Understanding the Peerless 700-079 Parts Diagram for Easy Repairs

In the realm of machinery, having a clear visualization of the internal elements is essential for efficient maintenance and repair. Such representations not only enhance comprehension but also facilitate effective troubleshooting, allowing users to navigate complexities with confidence.

Whether you’re an experienced technician or a novice enthusiast, grasping the arrangement of various mechanisms can significantly influence the outcome of your projects. This knowledge empowers individuals to make informed decisions when it comes to repairs and enhancements, ultimately improving functionality.

Delving into the details of these intricate layouts unveils the relationships between components, revealing how each part contributes to the overall performance. The ultimate goal is to achieve seamless operation, ensuring longevity and reliability in the equipment’s use.

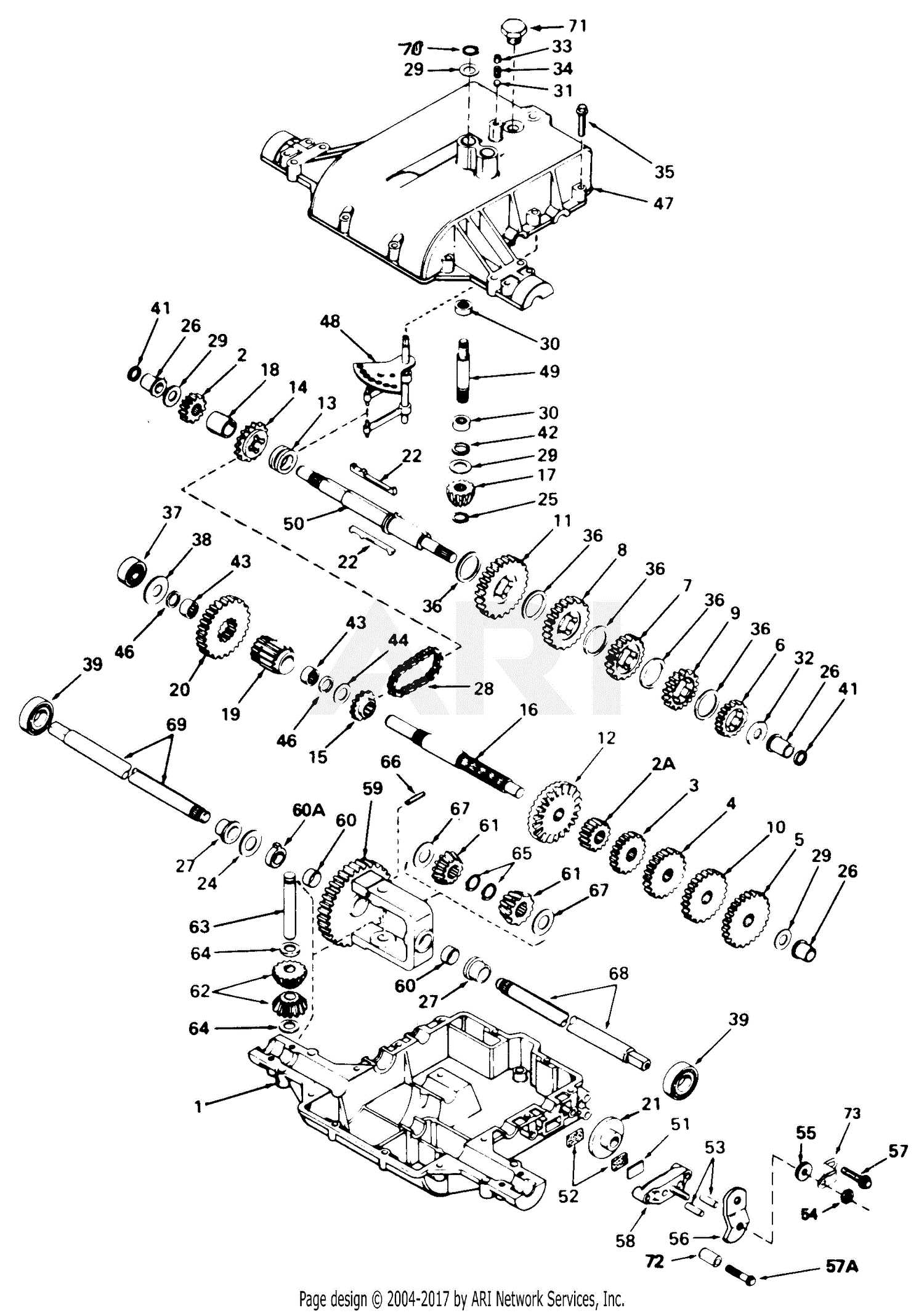

Understanding Peerless 700-079 Components

Gaining insight into the essential elements of machinery can significantly enhance operational efficiency. Each component plays a crucial role in the overall functionality, and understanding their interrelations is key to effective maintenance and troubleshooting. This section delves into the various elements, outlining their purposes and characteristics.

