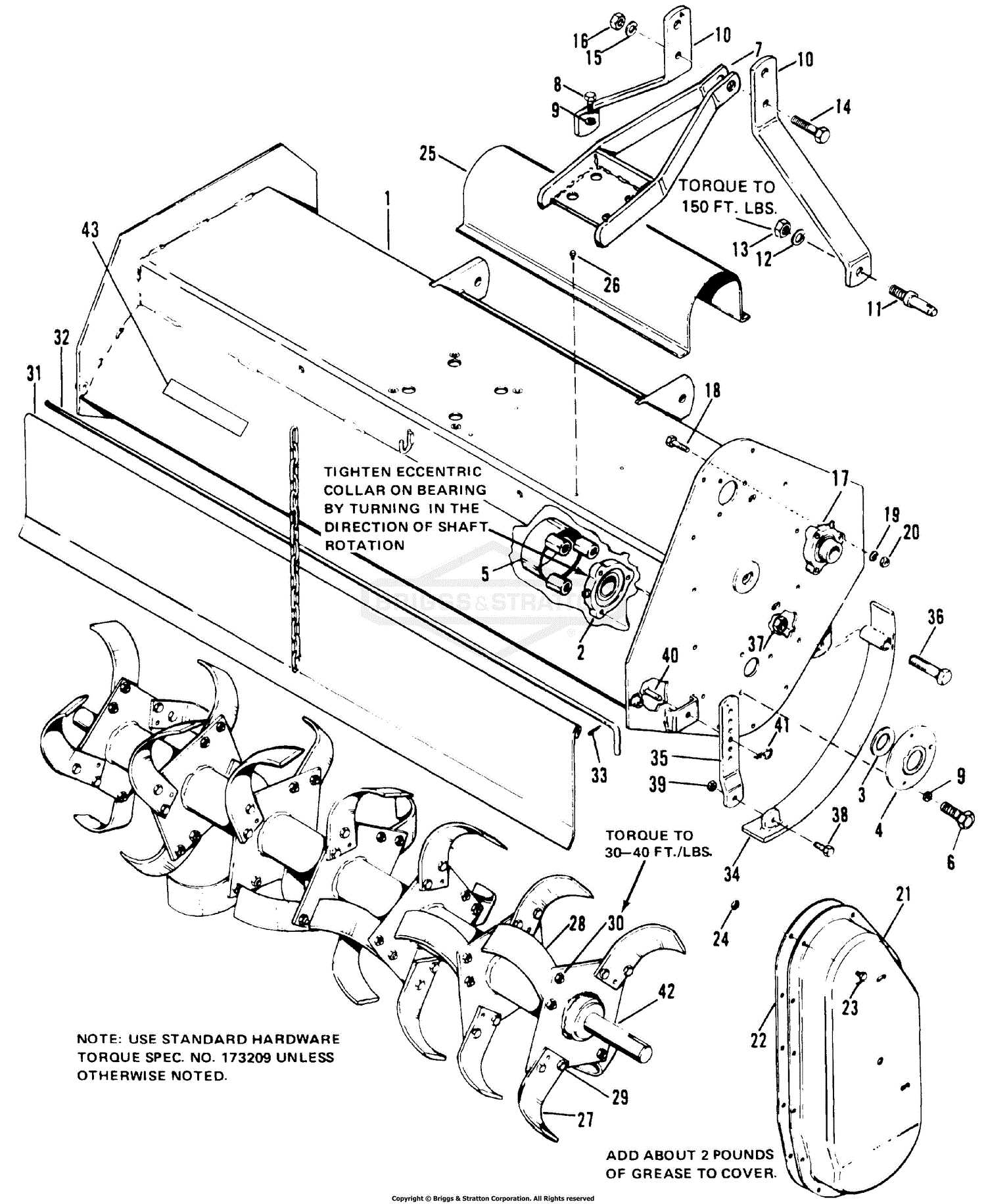

Rotary Tiller Parts Diagram Overview

When working with land cultivation tools, understanding the various mechanisms and their functions is essential. Each element plays a critical role in ensuring the equipment operates efficiently, helping to prepare the soil for planting and other agricultural tasks.

Proper maintenance and awareness of these components can significantly improve performance. From moving blades to gear systems, each piece must work in harmony for smooth operation. Regular inspection and timely replacement of worn-out elements can extend the lifespan of your machinery.

