Kohler 23 HP Engine Parts Diagram Explained

When delving into the mechanics of power units, having a clear visualization of their structure is essential. This section offers an insightful look into the configuration and organization of crucial elements that contribute to optimal performance. Understanding how these components interrelate can greatly enhance your maintenance and repair efforts.

By examining the intricate assembly of these systems, one can gain a deeper appreciation for the engineering behind their functionality. Each segment plays a vital role, and recognizing their specific positions and connections can simplify troubleshooting and upgrades. Whether you are a seasoned technician or a novice enthusiast, familiarizing yourself with this framework will empower you to approach projects with confidence.

Furthermore, clarity in the arrangement of these crucial pieces can lead to more efficient repairs and a better grasp of operational efficiency. As you navigate through the various sections, you will uncover valuable insights that can aid in prolonging the lifespan of your machinery. Let us embark on this journey to demystify the components and enhance our understanding of their workings.

Kohler 23 HP Engine Overview

This section provides a comprehensive look at a powerful and reliable 23 horsepower machine designed for various applications. It highlights key features and characteristics that make it a preferred choice for enthusiasts and professionals alike.

Key Features

- Robust construction ensuring durability and longevity.

- High efficiency providing excellent performance under load.

- Versatile design suitable for a range of equipment.

- Easy maintenance to enhance usability and reliability.

Applications

- Lawn care equipment

- Garden tractors

- Commercial landscaping

- Light construction machinery

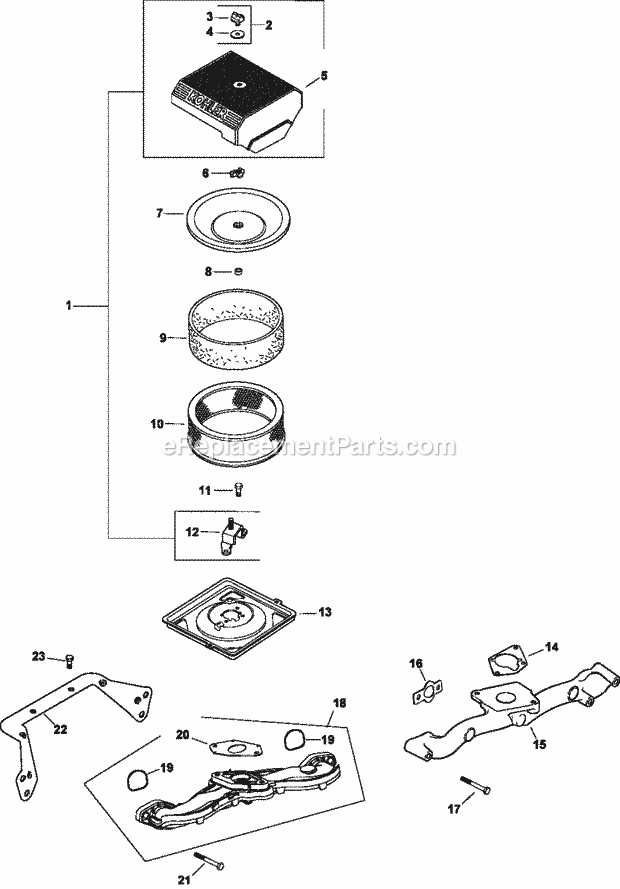

Essential Components of the Engine

The heart of any powerful machine consists of several critical elements that work in harmony to ensure optimal performance. Each component plays a unique role, contributing to the overall functionality and efficiency of the system.

Key Elements

Power Generation: This part is responsible for converting fuel into energy, creating the necessary force for operation. Its efficiency directly impacts the machine’s performance.

Supporting Structures

Cooling System: This essential mechanism regulates temperature, preventing overheating and ensuring longevity. An effective cooling setup is vital for maintaining consistent operation.

Understanding these foundational components allows for better maintenance and enhances overall functionality, leading to a more reliable experience.

