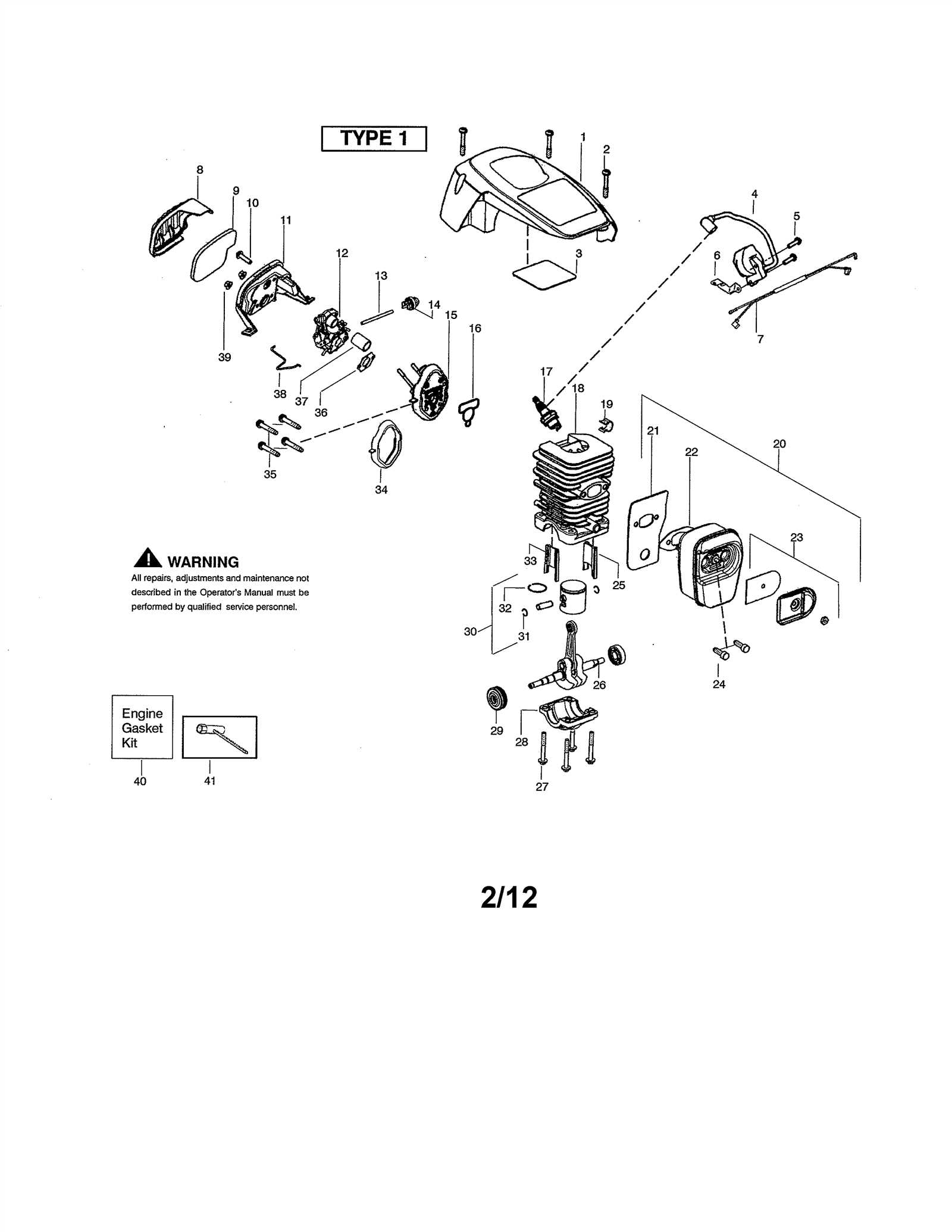

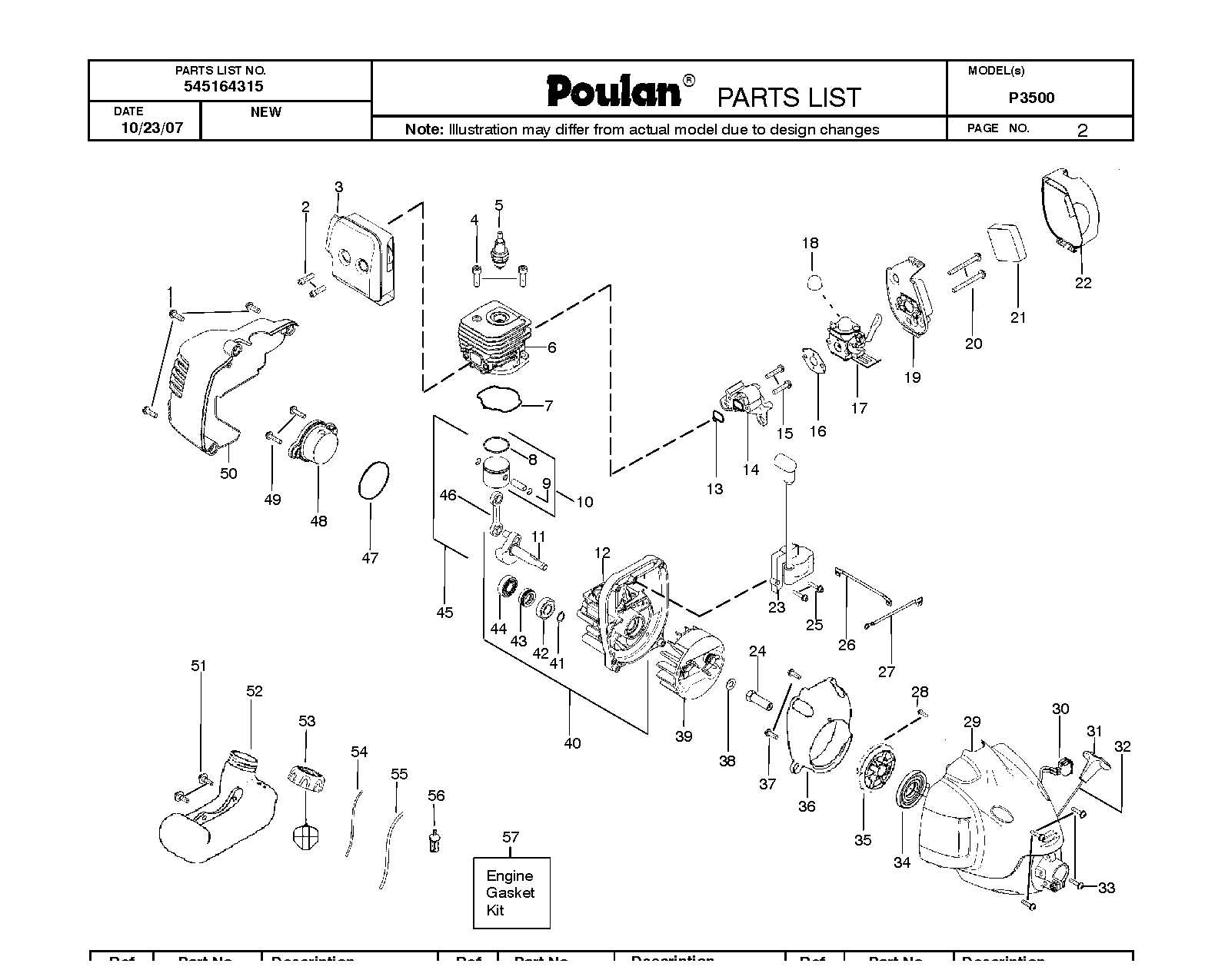

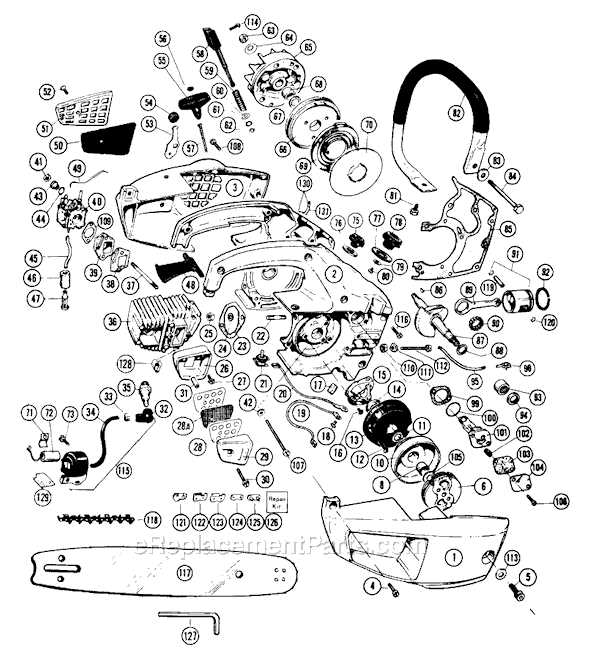

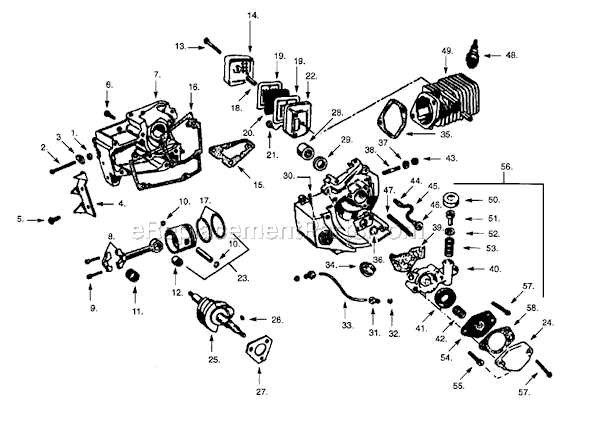

Poulan Chainsaw Parts Breakdown

Understanding the internal structure and various elements of outdoor cutting equipment can significantly enhance its performance and longevity. By familiarizing yourself with how individual mechanisms operate and interact, you can maintain your tool more effectively and troubleshoot issues with greater ease.

