T19 Transmission Parts Diagram Overview

In the realm of automotive mechanics, comprehending the intricate assembly of a gear mechanism is essential for both enthusiasts and professionals. This section delves into the various elements that constitute a specific model, offering insights into their functions and interconnections. Mastery of this subject not only enhances repair skills but also enriches overall knowledge of vehicle dynamics.

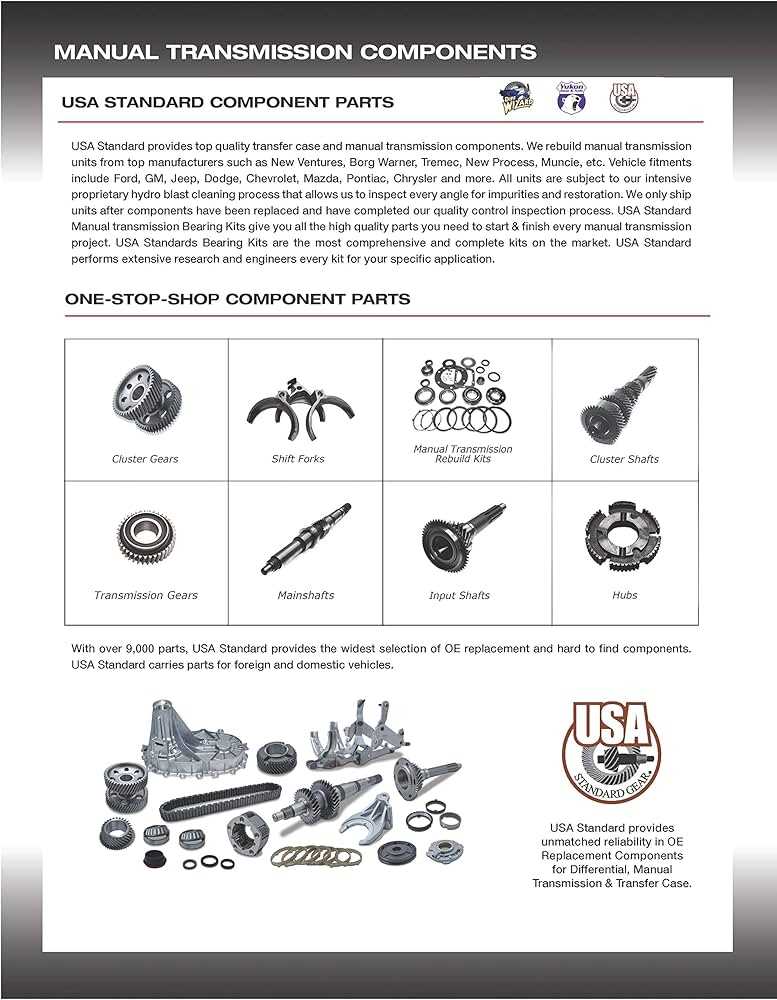

Visual representations play a crucial role in grasping the layout and arrangement of these components. By examining a well-structured illustration, one can better appreciate how each piece works harmoniously within the larger system. Such depictions facilitate a deeper understanding of functionality and maintenance requirements.

Furthermore, recognizing the significance of each individual element enables more effective troubleshooting and enhancements. With a solid grasp of the mechanics involved, individuals are better equipped to address performance issues and make informed decisions during upgrades or repairs. This knowledge lays the groundwork for a more robust appreciation of engineering in automotive design.

T19 Transmission Overview

This section provides a comprehensive insight into a specific mechanical assembly known for its robust design and functionality. It plays a crucial role in enhancing the performance of various vehicles, ensuring smooth operation and efficient power transfer from the engine to the wheels.

Characterized by its durable construction and reliability, this assembly has become a favored choice among automotive enthusiasts and professionals alike. Its innovative engineering allows for effective handling of different torque loads, making it suitable for both standard and demanding driving conditions.

Understanding the various components and their interactions is essential for optimal maintenance and performance. Each element contributes to the overall efficacy of the system, ensuring seamless operation and longevity. This overview aims to highlight the significance of each component within the assembly, shedding light on their specific functions and the impact they have on overall vehicle dynamics.

Key Components of T19 Transmission

Understanding the essential elements of a manual gear-shifting system is crucial for optimal performance and maintenance. These components work in harmony to ensure smooth gear changes, durability, and reliability in various driving conditions.

Main Elements

- Housing: The outer shell that protects internal components and houses the lubricant.

- Gear Sets: A collection of gears that facilitate different speed ratios.

- Shift Mechanism: The system that allows the driver to select and engage specific gears.

- Synchronizers: Devices that help match gear speeds for smooth engagement.

- Bearings: Support rotating elements, reducing friction and wear.

Supporting Features

- Clutch Assembly: Engages and disengages the engine from the drivetrain.

- Output Shaft: Transfers power to the drive axles.

- Lubrication System: Ensures all moving parts operate smoothly by reducing friction.

- Control Linkages: Connect the shift lever to the internal mechanism for gear selection.