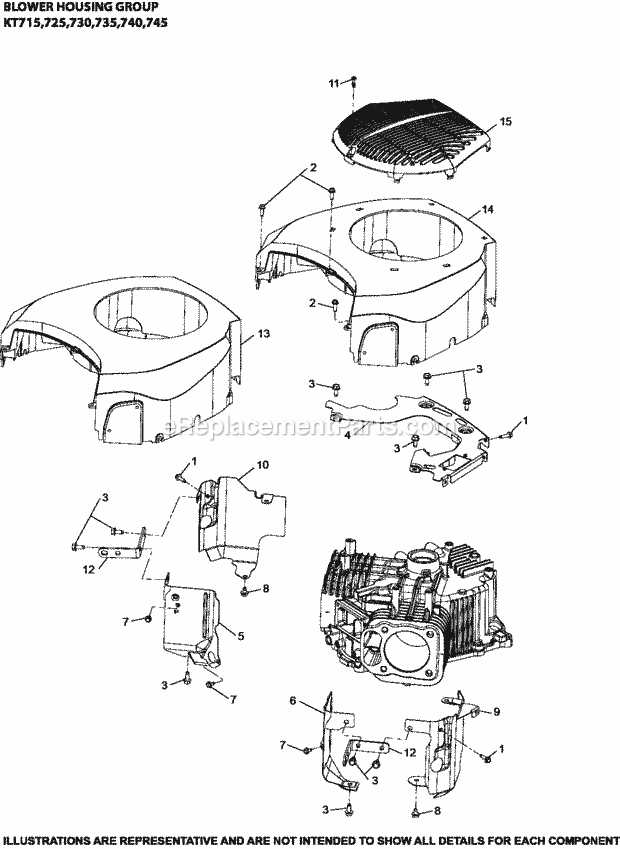

Understanding the Parts Diagram

Grasping the layout of components in a mechanical system is essential for effective maintenance and troubleshooting. A visual representation can significantly enhance one’s comprehension of how various elements interact, ensuring smoother operation and easier identification of issues.

Such illustrations often include labeled sections that provide insight into the specific roles of each item. This clarity is invaluable for both novice users and experienced technicians alike, facilitating more informed decision-making when it comes to repairs or upgrades.

| Component Name | Description |

|---|---|

| Crankshaft | Transforms linear motion into rotational motion. |

| Fuel System | Delivers fuel to the combustion chamber efficiently. |

| Ignition Module | Controls the timing of the spark to ignite the air-fuel mixture. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

Utilizing these visual guides can streamline the repair process, making it easier to locate and replace faulty components. Familiarity with the layout not only saves time but also promotes a deeper understanding of overall functionality.

Common Issues with Kohler Engines

Every mechanical system can encounter problems that affect performance and longevity. Understanding these issues helps in effective maintenance and troubleshooting, ensuring optimal functioning of the machinery.

Frequent Problems

- Inefficient fuel consumption

- Overheating due to cooling system failures

- Starting difficulties linked to battery or ignition issues

- Excessive vibration indicating imbalance or wear

Maintenance Tips

- Regularly check and replace filters.

- Ensure proper oil levels and quality.

- Inspect belts and hoses for wear and tear.

- Clean spark plugs and check ignition components.

Replacement Parts and Availability

Finding the right components for your machinery can greatly enhance its performance and longevity. Ensuring that you have access to quality replacements is essential for maintaining operational efficiency and reliability. This section outlines key considerations and resources for sourcing these essential items.

Where to Find Quality Components

There are several avenues to explore when looking for reliable replacements:

- Authorized dealers: Often the best source for genuine items, ensuring compatibility and quality.

- Online retailers: Numerous websites specialize in machinery components, providing a wide range of options and competitive pricing.

- Local repair shops: These establishments can often order specific items and may offer installation services as well.

- Aftermarket suppliers: For those seeking cost-effective alternatives, many reputable companies offer high-quality replicas.

Factors to Consider When Purchasing

When selecting replacements, keep the following factors in mind:

- Compatibility: Always verify that the selected component is suitable for your specific model.

- Quality: Research reviews and ratings to ensure reliability and durability.

- Warranty: Look for products that come with a guarantee, providing peace of mind.

- Price: Compare costs across different suppliers to find the best deal without compromising quality.

By considering these aspects and utilizing various resources, you can secure the necessary components to keep your machinery running smoothly.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for ensuring the extended life and optimal performance of your machinery. By following a few key practices, you can significantly enhance reliability and reduce the likelihood of unexpected issues.

- Regular Inspections: Frequently check for signs of wear, loose connections, or leaks. Early detection can prevent more significant problems.

- Consistent Cleaning: Keep all surfaces clean to avoid the buildup of debris and dirt, which can impede function and cooling.

- Oil Changes: Change lubricants as per the manufacturer’s recommendations to ensure smooth operation and prevent damage from contaminants.

- Air Filter Maintenance: Replace or clean air filters regularly to ensure optimal airflow and efficiency.

- Fuel Quality: Use high-quality fuel and consider adding stabilizers if the machinery will sit unused for extended periods.

Implementing these simple yet effective maintenance practices will promote longevity and ensure your machinery operates at its best for years to come.

