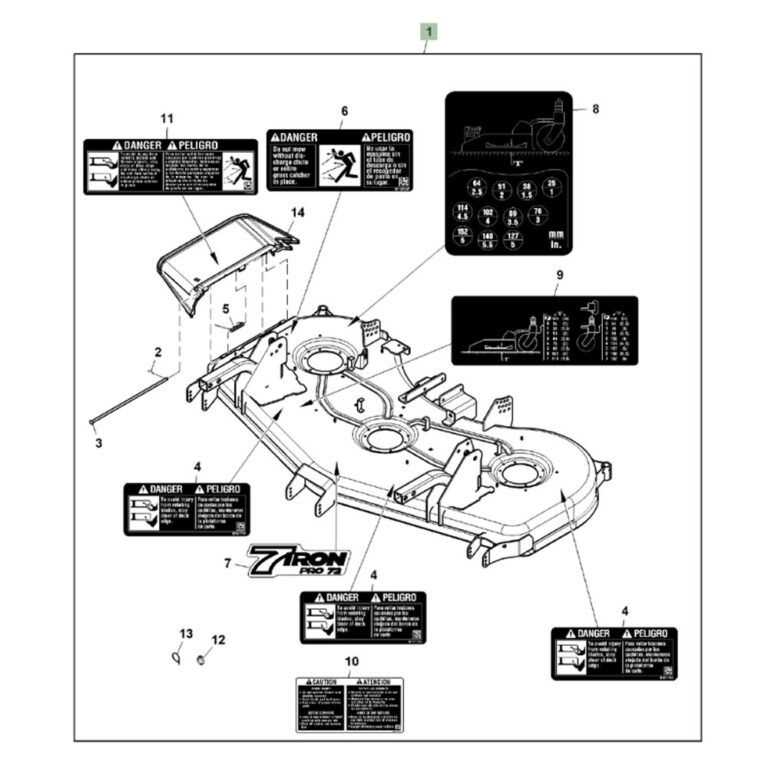

Understanding the Parts Diagram for John Deere 54 Mower Deck

In the realm of lawn maintenance, the efficiency and functionality of machinery play a pivotal role. Familiarity with various components enhances the user experience and ensures optimal performance. Grasping how these elements work together can significantly improve your maintenance tasks.

Visual representation of these components provides clarity, enabling operators to identify each segment and its purpose. This insight not only assists in troubleshooting but also aids in planning effective care routines. By exploring these schematics, enthusiasts can delve into the intricacies of their equipment.

Ultimately, mastering the structure of lawn care machinery empowers users to extend the lifespan of their tools and achieve a pristine landscape. Understanding each part’s function is essential for anyone looking to elevate their maintenance game.

Understanding John Deere Mower Decks

When it comes to maintaining a lawn, having the right equipment is essential for achieving the desired results. The components responsible for cutting grass play a crucial role in efficiency and performance. This section will explore the intricacies of these vital elements, shedding light on their functions and importance in the overall system.

Each component is designed with precision to ensure optimal operation. Understanding how these elements interact can enhance the performance of the entire apparatus. Moreover, regular maintenance can extend the lifespan of the equipment and improve its effectiveness.

In the following sections, we will delve deeper into the various parts, offering insights into their specific roles and how to troubleshoot common issues. This knowledge will empower users to make informed decisions about their equipment.