Familiarity with these core elements enhances the understanding of functionality and maintenance practices, ultimately contributing to the longevity of the system.

Importance of Transmission Diagrams

Understanding the intricate design and function of mechanical systems is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, providing clarity and aiding in troubleshooting. They break down complex assemblies into comprehensible segments, allowing technicians to grasp how components interact and function together.

Benefits of Visual Representations

- Enhanced Comprehension: Diagrams simplify the learning process, making it easier to grasp the relationships between various elements.

- Efficient Troubleshooting: When issues arise, these visuals help pinpoint problems more rapidly, reducing downtime.

- Accurate Repairs: Detailed images guide technicians in proper disassembly and reassembly, minimizing the risk of errors.

Applications in Maintenance

- Regular inspections can be conducted more effectively with a clear understanding of the system layout.

- Guidelines for replacing components are straightforward when visual aids illustrate the necessary steps.

- Training new personnel becomes more efficient, as they can visualize the mechanisms involved.

How to Read Transmission Schematics

Understanding mechanical layouts can greatly enhance your ability to troubleshoot and repair complex systems. These illustrations provide a visual representation of the components involved, their interconnections, and how they function together. Grasping the symbols and notations used in these schematics is essential for accurate interpretation.

Key Symbols and Notations

Familiarize yourself with common symbols that denote various elements. Each icon represents a specific component, and knowing these can streamline your understanding of the entire mechanism.

| Symbol | Description |

|---|---|

| ⚙️ | Gear or sprocket |

| Rotation direction | |

| Connection point | |

| Locking mechanism |

Reading the Layout

Start from the main components and trace the connections. Look for arrows that indicate flow direction and understand how each part influences the system’s overall performance. This methodical approach helps clarify complex relationships and functionality.

Common Issues with T19 Parts

When dealing with mechanical components, certain challenges frequently arise that can impact performance and longevity. Identifying these common concerns is crucial for maintaining efficiency and avoiding costly repairs. This section explores typical problems encountered with these crucial mechanisms and offers insights into their implications.

Frequent Problems

- Wear and Tear: Over time, regular usage can lead to deterioration of essential elements, affecting their functionality.

- Fluid Leaks: Improper seals or connections may result in leakage, which can compromise efficiency and lead to significant damage.

- Overheating: Excessive heat can cause components to warp or fail, often due to inadequate lubrication or high load conditions.

Signs of Trouble

- Unusual Noises: Grinding or clunking sounds during operation often indicate underlying issues.

- Difficulty Shifting: Hesitation or resistance when changing gears can signal problems with the internal mechanism.

- Fluid Contamination: Discoloration or debris in the fluid can suggest wear or damage within the system.

Maintenance Tips for T19 Transmissions

Proper upkeep of your vehicle’s gear system is essential for ensuring smooth operation and longevity. Regular attention can prevent costly repairs and enhance performance. Below are some essential suggestions to keep your mechanism in optimal condition.

1. Regular Fluid Checks: Make it a habit to inspect the fluid levels frequently. Adequate lubrication is crucial for reducing friction and heat. If the fluid appears dark or has a burnt smell, consider a change.

2. Routine Inspections: Periodically examine the entire assembly for any signs of wear or damage. Look for leaks, cracks, or unusual sounds while driving, as these can indicate underlying issues.

3. Adjustments and Alignments: Ensure that all connections are properly aligned. Misalignment can lead to premature wear and inefficient performance. Regular adjustments can significantly improve functionality.

4. Cleanliness is Key: Keep the surrounding area clean and free from debris. Dirt and grime can enter the system, leading to potential blockages and wear over time.

5. Professional Servicing: Engage a qualified technician for comprehensive maintenance checks. Professional evaluations can identify problems that may go unnoticed and help maintain overall efficiency.

By implementing these maintenance strategies, you can ensure that your vehicle’s gear mechanism remains reliable and performs at its best for years to come.

Replacement Parts for T19 Models

Maintaining the functionality of your vehicle’s gearbox is crucial for optimal performance. Over time, certain components may wear out or fail, necessitating the need for replacements. Understanding which elements require attention can enhance reliability and extend the lifespan of the system.

Common Components Needing Replacement

Several elements are prone to wear and may require substitution. Gears are often subjected to significant stress and can develop damage over time. Shafts are also critical; if they become misaligned or worn, they can compromise the overall operation. Additionally, seals and bearings play vital roles in maintaining the integrity of the unit, preventing leaks and ensuring smooth movement.

Choosing Quality Alternatives

When selecting replacements, it’s essential to prioritize quality. Opting for reputable brands can ensure compatibility and durability, reducing the likelihood of future issues. Moreover, sourcing from trusted suppliers can provide peace of mind regarding the authenticity and performance of the components.

Tools Required for T19 Repairs

When undertaking repairs on complex mechanical systems, having the right tools is essential for ensuring efficiency and accuracy. A well-equipped toolkit not only streamlines the process but also minimizes the risk of damage to components during maintenance. This section outlines the necessary equipment that will facilitate effective repairs.