Tools Required for Repairs

When undertaking maintenance tasks, having the right tools is crucial for efficiency and effectiveness. The proper instruments not only streamline the repair process but also ensure safety and precision.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Necessary for handling various types of screws.

- Pliers: Useful for gripping and manipulating components.

- Socket set: Provides versatility for different fastener sizes.

- Torque wrench: Ensures bolts are tightened to specific specifications.

Additionally, consider these specialized tools:

- Compression tester: Measures the pressure within the system.

- Multimeter: Checks electrical systems and connections.

- Oil filter wrench: Simplifies the removal of oil filters.

Having these tools at your disposal will significantly enhance your repair experience and contribute to achieving ultimate functionality.

Comparing Kohler Engines Models

This section aims to explore various models produced by a well-known manufacturer, highlighting their distinct features and applications. Understanding the differences can guide users in selecting the most suitable option for their needs.

- Power Output: Different models offer varying horsepower ratings, catering to diverse operational requirements.

- Fuel Efficiency: Some variants prioritize fuel conservation, making them ideal for prolonged use.

- Size and Weight: Compact designs are available for smaller machinery, while heavier models provide robust performance for larger tasks.

- Maintenance Needs: Certain models require less frequent servicing, appealing to users who prefer low upkeep.

Ultimately, comparing these options can help users make informed decisions based on their specific demands and preferences.

