Comprehensive Guide to Sears Snowblower Parts Diagram

Maintaining winter machinery is crucial for optimal performance during the chilly months. Knowing the internal components and their arrangements can significantly enhance your understanding and ability to troubleshoot issues that may arise.

Visual aids play an ultimate role in this process, providing clarity and facilitating easier repairs. A comprehensive visual representation of the equipment’s elements allows users to quickly identify each section and its function, ensuring smoother operation.

By exploring these visual resources, individuals can delve into the mechanics behind their tools, fostering confidence and competence when addressing potential malfunctions. This knowledge empowers users to keep their equipment in top shape, ready to tackle any winter challenge.

Sears Snowblower Parts Overview

This section provides a comprehensive look at the essential components that make up a powerful winter machine. Understanding each element’s function is crucial for maintaining optimal performance during harsh weather conditions.

Core Components: At the heart of the equipment lie critical elements such as the engine, transmission, and auger assembly. These parts work in unison to ensure efficient snow clearing.

Maintenance Tips: Regular inspection and timely replacement of worn-out elements can significantly extend the lifespan of your machinery. Pay attention to the belts and shear pins, as they often bear the brunt of rigorous use.

Accessories: Various attachments and enhancements can improve functionality. Options like drift cutters and tire chains can boost performance on challenging terrains.

Overall, a thorough grasp of these integral components enables users to tackle winter challenges effectively and ensures reliable operation throughout the season.