Each mechanical element plays a crucial role in the overall functionality of the equipment, from powering the device to ensuring precise and safe operation. Whether you’re looking to maintain or repair your device, knowing the function of each component is key to keeping it in optimal condition.

Proper maintenance and timely replacements of essential elements not only extend the lifespan of your tool but also improve its efficiency and reliability. In this guide, we will explore the various elements of outdoor cutting equipment and how they contribute to the machine’s smooth operation.

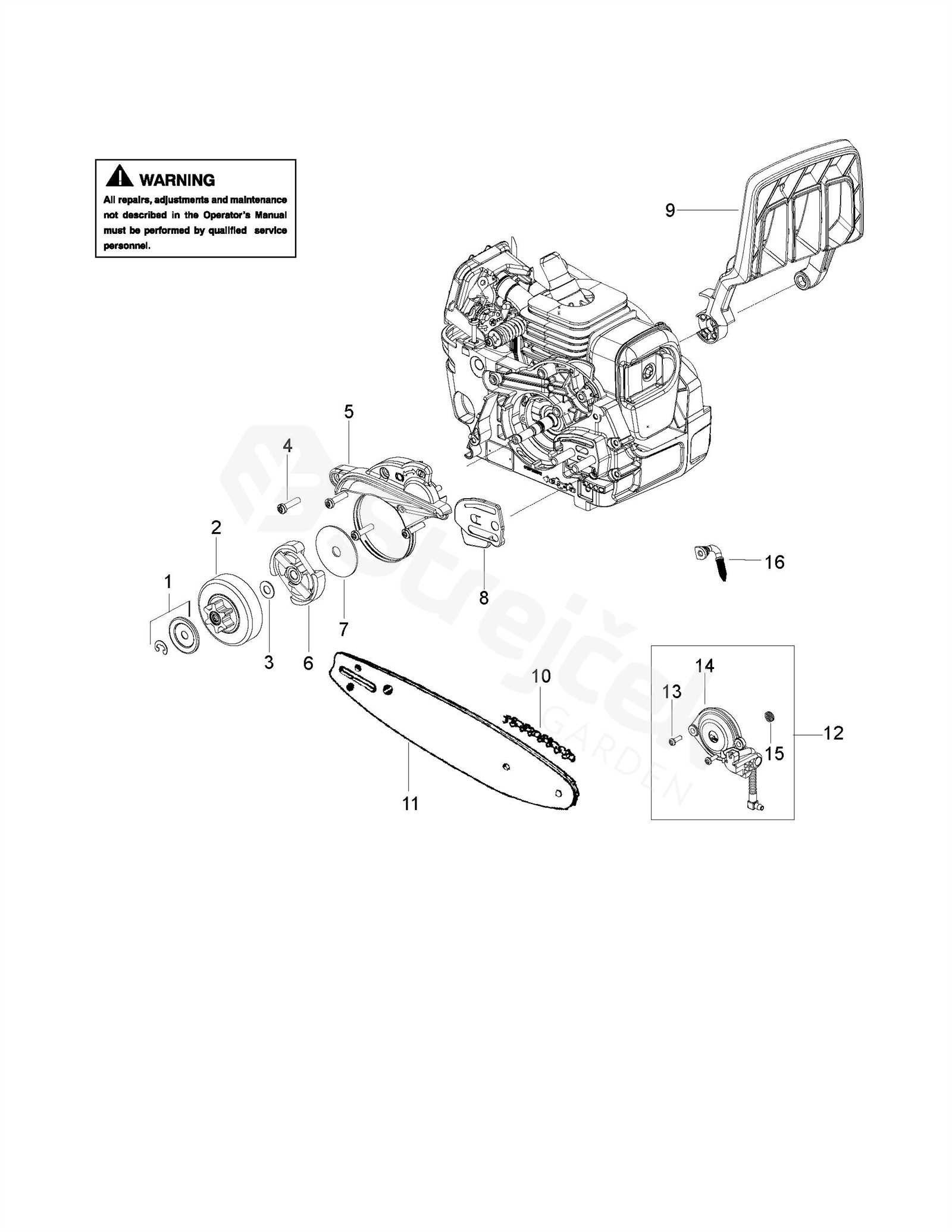

Poulan Chainsaw Component Overview

Understanding the essential elements of this tool is key to its effective use and maintenance. These devices are made up of several crucial mechanisms that work together to ensure smooth operation and precise cutting. By identifying the core functions of each section, users can better manage their equipment, ensuring longevity and reliability.

