Understanding the Components of a Windshield Parts Diagram

The intricacies of a vehicle’s glass assembly play a crucial role in ensuring safety, visibility, and overall performance. From the structural framework to the smaller elements that enhance functionality, each component is designed with precision. Grasping the layout of these elements can significantly improve maintenance practices and repair processes.

Delving into the various elements involved, it becomes clear that they are not merely decorative but serve essential purposes. Some contribute to the overall integrity, while others are pivotal in providing a clear view of the surroundings, especially in adverse weather conditions. Recognizing the significance of each segment helps in understanding how they work together harmoniously.

By familiarizing oneself with the different aspects of this assembly, car owners can become more informed about potential issues and necessary upkeep. This knowledge can lead to better decision-making when it comes to repairs and replacements, ultimately enhancing the longevity and reliability of the vehicle.

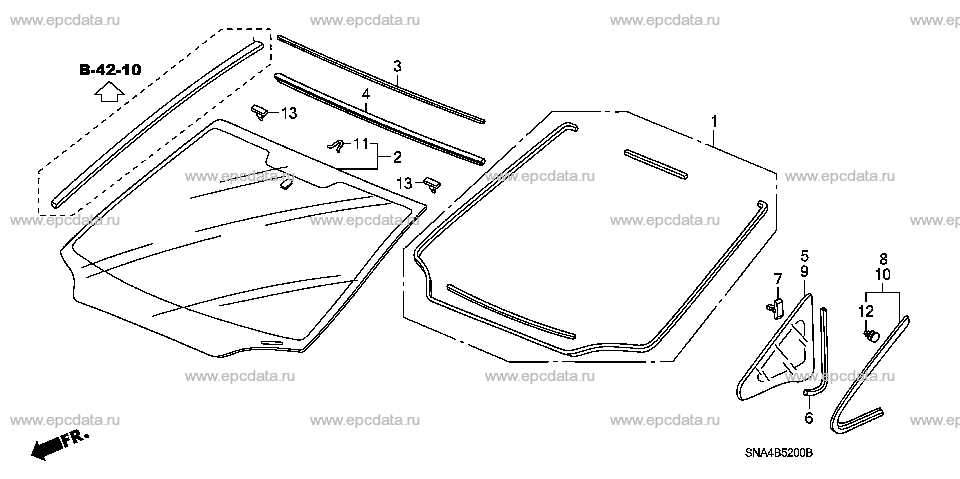

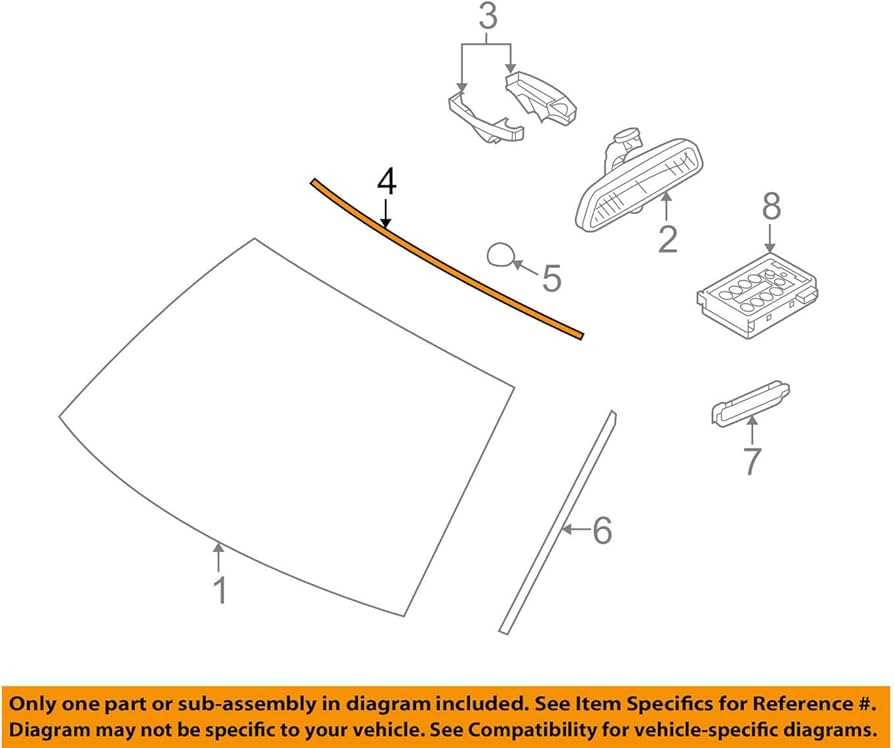

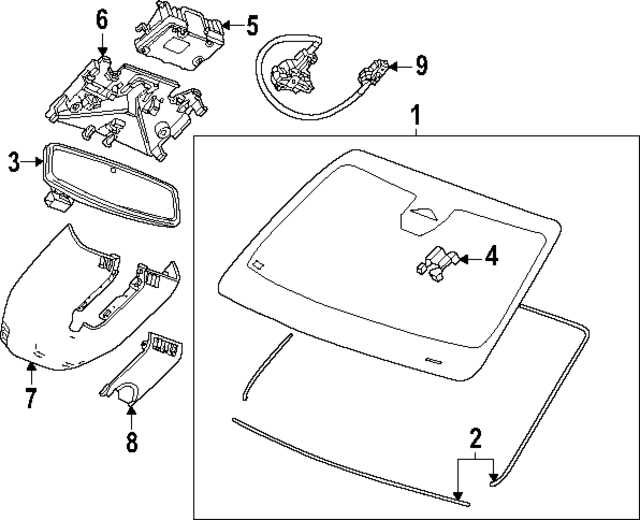

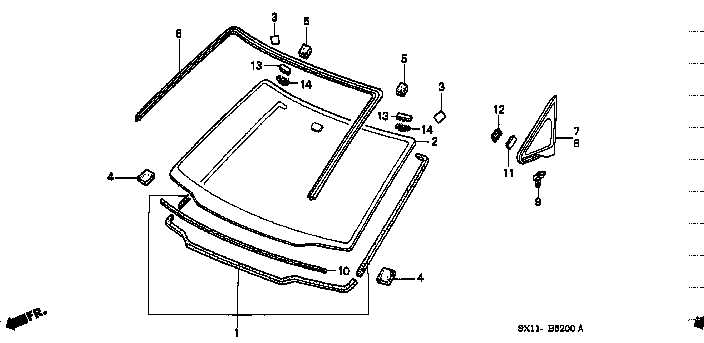

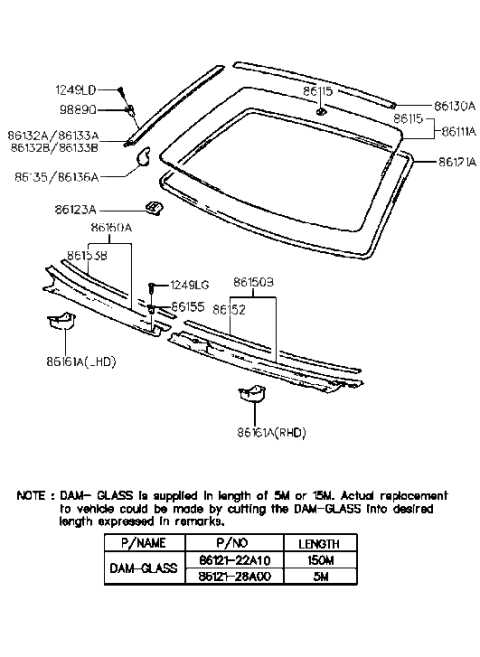

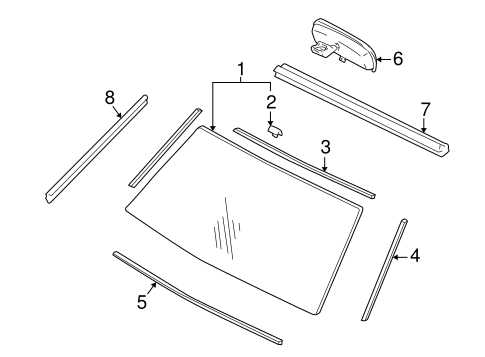

Understanding Windshield Components

Grasping the various elements that make up the front view barrier of a vehicle is essential for both maintenance and safety. Each component plays a crucial role in ensuring clarity, protection, and structural integrity while driving.