Main Elements

- Transmission System: Responsible for transferring power from the engine to the wheels, ensuring smooth movement.

- Shifting Mechanism: Facilitates gear changes, allowing for adjustments in speed and torque as needed.

- Input Shaft: Connects the engine output to the transmission, acting as the primary conduit for power delivery.

Additional Components

- Output Shaft: Distributes power to the wheels, directly influencing vehicle speed and handling.

- Control Linkages: Provide the necessary connections between the gear selector and the transmission, ensuring precise operation.

- Sealing Elements: Prevent leaks and protect internal components from contaminants, extending the lifespan of the system.

By familiarizing oneself with these critical components, operators can make informed decisions regarding maintenance and repairs, ultimately leading to improved performance and longevity of the machinery.

Overview of Peerless 700-079 Model

This section provides a comprehensive look at a specific mechanical model known for its efficiency and reliability in various applications. Understanding its structure and functionality is essential for users seeking optimal performance.

- Design: The model features a robust and user-friendly design, ensuring ease of operation.

- Functionality: It operates seamlessly across multiple environments, adapting to different needs.

- Maintenance: Regular upkeep is straightforward, contributing to its longevity and effectiveness.

In summary, this model stands out due to its balanced combination of durability and performance, making it a favored choice among users.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. They offer clarity, enabling users to identify and locate specific elements efficiently. This not only aids in maintenance but also enhances the overall comprehension of the equipment’s structure.

Facilitating Maintenance

When issues arise, having a clear visual reference simplifies troubleshooting. Users can quickly pinpoint malfunctioning pieces, ensuring swift repairs and reducing downtime.

Enhancing Understanding

These visuals provide an educational tool for operators, fostering a deeper appreciation of how different elements interact within a system. This knowledge is vital for optimal operation and safety.

| Benefit | Description |

|---|---|

| Quick Identification | Streamlines the process of locating components. |

| Effective Troubleshooting | Enables faster diagnosis of issues. |

| Improved Safety | Promotes awareness of operational parts. |

| Enhanced Learning | Assists in understanding mechanical relationships. |

Common Issues with Peerless 700-079

When working with specific mechanical systems, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common issues can aid in troubleshooting and maintenance.

- Leakage: Fluid leaks can arise from worn seals or gaskets, leading to decreased functionality.

- Noise: Unusual sounds may indicate internal wear or misalignment of components.

- Difficulty in Shifting: Problems with engaging gears can stem from improper adjustments or internal damage.

- Overheating: Excessive heat can be a sign of inadequate lubrication or overloading.

Addressing these issues promptly can help maintain optimal operation and extend the lifespan of the equipment.