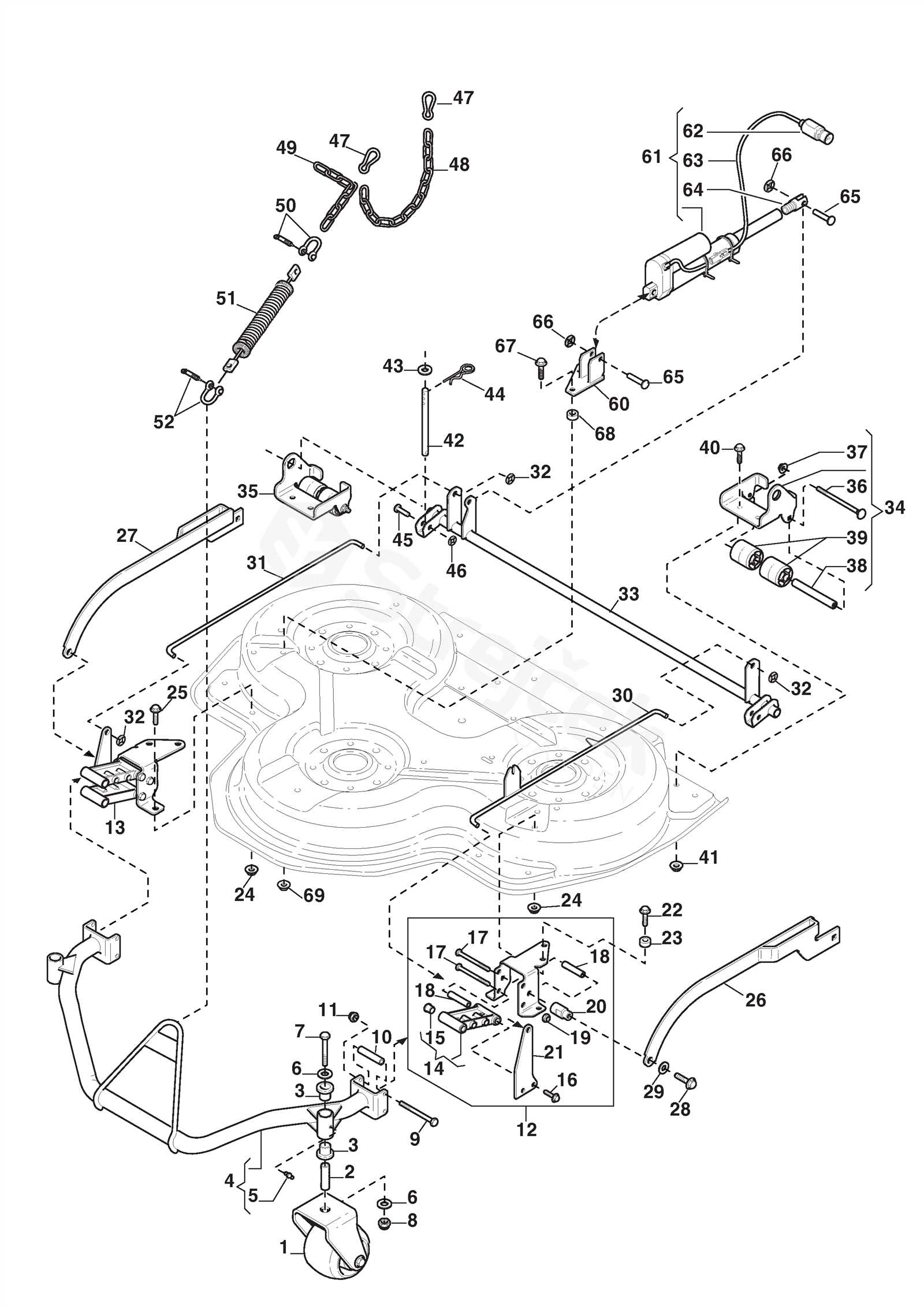

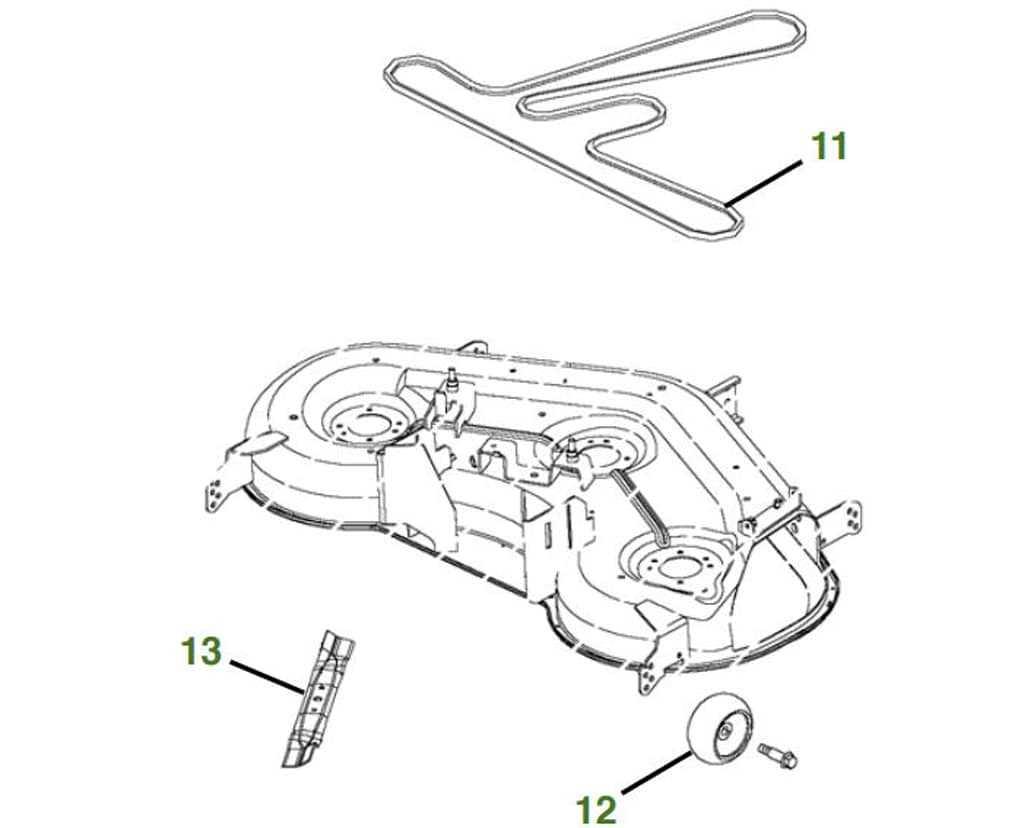

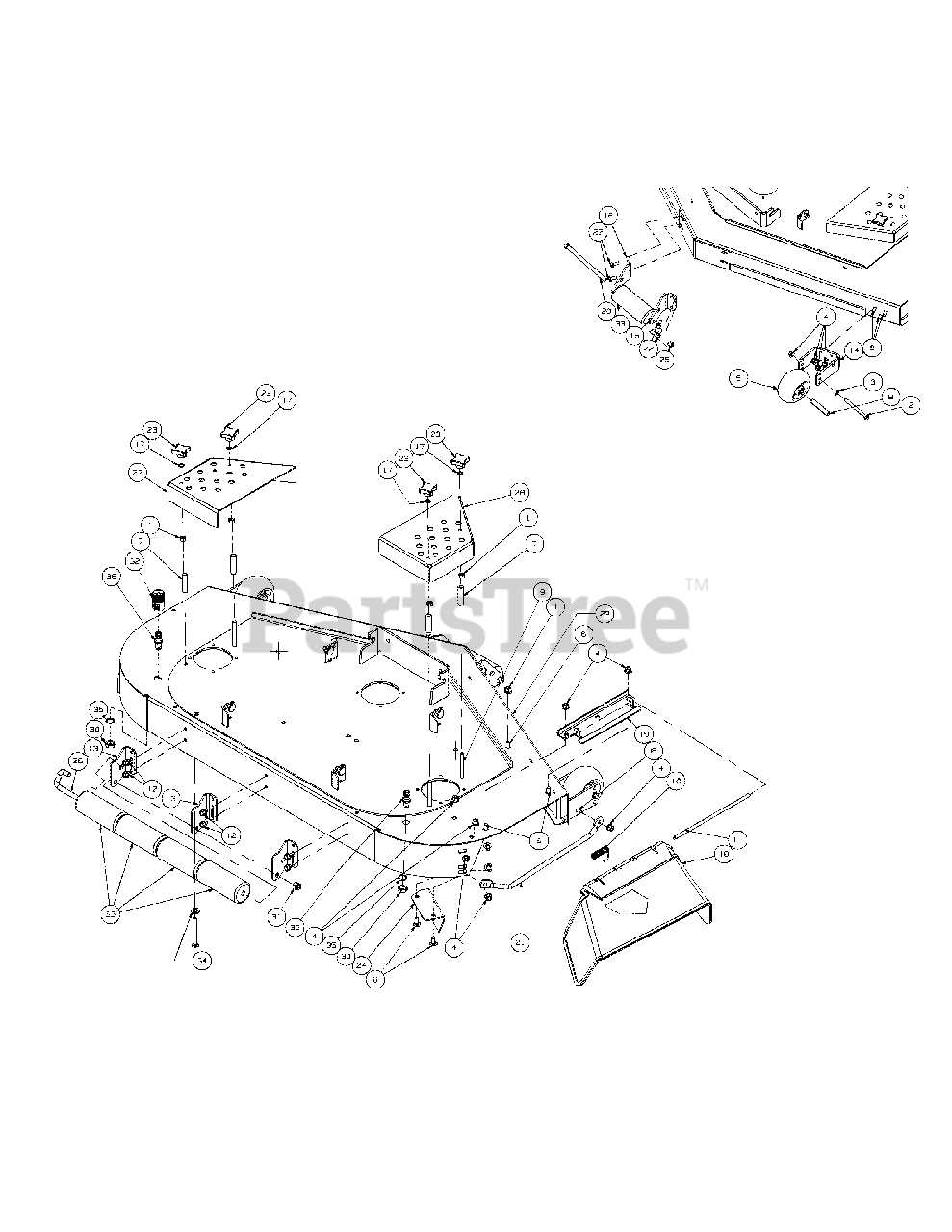

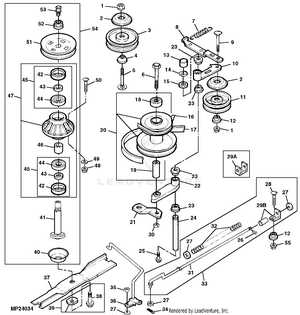

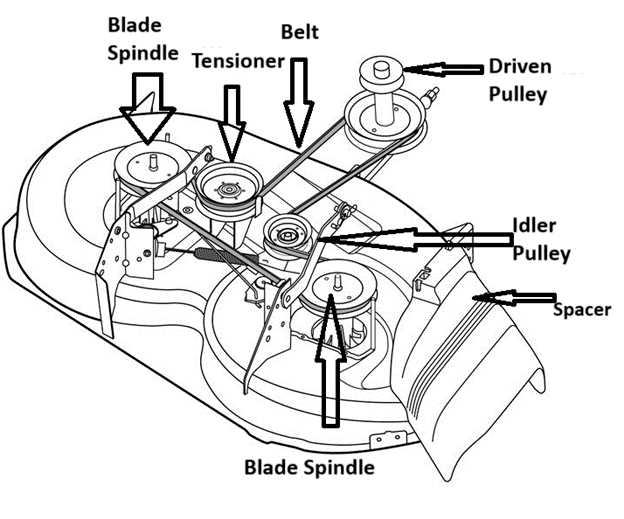

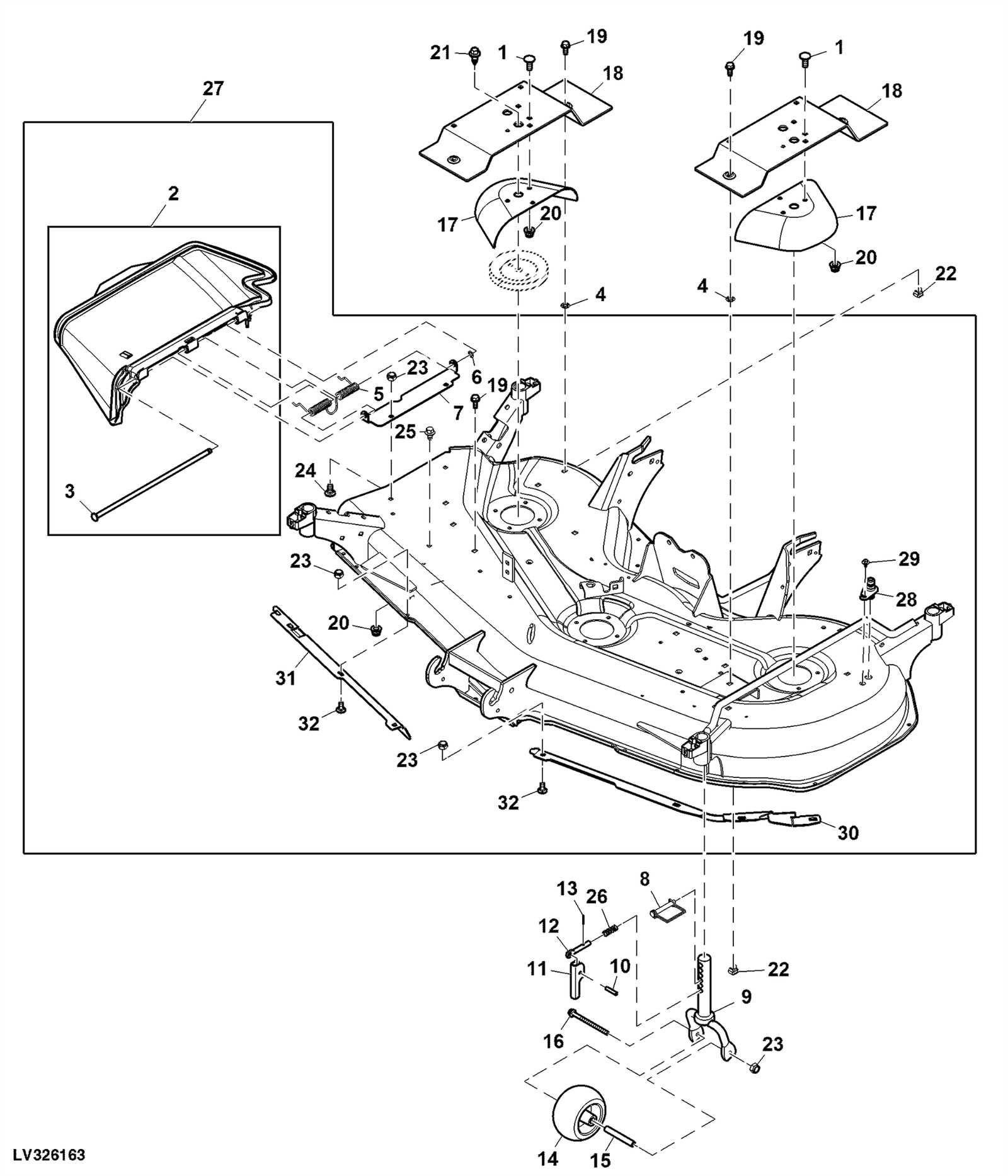

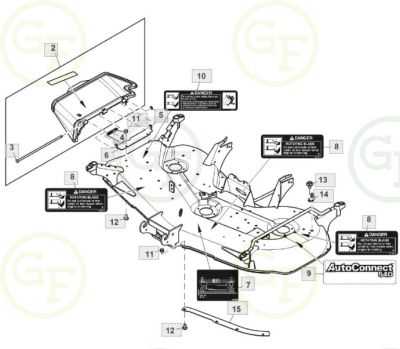

Components of the 54 Mower Deck