Main Elements

- Glass: The transparent surface that provides visibility and shields occupants from external elements.

- Sealant: The material that secures the glass to the frame, preventing leaks and providing support.

- Frame: The structural component that holds the glass in place and adds stability to the assembly.

Additional Features

- Wipers: Mechanisms that clear rain, snow, or debris from the glass surface for optimal visibility.

- Defrosters: Heating elements designed to remove fog and ice, ensuring clarity during adverse weather conditions.

- Trim: Decorative and protective pieces that enhance aesthetics while covering gaps between the glass and frame.

Importance of Windshield Clarity

Clear visibility through the front screen of a vehicle is crucial for safe driving. It ensures that the driver can accurately perceive their surroundings, assess distances, and react promptly to any hazards. Factors such as dirt, scratches, and moisture can significantly impair this clarity, leading to potential dangers on the road.

Impact on Safety

A transparent view is essential for avoiding accidents. Impairments can obscure important visual cues, increasing the likelihood of collisions. It is vital for drivers to maintain the cleanliness and integrity of their screen to enhance their overall safety.

Legal Implications

Many jurisdictions have regulations regarding visibility standards for vehicles. Failing to uphold these standards can result in fines or penalties. Thus, ensuring that the front view is clear not only promotes safety but also helps drivers comply with the law.

| Factor | Impact on Clarity |

|---|---|

| Dirt and Debris | Blocks visibility, reducing reaction time |

| Scratches | Distorts vision, creates blind spots |

| Weather Conditions | Causes reflections and glare, hampers clarity |

Common Windshield Repairs Explained

Cracks and chips in your vehicle’s front view can be a nuisance and a safety hazard. Addressing these issues promptly can not only improve visibility but also prevent further damage. This section outlines the most frequent types of repairs and what they entail.

Types of Damage

- Star Break: A central chip with multiple lines radiating outward, resembling a star.

- Spider Crack: A series of small cracks emanating from a single point, creating a spider web appearance.

- Surface Scratch: Minor abrasions that do not penetrate deeply but can affect clarity.

- Long Crack: A single line that extends across the surface, which may compromise structural integrity.

Repair Techniques

- Injection Method: A resin is injected into the damaged area to fill in gaps and restore strength.

- Polishing: For minor surface scratches, a polishing compound is used to buff out imperfections.

- Replacement: In cases of extensive damage, complete replacement of the viewing surface may be necessary.

- Sealing: For cracks that can be stabilized, a sealing agent may be applied to prevent further spreading.

Understanding these common issues and their solutions can help maintain safety and clarity while driving.

Different Types of Windshield Glass

Understanding the various types of glass used in vehicle front screens is essential for ensuring safety and clarity while driving. Each type has its unique characteristics, benefits, and applications, making it important to choose the right option for specific needs.

- Laminated Glass

This type consists of two or more layers of glass with an interlayer of plastic, providing enhanced safety and durability. It prevents shattering upon impact, reducing the risk of injury from flying shards.

- Tempered Glass

Produced through a heating and cooling process, this glass is designed to withstand greater stress and temperature fluctuations. It shatters into small, blunt pieces, minimizing injury risk in the event of breakage.

- Polycarbonate Glass

A lightweight alternative, polycarbonate offers excellent impact resistance. While not as scratch-resistant as tempered or laminated options, it is commonly used in high-performance and specialized vehicles.

- Glass with UV Protection

Incorporating special coatings, this type blocks harmful ultraviolet rays, protecting passengers and the vehicle’s interior from sun damage. It enhances comfort by reducing glare as well.

cssCopy code

Each glass type has its strengths and weaknesses, and selecting the appropriate one depends on factors like vehicle type, driving conditions, and personal safety preferences.

