Understanding the John Deere 261 Grooming Mower Parts Diagram

When it comes to maintaining lush and well-groomed landscapes, a reliable and efficient machine is essential. This particular model offers an array of features designed to enhance performance and ensure optimal results in lawn care. Familiarity with its internal workings can significantly impact maintenance and repair, ultimately prolonging the lifespan of the equipment.

To effectively navigate the complexities of this essential tool, it’s important to delve into the various elements that make up its design. Each component plays a critical role in the overall functionality, contributing to smooth operation and efficiency. A comprehensive understanding of these elements not only aids in troubleshooting but also empowers users to conduct timely upkeep.

In this guide, we will explore a detailed visual representation of the machine’s assembly, highlighting key components and their respective functions. This resource aims to provide clarity and enhance your expertise, making it easier to tackle maintenance tasks with confidence.

Understanding the John Deere 261 Mower

This section aims to explore the intricacies of a well-regarded landscaping tool designed for precision cutting. With a focus on functionality and efficiency, the equipment plays a pivotal role in maintaining pristine outdoor spaces.

Key Features

The machine boasts several notable attributes, including durability, ease of use, and adaptability to various terrains. These qualities make it an ultimate choice for both professional landscapers and avid gardeners.

Maintenance Essentials

Key Features of the 261 Model

This model stands out due to its advanced engineering and practical design, tailored for efficient performance in various landscaping tasks. Its thoughtful construction ensures optimal results, making it a favorite among professionals and enthusiasts alike.

Efficient Cutting Performance

The cutting system is engineered to provide a precise and uniform finish, allowing for quick and effective trimming. This feature not only enhances aesthetic appeal but also promotes healthy growth of the grass.

User-Friendly Design

Equipped with intuitive controls and ergonomic features, this model facilitates easy operation. The streamlined design minimizes operator fatigue, ensuring a comfortable experience even during prolonged use.

Importance of Grooming Mowers

These specialized machines play a vital role in maintaining healthy and aesthetically pleasing landscapes. Their efficiency not only enhances the visual appeal of outdoor spaces but also promotes the well-being of grass and other plants.

Key Benefits

- Ensures uniform cutting for a polished look.

- Promotes healthier turf growth by reducing stress on plants.

- Facilitates better air and water penetration into the soil.

- Reduces the occurrence of pests and diseases.

Applications

- Public parks and recreational areas.

- Private estates and gardens.

- Golf courses and sports fields.

- Commercial landscapes and green spaces.