Power source plays a central role in delivering the necessary energy for operation. Whether fueled by gasoline or electricity, this component directly affects performance and efficiency.

The cutting mechanism is the primary feature responsible for the device’s intended task. It consists of multiple parts working in tandem to deliver clean, efficient cuts.

Identifying Key Chainsaw Mechanisms

Understanding the vital components within a cutting tool is crucial for efficient operation and maintenance. By recognizing the primary mechanisms, users can ensure smooth functionality, extend the tool’s lifespan, and address potential issues effectively.

Main Power Drive

The main drive is responsible for transferring power from the engine to the cutting chain. It includes a combination of gears, clutches, and the drive sprocket, which work together to maintain the chain’s rotation speed and tension.

Cutting System

The cutting system encompasses the bar and chain assembly. This system is designed to handle high-speed cutting with precision, allowing users to work through various materials with minimal resistance. Proper alignment and tension are essential for optimal performance.

| Mechanism | Function |

|---|---|

| Engine Drive | Delivers power to the chain |

| Clutch | Regulates chain speed |

| Bar and Chain | Performs the cutting action |

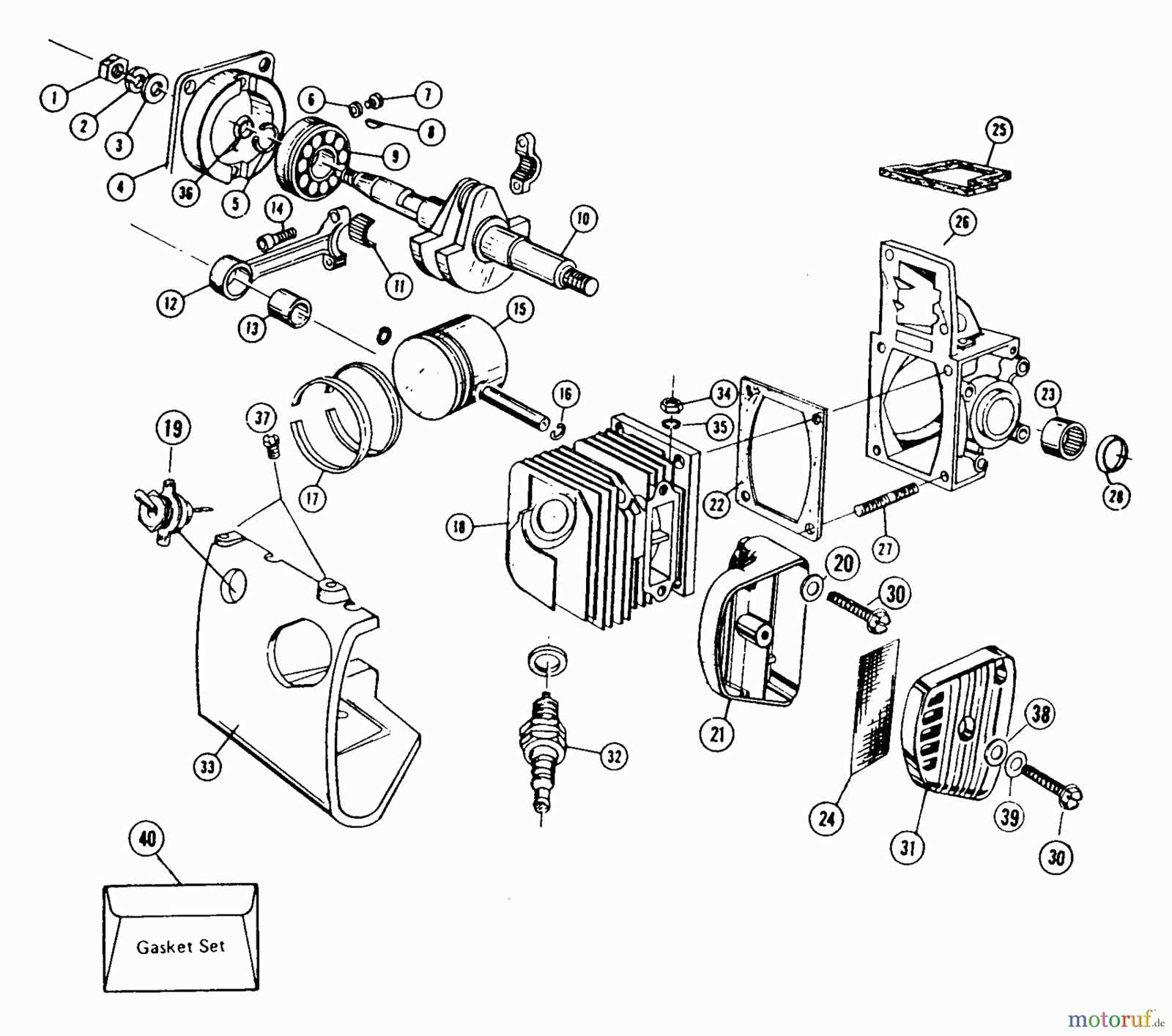

Guide to Engine Parts and Functions

The core of any mechanical tool lies in its engine, which is composed of multiple interconnected elements. Each component serves a distinct role, working together to generate power and ensure smooth operation. Understanding these elements is essential for proper maintenance and effective troubleshooting.

Core Components of the Engine