Basic Hand Tools

Start with a standard set of hand tools, including wrenches, sockets, and ratchets. These items are fundamental for loosening and tightening fasteners. Additionally, a good screwdriver set is vital for various screws encountered throughout the assembly.

Specialized Equipment

For more intricate tasks, specialized instruments such as gear pullers and torque wrenches are necessary. A seal installer can also be invaluable for ensuring that seals are properly fitted, preventing future leaks. Investing in quality tools will lead to a more successful and enjoyable repair experience.

Upgrading Your T19 Transmission

Enhancing the performance of your gear system can significantly improve the overall driving experience. Whether you’re seeking increased durability, better gear ratios, or improved shifting, there are several avenues to explore. This guide will help you navigate the options available for optimizing your setup.

First, consider the internal components. Upgrading gears, bearings, and synchronizers can lead to smoother operation and enhanced reliability. Many enthusiasts opt for high-performance alternatives that provide better torque handling and reduced wear over time.

Next, focus on the external elements that influence performance. A robust housing can protect the internal mechanisms from damage, while an efficient cooling system ensures that the assembly operates within safe temperature ranges. Additionally, proper sealing can prevent fluid leaks that compromise functionality.

| Upgrade Option | Benefits |

|---|---|

| High-Performance Gears | Improved torque capacity and smoother shifts |

| Upgraded Bearings | Increased durability and reduced friction |

| Enhanced Cooling System | Prevents overheating and maintains performance |

| Robust Housing | Protects components from external damage |

| Efficient Sealing | Prevents fluid leaks and contamination |

By carefully selecting which enhancements to pursue, you can tailor your gear mechanism to better meet your driving needs. Consider the balance between performance gains and your specific requirements for the best results.

Understanding Gear Ratios in T19

Gear ratios play a crucial role in the performance and efficiency of any drivetrain system. By determining the relationship between the input and output speeds, these ratios help in optimizing power delivery and fuel efficiency. A clear grasp of how these ratios function can significantly enhance vehicle operation and longevity.

The Basics of Gear Ratios

At its core, the gear ratio is a comparison of the number of teeth on two gears that are meshed together. This relationship dictates how many times one gear must turn to make the other turn once. Understanding this concept involves several key elements:

- Input Gear: The gear connected to the power source.

- Output Gear: The gear that transmits the power to the wheels.

- Teeth Count: The number of teeth on each gear influences the overall ratio.

Calculating Gear Ratios

To calculate the gear ratio, the formula is straightforward:

- Count the teeth on the input gear.

- Count the teeth on the output gear.

- Divide the number of teeth on the input gear by the number of teeth on the output gear.

For example, if the input gear has 10 teeth and the output gear has 30 teeth, the gear ratio would be 1:3. This means the input gear must rotate three times to make the output gear rotate once.

Understanding these ratios is essential for anyone looking to modify or maintain their vehicle effectively, as they influence acceleration, towing capacity, and overall performance.

Differences Between T19 and Other Transmissions

When comparing various gear-shifting systems, it’s essential to consider their unique features, applications, and performance characteristics. Each system offers distinct advantages and disadvantages, influencing factors such as power delivery, fuel efficiency, and overall driving experience.

Construction and Design

The design of these gear systems can vary significantly. While some are built for high durability and robust performance, others prioritize lightweight construction and ease of installation. This leads to differences in how effectively power is transmitted from the engine to the wheels, impacting acceleration and towing capabilities.

Shift Mechanism

Another critical distinction lies in the shifting mechanism. Some systems utilize a more traditional manual approach, requiring driver engagement for gear changes, while others offer semi-automatic or fully automatic options. This variance not only affects driver involvement but also influences responsiveness and control during various driving conditions.

Understanding these differences helps enthusiasts and professionals choose the right system for their specific needs, whether for off-road adventures, daily commuting, or performance driving.

Resources for T19 Transmission Owners

For enthusiasts and owners looking to enhance their knowledge and maintenance skills, a variety of resources are available. These materials can guide you through troubleshooting, repairs, and upgrades, ensuring optimal performance of your vehicle’s drivetrain components.

Online Forums and Communities

Joining dedicated online forums can be invaluable. These platforms allow you to connect with fellow enthusiasts, share experiences, and seek advice. Members often discuss common issues, recommended modifications, and best practices, providing a wealth of knowledge at your fingertips.

Manuals and Guides

Comprehensive manuals and instructional guides are essential for understanding the inner workings of your equipment. These documents often include step-by-step procedures, maintenance schedules, and detailed diagrams that can assist in both routine upkeep and complex repairs. Look for resources that are tailored specifically to your model for the most accurate information.

Online Retailers offer a wide selection of components and accessories that can enhance the functionality of your system. Investing in quality items can lead to improved reliability and longevity. Always consider checking reviews and recommendations from other users before making a purchase.

By utilizing these resources, you can ensure that your system remains in top condition, enhancing your overall driving experience.