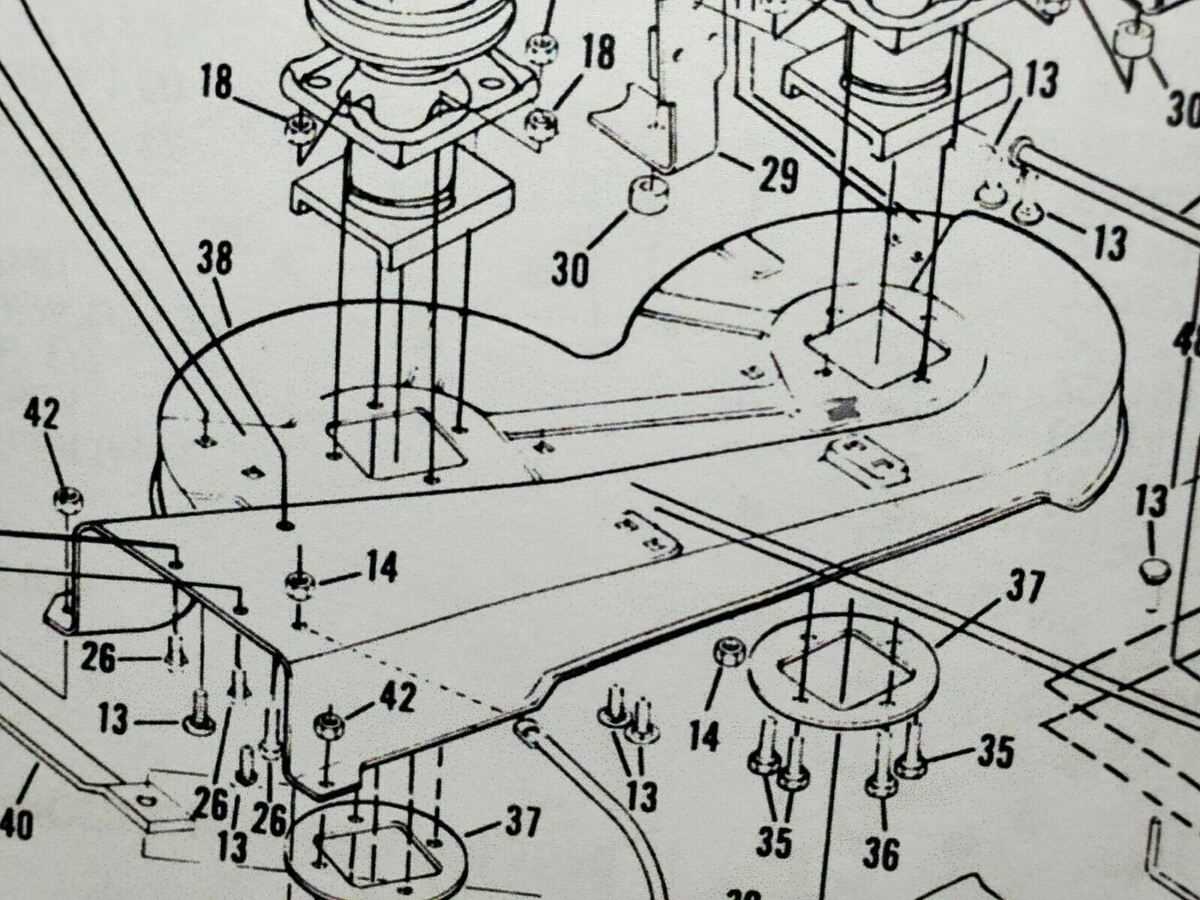

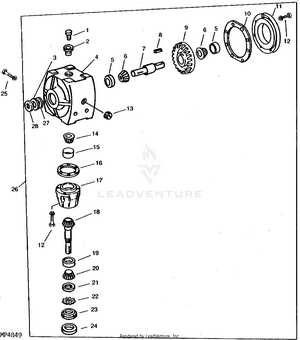

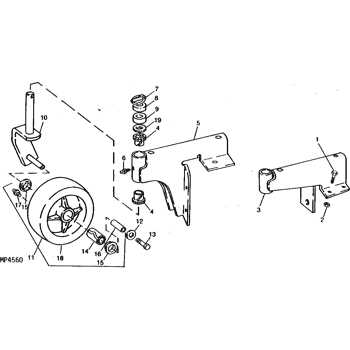

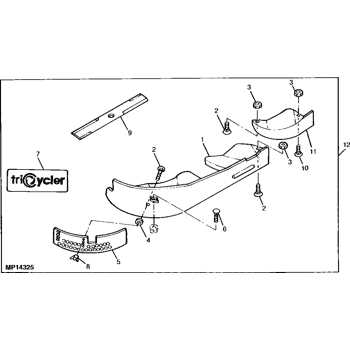

Common Parts of the 261 Mower

This section explores the essential components that contribute to the efficiency and functionality of a specific cutting machine. Understanding these elements can enhance maintenance and improve overall performance, ensuring optimal results in landscaping tasks.

Key Components

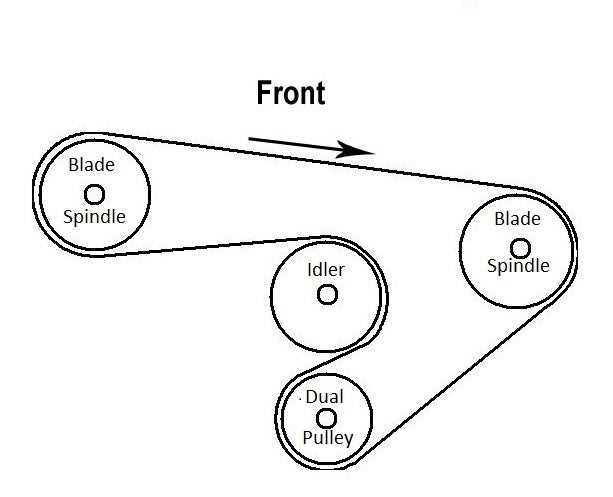

Among the crucial elements are the blades, designed for precision cutting, and the deck, which houses the operational mechanisms. Additionally, the drive belt plays a vital role in transmitting power, while the engine is central to providing the necessary force.

