Understanding the Vevor Ice Machine Parts Diagram for Efficient Maintenance

When it comes to the operation of refrigeration systems, comprehending the intricate relationships between various components is crucial. A well-functioning apparatus relies on each element working harmoniously, ensuring optimal performance and longevity. This knowledge not only aids in maintenance but also empowers users to troubleshoot effectively when issues arise.

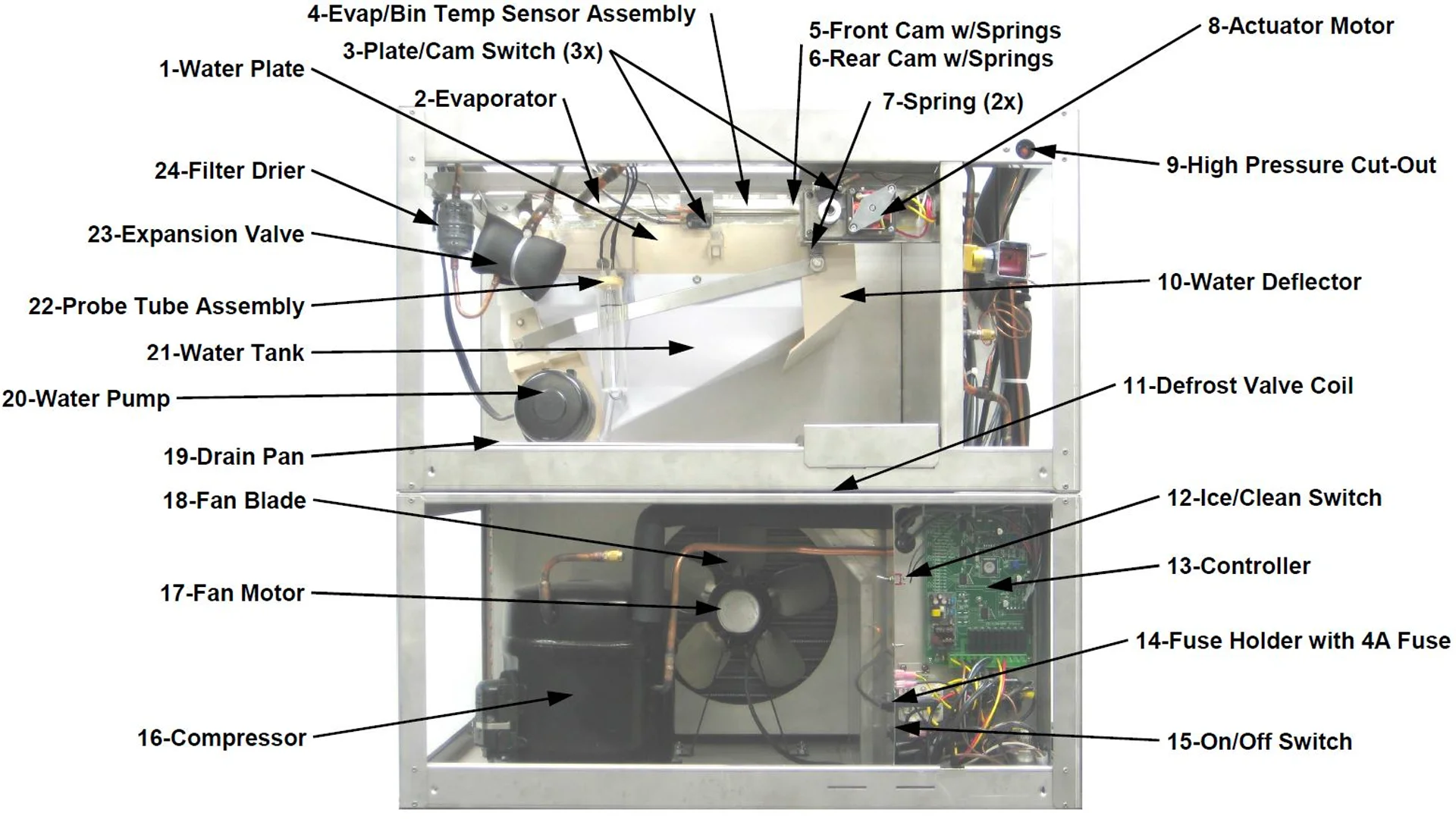

Visualization of the internal layout is essential for grasping how each component interacts. By dissecting the structure, one can gain insights into the flow of energy and the roles played by individual pieces. This exploration enables a deeper appreciation for the engineering that goes into crafting efficient cooling solutions.