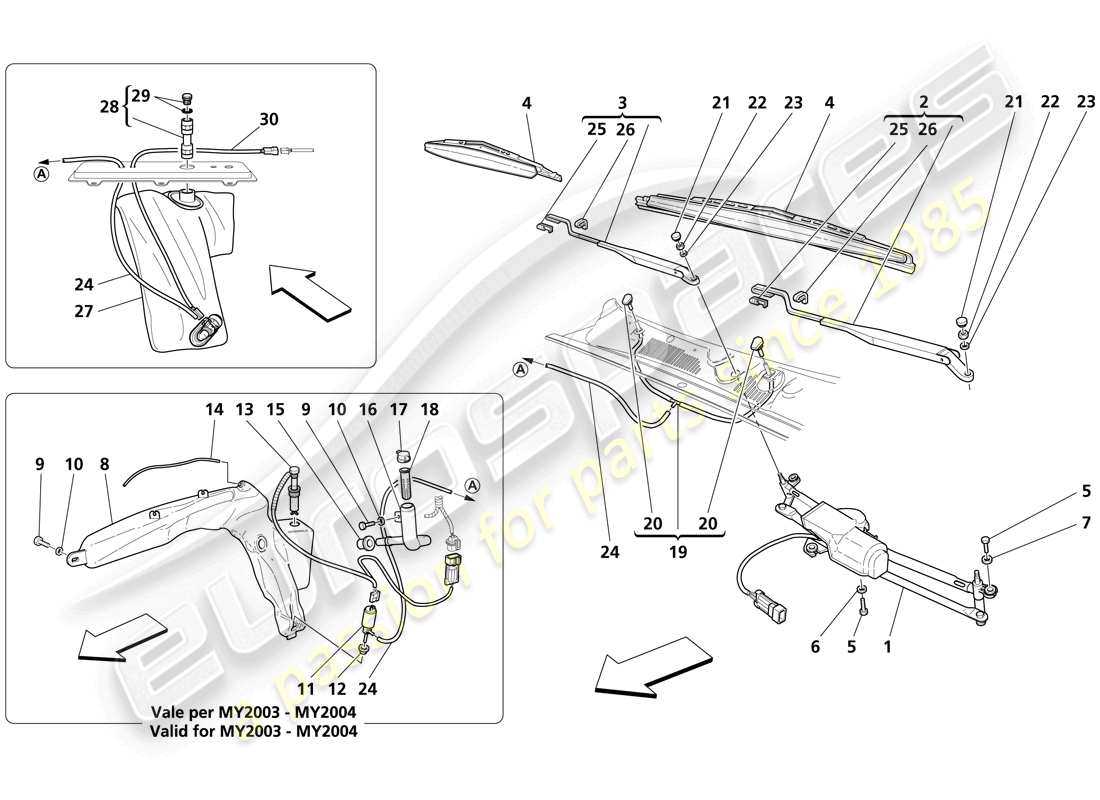

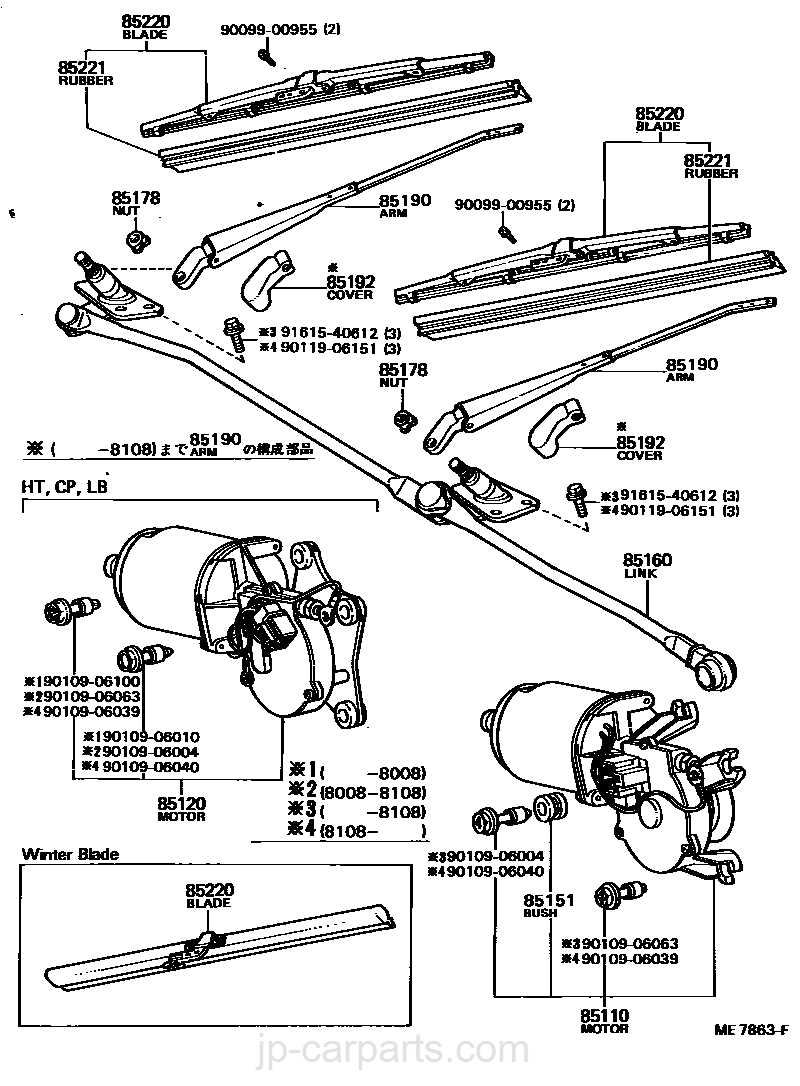

How Windshield Wipers Function

The operation of cleaning the transparent surface in front of a vehicle is a critical aspect of ensuring visibility during adverse weather conditions. This mechanism relies on a coordinated system of components that work together to remove rain, snow, and debris, enhancing safety and comfort while driving.

Key Components of the Wiping Mechanism

- Motor: The electric motor powers the entire operation, providing the necessary force to move the blades.

- Linkage: A series of joints and rods connects the motor to the blades, translating the motor’s rotation into a sweeping motion.

- Blades: These flexible strips of rubber or silicone make contact with the surface, ensuring effective removal of moisture and dirt.

- Arms: The arms hold the blades in place and enable them to pivot back and forth as needed.

Operational Process

- The driver activates the system using a switch, sending power to the motor.

- The motor begins to rotate, moving the linkage that connects to the arms.

- The arms pivot, causing the blades to sweep across the transparent surface.

- As the blades move, they collect water and debris, clearing the view for the driver.

- Some systems include intermittent settings, allowing the blades to pause between sweeps, adapting to varying conditions.

This coordinated action not only improves visibility but also contributes to overall road safety, demonstrating the importance of maintaining this vital system in vehicles.

Windshield Sealant Types and Uses

Choosing the right adhesive for automotive glass is crucial for ensuring safety and longevity. Various formulations are available, each designed to meet specific requirements for application, environmental resistance, and durability. Understanding the different types can help in selecting the most suitable option for a given situation.

Types of Adhesives

There are primarily two categories of adhesives: polyurethane and silicone. Polyurethane is widely favored for its excellent bonding properties and flexibility, making it ideal for structural applications. It cures to form a strong, weather-resistant seal, providing significant protection against water infiltration and environmental damage. Silicone, on the other hand, is often used for its versatility and ease of application. While it may not offer the same structural strength as polyurethane, it excels in situations where a less rigid bond is required, allowing for slight movement and expansion.

Application Considerations

When selecting an adhesive, factors such as cure time, temperature tolerance, and compatibility with the vehicle’s materials should be considered. Fast-curing formulations are essential for quick repairs, especially in commercial settings. Conversely, in environments with extreme temperatures, choosing a sealant that can withstand these conditions is vital for ensuring long-term performance. Proper application techniques are also critical, as improper sealing can lead to leaks and reduced safety.

