraulic systems, to ensure optimal operation. Replace fluids as recommended and ensure there are no leaks. Regular fluid maintenance helps prevent overheating and damage to key components.

Sharpen Cutting Elements: Blades and other cutting tools should be sharpened regularly to maintain their effectiveness. Dull tools not only reduce efficiency but can also strain the machine, leading to faster deterioration of key systems.

DIY Repairs: Step-by-Step Guide

When it comes to maintaining your outdoor equipment, performing basic fixes yourself can save time and money. By following a structured approach, you can tackle common issues without needing professional assistance. Whether you’re replacing components or resolving mechanical problems, this guide will walk you through the essential steps.

Step 1: Identify the Issue

Begin by carefully inspecting your machine to determine what needs to be repaired. Look for signs of wear, unusual sounds, or malfunctioning mechanisms.

Step 2: Gather Necessary Tools

Once the problem is identified, ensure you have all the tools required for the job. Common tools include wrenches, screwdrivers, and pliers. Having everything ready before starting will make the process smoother.

Step 3: Follow Disassembly Instructions

Carefully remove the affected components, paying attention to how everything is connected. If possible, take notes or photos during the disassembly to ensure accurate reassembly later.

Step 4: Replace or Repair the Faulty Part

Once the damaged section is exposed, decide whether it needs replacement or can be fixed. If replacement is necessary, ensure the new piece matches specifications and install it correctly.

Step 5: Reassemble and Test

After completing the repair, reassemble the machine following your earlier notes or photos. Tighten all screws and bolts securely, then test the equipment to ensure it operates smoothly.

By following these steps, you can confidently handle routine maintenance and keep your machine in top