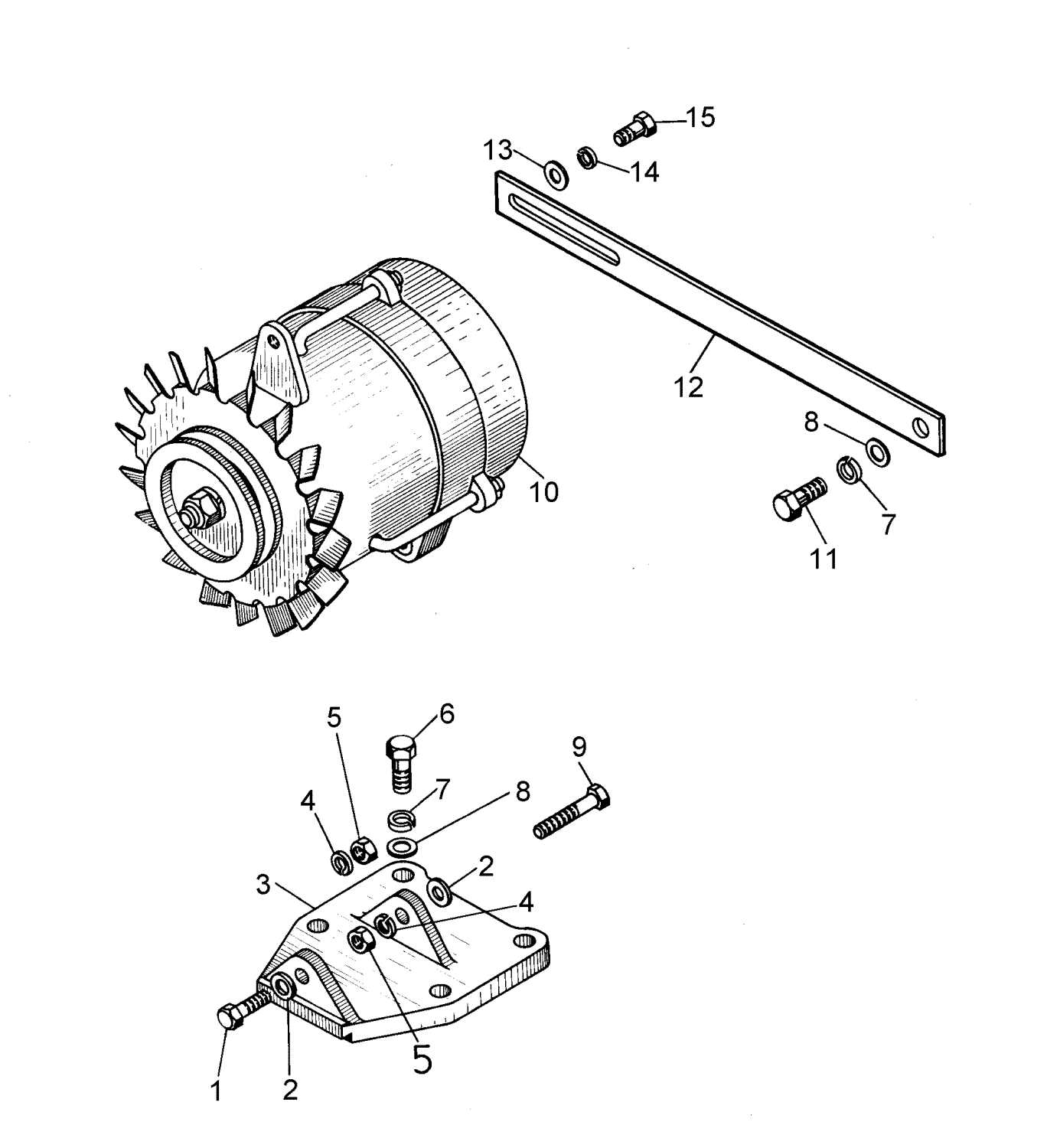

Key Components of the Diagram

Understanding the essential elements of mechanical assemblies is crucial for effective maintenance and repair. Each component plays a significant role in the overall functionality and performance of the system. A detailed visual representation can provide valuable insights into how these parts interact and contribute to the operation.

Mechanical Elements: These include gears, bearings, and levers, which are vital for transferring motion and energy throughout the apparatus. Their precise arrangement ensures optimal efficiency and longevity.

Connection Points: Various joints and fasteners link the components together, allowing for structural integrity. Recognizing these connections is essential for troubleshooting and replacement.

Control Mechanisms: Switches and regulators are critical for managing the operation of the device. Understanding their placement and function helps in diagnosing issues related to performance.

Support Structures: Frameworks and bases provide stability and support to the assembly. These elements must be assessed for wear and damage to maintain safety and functionality.

By familiarizing oneself with these key elements, individuals can better navigate the complexities of mechanical systems, leading to improved maintenance practices and operational reliability.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly, maintenance, or repair tasks. These illustrations serve as a guide, offering insights into the structure and arrangement of various elements within a machine or device. Grasping how to interpret these visuals can significantly enhance your ability to work with mechanical systems.

Key Elements to Identify

- Labels: Look for annotations that indicate the name or number of each element. These can help you quickly locate the specific parts needed.

- Connections: Pay attention to lines and arrows that depict how components interact or connect with one another.

- Legend: Often, a key or legend is included, explaining symbols or shorthand used throughout the visual.

Steps to Follow

- Start from the Top: Begin your examination at the upper section of the visual, usually where the primary components are displayed.

- Trace the Flow: Follow the connections as you move downward or across the illustration, ensuring you understand how each piece relates to the others.

- Refer to the Legend: Utilize the accompanying key for clarification on symbols or terminology that may not be immediately clear.

Benefits of Accurate Diagrams

Having precise visual representations is crucial in various fields, as they facilitate understanding and efficiency. Such illustrations serve as essential tools for both professionals and novices, ensuring that complex systems are easier to navigate. By offering clarity, they enhance communication and reduce the chances of errors during implementation.

Enhanced Understanding

Accurate visuals simplify intricate concepts, making them accessible to a broader audience. They break down complex information into digestible segments, allowing individuals to grasp essential components quickly. This clarity not only fosters comprehension but also encourages learning and retention.

Improved Efficiency

When users can rely on well-crafted representations, they can execute tasks more effectively. Clear depictions guide users step-by-step, minimizing the likelihood of mistakes and streamlining workflows. As a result, projects progress more smoothly, ultimately saving time and resources.

Where to Find Replacement Parts

Finding suitable components for repairs or upgrades can be a straightforward process if you know where to look. Various sources offer high-quality options to ensure your device functions optimally.

- Official manufacturer websites often provide direct purchasing options.

- Local hardware stores may carry compatible alternatives.

- Online marketplaces, such as Amazon or eBay, can have a wide range of choices.

- Specialty retailers focus on specific brands and models.