Whether you are a seasoned technician or a novice user, familiarizing yourself with these assemblies can enhance your operational efficiency. Understanding the arrangement of the various sections not only simplifies repairs but also promotes informed decision-making when upgrading or purchasing new units.

Understanding Vevor Ice Machine Components

In any system designed for producing frozen water, recognizing the various elements that contribute to its operation is essential. Each component plays a crucial role in ensuring efficiency and reliability. Familiarity with these features aids in troubleshooting and maintenance, ultimately prolonging the lifespan of the equipment.

Main Elements of the System

The functionality of a freezing apparatus relies on a variety of key components. Understanding these elements allows users to comprehend how they interact to produce the desired outcome.

| Component | Description |

|---|---|

| Compressor | Responsible for circulating refrigerant throughout the system, facilitating the cooling process. |

| Condenser | Helps in dissipating heat from the refrigerant, converting it from gas to liquid. |

| Evaporator | Absorbs heat from the surrounding environment, allowing the refrigerant to evaporate and cool the area. |

| Water Reservoir | Stores water before it is transformed into solid form, ensuring a steady supply for production. |

| Control Panel | Enables users to manage and monitor the various functions of the equipment. |

Importance of Each Element

Every element in the freezing system serves a specific purpose that contributes to the overall functionality. By maintaining each part and understanding its role, users can enhance performance and prevent common issues that may arise during operation.

Importance of Ice Machine Parts

The functionality of any cooling apparatus relies heavily on its individual components. Each element plays a crucial role in ensuring that the entire system operates efficiently and effectively. Understanding these elements is essential for maintaining optimal performance and longevity.

High-quality components not only enhance the performance of the equipment but also contribute to energy efficiency and reliability. Neglecting any single part can lead to diminished output, increased energy consumption, and potential breakdowns, resulting in costly repairs and downtime.

| Component | Function | Impact of Failure |

|---|---|---|

| Condenser | Dissipates heat from the refrigerant | Overheating, reduced cooling capacity |

| Evaporator | Absorbs heat to produce cold | Inefficient cooling, ice buildup |

| Compressor | Pumps refrigerant through the system | System failure, total breakdown |

| Expansion Valve | Regulates refrigerant flow | Inconsistent temperature, inefficient operation |

| Control Board | Manages system operations | Operational failures, erratic behavior |

Regular maintenance and timely replacement of these crucial elements can significantly extend the lifespan of the cooling equipment, ensuring consistent performance and reducing operational costs. Prioritizing the integrity of each component is vital for anyone relying on such technology.

Key Functions of Each Component

Understanding the roles of various elements in a cooling unit is essential for optimal performance and maintenance. Each component serves a specific purpose that contributes to the overall efficiency and functionality of the system. Below, we explore the key functions of these integral parts.

The compressor plays a vital role by circulating refrigerant and maintaining pressure, which is crucial for the cooling process. It compresses the refrigerant gas, allowing it to absorb heat from the surroundings and transform into a liquid state.

The condenser is responsible for dissipating heat from the refrigerant. As the gas enters this part, it cools down and changes back into a liquid, releasing the absorbed heat into the environment. This process is essential for maintaining the cooling cycle.

The evaporator works to absorb heat from the interior environment, using the refrigerant to chill the air or water. As the liquid refrigerant passes through this component, it evaporates and absorbs heat, providing the desired cooling effect.

The expansion valve regulates the flow of refrigerant into the evaporator. By reducing the pressure of the liquid refrigerant, it allows the refrigerant to expand and cool before entering the evaporator, thereby enhancing the efficiency of the cooling cycle.

The control system oversees the operation of all components, ensuring they function harmoniously. It monitors temperature settings, adjusts the compressor speed, and manages the overall performance to maintain optimal conditions.

Common Issues with Ice Machines

Many users encounter various challenges when operating their freezing units. Understanding these frequent complications can help maintain efficiency and prolong the lifespan of the equipment. Below are some of the most prevalent problems and their potential causes.