Understanding the essential elements that comprise this cutting apparatus is crucial for optimal performance and maintenance. Each component plays a specific role in ensuring efficiency and effectiveness during operation.

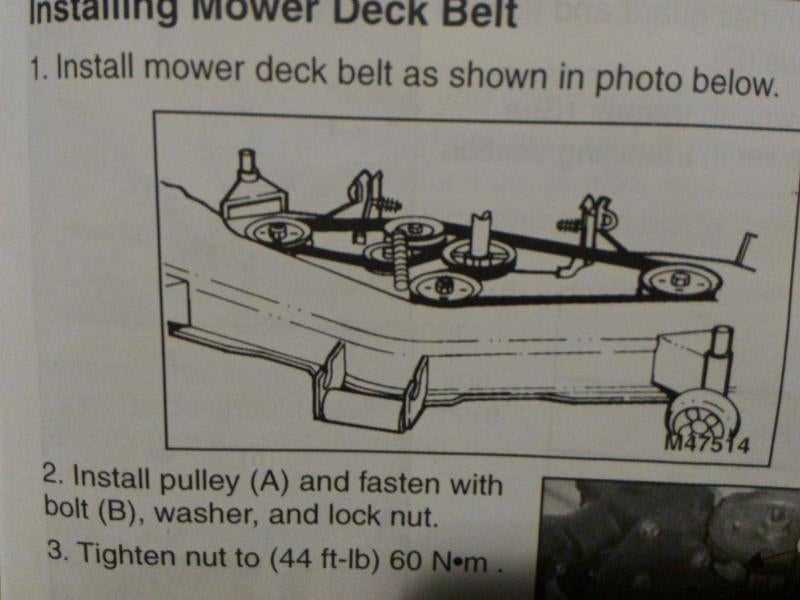

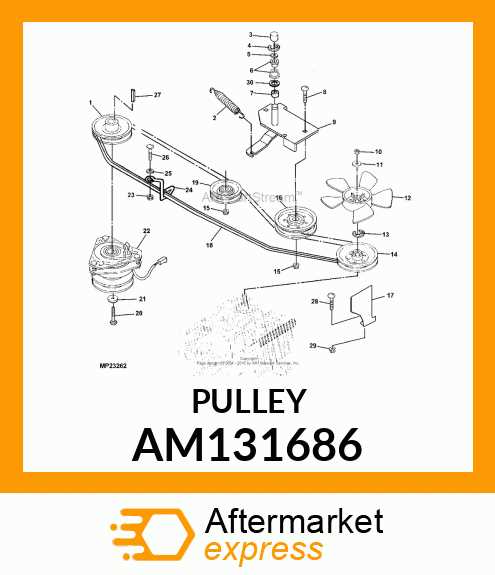

The central element is the housing, which encases various internal mechanisms. Blades are mounted within this structure, rotating at high speeds to achieve a clean cut. Additionally, pulleys and belts facilitate the transfer of power from the engine to the blades, while spindles provide stability and support. Adjusting mechanisms allow users to modify cutting height, ensuring versatility for different terrains.

Furthermore, the attachment points for the drive system and the discharge chute are integral for functionality. Regular inspection and replacement of worn components can significantly enhance longevity and performance.