Maintenance Essentials

Regular checks on the filters and spark plugs are necessary to keep the machine running smoothly. Furthermore, ensuring the wheels are in good condition enhances mobility and efficiency during use.

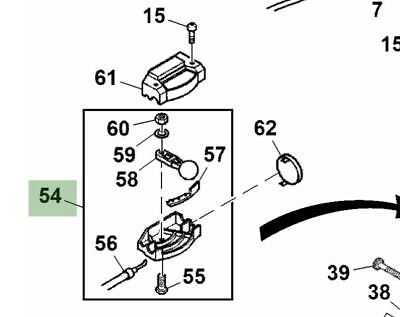

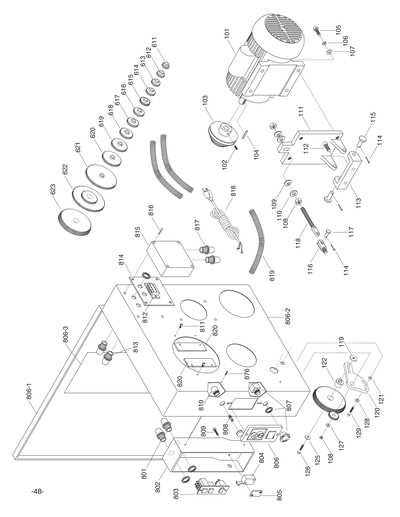

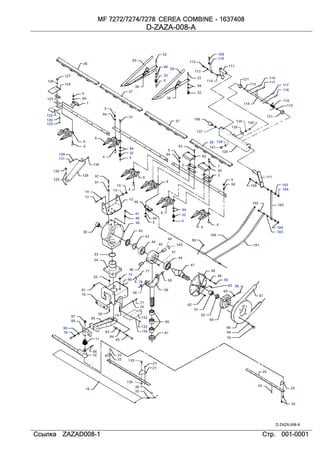

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding users through the various elements and their relationships.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with the Legend: Most diagrams include a legend that explains symbols and numbering.

- Identify Key Sections: Break down the illustration into manageable segments, focusing on one area at a time.

- Cross-Reference with the Manual: Use the accompanying documentation to gain further insights into each component.

By practicing these techniques, you can gain a deeper understanding of the intricacies involved in your machinery.

Identifying Replacement Components

Understanding the various elements of your machinery is essential for effective maintenance and repairs. Identifying specific components helps ensure you can easily locate and replace any necessary items, ultimately enhancing the equipment’s performance.

To successfully pinpoint replacement elements, follow these guidelines:

- Refer to the owner’s manual for a comprehensive list of components.

- Utilize online resources and forums for community support and insights.

- Examine the existing components for part numbers or manufacturer labels.

Additionally, consider these resources:

- Local dealerships for expert advice and genuine products.

- Aftermarket suppliers for alternative options.

- Online retailers for a wide selection of components.

By effectively identifying each part, you can streamline the replacement process and maintain the ultimate efficiency of your equipment.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By following a few essential maintenance practices, you can enhance the performance and reliability of your machine while preventing potential issues down the line.

Regular Inspection

Conducting frequent checks can help you identify wear and tear before it becomes a significant problem. Focus on the following:

- Examine blades for sharpness and damage.

- Inspect belts and cables for signs of fraying.

- Check fluid levels and look for leaks.

Cleaning and Lubrication

Maintaining cleanliness is vital for optimal functioning. Ensure to:

- Clear debris from the deck and undercarriage after each use.

- Lubricate moving parts to minimize friction.

- Use appropriate cleaning agents that won’t harm the finish of your equipment.

Implementing these maintenance tips will not only boost performance but also extend the life of your machinery, allowing you to achieve the best results in your tasks.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining performance and longevity. Ensuring that you use original items not only guarantees compatibility but also enhances reliability. Here are some trusted sources to consider:

- Manufacturer’s Website: The official site often provides a comprehensive catalog of original components, along with specifications and installation guides.

- Authorized Dealers: Reach out to local distributors who are licensed to sell genuine items. They often have access to the latest stock and can offer expert advice.

- Online Retailers: Reputable e-commerce platforms specialize in high-quality components. Always check for seller ratings and reviews before making a purchase.