In this guide, we will explore the key structural units, their functions, and tips for keeping your equipment in top condition. With the right knowledge, you can maximize the efficiency of your tools, ensuring productive and reliable use.

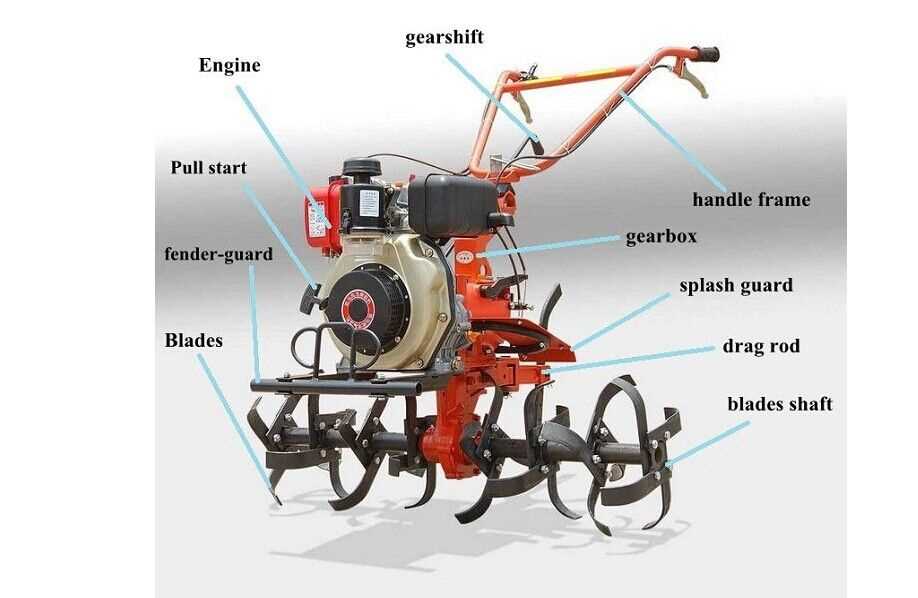

Understanding the Rotary Tiller Mechanism

The operational structure of soil preparation equipment relies on a coordinated system of components working together to break up and turn over the earth. This system is designed to ensure efficient soil cultivation, allowing for improved aeration and nutrient mixing. The core of this process revolves around the interaction between moving elements and the soil, making it possible to achieve the desired level of soil readiness for planting or other agricultural activities.

Key features of this mechanism include specially shaped blades and a drive system, which work in harmony to handle even tough ground conditions. By adjusting the speed and depth of the blades, users can control how the soil is processed, ensuring it meets the specific needs of the task at hand. The equipment’s durability and efficiency come from its ability to withstand repeated use in various terrains.

Understanding how this machinery functions is essential for anyone looking to maximize its potential. Proper use, combined with regular maintenance, ensures longevity and consistent performance in a wide range of soil conditions.

