Understanding Polaris RZR Front Differential Components

This section provides a comprehensive overview of the various components involved in the operation of a crucial mechanical system. By examining the intricate layout of the elements, users can gain insights into their functionality and interrelationships, enhancing overall maintenance and performance.

Through a detailed exploration, we aim to illuminate the significance of each segment within the assembly. Understanding these components not only aids in troubleshooting but also empowers enthusiasts to make informed decisions regarding upgrades and repairs, ensuring optimal functionality and longevity.

Understanding Polaris RZR Differentials

Comprehending the components and functionality of the drive mechanism is essential for optimal performance. These crucial elements play a significant role in ensuring smooth power transfer and enhancing maneuverability on various terrains. A thorough grasp of their operation can lead to improved maintenance practices and overall vehicle efficiency.

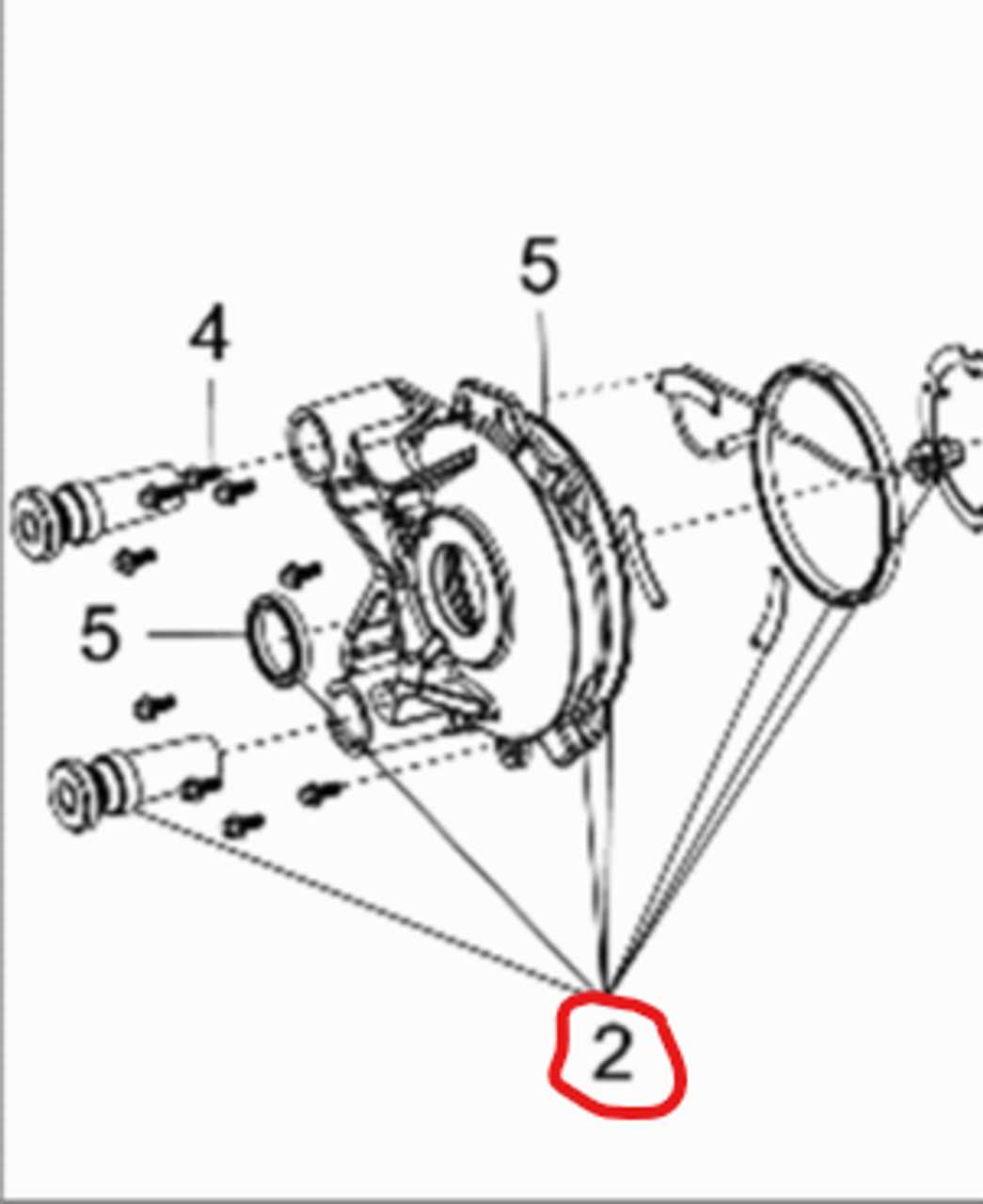

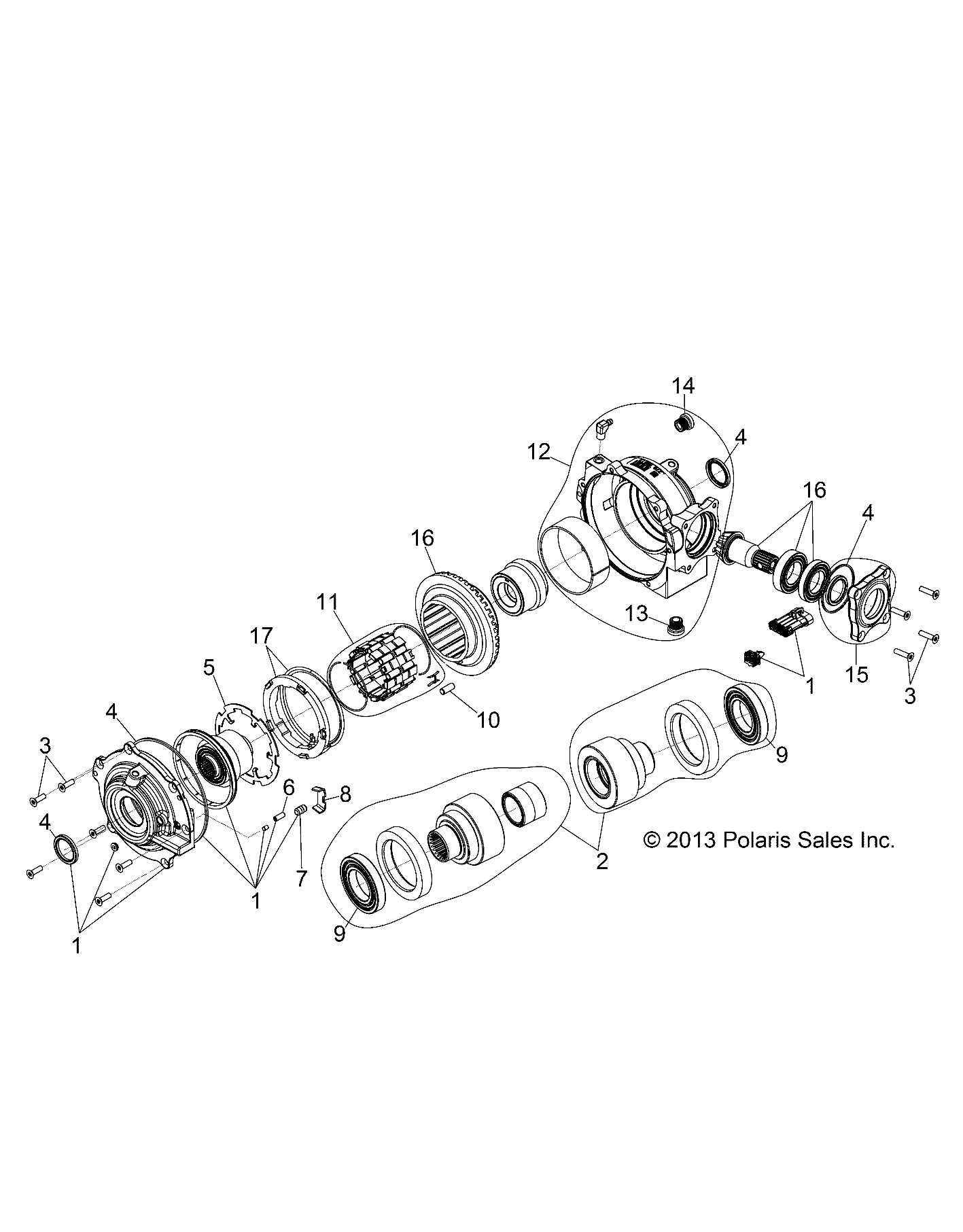

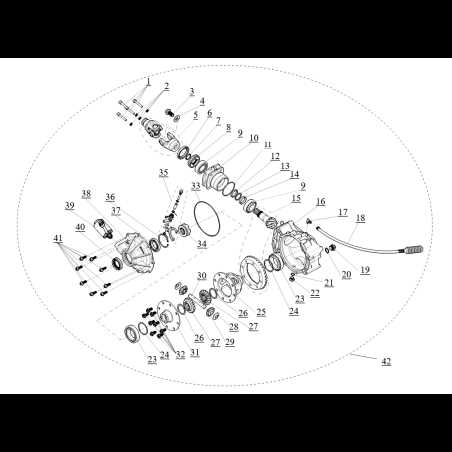

The assembly consists of multiple elements that work in harmony to distribute torque and manage traction. Each component contributes to the overall system, allowing for seamless transitions during movement. Recognizing how these parts interact can empower users to diagnose issues and make informed decisions regarding upgrades or repairs.

Regular inspection and understanding of these systems are vital for any enthusiast. By familiarizing oneself with the layout and function of each piece, one can ensure longevity and reliability. This knowledge not only aids in troubleshooting but also enhances the overall driving experience.

Key Components of the Front Differential

The effective functioning of an all-terrain vehicle’s drive system relies heavily on several essential elements within the gear mechanism. Understanding these components is crucial for maintenance and performance optimization.

Main Elements

- Housing: The structure that encases and protects the internal mechanisms.

- Gears: These are pivotal for transferring torque from the engine to the wheels, ensuring smooth motion.

- Bearings: They support the rotating parts and minimize friction, contributing to longevity.