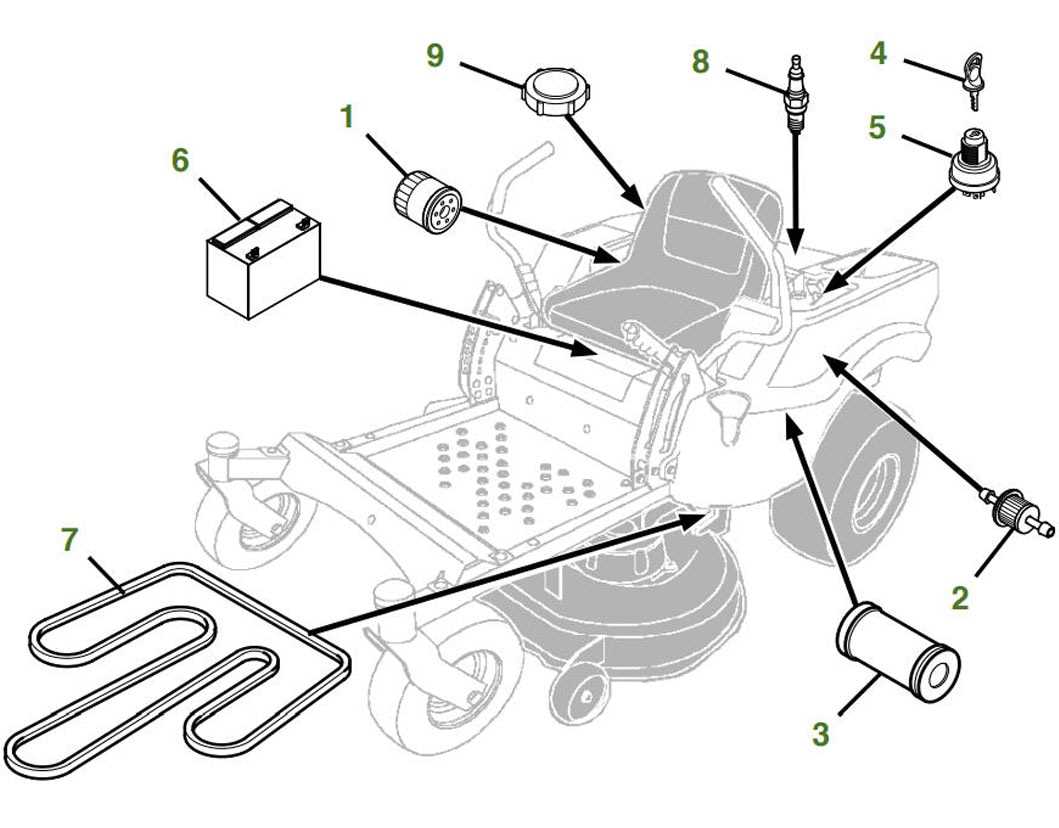

Identifying Common Issues and Repairs

Understanding frequent problems and necessary fixes is essential for maintaining the efficiency and longevity of your equipment. By recognizing signs of wear or malfunction early, you can prevent more extensive damage and costly repairs. This section outlines some typical issues encountered and provides guidance on addressing them effectively.

One common challenge is uneven cutting, which may stem from dull blades or improper height adjustments. Regularly inspecting and sharpening the cutting elements can enhance performance and ensure a consistent finish. If you notice streaks or patches, adjusting the cutting height or replacing worn components might be necessary.

Another issue often reported is excessive vibration during operation. This can indicate loose bolts or imbalanced components. Conducting a thorough inspection and tightening any loose parts can resolve this concern. In some cases, it may also be beneficial to check for bent or damaged elements that could lead to further instability.