1. Insufficient Production

A common complaint is the inadequate output of frozen products. This issue can stem from several factors, including:

- Low water supply or pressure

- Clogged filters

- Improper temperature settings

- Malfunctioning components

2. Excessive Noise

Another frequent issue is unusual sounds during operation. This can be attributed to:

- Loose or damaged parts

- Vibrations from the unit

- Inadequate insulation

- Foreign objects inside the compartment

By recognizing these common issues, users can take proactive measures to address them, ensuring smooth and reliable performance.

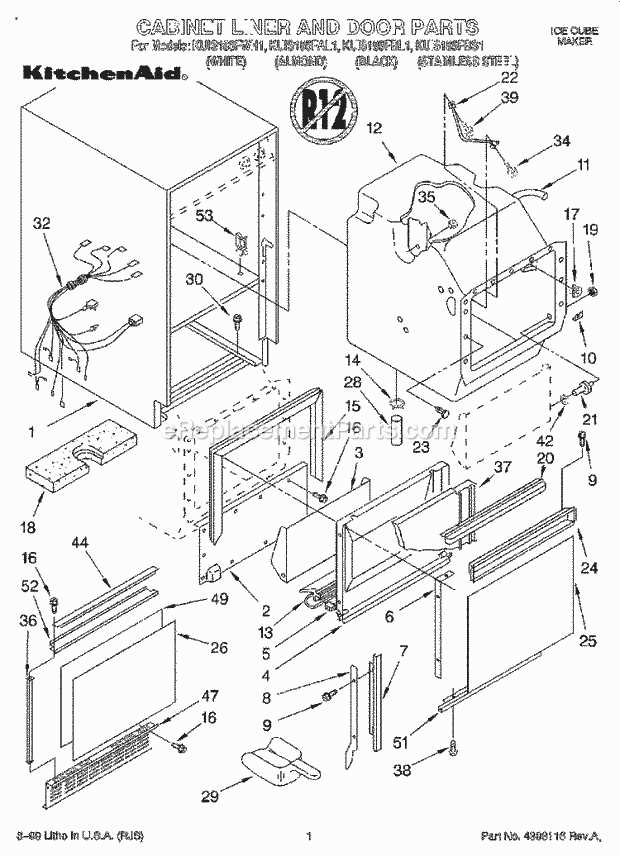

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to maintain and repair equipment. By familiarizing yourself with the various symbols and annotations, you can quickly identify the essential elements and their relationships.

Here are some key steps to effectively interpret a schematic:

- Familiarize Yourself with Symbols: Each representation may use specific symbols for various components. Spend some time reviewing the legend or key that accompanies the schematic.

- Identify Major Sections: Schematics are typically divided into sections, each representing a different aspect of the overall system. Locate these sections to understand the flow and connectivity.

- Trace Connections: Follow the lines that connect the components. These lines indicate how elements are linked, which can help in troubleshooting issues.

- Note Any Annotations: Descriptive text can provide valuable information about function, specifications, or operational guidance. Pay attention to these notes as they often clarify component roles.

- Consult Additional Resources: If the diagram is complex, consider seeking supplementary materials, such as manuals or online guides, to deepen your understanding.

By practicing these steps, you can enhance your comprehension of schematic illustrations, leading to more efficient maintenance and repair efforts.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your cooling unit requires regular care and attention. By following a few simple guidelines, you can extend the lifespan of your appliance and enhance its efficiency. Here are some key practices to consider.

Regular Cleaning

- Clean the exterior and interior components to prevent dust accumulation.

- Use a gentle detergent and water for surfaces, avoiding abrasive materials.

- Inspect and clean filters regularly to maintain airflow and efficiency.

Routine Inspections

- Check for signs of wear and tear, including leaks or unusual noises.

- Examine connections and seals to ensure they are secure and intact.

- Monitor performance and address any irregularities promptly.

Implementing these practices will not only enhance the functionality of your cooling unit but also help prevent costly repairs in the future.

Replacing Worn-Out Parts Effectively

Maintaining optimal functionality of your equipment often requires timely replacement of degraded components. Addressing wear and tear is crucial to ensure smooth operation and extend the lifespan of the device. Recognizing signs of deterioration and understanding the replacement process can save both time and resources in the long run.