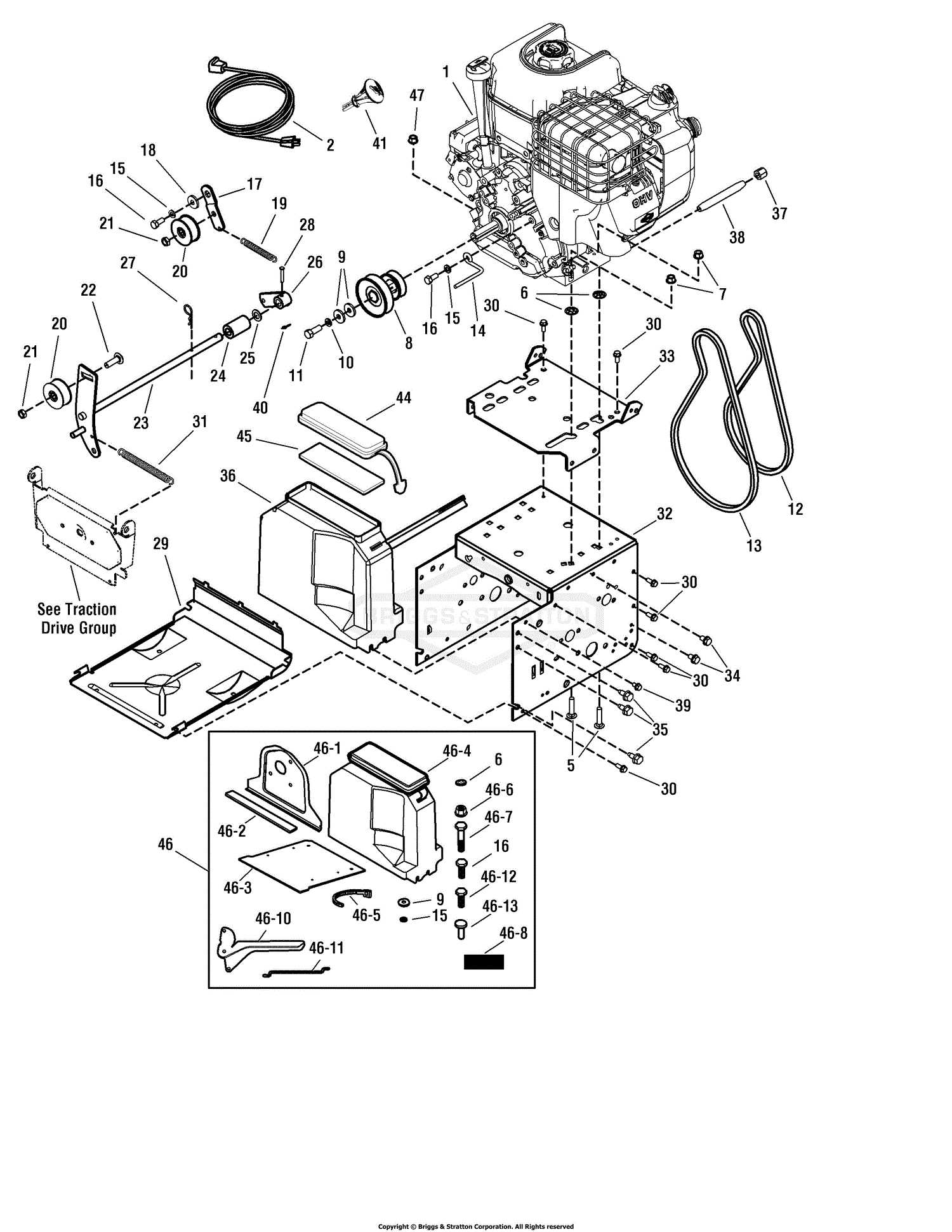

Understanding Snowblower Component Functions

Exploring the essential functions of various components within a snow-clearing machine can enhance both performance and maintenance. Each element plays a critical role in ensuring efficient operation, contributing to overall effectiveness in handling winter challenges. Grasping these functions allows operators to troubleshoot issues and optimize usage.

Main Drive Mechanism

The primary drive system is responsible for translating power from the engine to the auger and impeller. This component ensures that the machine can move forward, cutting through compacted snow. Understanding how this mechanism operates helps in recognizing potential issues such as slippage or loss of power.

The auger assembly is designed to break up and gather snow, feeding it into the impeller for expulsion. This component must be robust to handle varying snow conditions. Proper maintenance, including regular inspections and replacements, ensures it functions efficiently, minimizing downtime during heavy snowfall.

Common Issues with Sears Models

When it comes to winter machinery, users often encounter a range of challenges that can impact performance and reliability. Understanding these common problems can help in identifying solutions and ensuring optimal functionality. Familiarity with typical issues can also guide maintenance practices and improve overall user experience.

One prevalent concern is the engine not starting, which may be attributed to fuel system problems, including clogged filters or stale gasoline. Additionally, users frequently report difficulties with ignition systems, where spark plugs may need replacement or adjustment.

Another issue involves the equipment’s inability to effectively clear snow, often linked to dull blades or improper chute adjustments. Regular inspection of these components is crucial for maintaining efficient operation.

Furthermore, wear and tear on belts and cables can lead to operational failures. Ensuring these parts are in good condition through routine checks can prevent unexpected breakdowns during heavy use.

Lastly, leaking fluids can be a sign of more serious underlying issues, such as damaged seals or gaskets. Addressing these leaks promptly is essential to avoid further complications and maintain the machine’s longevity.