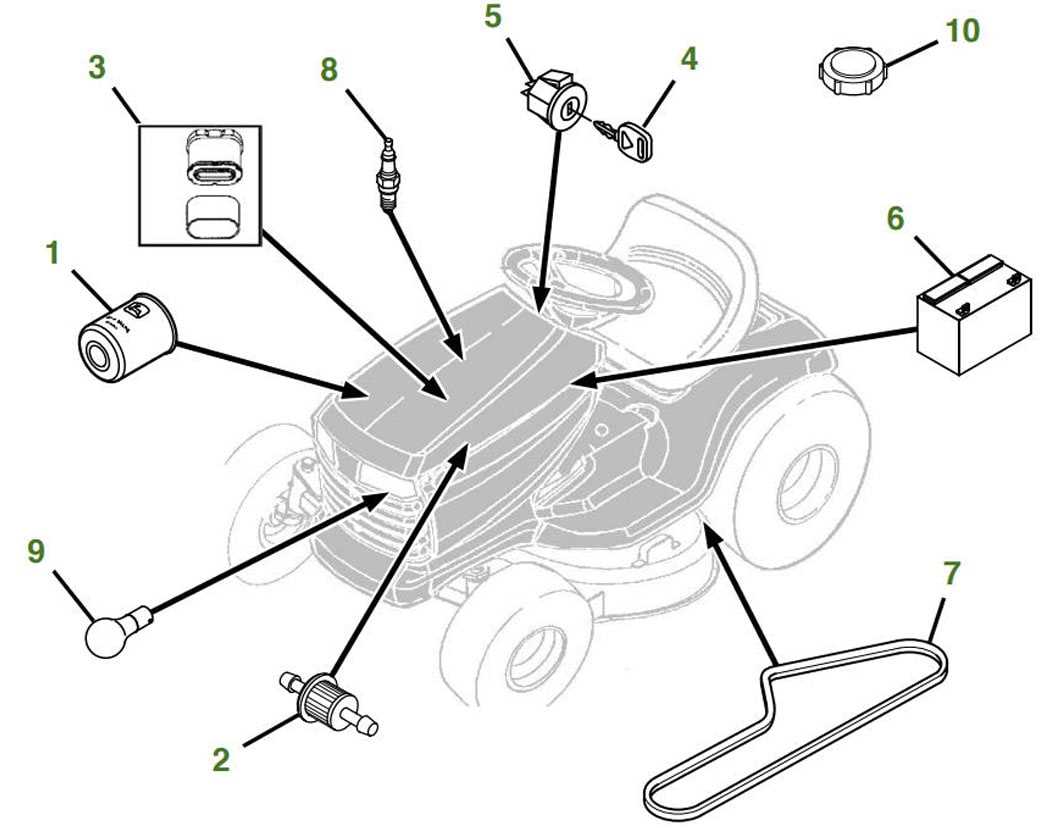

Additionally, difficulty in starting the engine is a common frustration. This problem can arise from fuel delivery issues or electrical failures. Checking fuel levels, inspecting filters, and ensuring battery connections are secure are critical first steps in troubleshooting this situation.

By staying vigilant and addressing these issues promptly, you can maintain optimal performance and extend the lifespan of your machinery. Regular maintenance and awareness of potential problems will ensure your equipment operates smoothly and efficiently.

Replacement Parts for John Deere Decks

Ensuring optimal performance of your equipment requires understanding the various components that may need replacement over time. These essential elements play a crucial role in maintaining efficiency and longevity.

When considering replacements, it’s important to identify the specific components that may wear out or become damaged. Below are common types of elements that may require attention:

- Blades: Vital for achieving a clean cut, sharp blades enhance the overall effectiveness of your machinery.

- Belts: These ensure proper power transmission; worn or frayed belts can lead to decreased performance.

- Spindles: These rotating components are critical for blade movement and require regular inspection.

- Bearings: Essential for smooth operation, bearings can wear down and lead to increased friction.

- Washers and Nuts: Small but significant, these fasteners secure various components and may need replacement to maintain integrity.

For effective maintenance, it’s advisable to keep a checklist of parts that should be monitored regularly. Regular inspections will help prevent larger issues and ensure your equipment remains in top condition.

By focusing on these components and their maintenance, users can achieve enhanced performance and durability in their machinery.

How to Access the Parts Diagram

Understanding the assembly of your equipment is essential for efficient maintenance and repair. Accessing a schematic can simplify this process, allowing you to visualize components and their connections.

Here are steps to help you reach the schematic:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Search for your model number or name.

- Look for links related to manuals or schematics.

- Select the appropriate document for your equipment.

Using these steps, you can easily locate the necessary visual aids to guide your repairs and maintenance tasks effectively.

Maintenance Tips for Mower Decks

Proper upkeep of cutting equipment is essential for optimal performance and longevity. Regular care ensures that your tool remains efficient and delivers the best results while minimizing the risk of breakdowns. Implementing a few straightforward practices can make a significant difference in maintaining functionality.

Regular Cleaning

After each use, it is crucial to remove any grass clippings, dirt, and debris. This helps prevent rust and other damage. Use a hose or scraper to clear away any buildup that can affect cutting efficiency.

Blade Maintenance

Inspect and sharpen blades regularly to ensure a clean cut. Dull blades can tear grass rather than cut it, leading to uneven growth and increased vulnerability to disease. Replace any damaged blades promptly to maintain performance.