Key components include the combustion chamber, the cylinder, and the crankshaft. The combustion chamber is where fuel ignites, creating the necessary energy. The cylinder houses the piston, which moves due to the force of combustion, and the crankshaft converts this movement into rotational energy.

Supporting Elements and Their Roles

Beyond the main components, several supporting parts contribute to engine efficiency. These include the cooling system, which prevents overheating, and the lubrication system, which ensures that moving parts function smoothly with minimal friction. Together, these systems protect the engine and enhance performance.

Essential Chainsaw Cutting Components

To ensure optimal performance and precise cutting, several key elements work together within the tool’s structure. These components must be well-maintained and properly aligned for efficient operation, providing stability and strength during even the most demanding tasks.

Guide Bar

The guide bar directs the movement of the cutting chain, ensuring smooth operation and consistent performance. It serves as the frame on which the cutting action is performed, and its length and condition can greatly impact the precision and speed of cutting.

Cutting Chain

The cutting chain, made up of interconnected teeth, does the primary work of slicing through material. Each tooth is designed to chip away at the surface, and its sharpness and tension are critical for clean and accurate cuts. Regular maintenance, including sharpening and tension adjustment, helps maintain its efficiency.

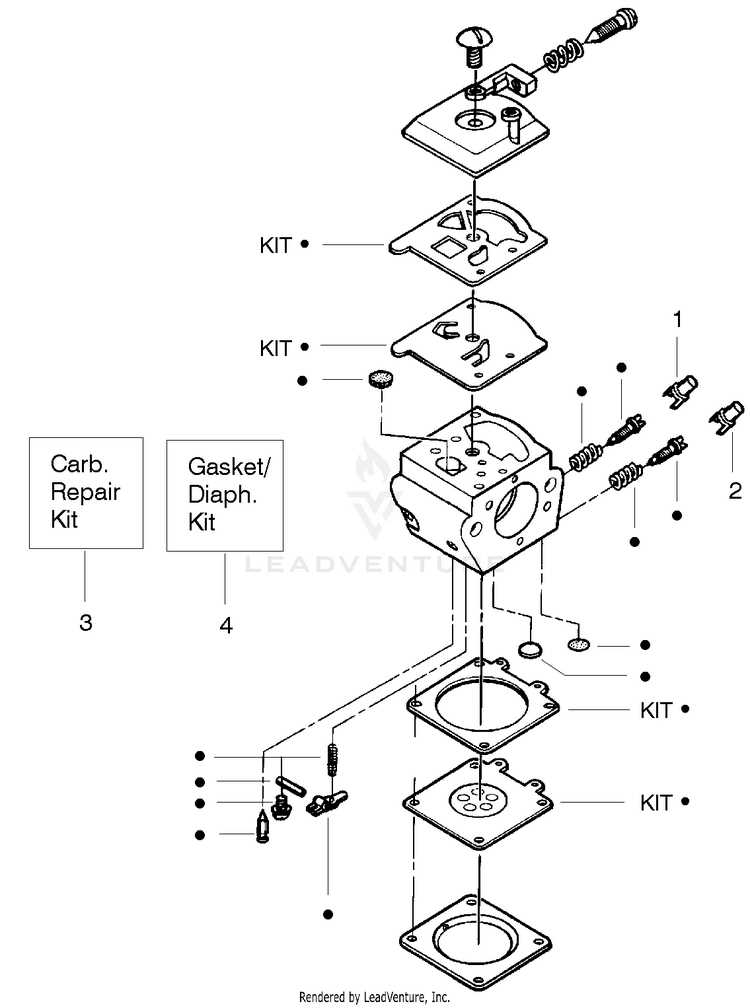

Understanding the Fuel and Air Systems

The performance of any small engine relies on the precise balance between the fuel and air systems. These two elements work together to ensure efficient combustion, which powers the machine. The key to maintaining smooth operation is understanding how these systems interact and how various components regulate this critical balance.