Identifying Windshield Damage Types

Understanding the various types of damage that can occur to vehicle glass is essential for ensuring safety and clarity while driving. Different forms of impairment can arise from environmental factors, accidents, or wear over time. Recognizing these issues early can prevent further complications and ensure effective repairs.

Common Types of Damage

There are several prevalent categories of damage that can affect the transparent barrier. The most frequent include chips, which are small indentations often caused by flying debris, and cracks, which may range from minor lines to extensive fissures that compromise structural integrity. Each type has specific characteristics and requires distinct approaches for evaluation and repair.

Assessing the Severity

To determine the seriousness of the damage, consider factors such as size, location, and depth. Smaller, superficial issues may be easily repaired, while larger or more central flaws often necessitate a complete replacement. Evaluating these elements promptly can help maintain visibility and safety on the road.

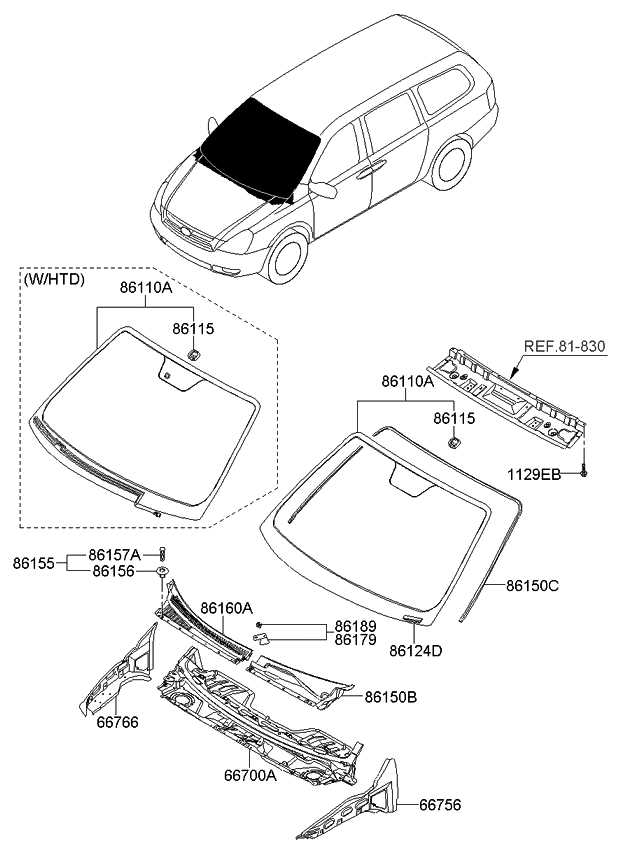

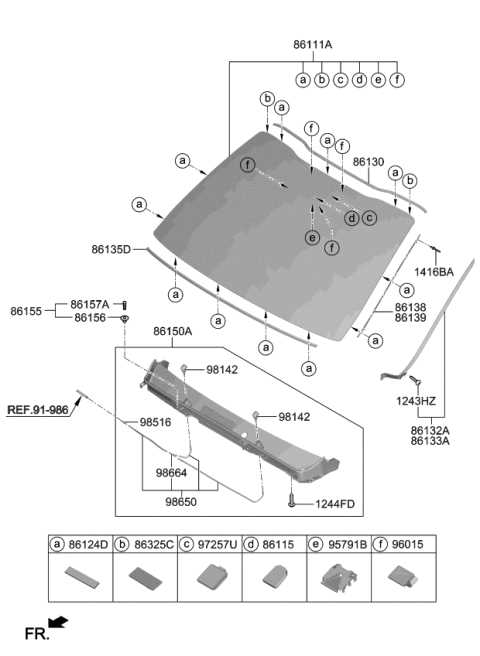

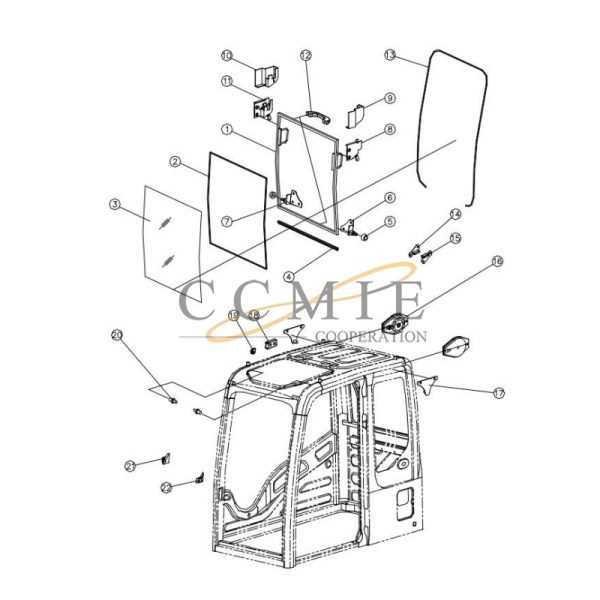

Windshield Installation Process Overview

This section provides a comprehensive guide on the procedure for installing a transparent shield that protects the interior of a vehicle from external elements. The process requires precision and care to ensure a secure fit and optimal performance.

Preparation Steps

- Gather necessary tools and materials, including adhesive, a sealant, and cleaning supplies.

- Remove any existing shield and clean the frame thoroughly to eliminate old adhesive and debris.

- Inspect the surrounding structure for any damage that may need repairs before installation.

Installation Procedure

- Apply adhesive evenly along the edge of the frame, ensuring proper coverage.

- Carefully position the new shield, aligning it with the frame to avoid misplacement.

- Press firmly to create a strong bond, checking for any gaps or misalignments.

- Allow the adhesive to cure according to the manufacturer’s instructions before handling the vehicle.

Safety Features of Modern Windshields

Contemporary automotive glass has evolved significantly, incorporating advanced technologies designed to enhance occupant protection and vehicle integrity. These innovations play a crucial role in ensuring a safer driving experience by mitigating risks associated with accidents and environmental factors.

