Understanding Commercial Toilet Parts with Diagrams

In the realm of sanitary environments, a comprehensive grasp of essential components is crucial for both functionality and maintenance. These elements work together seamlessly to ensure optimal performance and user satisfaction. By exploring the intricate layout of these fixtures, one can uncover the nuances that contribute to their efficiency.

Whether it’s the interplay of mechanisms that regulate flow or the design features that enhance durability, understanding these critical elements provides invaluable insights. This knowledge empowers maintenance professionals and users alike to address issues proactively, ensuring that facilities remain in prime condition.

In this section, we will delve into the various configurations and mechanisms involved, highlighting the ultimate importance of each element. By familiarizing oneself with these aspects, one can appreciate the engineering behind everyday conveniences.

Understanding Commercial Toilet Components

Grasping the various elements that contribute to the functionality of restroom fixtures is essential for effective maintenance and efficient operation. Each component plays a critical role in ensuring optimal performance and user satisfaction. A comprehensive understanding of these elements can greatly enhance troubleshooting and repair efforts.

Key Components and Their Functions

Among the primary elements, the flushing mechanism stands out as vital for efficient waste removal. This system relies on a combination of valves and seals that work in harmony to initiate and regulate the flow of water. Additionally, the water supply connections ensure a steady influx, contributing to the fixture’s reliability. Other significant components include the bowl and tank, which house the necessary mechanisms while providing the essential structure for everyday use.

Importance of Regular Maintenance

Regular upkeep of these essential components not only prolongs the lifespan of the fixtures but also minimizes unexpected breakdowns. Periodic inspections can identify wear and tear, ensuring that issues are addressed promptly. This proactive approach helps maintain a clean and functional environment, crucial for any establishment.

Essential Parts of Toilet Mechanism

Understanding the fundamental components of a flushing system is crucial for effective maintenance and troubleshooting. Each element plays a specific role in ensuring smooth operation and optimal performance, contributing to a reliable experience in any restroom setting.

Key Components

Among the primary elements are the flush valve, which initiates the release of water from the tank, and the fill valve, responsible for replenishing the tank after each use. These mechanisms work in tandem to create a seamless cycle, ensuring that everything functions as intended.

Supportive Elements

Additional features, such as the float and chain, enhance the overall efficiency of the system. The float regulates the water level, preventing overflow, while the chain connects the handle to the flush mechanism, allowing for user-friendly operation. Understanding these supportive components can help in identifying issues and ensuring longevity.

Diagrams of Common Toilet Models

Understanding the inner workings of various restroom fixtures can significantly enhance maintenance and troubleshooting. Different models feature distinct configurations, and visual representations are invaluable for identifying components and their functions.

Here are some widely used models and their key features:

- Gravity-Flush Models:

- Utilize gravity to facilitate waste removal.

- Commonly found in residential settings.

- Simple and effective design.

- Pressure-Assisted Models:

- Employ pressurized air to enhance flushing power.

- Ideal for high-traffic environments.

- Require more maintenance due to complex mechanisms.

- Dual-Flush Models:

- Offer two flush options for liquid and solid waste.

- Promote water conservation.

- Gaining popularity in eco-friendly designs.

When examining these fixtures, it’s important to familiarize yourself with common elements such as the cistern, flush valve, and fill valve, as these components play a crucial role in overall functionality. Proper identification and understanding can lead to more efficient repairs and enhanced performance.

How Flush Mechanisms Work

Understanding the operation of flushing systems is essential for effective sanitation solutions. These systems are designed to efficiently remove waste and maintain hygiene. The mechanisms rely on a combination of components that work in harmony to achieve optimal performance.

Key Components

- Tank: Stores water until it is needed for flushing.

- Flush Valve: Releases water from the tank into the bowl.

- Float Mechanism: Regulates water levels in the tank.

- Flapper: Acts as a seal that opens and closes the flush valve.

Operational Process

- When the user initiates a flush, the handle or button triggers the flush valve.

- The flapper lifts, allowing water to flow from the tank to the bowl.

- As water rushes in, it creates a siphoning effect, removing waste.

- Once the tank is empty, the float drops, causing the fill valve to activate and refill the tank.

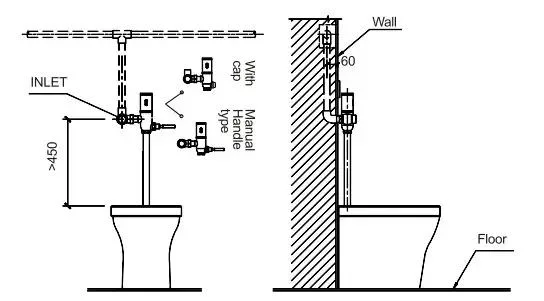

Water Supply Connections Explained

Understanding the intricacies of water delivery systems is essential for efficient operation and maintenance. These connections play a crucial role in ensuring a reliable flow of water, contributing to overall functionality.