Supporting Components

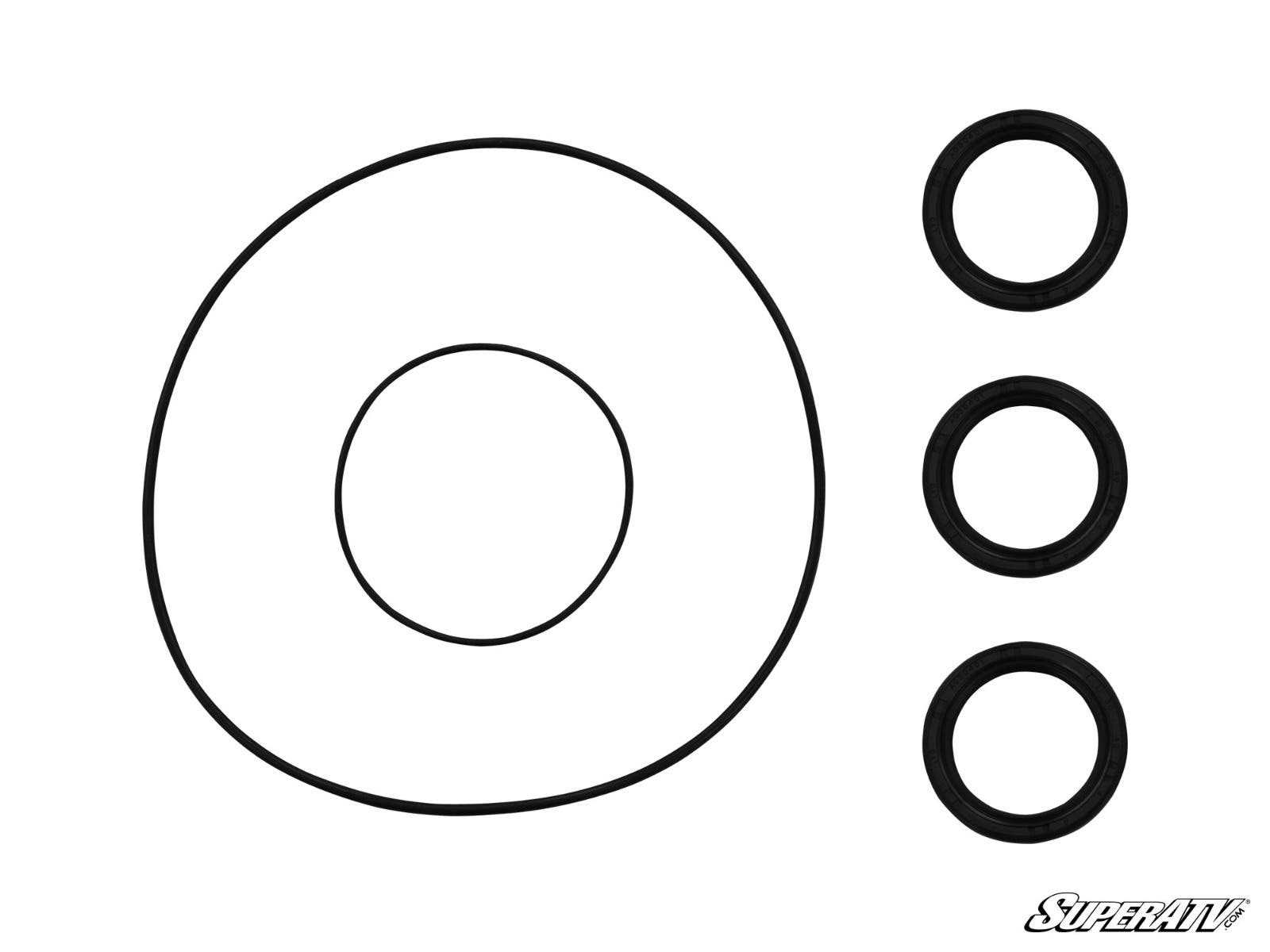

- Seals: Prevent leakage of lubricants, ensuring smooth operation.

- Shafts: Connect various elements and transmit power efficiently.

- Fluid: Lubrication is essential for reducing wear and maintaining optimal performance.

Importance of Differential Maintenance

Regular upkeep of drivetrain components is essential for optimal vehicle performance. These intricate systems ensure smooth operation and enhance the longevity of your vehicle. Proper care can prevent costly repairs and improve handling, making maintenance a critical aspect for enthusiasts and everyday users alike.

Benefits of Regular Maintenance

- Improved vehicle stability and control.

- Increased lifespan of mechanical components.

- Enhanced fuel efficiency and performance.

- Reduced risk of unexpected breakdowns.

Key Maintenance Practices

- Regularly inspect fluid levels and replace when necessary.

- Check for signs of wear or damage in surrounding components.

- Perform routine cleaning to prevent debris accumulation.

- Follow manufacturer guidelines for service intervals.

Common Issues with Front Differentials

Many vehicles experience various challenges with their power distribution systems, which can lead to reduced performance and potential damage. Understanding these issues is crucial for effective maintenance and repair.

Noise and Vibration: Unusual sounds or vibrations during operation may indicate wear or damage in the internal components. This can be caused by improper lubrication or misalignment.

Fluid Leaks: Leaks from seals or gaskets can result in a loss of essential lubricants, leading to overheating and premature wear of internal parts. Regular inspection can help identify these leaks early.