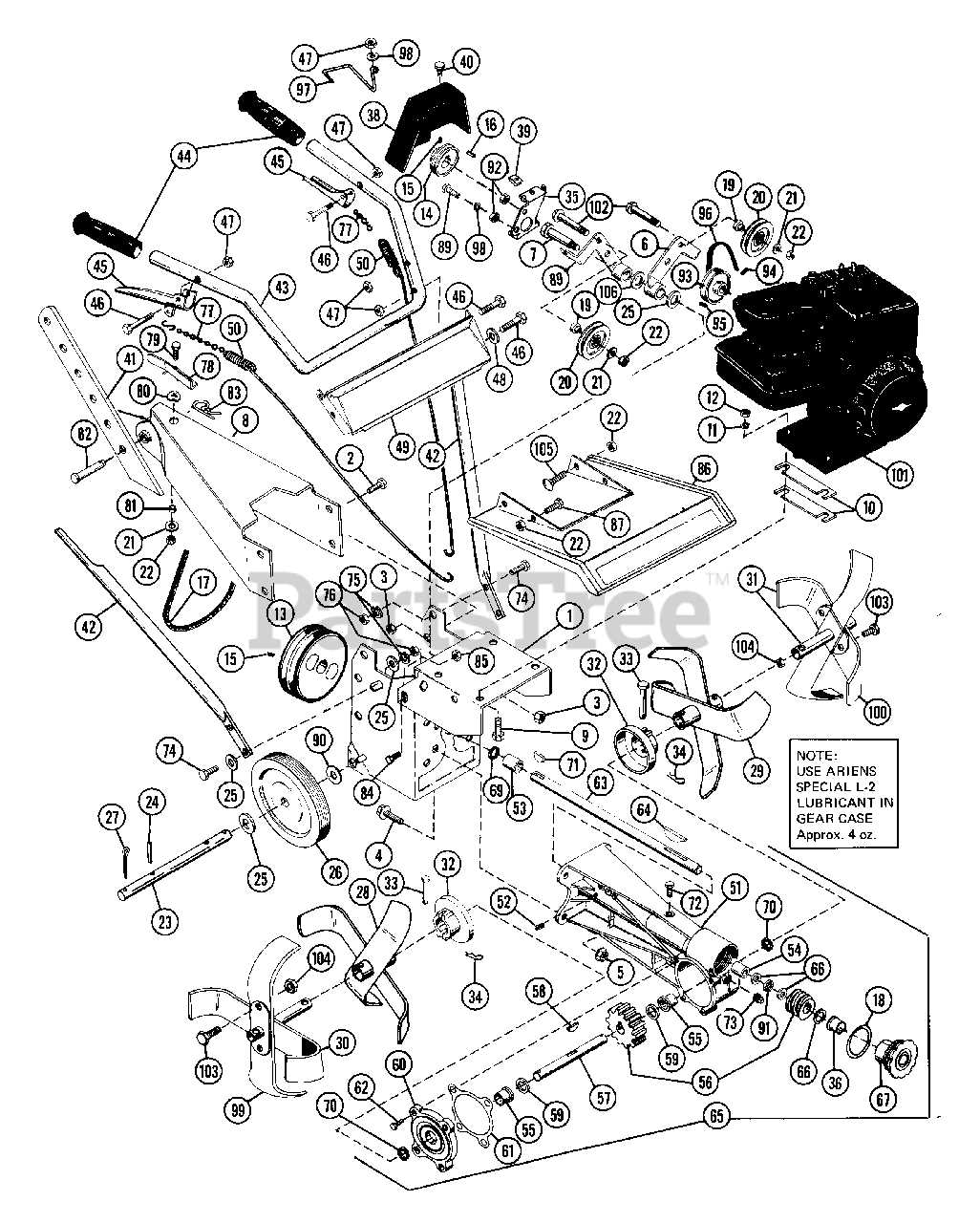

Main Components of a Rotary Tiller

The mechanism responsible for soil preparation and maintenance consists of several essential elements that work together to ensure efficient soil treatment. Each part contributes to the overall functionality, providing stability, durability, and adaptability to different soil conditions.

Blade Assembly

The cutting edges, positioned along a rotating structure, are designed to penetrate and turn over soil. These blades vary in shape and material, depending on the type of terrain they are intended for. Proper maintenance of these cutting components is crucial for achieving optimal performance.

Frame and Drive System

The supportive structure connects the machine to a power source, usually a tractor. The drive system transfers energy to the rotating blades, ensuring consistent movement and torque. The design and materials used for the frame are vital for handling stress and rough conditions.

| Component | Function |

|---|---|

| Cutting Blades | Breaks and turns soil |

| Transmission | Transfers power to blades |

| Frame | Provides structural support |

How the Gearbox Powers the Blades

The gearbox serves as a vital mechanism that transforms engine energy into movement for the cutting tools. Through a series of internal components, this system transmits power efficiently to the working elements, ensuring that they perform their task with precision. Without this crucial connection, the motion necessary for soil engagement would be impossible.

The energy produced by the motor is first channeled through gears within the unit. These gears regulate the force and direction, adjusting the speed and torque to match the requirements of the task. By controlling the pace at which the working elements spin, the system ensures optimal performance for different conditions.

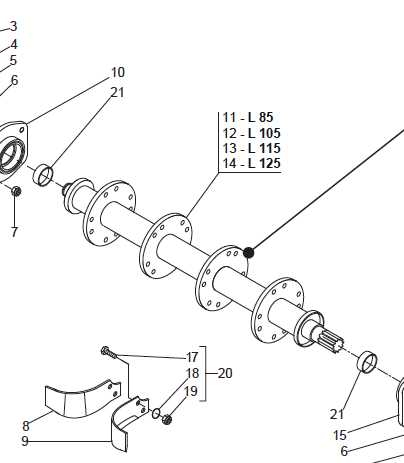

Connecting the Drive Shaft to the Engine

The process of attaching the transmission component to the motor is essential for ensuring proper power transfer. This connection plays a crucial role in the smooth functioning of the machinery, as it directly affects the efficiency and performance of the equipment.