Key Safety Innovations

- Impact Resistance: Modern glass is engineered to withstand high impact forces, reducing the likelihood of shattering upon collision.

- UV Protection: Enhanced coatings help filter harmful ultraviolet rays, protecting both passengers and interior materials.

- Acoustic Insulation: Special laminations minimize noise, contributing to a quieter cabin environment, which can improve driver focus.

Advanced Technologies

- Heads-Up Display: Integrating display technologies allows critical information to be projected onto the glass, keeping the driver informed without diverting attention from the road.

- Lane Departure Warnings: Certain systems utilize sensors to monitor lane positioning, alerting drivers if they inadvertently drift.

- Rain Sensors: Automatic wipers activated by rainfall detection enhance visibility during adverse weather conditions.

Regulations for Windshield Standards

Standards governing the transparency and structural integrity of vehicle front glass play a crucial role in ensuring safety and visibility for drivers and passengers. These regulations are designed to provide guidelines for manufacturers, ensuring that their products meet specific criteria for quality and performance. Compliance with these standards is essential for maintaining public safety on the roads.

| Standard | Description | Regulatory Body |

|---|---|---|

| ANSI Z26.1 | Sets forth specifications for the performance of vehicle glass, including impact resistance and optical clarity. | American National Standards Institute |

| FMVSS 205 | Establishes the minimum requirements for the glazing materials used in motor vehicles, focusing on safety and durability. | National Highway Traffic Safety Administration |

| ISO 12543 | Covers the classification and specifications for glass in road vehicles, emphasizing the importance of quality control. | International Organization for Standardization |

Adherence to these guidelines is vital not only for manufacturers but also for consumers, as it ensures that the products installed in vehicles provide adequate protection and visibility under various conditions. Regular updates to these regulations reflect advancements in materials and technologies, further enhancing safety standards in the automotive industry.