Overheating: Excessive heat may stem from insufficient lubrication or overloading. Monitoring temperature levels can prevent severe damage to the system.

Inconsistent Power Distribution: Uneven power delivery can result in handling issues, making the vehicle difficult to control. This can often be traced back to worn gears or bearings.

Wear and Tear: Continuous use can lead to degradation of components. Regular maintenance checks can help prolong the lifespan of the entire system.

How to Diagnose Differential Problems

Identifying issues within the drive mechanism is crucial for maintaining optimal performance. A well-functioning assembly ensures smooth operation, while any malfunction can lead to significant challenges in vehicle handling and power distribution.

Listen for Unusual Noises: Pay attention to any strange sounds such as grinding or whining when the vehicle is in motion. These noises often indicate internal wear or damage.

Check for Fluid Leaks: Inspect the area around the assembly for any signs of fluid leakage. Low levels of lubricant can lead to overheating and increased friction, causing further damage.

Monitor Performance: Observe how the vehicle handles during turns and acceleration. Any unusual vibrations or loss of traction may suggest issues within the power distribution system.

Inspect for Play: Examine the connection points for any excessive movement. Worn or damaged components can lead to improper alignment and functionality.

Upgrading Your RZR Differential Parts

Enhancing the components of your vehicle’s drivetrain can significantly improve its performance and durability. By selecting high-quality alternatives, you can achieve better traction and handling, making your rides more enjoyable. This section delves into the benefits of upgrading your drivetrain components and the key features to consider when making selections.