Before starting the assembly, it is important to inspect all elements to ensure they are in optimal condition. Make sure that the shaft and coupling points are free of debris or wear that could interfere with the attachment. Proper alignment is also key to avoid unnecessary strain on the system.

Once the inspection is complete, carefully position the components and securely attach the drive shaft to the engine. Make sure all bolts and fasteners are tightened according to the specifications to prevent any movement during operation. A well-connected system ensures long-term durability and reliable performance.

Blade Configurations for Different Soil Types

Understanding the arrangement of blades is crucial when adapting machinery to various soil conditions. The effectiveness of soil cultivation largely depends on the proper setup, ensuring optimal penetration and mixing. By selecting the appropriate blade layout, it is possible to enhance performance and achieve desired results, whether working with soft, sandy soil or denser, clay-based terrains.

Blades for Soft Soil typically feature wider, less aggressive designs, allowing them to glide through the soil smoothly without unnecessary resistance. This configuration minimizes disruption, preventing the soil from becoming overly compacted.

Blades for Dense or Clay Soil, on the other hand, tend to be more robust and sharper, designed to cut through heavier materials effectively. These blades can penetrate deeper and break up the tough layers, ensuring proper aeration and preparation of the ground.

By adjusting blade spacing and angles, the machinery can be fine-tuned for the specific challenges presented by different soil compositions, making the process more efficient and reducing wear on the equipment.

Maintenance of Rotary Tiller Bearings

Proper upkeep of the bearings in agricultural machinery is essential for optimal performance and longevity. Regular inspections and maintenance routines can prevent premature wear and ensure smooth operation. This section outlines key practices for maintaining these critical components, helping to avoid costly repairs and downtime.

Regular Inspections

Conducting frequent inspections of the bearings is crucial. Check for signs of wear, such as unusual noises or vibrations during operation. Inspect for any signs of damage or misalignment that may hinder performance. Addressing these issues early can prevent more significant problems down the line.

Lubrication Practices

Proper lubrication is vital for the smooth functioning of bearings. Use the recommended lubricant and apply it according to the manufacturer’s guidelines. Regularly replace old lubricant to prevent contamination and ensure optimal protection against friction and wear. Maintaining appropriate lubrication levels will significantly extend the life of the bearings.