Begin by identifying the specific elements that show signs of damage or inefficiency. This might involve regular inspections to catch issues early, thereby preventing more extensive damage. Once you have pinpointed the components needing attention, it’s essential to source high-quality replacements that meet the manufacturer’s specifications. Using inferior parts can lead to further complications and negate any benefits gained from the replacement.

When replacing components, follow a systematic approach. Document the current setup to ensure that reassembly is straightforward. Take the time to clean the surrounding area and remove any debris, as this can affect the performance of the new elements. Pay attention to the installation process; precise alignment and secure fittings are vital for optimal operation.

After installation, it’s important to monitor the new components closely. Regular checks will help confirm that everything is functioning as intended and can alert you to any potential issues before they escalate. By adopting this proactive approach, you can maintain the efficiency and reliability of your equipment for years to come.

Tools Needed for Repairs

When it comes to conducting maintenance or fixing equipment, having the right tools at your disposal is crucial for a successful outcome. A well-prepared toolkit not only streamlines the repair process but also minimizes the risk of damage to the components involved. Understanding which instruments to gather can save time and ensure a smoother workflow.

Essential items typically include screwdrivers, wrenches, pliers, and socket sets, each serving a specific purpose in disassembling and reassembling units. Additionally, having a multimeter can help diagnose electrical issues, while a vacuum pump might be necessary for specific tasks. Safety gear, such as gloves and goggles, is also important to protect yourself during repairs.

Finally, consider having cleaning supplies and lubricants on hand to ensure that all surfaces are maintained properly. By equipping yourself with the appropriate tools and materials, you can effectively tackle various repair challenges with confidence.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance. Whether you’re looking to replace worn-out elements or upgrade existing ones, knowing where to find quality replacements can save both time and money. Various avenues exist to help you secure the necessary items, ensuring your device continues to function smoothly.

Online Retailers

One of the most convenient options is exploring online platforms. Numerous retailers specialize in various components, providing a wide selection to choose from. Websites often feature detailed descriptions, compatibility information, and customer reviews, which can assist in making informed purchasing decisions. Additionally, many offer shipping options, allowing you to receive your items directly at your doorstep.

Local Supply Stores

For those who prefer a hands-on approach, visiting local supply shops can be beneficial. These establishments often carry a range of components and accessories, and the staff can provide valuable guidance based on your specific needs. Furthermore, purchasing in person allows for immediate acquisition, eliminating waiting times associated with online orders.

Upgrades to Improve Performance

Enhancing operational efficiency is crucial for achieving optimal results in any setup. By implementing strategic modifications, users can significantly boost functionality and reliability. Here are some recommended upgrades that can lead to noticeable improvements.

- High-Efficiency Compressor: Replacing the standard compressor with a more efficient model can lead to quicker production times and reduced energy consumption.

- Advanced Cooling System: Upgrading to a modern cooling technology can enhance heat exchange, allowing for better temperature management and consistent output.

- Quality Control Sensors: Incorporating precision sensors can help in monitoring conditions, ensuring optimal performance and minimizing downtime.

In addition to the above, regular maintenance and timely replacements of worn-out components can also play a vital role in maintaining high efficiency.

- Enhanced Filtration: Installing superior filters can improve water quality, leading to better end products and longer equipment life.

- Smart Control Systems: Upgrading to intelligent controls allows for automation, reducing manual input and optimizing operational parameters.

- Improved Insulation: Adding better insulation materials can minimize energy loss, contributing to overall efficiency.

By considering these enhancements, users can ensure their setup operates at peak performance, ultimately leading to increased productivity and satisfaction.

FAQs About Vevor Ice Machines

This section addresses common inquiries regarding the operation, maintenance, and troubleshooting of equipment designed for producing frozen water. Here, users can find concise answers to their pressing questions, ensuring they get the most out of their devices.

Common Questions

- What should I do if my unit is not producing as expected?

- How often should I clean the appliance?

- Are there any specific maintenance tips to prolong its lifespan?

Technical Support

- Where can I find replacement components if needed?

- Is there a warranty available for the equipment?

- How can I contact customer support for additional help?