Fuel Delivery Mechanism

The fuel system is designed to provide the engine with the correct amount of fuel, whether during idle or heavy operation. This involves the use of a carburetor, which mixes fuel with air before it enters the combustion chamber. A properly tuned fuel system ensures that the mixture is neither too rich nor too lean, allowing for optimal performance and fuel efficiency.

Airflow Regulation

Equally important is the air system, which controls the flow of oxygen needed for combustion. Filters are employed to prevent debris from entering the engine, and air intake valves regulate how much air is mixed with the fuel. Regular maintenance of these components is essential to avoid blockages and ensure that the engine breathes freely.

Chainsaw Ignition System Breakdown

The ignition mechanism is a crucial element in the operation of any cutting tool, ensuring that the engine starts efficiently and runs smoothly. Understanding its components and functions can significantly enhance maintenance and troubleshooting processes.

Key Components of the Ignition Mechanism

At the heart of the ignition system are several vital parts that work together to create the spark necessary for combustion. These include the spark plug, ignition coil, and various wiring connections that facilitate electrical flow. Each component plays a distinct role in generating and delivering the spark, making their proper function essential for optimal performance.

Functionality and Maintenance

Regular inspection and maintenance of the ignition assembly can prevent common issues, such as starting difficulties and engine misfires. Ensuring that connections are secure, replacing worn-out components, and cleaning the spark plug can prolong the life of the tool and maintain its efficiency.

| Component | Function |

|---|---|

| Ignition Coil | Transforms low voltage to high voltage for spark generation |

| Spark Plug | Ignites the fuel-air mixture within the combustion chamber |

| Wiring Harness | Connects electrical components, ensuring proper signal transmission |