Tools Needed for Repairs

When tackling maintenance tasks on your equipment, having the right tools at hand is essential for efficiency and effectiveness. Proper instruments not only simplify the process but also ensure safety and precision during repairs. Below is a list of recommended tools that will assist you in achieving optimal results.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts |

| Wrench Set | Useful for various nut sizes |

| Screwdriver Set | To handle screws in multiple configurations |

| Pliers | For gripping and twisting tasks |

| Torque Wrench | Ensures bolts are tightened to specifications |

| Safety Glasses | Protects your eyes during work |

| Gloves | Offers hand protection from sharp edges |

Safety Precautions When Repairing

When undertaking maintenance tasks on outdoor equipment, prioritizing safety is essential. Ensuring a secure environment not only protects the individual performing the repairs but also extends the lifespan of the machinery. Familiarizing oneself with safety protocols can prevent accidents and injuries during the process.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Work in a well-ventilated area to avoid inhaling fumes or dust.

- Ensure the equipment is turned off and disconnected from any power source before beginning repairs.

- Keep the work area organized to prevent trips and falls.

Specific Precautions

- Inspect tools for damage before use and replace any that are worn or broken.

- Be cautious of sharp edges and moving parts during disassembly and assembly.

- Follow manufacturer instructions carefully to ensure proper procedures are followed.

- Keep children and pets away from the work area to minimize distractions and potential hazards.

Comparing Different Mower Deck Models

When assessing various cutting platforms, it’s essential to understand the distinct features and specifications that differentiate them. Each model offers unique advantages tailored to specific needs and preferences, making it crucial to analyze them thoroughly before making a decision.

| Model | Cutting Width | Weight | Blade Count |

|---|---|---|---|

| Model A | 54 inches | 200 lbs | 3 |

| Model B | 60 inches | 220 lbs | 3 |

| Model C | 48 inches | 180 lbs | 2 |

Understanding these differences allows users to select the ultimate option for their specific landscape needs, ensuring efficiency and optimal performance.

Using Genuine John Deere Parts

Utilizing authentic components is essential for maintaining the performance and longevity of your equipment. These high-quality elements are designed to fit seamlessly and function optimally, ensuring that your machinery operates at its best. Investing in genuine parts can prevent frequent repairs and enhance overall efficiency.

Benefits of Authentic Components

Opting for original elements comes with numerous advantages. Firstly, they are crafted to meet strict manufacturing standards, providing reliability that aftermarket options often lack. Additionally, using these authentic items helps maintain the warranty of your machinery, safeguarding your investment over time.

Ensuring Compatibility and Performance

Authentic components are engineered specifically for your equipment, ensuring perfect compatibility. This tailored fit not only improves performance but also minimizes the risk of damage caused by improper installation or inferior quality. For optimal results and peace of mind, always choose genuine items.

Step-by-Step Repair Guide

Maintaining your equipment is essential for optimal performance and longevity. This guide provides a comprehensive approach to troubleshooting and fixing common issues, ensuring your machine operates smoothly.

1. Gather Necessary Tools: Before starting any repairs, collect all required tools. Common items include wrenches, screwdrivers, and safety gear. Having everything on hand will streamline the process.

2. Safety First: Always prioritize safety. Disconnect the power source and wear protective equipment such as gloves and goggles to prevent injuries during the repair.

3. Identify the Problem: Carefully examine the unit for any visible signs of wear or damage. Listen for unusual sounds or observe irregular performance to pinpoint the issue.

4. Consult the Manual: Reference the user manual for specific instructions related to your model. This resource can provide valuable insights into troubleshooting techniques and repair procedures.

5. Disassemble as Needed: If necessary, disassemble the components carefully. Keep track of screws and small parts by organizing them in containers to avoid losing them during the process.

6. Replace or Repair Components: Once you have access to the affected area, either replace faulty components or make necessary adjustments. Ensure you use compatible replacement items to maintain functionality.

7. Reassemble and Test: After repairs are completed, reassemble the unit methodically. Once fully reassembled, reconnect the power source and conduct a test to confirm that the issue has been resolved.

8. Regular Maintenance: To prevent future problems, implement a regular maintenance schedule. Routine checks and cleaning can significantly enhance the efficiency and lifespan of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and components of a specific lawn care tool. Here, you will find answers that can help enhance your understanding and ensure optimal performance.

General Inquiries

- What are the key components involved in the operation of this tool?

- How often should maintenance be performed to ensure longevity?

- What are the signs that indicate a need for replacement parts?

Repair and Replacement

- How do I identify the correct components for replacement?

- Are there any recommended suppliers for high-quality replacements?

- What tools are necessary for performing repairs?

Resources for Further Learning

Expanding your knowledge on maintenance equipment can greatly enhance your understanding and ability to manage various tasks. This section provides valuable resources to help you deepen your expertise and troubleshoot effectively.

Online Tutorials and Videos

- YouTube channels dedicated to garden machinery maintenance

- Webinars hosted by industry experts

- DIY blogs with step-by-step guides