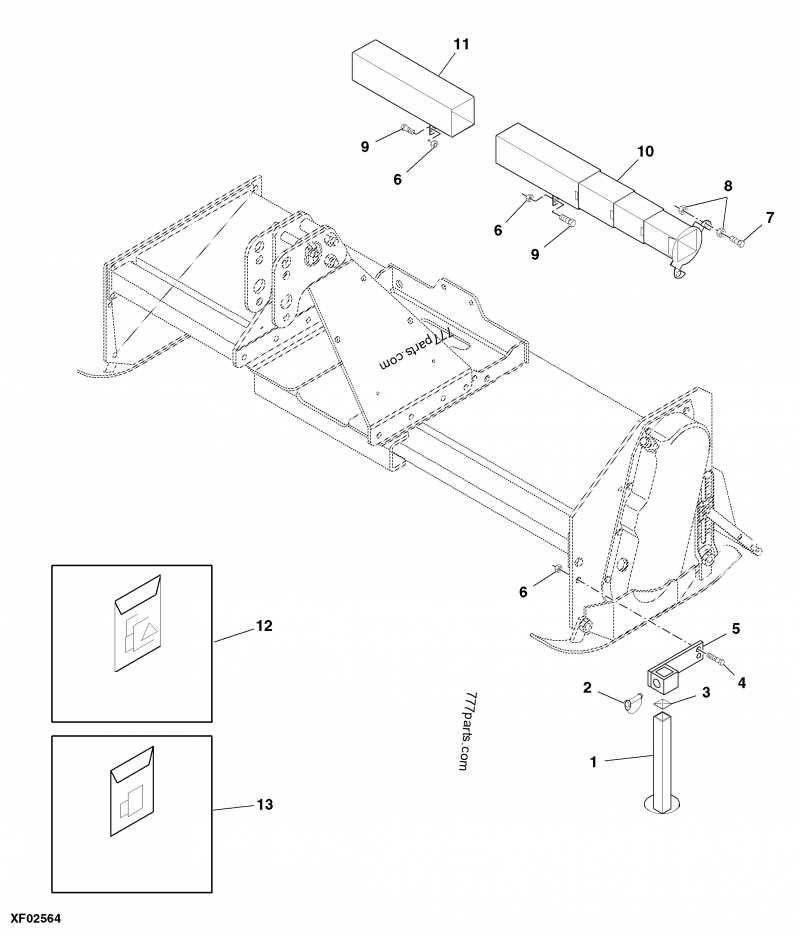

Protecting the Tiller with Safety Shields

Ensuring the longevity and efficiency of agricultural machinery requires thoughtful consideration of safety features. Protective barriers are essential for minimizing risks associated with the operation of these machines. By incorporating safety shields, users can safeguard both themselves and the equipment from potential hazards.

Benefits of Using Protective Barriers

- Injury Prevention: Shields serve as a first line of defense against accidental contact with moving parts.

- Debris Protection: These barriers help prevent stones, soil, and other materials from causing damage during operation.

- Improved Visibility: Properly designed shields can enhance visibility, allowing operators to monitor their work area effectively.

Types of Safety Shields

- Fixed Shields: Permanently attached to the machine, these provide continuous protection.

- Adjustable Shields: These can be repositioned based on specific tasks, offering flexibility for different working conditions.

- Removable Shields: Designed for easy attachment and detachment, these are ideal for maintenance and storage.

Clutch Systems and Their Importance

Clutch mechanisms play a crucial role in the functionality of agricultural equipment, facilitating the transfer of power between the engine and the working components. These systems enable operators to manage the engagement and disengagement of the implement, ensuring optimal performance and control during operation.

Understanding the significance of these systems involves recognizing their key functions:

- Power Transmission: Clutch systems ensure a seamless flow of power, allowing the machinery to function efficiently without unnecessary strain on the engine.

- Operator Control: By enabling easy engagement and disengagement, these mechanisms provide operators with better control over the equipment, enhancing safety and precision.

- Wear and Tear Management: Properly functioning clutches reduce the risk of damage to both the engine and the implement, contributing to the longevity of the machinery.

In conclusion, the effectiveness of agricultural machinery heavily relies on well-designed clutch systems, which not only enhance performance but also improve the overall user experience.

Frame Structure and Durability of Tillers

The framework of cultivation equipment plays a crucial role in its overall performance and longevity. A well-designed structure not only supports the essential components but also ensures stability and resilience during operation. This section explores the significance of the frame’s construction and the materials used, highlighting their impact on the implement’s efficiency and lifespan.

Importance of Strong Construction

A robust framework is vital for the effective functioning of agricultural tools. Here are some key benefits of a strong build:

- Enhances stability during usage, preventing wobbling or shifting.

- Improves resistance to wear and tear, prolonging service life.

- Facilitates better handling of various soil conditions, ensuring consistent performance.

Material Considerations

The choice of materials significantly affects the durability of the implement’s frame. Common materials include:

- Steel: Known for its strength and resistance to deformation, making it ideal for heavy-duty applications.

- Aluminum: Lightweight and resistant to corrosion, suitable for reducing overall weight without compromising strength.

- Composite Materials: These offer a combination of durability and reduced weight, increasingly popular in modern designs.

Understanding the role of frame structure and material choices is essential for maximizing the efficiency and lifespan of agricultural implements.

Proper Alignment of the Tiller’s Hitch

Ensuring the correct positioning of the attachment mechanism is essential for optimal performance. Accurate alignment contributes significantly to the efficiency and longevity of the equipment, reducing wear and tear while enhancing functionality.

Achieving a Proper Fit requires careful attention to the connection points. Misalignment can lead to uneven distribution of force, causing strain on various components. Therefore, it is vital to regularly inspect and adjust the hitch to maintain a straight and level connection.

Utilizing adjustment tools and following the manufacturer’s guidelines will facilitate achieving the right angle. Additionally, checking the stability of the connection can prevent potential issues during operation, ensuring a smoother experience and better results in the field.