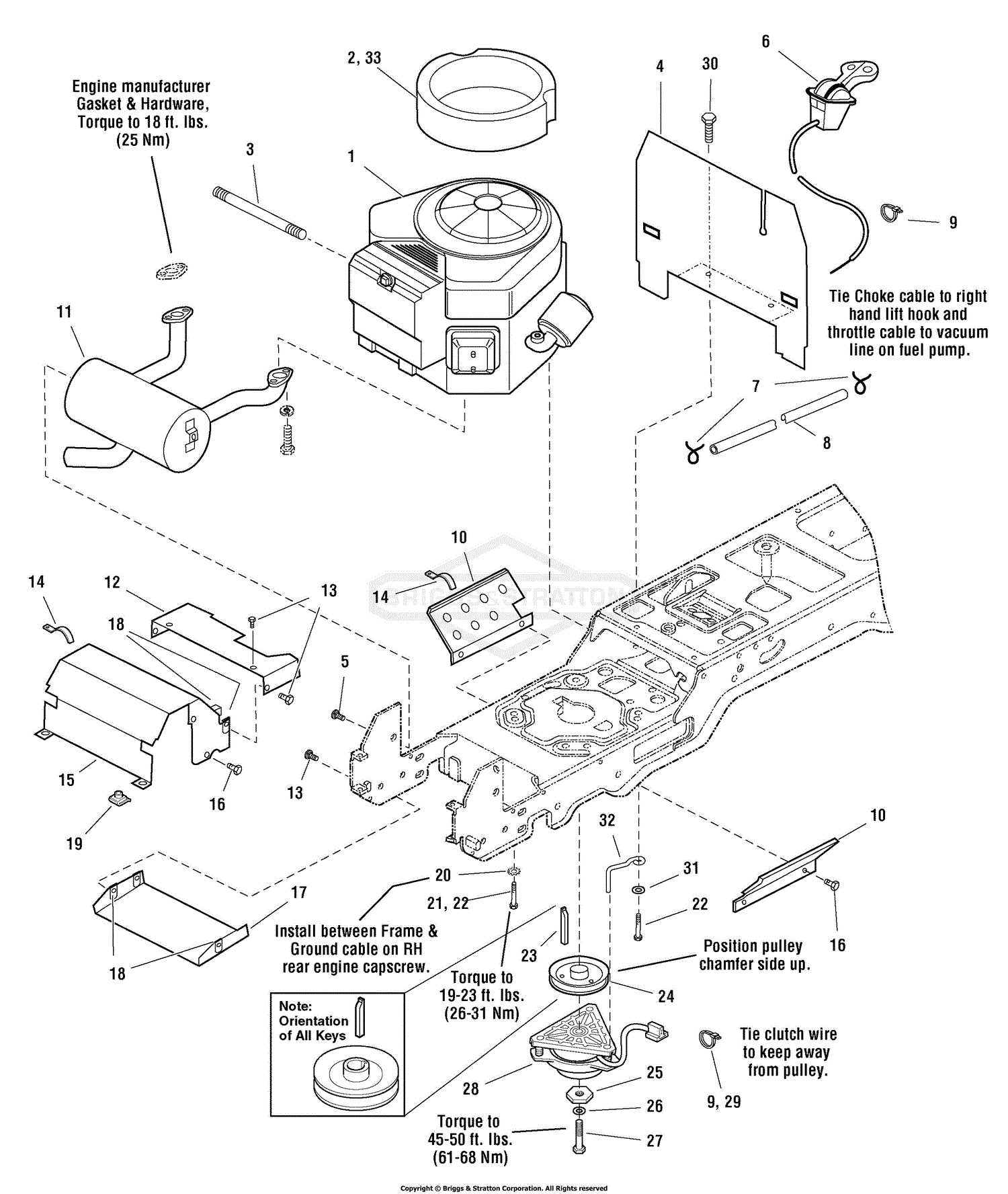

Installation Guidelines for Parts

Proper assembly is crucial for optimal functionality and longevity of your machinery. Following specific instructions ensures that components fit securely and perform efficiently. This section provides essential tips to facilitate a smooth installation process.

Preparation Steps

Before beginning the installation, gather all necessary tools and materials. Clean the working area to prevent contamination and ensure visibility. Review the specifications and familiarize yourself with each component to understand their roles within the system.

Assembly Process

Start by securing the base unit to prevent movement during assembly. Align each component precisely as per the provided specifications. Use appropriate fasteners and ensure they are tightened to the recommended torque. Double-check connections for any signs of wear or damage, and replace if necessary. Finally, conduct a thorough inspection to confirm that everything is installed correctly and safely.

Following these guidelines will help maintain the performance and reliability of your machinery.

Performance Upgrades for Efficiency

Enhancing functionality and optimizing fuel consumption are key goals for improving overall output. By focusing on specific modifications, one can achieve a remarkable boost in efficiency, leading to better operational performance and reduced energy costs.

Common Upgrades

There are several modifications that can be easily implemented to achieve these improvements. These include enhancing air intake, upgrading fuel systems, and adjusting ignition components.

| Upgrade Type | Description |

|---|---|

| Air Filter | Improving airflow leads to better combustion and power delivery. |

| Fuel Injectors | Upgrading to high-performance injectors optimizes fuel delivery. |

| Ignition Timing | Adjusting timing can enhance power output and efficiency. |

Benefits of Upgrades

Implementing these enhancements not only boosts performance but also extends the lifespan of components. Improved efficiency translates to lower emissions and reduced operational costs, making these upgrades a worthy investment for any operator.

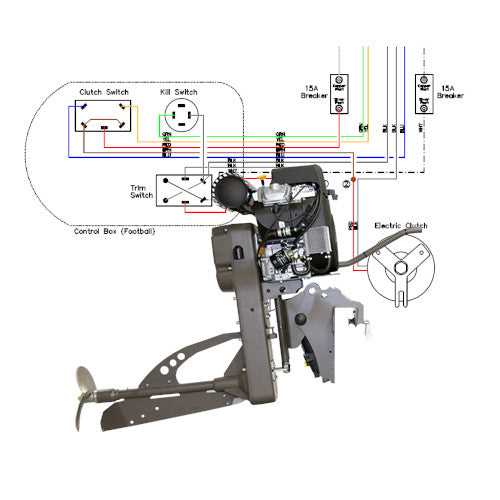

Wiring and Electrical Components

This section focuses on the intricate network of wires and electrical elements essential for optimal functionality. Understanding these components is crucial for maintenance and troubleshooting, ensuring efficient operation and longevity.

Key Electrical Elements

- Ignition System: Responsible for starting the unit, it includes the ignition coil and spark plug.

- Charging System: Comprises components that maintain battery voltage, featuring the alternator and voltage regulator.

- Starter Motor: Initiates the power cycle, converting electrical energy into mechanical movement.

Wiring Configuration

- Identify the main power connections.

- Trace the wiring harness to locate critical junctions.

- Inspect for any signs of wear or damage to prevent electrical failures.

Proper understanding and maintenance of these components are vital for ensuring a reliable and efficient system. Regular checks can prevent issues that may lead to operational downtime.

FAQs About Kohler Engines

This section addresses common inquiries related to a specific brand of power sources used in various applications. Understanding these topics can help users make informed decisions and enhance their experience with these robust machines.

What types of applications are suitable for these power sources?

These robust units are commonly employed in gardening equipment, construction machinery, and various outdoor tools. Their reliability makes them ideal for both residential and commercial uses.

How can I ensure optimal performance and longevity?

Regular maintenance is key. This includes timely oil changes, air filter replacements, and routine inspections. Following the manufacturer’s guidelines will greatly enhance the lifespan and efficiency of your unit.