- Salvage yards or second-hand shops might have usable items at a lower price.

- Forums and online communities often share tips on where to locate rare components.

- Repair shops may sell spare parts and provide installation services.

- DIY websites sometimes list compatible options and links to purchase.

Maintaining Peerless 700-079 Efficiency

Ensuring optimal performance of your equipment involves regular maintenance and attention to detail. Proper care not only extends the lifespan of the machinery but also enhances its operational capabilities. By implementing systematic practices, you can achieve consistent efficiency and prevent potential breakdowns.

Regular Inspections

Conducting frequent inspections is vital to identify wear and tear early on. Check for any signs of leakage, unusual noises, or irregular movements. Timely detection of issues allows for swift corrective actions, preventing more significant problems down the line.

Lubrication and Cleaning

Regular lubrication is essential for smooth operation. Use high-quality oils to reduce friction between moving components. Additionally, keeping the machinery clean from dust and debris ensures that it runs efficiently, preventing overheating and unnecessary strain on the system.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for achieving optimal results. The appropriate tools not only facilitate the process but also ensure safety and efficiency. A well-equipped workspace is crucial for both novice and experienced individuals alike.

Basic Hand Tools: Essential implements such as screwdrivers, wrenches, and pliers are foundational for any repair job. These instruments allow for the disassembly and reassembly of components, making them indispensable for troubleshooting and fixing issues.

Power Tools: For more extensive tasks, power tools like drills and saws can significantly reduce manual labor. These tools increase precision and speed, making them valuable for larger projects where efficiency is paramount.

Measuring Instruments: Accurate measurements are vital in any repair process. Tools like tape measures, calipers, and levels help ensure that every adjustment is precise, ultimately contributing to the quality of the final outcome.

Safety Equipment: Protective gear, including gloves, goggles, and masks, should not be overlooked. Ensuring personal safety while performing repairs is critical, especially when handling potentially hazardous materials or sharp objects.

In conclusion, equipping yourself with the right tools and safety measures lays the groundwork for successful repair endeavors, allowing you to address challenges effectively and confidently.

Step-by-Step Repair Process

This section outlines a comprehensive guide for effectively addressing mechanical issues. Following a structured approach can ensure a smoother restoration, minimizing potential setbacks. Each step is designed to be clear and actionable, facilitating a seamless repair experience.

Preparation and Assessment

Begin by gathering the necessary tools and materials. Conduct a thorough evaluation of the device to identify the specific problem areas. Take note of any visible wear or damage that may require attention. Documenting these findings can help streamline the subsequent steps.

Disassembly and Repair

Carefully disassemble the unit, keeping track of each component as it is removed. Utilize a systematic approach to avoid losing any parts. Once the device is fully accessible, proceed with the necessary repairs, whether it involves replacing worn components or making adjustments to enhance functionality. After completing the repairs, reassemble the unit with attention to detail, ensuring all parts fit securely.

Tips for Troubleshooting Issues

Tackling mechanical problems can often be a daunting task, yet understanding some fundamental strategies can significantly ease the process. This section provides valuable insights to help you diagnose and resolve common challenges effectively.

Identifying Common Symptoms

Start by recognizing the signs of malfunction. Understanding the typical behaviors of the device can guide you in pinpointing the issue. Here are some common symptoms to watch for:

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| No power | Power supply issues | Check connections and replace the fuse if necessary |

| Unusual noises | Wear and tear on components | Inspect for loose parts and lubricate as needed |

| Inconsistent performance | Clogged pathways | Clean filters and check for blockages |

Systematic Approach to Problem Solving

Adopting a methodical approach is crucial in resolving issues efficiently. Follow these steps:

1. Gather Information: Document any changes or events leading to the malfunction.

2. Isolate the Issue: Test individual components to determine the source of the problem.

3. Implement Solutions: Apply fixes based on your findings, starting with the simplest remedies.

4. Evaluate Outcomes: After implementing changes, monitor the system to ensure the problem is resolved.

By following these guidelines, you can enhance your troubleshooting skills and ensure smoother operation of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to the components and mechanisms of various equipment. Understanding these elements can enhance maintenance and improve overall functionality.

-

What should I do if I notice a malfunction?

Identify the issue and check the manual for troubleshooting steps. If necessary, consult a professional for assistance.

-

How can I obtain replacement elements?

Replacement items can typically be sourced from authorized dealers or online retailers specializing in equipment supplies.

-

Are there any maintenance tips to prolong the lifespan?

Regular inspections, cleaning, and timely replacements are crucial for longevity. Always follow the manufacturer’s guidelines.

-

What if I can’t find the specific item I need?

Consider reaching out to customer support for assistance. They may offer alternatives or special ordering options.

-

Can I upgrade certain components for better performance?

Yes, many systems allow for upgrades. Review compatibility and performance enhancements before making changes.