- Specialized Forums and Communities: Joining groups focused on your equipment can provide insights and recommendations for sourcing authentic items from fellow users.

- Repair Shops: Local maintenance facilities often stock genuine items or can order them on your behalf, ensuring you receive the right parts.

By utilizing these resources, you can ensure that you acquire reliable components that will keep your machinery operating at its best.

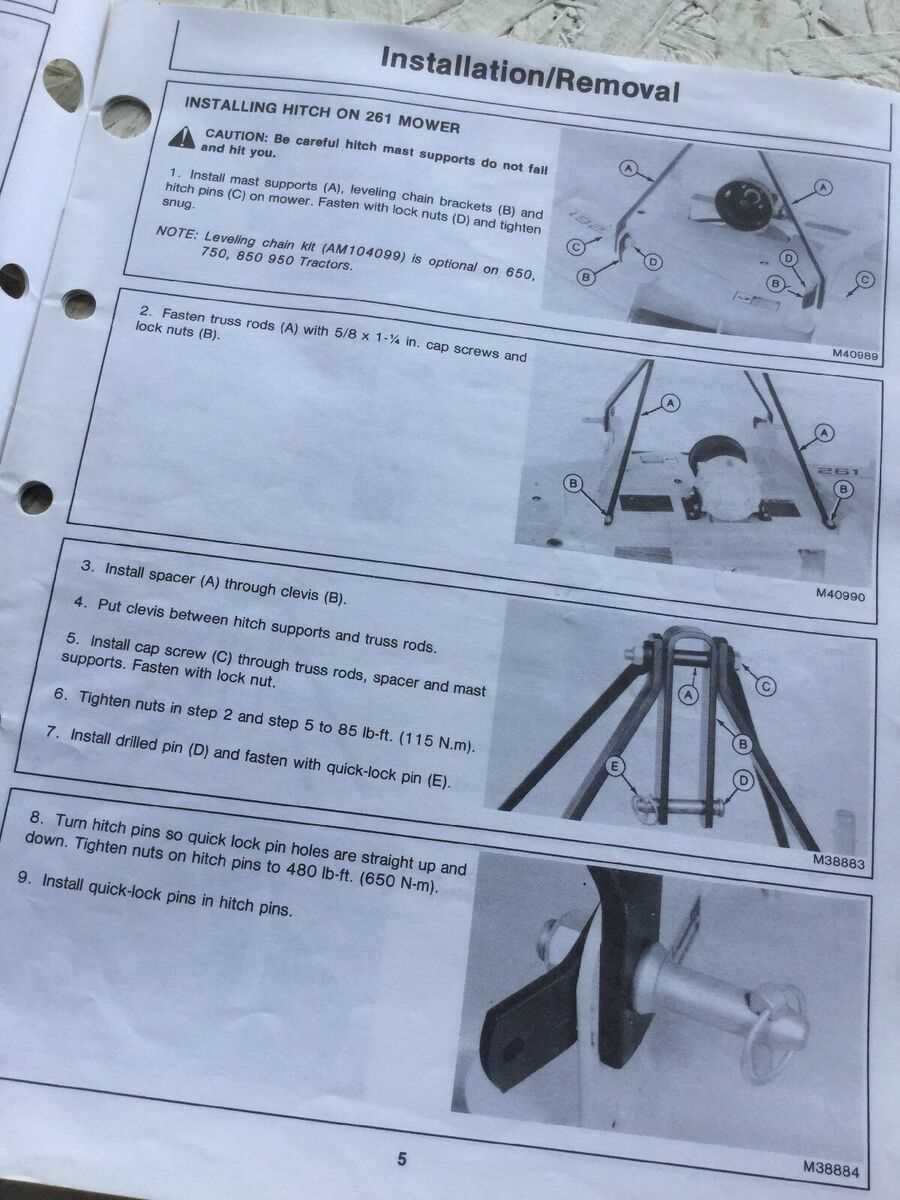

Assembly Instructions for New Parts

When integrating new components into your equipment, it’s essential to follow a structured approach to ensure proper functionality and longevity. This section provides clear guidelines to assist you in the assembly process, highlighting important considerations and steps.

1. Gather Your Tools: Before starting, make sure you have all necessary tools at hand. This includes wrenches, screwdrivers, and any specific instruments required for the new components.