Key components involved in these systems include:

- Supply lines: Tubing that transports water from the source.

- Shut-off valves: Devices that control water flow.

- Fittings: Connectors that link different sections of the system.

- Pressure regulators: Tools that maintain appropriate water pressure.

Proper installation and maintenance of these elements ensure optimal performance. Here are some important considerations:

- Ensure all connections are secure to prevent leaks.

- Regularly check valves for proper function.

- Inspect supply lines for wear and damage.

- Adjust pressure regulators as needed for efficiency.

By delving into these components, users can achieve the ultimate reliability in their water systems.

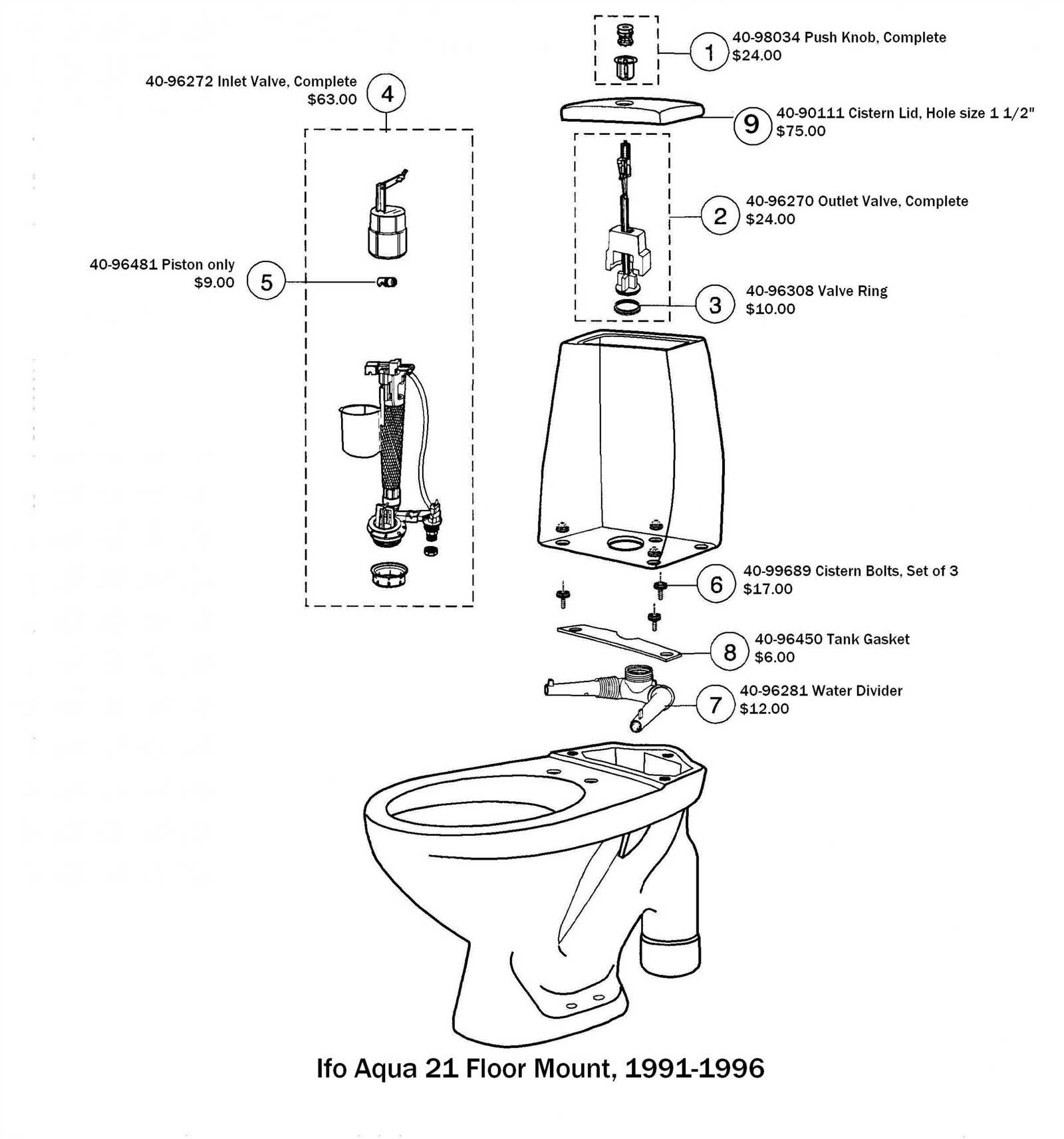

Identifying Tank and Bowl Parts

Understanding the components within a flushing system is essential for effective maintenance and troubleshooting. Each element plays a critical role in the overall functionality, and recognizing them can simplify repairs and replacements. Familiarity with these elements enhances your ability to address common issues that may arise.