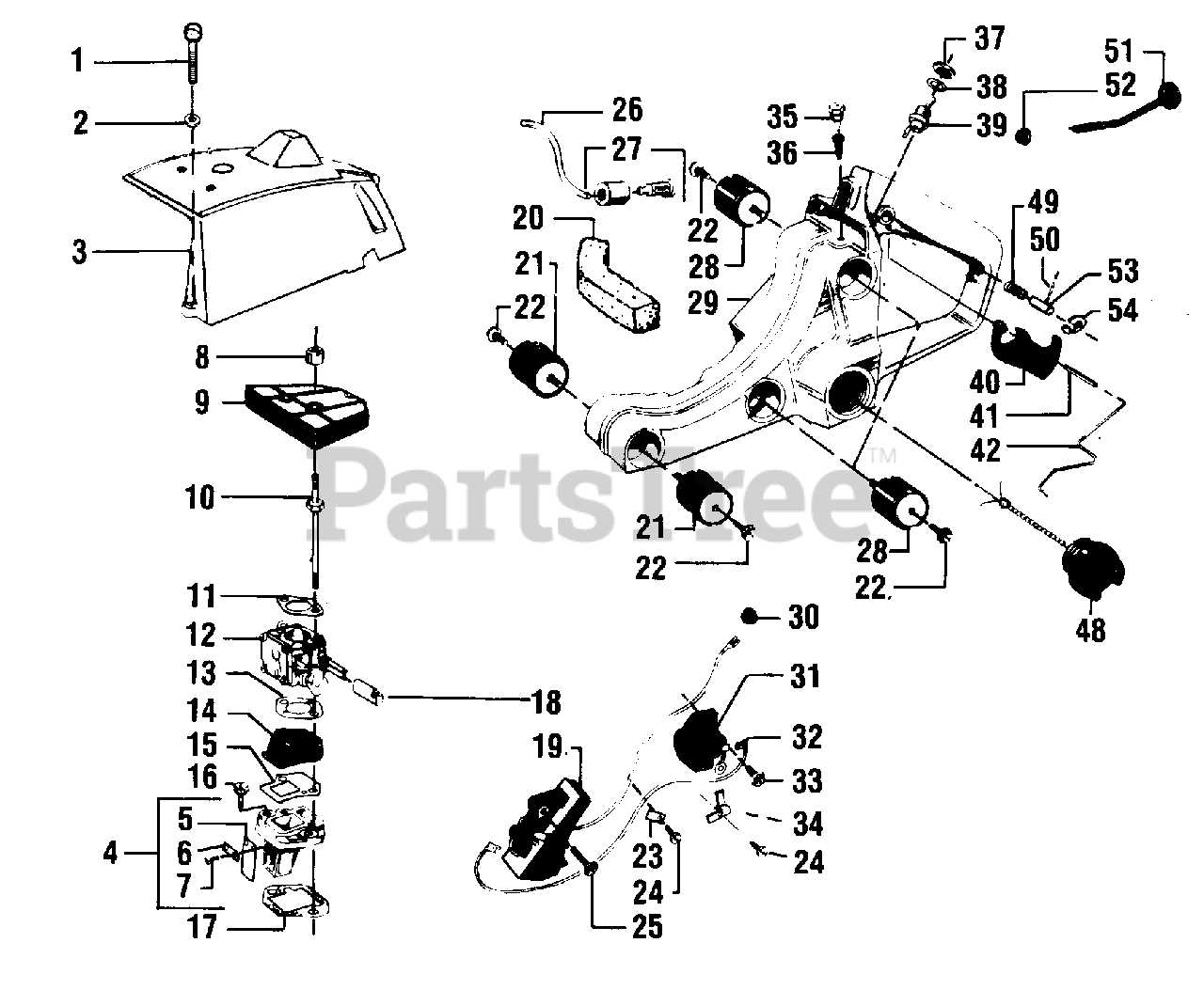

Handle and Trigger Assembly Insights

The handle and trigger assembly plays a crucial role in the functionality of a cutting tool, ensuring user control and safety. This section delves into the components and mechanics involved in this assembly, shedding light on its importance in overall operation.

Understanding the Mechanism: The assembly typically comprises a grip and a trigger mechanism that allows for precise operation. The design ensures that the user can easily manipulate the tool while maintaining a firm hold, which is essential for effective handling.

Key Components: Within this assembly, several key elements work in harmony. The trigger serves as the primary control point, regulating the activation of the tool. Additionally, safety features are often integrated to prevent accidental activation, enhancing overall user security.

Conclusion: A thorough comprehension of the handle and trigger assembly not only aids in maintenance and repairs but also contributes to safer and more efficient operation. Understanding these components is vital for anyone seeking to optimize the performance of their cutting equipment.

Detailed Look at Safety Features

Understanding the various safety mechanisms in power cutting tools is essential for ensuring user protection during operation. These features are designed to minimize risks associated with the use of high-powered machinery, making them safer for both experienced users and beginners.

One of the key elements of these devices is the chain brake, which is activated in case of sudden movement or kickback. This mechanism instantly stops the chain, preventing potential injuries. Additionally, ergonomic handles contribute to a secure grip, reducing the chances of slippage while cutting. Another important aspect is the throttle lock, which prevents accidental acceleration, allowing for controlled operation.

Moreover, many tools are equipped with protective guards that shield users from debris and moving parts, enhancing safety during use. Regular maintenance and adherence to operational guidelines also play a critical role in maximizing the effectiveness of these safety features, ensuring that the equipment operates smoothly and safely throughout its lifespan.