2. Review the Manual: Consult the accompanying manual for detailed instructions related to the new components. Familiarize yourself with any diagrams or notes provided, as they can significantly aid in the assembly process.

3. Prepare the Workspace: Ensure your workspace is clean and well-lit. Organize all components to avoid confusion during assembly. A clutter-free area helps in maintaining focus and efficiency.

4. Follow Step-by-Step Instructions: Begin assembling according to the step-by-step guidelines. It’s important to adhere to the recommended sequence to avoid any complications later. If specific alignment or orientation is required, pay close attention to those details.

5. Secure Connections: As you attach new components, ensure that all connections are tight and secure. Loose fittings can lead to performance issues or damage over time.

6. Double-Check Your Work: After assembly, review each step to confirm that everything is in place and correctly fastened. This final check can save time and effort in troubleshooting later on.

By following these guidelines, you can effectively assemble your new components, ensuring your equipment operates smoothly and efficiently.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools at your disposal is essential. A well-equipped workspace can make the difference between a smooth repair process and a frustrating experience. Knowing what instruments you need can help streamline your tasks and ensure effective results.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers are fundamental for any repair job. These tools allow you to easily access and tighten various components, making adjustments or replacements much more manageable.

Specialized Equipment: Depending on the nature of the repairs, you may need specific tools designed for particular tasks. This could include socket sets for deeper access or torque wrenches to ensure proper tightness on critical fasteners.

Safety Gear: Always prioritize safety while working on your machinery. Gloves, goggles, and masks can protect you from debris and chemicals, ensuring a safer working environment.

Cleaning Supplies: Keeping your tools and equipment clean is vital for longevity and performance. Having brushes, cloths, and appropriate cleaning agents on hand will help maintain your machinery in optimal condition.

By gathering these necessary tools, you can approach repairs with confidence, ensuring that each task is completed efficiently and safely.

Common Issues and Solutions

This section aims to address frequent problems encountered with equipment maintenance, offering effective solutions to enhance performance and longevity. Understanding these common challenges can empower users to tackle issues proactively, ensuring optimal functionality.

Overheating Problems

One prevalent concern is overheating, which can lead to diminished efficiency. Regularly check the cooling system for blockages and ensure that the airflow is unobstructed. Additionally, monitoring fluid levels can help maintain proper temperature regulation.

Uneven Cutting

Uneven cutting can disrupt the overall appearance of the landscape. To resolve this, verify that the cutting blades are sharp and properly aligned. Routine adjustments and maintenance are essential for achieving the desired results. Keeping the equipment clean also contributes to uniform performance.

Customer Reviews of the 261 Mower

Feedback from users offers valuable insights into the performance and reliability of this particular model. Many individuals who have utilized this equipment share their experiences, highlighting various aspects such as ease of use, efficiency, and overall satisfaction.

Overall, customers appreciate the following features:

- Performance: Users frequently mention the effective cutting capabilities, resulting in a well-maintained lawn.

- Durability: Many reviews emphasize the robust construction, allowing for extensive use without significant wear and tear.

- User-Friendly Design: Operators often note the intuitive controls and comfortable handling, making it suitable for both novices and experienced users.

- Maintenance: Feedback indicates that upkeep is straightforward, which adds to the convenience of ownership.

However, some reviews point out a few areas for improvement:

- Weight: A number of users find the machine to be heavier than expected, which can make maneuvering more challenging.

- Noise Level: Several customers have commented on the operational noise, suggesting it could be quieter for a more pleasant experience.

- Price: While many consider it a worthwhile investment, some feel the initial cost is on the higher side.

In summary, user feedback reveals a generally positive reception, with many praising its efficiency and reliability, while also suggesting minor enhancements to improve the overall experience.

Comparing the 261 with Other Models

This section explores the distinctions between this specific model and its counterparts in the market. By analyzing features, performance, and usability, one can better understand how each variant meets the diverse needs of users.

Key factors to consider include:

- Engine power and efficiency

- Cutting width and height adjustment options

- Weight and maneuverability

- Durability of components

- Ease of maintenance and service availability

When evaluating these models, users may find:

- Some models excel in fuel efficiency.

- Others may offer advanced technology for enhanced performance.

- Comparative analysis reveals strengths and weaknesses in cutting precision.

Ultimately, understanding these differences aids in making an informed choice tailored to specific landscaping needs.