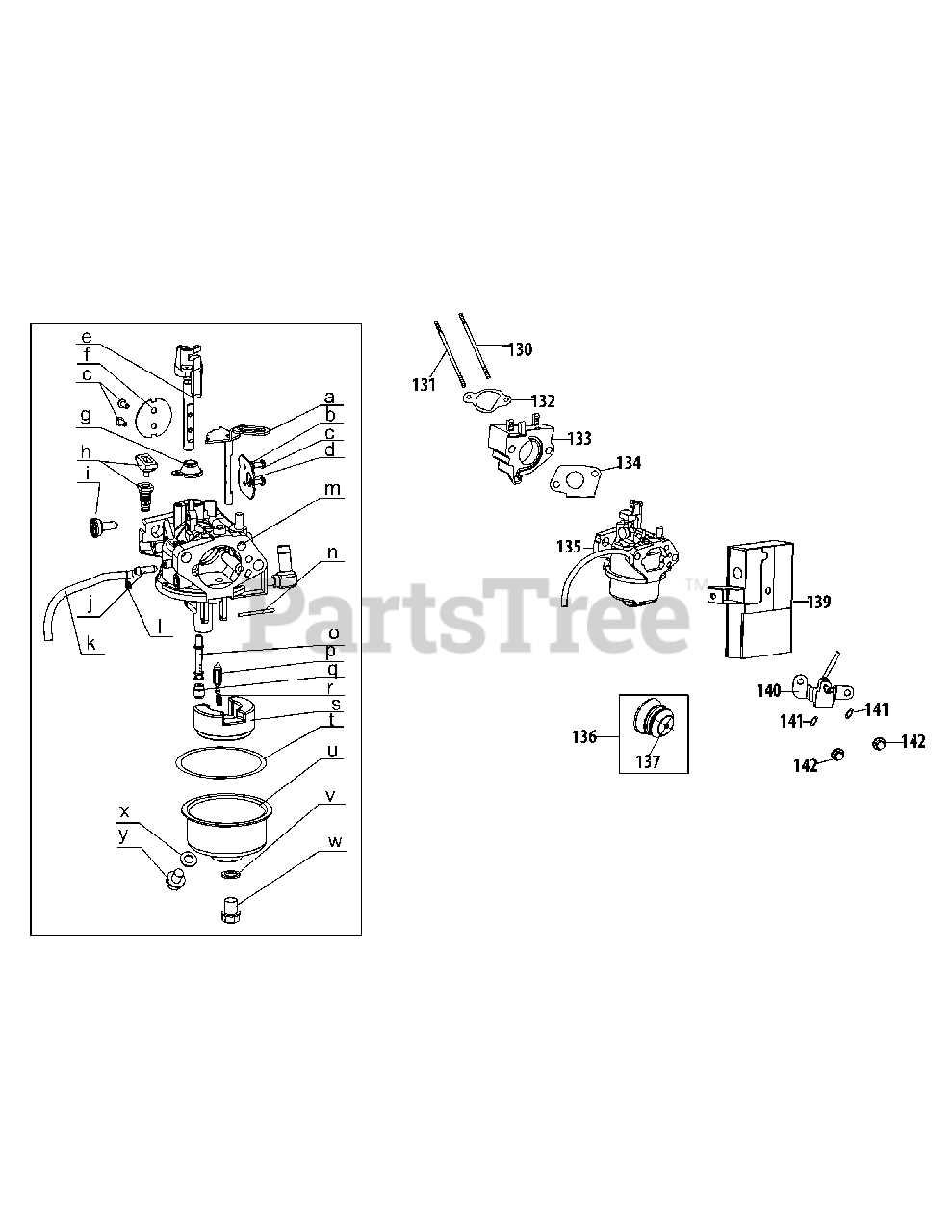

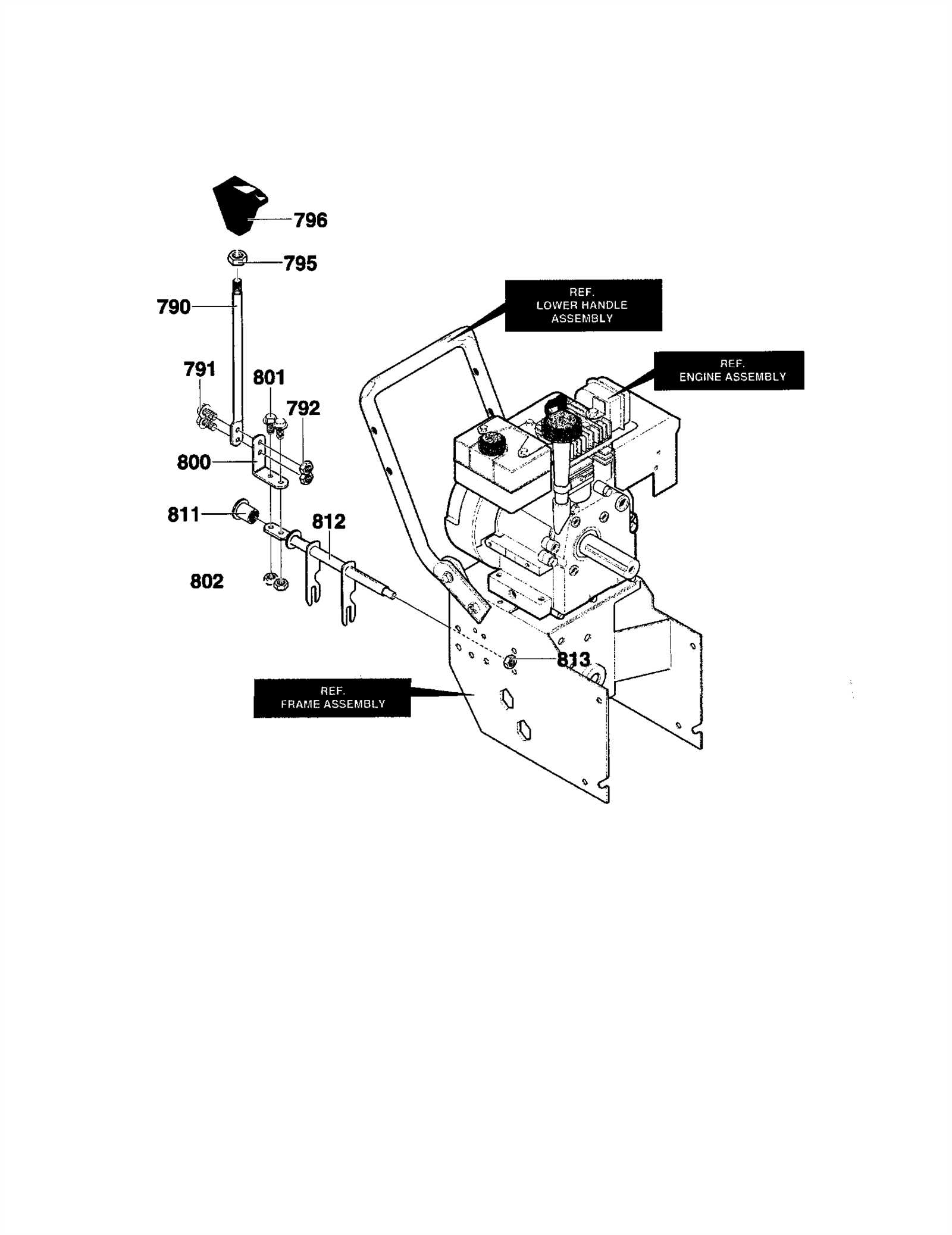

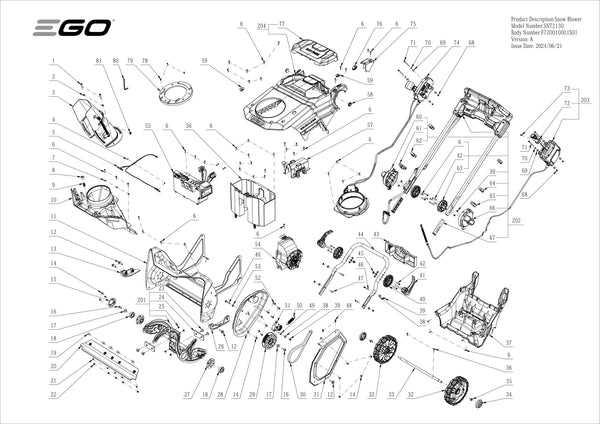

How to Read Parts Diagrams

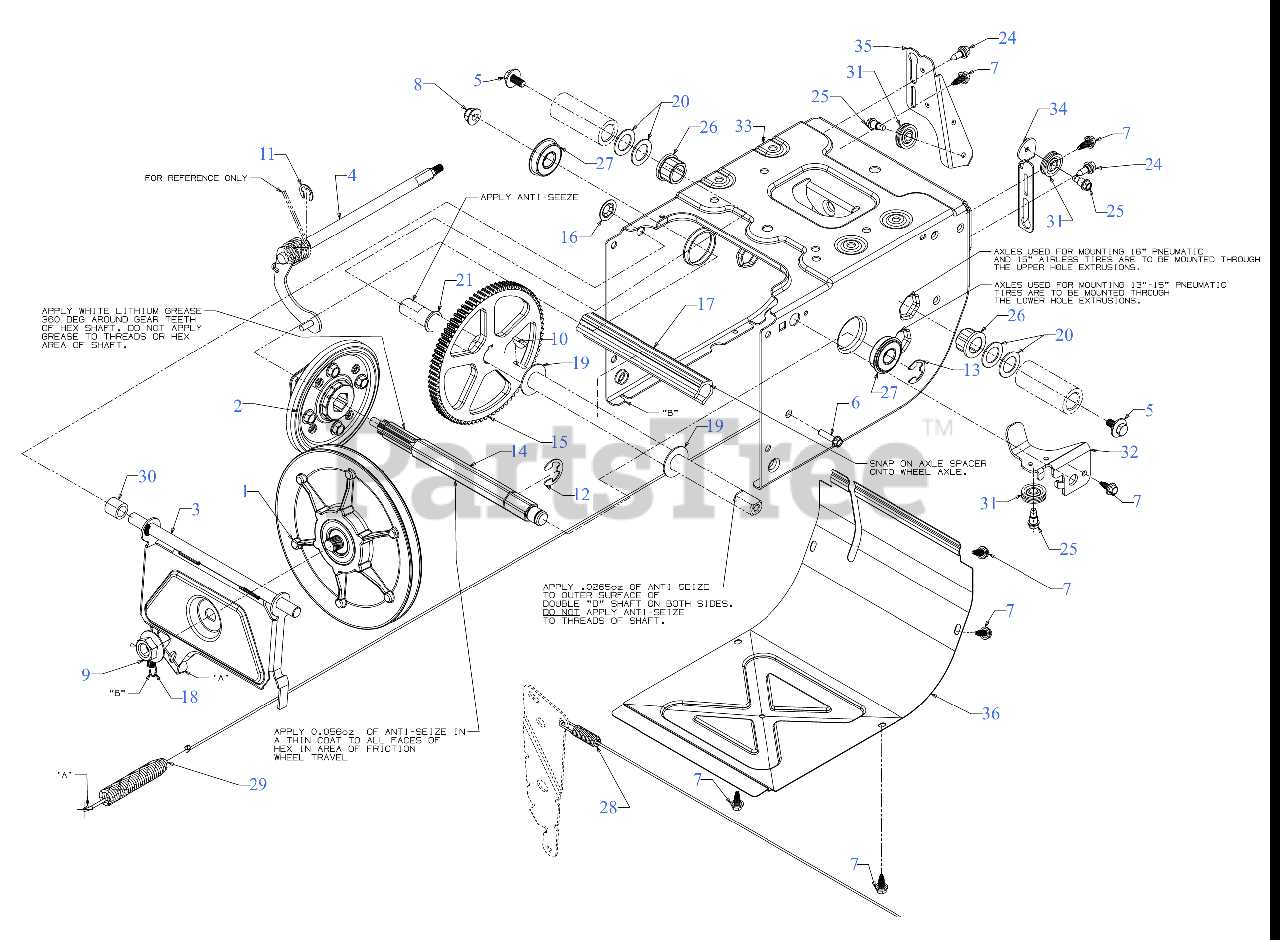

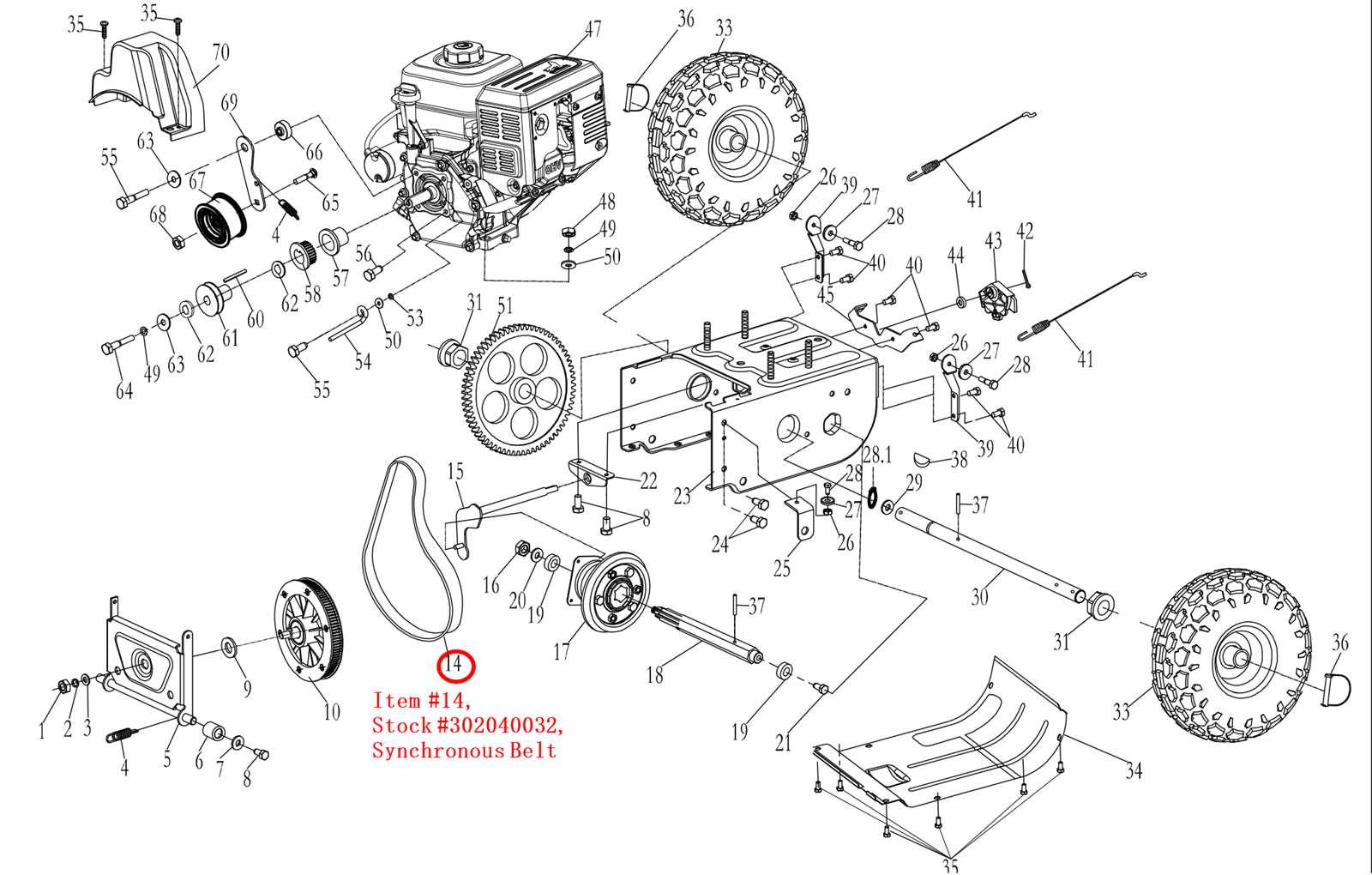

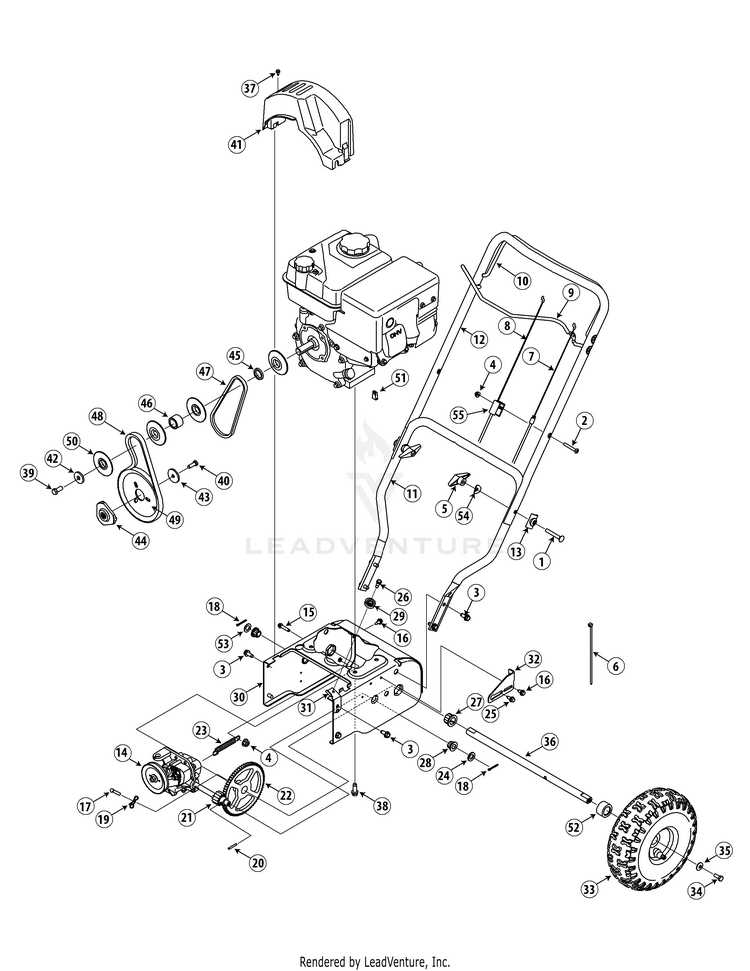

Understanding visual representations of components can significantly enhance your ability to identify and replace necessary elements in various machines. These illustrations serve as valuable guides, helping you navigate through the intricate details of assembly and disassembly.

Familiarize Yourself with Symbols

Every illustration employs a specific set of symbols and notations. Familiarizing yourself with these conventions is essential. Look for labels that indicate size, orientation, and function. Recognizing these symbols will enable you to comprehend the overall structure and relationships between different components.

Follow the Numbering System

Most visual guides include a systematic numbering or lettering scheme. This organization helps you easily locate and reference individual elements. Pay close attention to the accompanying list, which usually provides detailed descriptions of each item. This information is crucial for ensuring you select the correct replacements during repairs or maintenance.