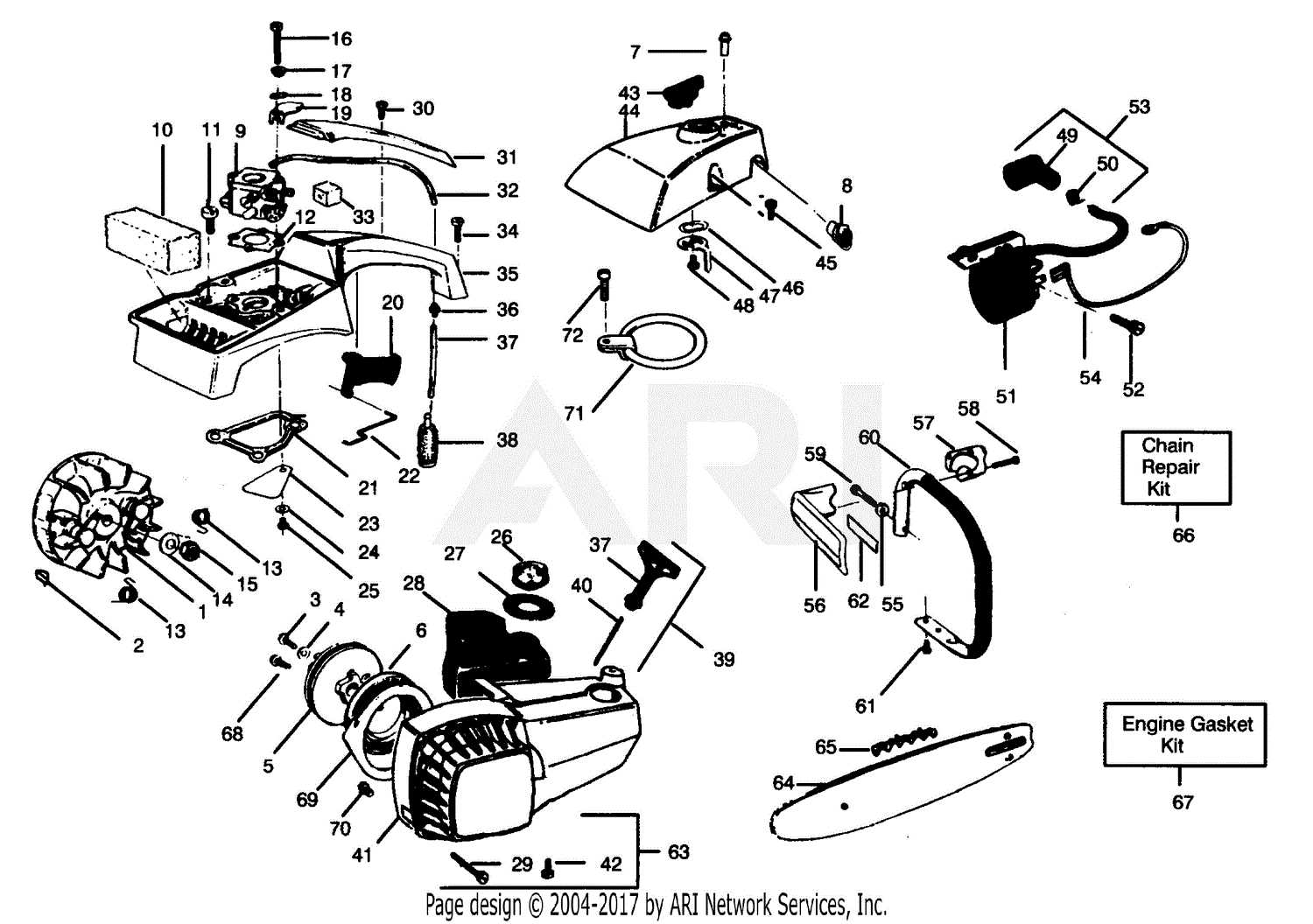

Understanding Chainsaw Lubrication Parts

Effective lubrication is crucial for the longevity and performance of any cutting tool. It helps minimize friction between moving components, ensuring smooth operation and reducing wear and tear. By understanding the various elements involved in the lubrication system, users can better maintain their equipment and enhance its efficiency.

The primary components of the lubrication system typically include a reservoir, pump, and delivery mechanism. The reservoir stores the oil, while the pump distributes it to the necessary areas, ensuring that vital components receive adequate lubrication. This process not only keeps the tool running smoothly but also prevents overheating and damage due to insufficient lubrication.

Regular maintenance of the lubrication system is essential for optimal performance. Users should routinely check oil levels, inspect hoses for any signs of wear, and ensure that the pump is functioning correctly. By paying attention to these elements, operators can significantly extend the lifespan of their cutting equipment and maintain its reliability during use.

Guide to Chainsaw Chain and Bar

Understanding the components that contribute to cutting efficiency is crucial for anyone working with power tools. The elements responsible for the cutting action are pivotal for achieving optimal performance. Knowing their characteristics and functionalities will help in selecting the right combinations for specific tasks.

Understanding the Cutting Mechanism

The cutting mechanism consists of a bar and a series of linked segments. Each segment plays a significant role in slicing through various materials. The interplay between the length of the bar and the design of the links affects the overall cutting speed and precision. Proper alignment and maintenance of these elements are essential for effective operation.

Choosing the Right Components

Selecting appropriate segments and bars depends on the intended usage. Factors such as the type of material being cut, the size of the project, and the desired finish should guide your choices. Regular inspection and timely replacement of worn parts will ensure sustained efficiency and safety during operation.

Common Replacement Parts Explained

In the realm of outdoor power equipment, understanding the essential components that may require replacement is crucial for maintaining optimal performance. Various elements work together to ensure efficiency and safety during operation. Knowing what these components are and how they function can aid in timely replacements, ultimately prolonging the life of the tool.

Key components include the cutting edge, which is responsible for the actual cutting action, and the power source, providing the necessary energy for operation. Additionally, components such as the guide system and drive mechanisms play a significant role in the functionality and control of the equipment. Regular maintenance and timely replacement of these elements can prevent larger issues and enhance overall effectiveness.

Troubleshooting Chainsaw Parts Issues

Understanding common challenges related to the components of cutting equipment is essential for maintaining optimal performance. Various issues can arise, often stemming from wear, improper maintenance, or incorrect assembly. By identifying these problems early, users can enhance the longevity and efficiency of their devices.

One frequent concern is the failure of the ignition system, which can lead to starting difficulties. Checking the spark plug for wear and ensuring proper connections can often resolve this issue. Additionally, fuel delivery problems can arise from clogged filters or damaged lines, impacting the overall functionality. Regular inspection and cleaning of these components can prevent significant disruptions.

Another area to examine is the cutting mechanism. Dull or damaged blades can hinder performance and result in uneven cuts. Sharpening or replacing the blades as needed ensures smooth operation. Furthermore, loose or misaligned components may create vibrations and decrease effectiveness, making it crucial to verify that everything is properly secured and aligned.