The upper section of the fixture, often referred to as the reservoir, contains several key components, including the fill valve, flush valve, and float. Each of these elements has a specific function that contributes to the water management process, ensuring efficient operation during use. Knowledge of how these components interact can aid in diagnosing malfunctions.

Below, the basin serves as the primary interface, designed to facilitate waste removal. This area typically includes the rim, trapway, and discharge outlet. Understanding these elements is crucial for ensuring proper flow and drainage, which can prevent clogs and enhance overall performance. Being able to identify and assess the condition of these parts is vital for maintaining optimal functionality.

Maintenance Tips for Longevity

Ensuring the durability of essential fixtures requires consistent upkeep and attention. Regular maintenance not only prolongs their lifespan but also enhances functionality, leading to fewer issues over time.

Regular Inspections

Conducting frequent checks can help identify wear and tear early. Look for signs of leaks, corrosion, or any unusual noises, and address them promptly.

Proper Cleaning Techniques

Utilize gentle, non-corrosive cleaning agents to avoid damaging surfaces. Avoid harsh chemicals that may degrade components over time, and focus on thorough yet safe cleaning practices.

| Maintenance Task | Frequency |

|---|---|

| Inspect for leaks | Monthly |

| Clean surfaces | Weekly |

| Replace worn parts | As needed |

| Check for proper function | Quarterly |

Common Issues and Solutions

In any restroom facility, certain challenges often arise that can affect functionality and user experience. Identifying these common problems and understanding their solutions can significantly enhance overall performance and satisfaction.

Leaking Fixtures: A frequent issue is the presence of leaks, which can lead to water waste and damage. Inspecting seals and gaskets regularly and replacing worn components can effectively resolve this issue.

Clogged Systems: Blockages are another prevalent concern, often resulting in poor drainage. Using appropriate tools, such as plungers or augers, can help to clear obstructions and restore proper flow.

Low Water Pressure: Insufficient water pressure can hinder functionality. Checking for kinks in hoses and ensuring valves are fully open can help to address this problem.

Strange Noises: Unusual sounds can indicate underlying issues. Investigating connections and tightening loose fittings can often eliminate these disturbances.