Essential Maintenance Tips for Snowblowers

Regular upkeep is crucial for ensuring the longevity and efficiency of your winter equipment. By following a few essential practices, you can keep your machine in peak condition, ready to tackle any snowy challenge. This section explores key maintenance strategies that will enhance performance and reliability.

Regular Inspection

Frequent checks of your machinery can prevent minor issues from escalating. Look for wear and tear, ensuring that all components are secure and functioning properly. Pay special attention to belts, blades, and any other moving parts, as these are often the first to show signs of stress.

Proper Storage

After use, storing your equipment correctly is vital. Clean the unit thoroughly to remove any debris and moisture, which can lead to corrosion. Ideally, keep it in a dry, sheltered area, and consider using a cover to protect it from dust and dirt when not in use.

Identifying Replacement Parts Easily

Understanding the various components of your equipment is crucial for effective maintenance and repair. By familiarizing yourself with the different elements involved, you can streamline the process of finding what you need. A clear visualization of these elements can significantly enhance your ability to pinpoint the necessary replacements quickly.

Start by examining the manual or reference materials that accompany your machinery, as these often include helpful illustrations and labels. When looking for specific items, note the unique characteristics and model numbers, which can aid in distinguishing between similar components. Utilizing online resources and forums can also provide valuable insights from other users who may have faced similar challenges.

Lastly, keeping an organized inventory of your equipment’s essentials will not only make replacements easier but also ensure that you have everything on hand for future maintenance tasks. This proactive approach ultimately leads to a more efficient and less stressful experience.

Where to Find Sears Parts Online

Finding the right components for your equipment can be a straightforward process with the right resources at your disposal. Various online platforms offer extensive catalogs, making it easier to locate what you need for your maintenance or repair tasks.

- Manufacturer’s Website: Start with the official site, which often provides a comprehensive listing of available items.

- Online Retailers: Websites like Amazon and eBay frequently stock a variety of components, often at competitive prices.

- Specialized Stores: There are numerous dedicated retailers that focus on outdoor equipment, providing expert advice and a broad selection.

- Forums and Community Groups: Online communities can be invaluable for recommendations on where to purchase specific items.

By utilizing these resources, you can delve into an ultimate collection of options to ensure your machinery runs smoothly.

Comparing Models: What to Know

When selecting a machine designed for winter clearing tasks, it’s essential to understand the differences between various models available on the market. Each option offers unique features, performance levels, and user experiences that can significantly impact efficiency and ease of use.

Power and Performance: One of the key aspects to consider is the power of the engine. Different models come with varying horsepower, which directly influences their capability to handle heavy or compacted snow. A more robust engine typically provides better performance in challenging conditions.

Build Quality: The materials used in construction play a crucial role in durability and longevity. It’s advisable to look for models made from high-quality components that can withstand harsh environments and regular use without frequent breakdowns.

Features and Accessories: Various models offer additional features such as adjustable handles, electric start options, and different clearing widths. Evaluating these functionalities can help determine which unit will best meet your specific needs.

User Reviews: Before making a purchase, exploring customer feedback can provide valuable insights into the real-world performance of different machines. Users often share their experiences regarding ease of operation, maintenance requirements, and overall satisfaction, helping you make a more informed choice.

Ultimately, taking the time to compare different options based on these factors will lead to a more suitable selection for your winter maintenance needs.

Tools Needed for Repairs

Having the right equipment is essential for successful maintenance and repair tasks. Proper tools not only simplify the process but also ensure safety and efficiency. Below is a list of essential implements that can aid in carrying out repairs effectively.

Essential Hand Tools

- Wrenches: Adjustable and socket types for various fasteners.

- Screwdrivers: A set of flathead and Phillips for different screws.

- Pliers: Needle-nose and regular for gripping and bending.

- Hammers: Claw and rubber for driving and removing components.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the specified torque.

- Multimeter: Useful for checking electrical connections and diagnosing issues.

- Lubrication Tools: Grease guns or oil cans for maintenance of moving parts.

- Safety Gear: Gloves, goggles, and ear protection to ensure personal safety.

Equipping yourself with these tools can make the repair process smoother and more effective, helping to achieve optimal results with minimal hassle.

Safety Precautions During Maintenance

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. By adhering to specific guidelines, you can create a secure environment that minimizes risks while working on machinery.