Benefits of Enhanced Components

Upgrading essential components often leads to improved power transfer and reduced wear. Enhanced materials can withstand greater stress, ensuring your vehicle operates efficiently even in challenging conditions. Furthermore, the right upgrades can enhance your vehicle’s response to steering inputs, providing a more engaging driving experience.

Key Features to Consider

When selecting new components, consider compatibility with your vehicle’s existing systems, as well as the material strength and design. Look for products that offer a balance between weight and durability. Investing in quality components not only boosts performance but also extends the lifespan of your drivetrain, ensuring reliability during every adventure.

Step-by-Step Repair Process

This section outlines a comprehensive approach to repairing the critical components of an all-terrain vehicle’s drivetrain system. Following these steps can help ensure proper functionality and longevity of the system while maintaining safety standards.

Preparation and Safety Measures

Before commencing any repair work, it’s essential to gather the necessary tools and ensure a safe working environment. This includes wearing appropriate safety gear and having a well-lit area to perform the task.

Disassembly of the Assembly

Begin by carefully removing any covers or guards that protect the components. Make sure to document the order of disassembly, as this will aid in reassembly later. Use the appropriate tools to avoid damaging any parts during this process.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and equipment. |

| 2 | Wear safety gear before starting. |

| 3 | Remove protective covers carefully. |

| 4 | Document the disassembly order. |

Tools Needed for Differential Repairs

Proper maintenance of gear assemblies requires a specific set of tools to ensure effective repairs and adjustments. Having the right instruments not only facilitates the process but also enhances the safety and accuracy of the work being performed.

Here are some essential tools to consider:

- Socket Set: A comprehensive socket set is crucial for loosening and tightening fasteners.

- Wrench Set: Various sizes of wrenches help access hard-to-reach areas and provide the leverage needed.

- Torque Wrench: Ensures that all bolts are tightened to the manufacturer’s specifications.

- Pry Bar: Useful for separating components and applying force where necessary.

- Gasket Scraper: Helps in removing old gaskets without damaging surfaces.

- Fluid Catch Pan: Essential for managing any fluids that may leak during repairs.

Additionally, safety equipment such as gloves and goggles should be worn to protect against potential hazards during the repair process.

Tips for Enhancing Performance

Improving the efficiency and functionality of your all-terrain vehicle can significantly elevate your overall experience. By focusing on several key areas, you can optimize performance and ensure smoother rides across various terrains.

Regular Maintenance

Consistent upkeep is crucial for any machine. Regularly checking and replacing essential components will prevent wear and tear, ensuring that your vehicle operates at its peak. Focus on lubrication, alignment, and overall cleanliness to maintain optimal performance.

Upgraded Components

Investing in enhanced accessories and upgrades can lead to noticeable improvements. Consider high-performance parts that can elevate power delivery and handling. Carefully select modifications that complement your vehicle’s capabilities and enhance its agility.

Preventative Measures for Longevity

Ensuring the extended lifespan of crucial mechanical components involves implementing effective maintenance strategies. By adopting proactive practices, users can minimize wear and tear, enhance performance, and reduce the likelihood of costly repairs.

Regular inspections play a vital role in identifying potential issues before they escalate. Additionally, utilizing high-quality lubricants and fluids is essential for optimal function and protection against friction and corrosion. Following the manufacturer’s guidelines for service intervals will further contribute to the durability of these systems.

| Maintenance Activity | Recommended Frequency | Benefits |

|---|---|---|

| Fluid Replacement | Every 100 hours | Prevents degradation and ensures smooth operation |

| Inspection of Seals | Every 50 hours | Identifies leaks and maintains integrity |

| Visual Check of Components | Before each use | Detects wear and potential failures early |

Resources for Polaris RZR Owners

For enthusiasts of off-road vehicles, having access to reliable information and resources is essential for maintenance and upgrades. This section provides various avenues where owners can find valuable insights, tips, and parts to enhance their driving experience.

Online Communities and Forums

Joining online platforms dedicated to enthusiasts can be immensely helpful. These forums offer a space for sharing experiences, troubleshooting issues, and discussing modifications. Members often share tips, recommendations for aftermarket components, and solutions to common challenges faced during maintenance.

Manufacturer and Retailer Support

Many manufacturers provide detailed guides and support materials on their websites. Additionally, reputable retailers often have resources such as installation guides, how-to videos, and customer reviews. Utilizing these resources can greatly assist in ensuring that all upgrades and repairs are performed correctly.