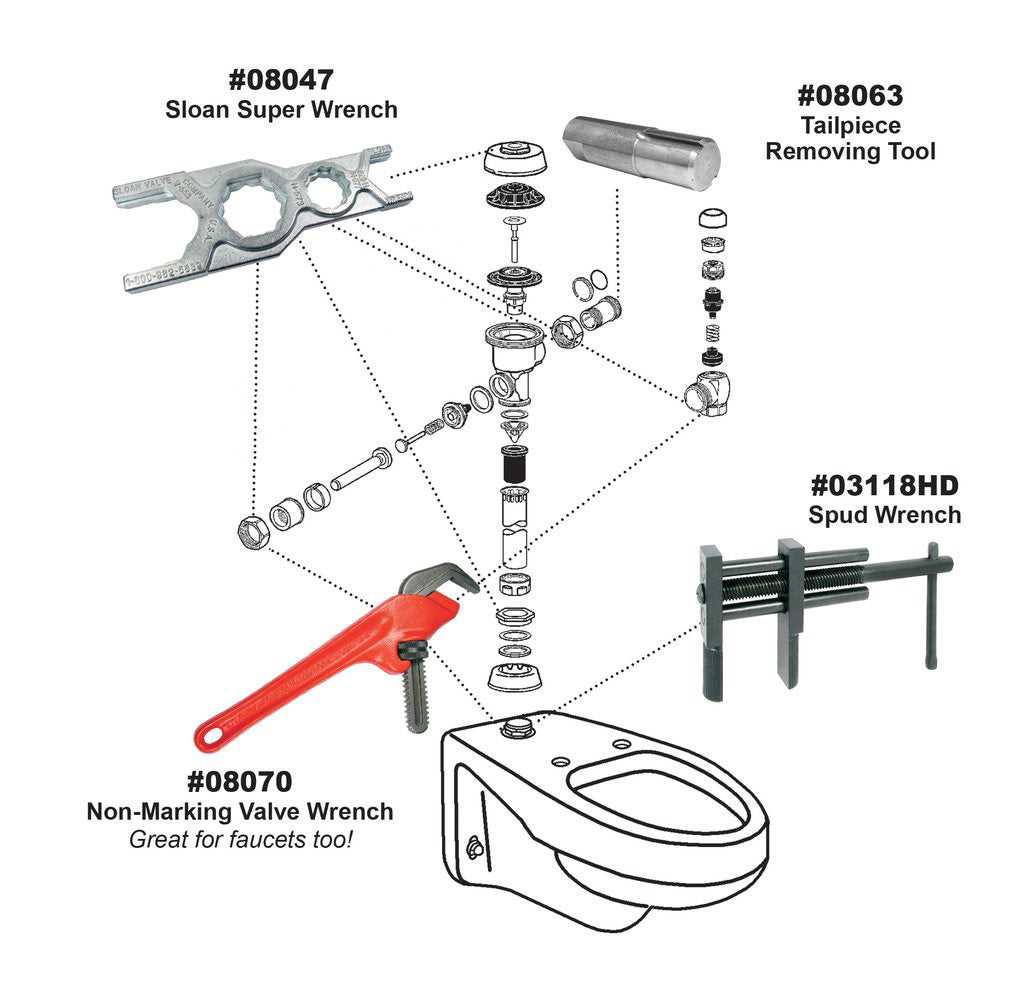

Tools for Repairing Toilets

Having the right tools is essential for effective maintenance and troubleshooting of bathroom fixtures. A well-equipped toolkit not only simplifies the repair process but also enhances efficiency and ensures longevity of the installations.

Essential Tools

Start with basic items such as a wrench, screwdriver, and plunger. These are fundamental for most repairs. Additionally, an auger can help clear stubborn clogs, while a sealant is useful for preventing leaks.

Advanced Equipment

For more complex issues, consider investing in a pipe cutter or a water pressure gauge. These tools allow you to delve deeper into plumbing problems and make necessary adjustments to ensure optimal functionality.

Upgrading Components for Efficiency

Improving the functionality and performance of essential fixtures can significantly enhance overall efficiency. By replacing outdated mechanisms with modern alternatives, facilities can reduce waste, lower utility costs, and extend the lifespan of their equipment. This section delves into the benefits and options for upgrading key elements to promote sustainability and effectiveness.

Benefits of Upgrading

Modernizing components offers numerous advantages. Enhanced efficiency translates to lower water consumption, which is not only environmentally friendly but also reduces operational expenses. Additionally, updated fixtures often require less maintenance, minimizing downtime and service interruptions.

Key Components to Consider

| Component | Upgrade Option | Benefits |

|---|---|---|

| Flushing Mechanism | Pressure-assisted flush systems | Improved water usage and stronger performance |

| Water Supply Valve | Low-flow valves | Reduced water consumption and enhanced flow control |

| Seal and Gasket Kits | High-efficiency materials | Better durability and leak prevention |

| Flush Handle | Sensor-activated options | Hands-free operation and hygiene improvement |

By carefully selecting which components to upgrade, facilities can create a more efficient and sustainable environment. Prioritizing modern solutions not only conserves resources but also enhances user experience and satisfaction.

Safety Guidelines During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Adhering to proper protocols not only protects the individual performing the work but also safeguards the surrounding environment. Recognizing potential hazards and taking proactive measures can prevent accidents and promote a secure work atmosphere.

Essential Precautions

- Always turn off the water supply before starting any repair work.

- Wear appropriate protective gear, including gloves and goggles, to shield against contaminants.

- Use tools that are in good condition and suitable for the task at hand.

- Ensure the workspace is well-lit and free from clutter to avoid tripping hazards.

- Keep children and pets away from the repair area to prevent distractions and accidents.

Handling Materials Safely

- Read the labels and safety data sheets of any cleaning agents or chemicals used.

- Dispose of any waste materials according to local regulations to avoid environmental harm.

- Store tools and materials securely after use to prevent unauthorized access.

When to Call a Professional

Recognizing the right moments to seek expert assistance can save time, money, and frustration. Certain issues may seem manageable but can escalate if not handled correctly. Understanding when to involve a skilled technician ensures safety and efficiency in resolving complex situations.

| Signs to Consider | Recommended Action |

|---|---|

| Persistent leaks or clogs | Contact a specialist |

| Unusual noises or odors | Consult a professional |

| Frequent malfunctions | Seek expert advice |

| Issues with functionality | Hire a qualified technician |

Resources for Further Learning

Exploring the intricacies of plumbing components can significantly enhance your understanding and skills in maintenance and repair. There are various materials available that provide valuable insights into the functionality and design of essential fixtures.

Books on plumbing basics and advanced techniques often serve as comprehensive guides. Additionally, online tutorials and video demonstrations can offer practical, visual knowledge that complements traditional learning methods.

Joining forums and online communities dedicated to plumbing discussions can also provide support and share experiences, helping you delve deeper into specialized topics.

Lastly, consider enrolling in workshops or courses offered by local institutions, which can provide hands-on experience and the ultimate opportunity to apply your knowledge in real-world scenarios.