Before starting any maintenance work, consider the following essential precautions:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to protect against hazards. |

| Disconnect Power Source | Ensure the device is unplugged or the battery is removed to prevent accidental starts. |

| Work in a Well-Ventilated Area | Maintain good airflow to avoid inhaling harmful fumes or dust. |

| Keep Tools Organized | Store tools properly to prevent trips and falls during the maintenance process. |

| Read Manufacturer’s Manual | Consult the manual for specific safety instructions related to the equipment. |

By implementing these precautions, you can significantly enhance your safety and efficiency while performing maintenance tasks.

DIY Repair: Step-by-Step Guide

Undertaking repairs on your equipment can be a fulfilling and cost-effective endeavor. This guide will provide you with a clear framework to tackle common issues, ensuring you can restore functionality with minimal hassle. Whether you’re a seasoned handyman or a novice, following these steps will enhance your confidence and skills.

Step 1: Gather Your Tools

Before you start, assemble all necessary tools and materials. A well-organized workspace will streamline the process and help you avoid interruptions. Common tools may include wrenches, screwdrivers, and pliers.

Step 2: Consult the Manual

Refer to the user manual for specific instructions related to your model. Understanding the components and their functions will aid in identifying issues effectively. If you don’t have a physical copy, check online resources for digital versions.

Step 3: Identify the Problem

Carefully examine the equipment to pinpoint the malfunction. Look for visible signs of wear, such as cracks, corrosion, or loose connections. Document your observations to assist in the repair process.

Step 4: Disassemble Carefully

When you’re ready to begin, disassemble the unit with care. Keep track of all screws and small parts by placing them in labeled containers. This organization will make reassembly much simpler.

Step 5: Replace or Repair Components

Once disassembled, assess which components need replacement or repair. Use compatible substitutes where necessary. Follow manufacturer specifications to ensure proper fit and functionality.

Step 6: Reassemble and Test

After replacing or repairing the required parts, carefully reassemble the unit. Double-check that all connections are secure. Once reassembled, conduct a thorough test to confirm that the equipment operates correctly.

Step 7: Regular Maintenance

To prolong the lifespan of your equipment, establish a routine maintenance schedule. Regular cleaning and inspections can help prevent future issues and ensure optimal performance.

Winter Readiness Checklist for Snowblowers

As the winter season approaches, ensuring your outdoor clearing equipment is in optimal condition is essential for effective operation. A well-prepared machine not only enhances performance but also extends its lifespan. Below is a comprehensive checklist to help you get ready for the snowy months ahead.

1. Inspect the Fuel System: Check the fuel for any contaminants and ensure it’s fresh. Old fuel can lead to starting issues, so consider replacing it if it’s been stored for a while.

2. Examine the Ignition Components: Inspect the spark plug for wear and replace it if necessary. A clean and functional ignition system is crucial for reliable starts.

3. Test the Oil Levels: Ensure the oil is at the appropriate level and is not contaminated. Change the oil if it appears dirty or if you haven’t done so recently.

4. Check the Belts and Cables: Look for any signs of wear or damage on belts and cables. Replace any frayed or cracked components to prevent breakdowns during use.

5. Inspect the Auger and Chassis: Ensure that the auger is free from debris and in good condition. Examine the chassis for any cracks or loose components that could affect performance.

6. Test the Electrical System: Verify that all electrical connections are secure and functioning. Check the battery if your equipment has one, ensuring it holds a charge and operates correctly.

7. Review Safety Features: Confirm that all safety mechanisms are in place and functioning as intended. This includes the emergency shut-off and any safety switches.

8. Clean and Store Properly: After your inspections and maintenance, give your equipment a thorough cleaning to remove any dirt or debris. Proper storage will help keep it in good shape until it’s needed.

By following this checklist, you can ensure that your clearing equipment is ready to tackle whatever winter throws your way, providing you with peace of mind and efficiency when the snow begins to fall.

Customer Reviews: Parts and Performance

This section explores user experiences regarding components and functionality, highlighting their perspectives on durability and effectiveness. Customers often share insights that reflect the reliability and efficiency of these essential tools.

Durability Insights

Many users emphasize the importance of longevity in their reviews. High-quality materials contribute to a positive experience, reducing the frequency of replacements and repairs. Customers appreciate when their equipment withstands challenging conditions without significant wear.

Efficiency Feedback

Performance is a crucial factor for users. Responsive operation and ease of use are frequently mentioned, with customers noting that efficient machinery saves time and effort during demanding tasks. Positive experiences often lead to recommendations among peers.