Kubota ZG127E Parts Diagram for Ultimate Maintenance

In the realm of outdoor machinery, maintaining optimal performance is crucial. A thorough comprehension of the internal workings of these machines can significantly enhance their longevity and efficiency. By exploring the intricate arrangement of various elements within these devices, operators can identify potential issues and ensure smooth operation.

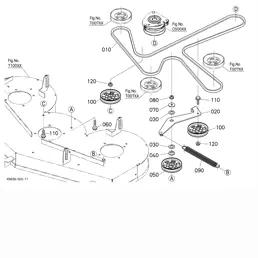

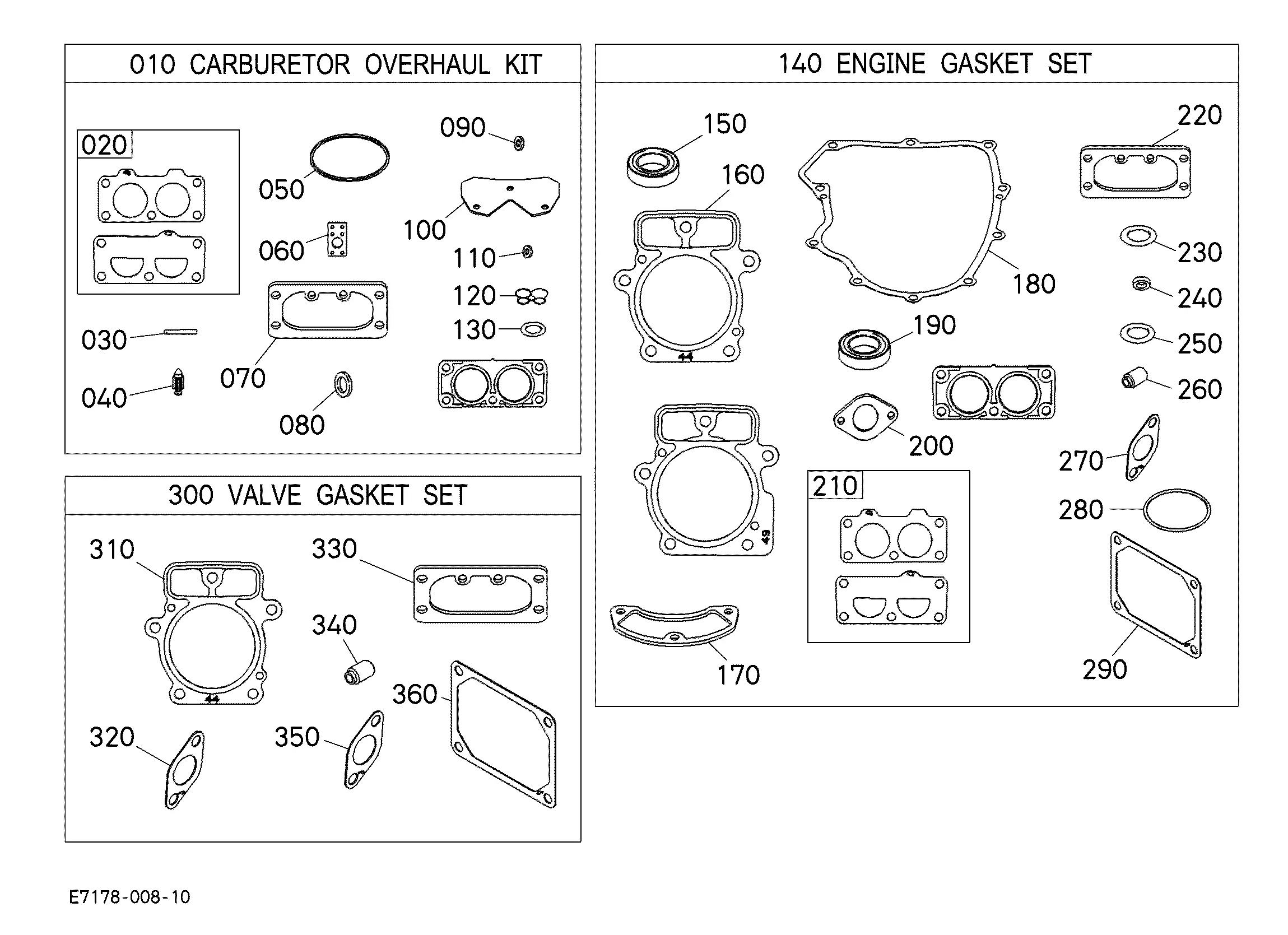

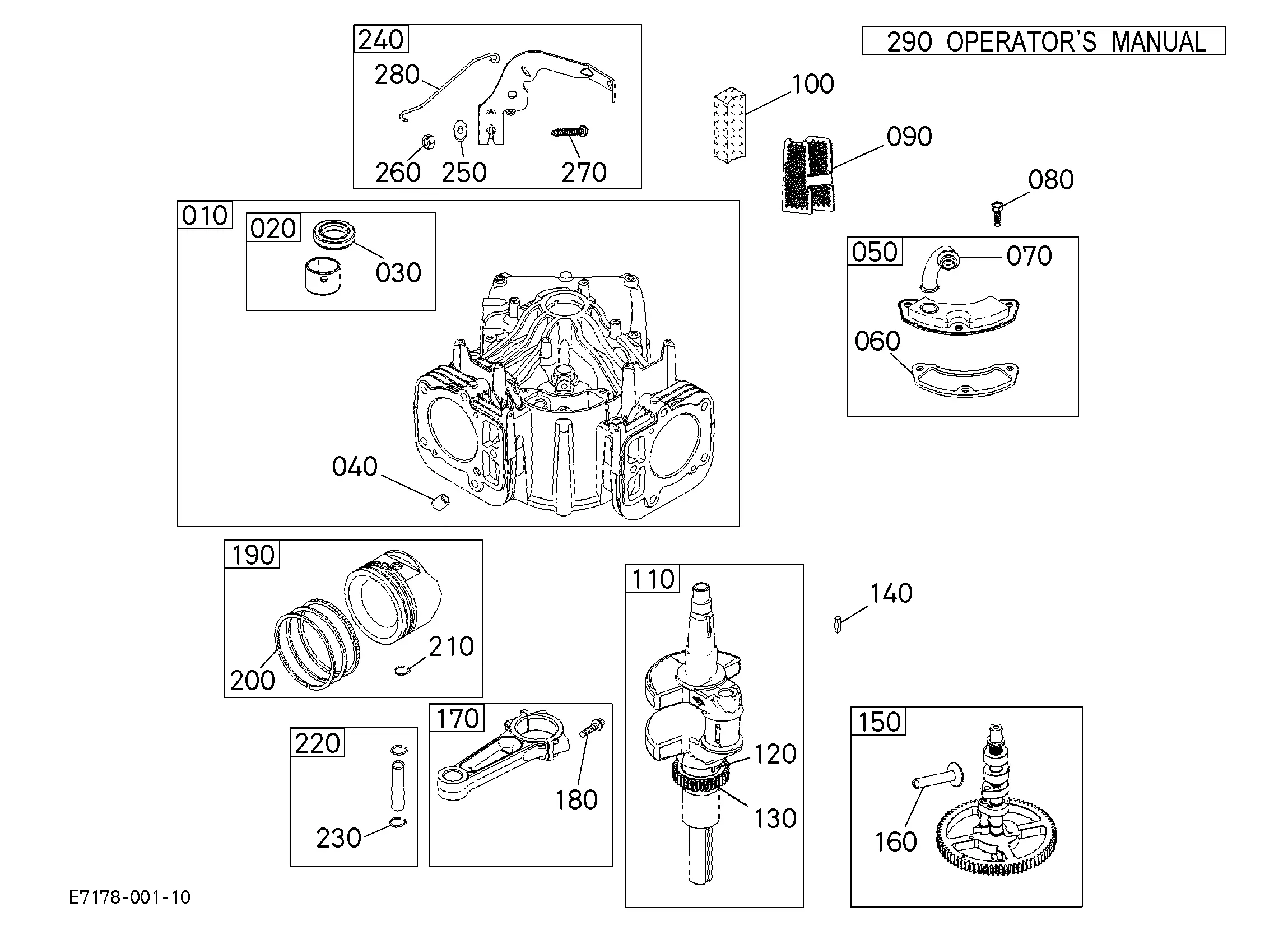

The illustration of component relationships serves as a valuable reference for technicians and enthusiasts alike. It not only aids in recognizing each part’s function but also facilitates the assembly and disassembly process during maintenance or repair tasks. With a detailed layout, users can confidently approach challenges that may arise during operation.

Understanding the connections and functionalities of different components empowers users to make informed decisions when it comes to repairs or upgrades. This knowledge fosters a deeper appreciation for the engineering behind these tools, leading to more effective care and utilization.

Kubota ZG127E Overview

This section provides a comprehensive look at a versatile mowing machine designed for efficiency and ease of use. Known for its robust construction and reliable performance, it caters to various landscaping needs, making it a favorite among both professionals and enthusiasts.

Key Features

Equipped with a powerful engine, this model offers exceptional maneuverability and speed. Its cutting deck is engineered for precision, ensuring a clean and even finish. Additionally, the user-friendly controls enhance the overall operating experience.

Performance and Durability

Durability is a hallmark of this machine, with high-quality materials used throughout its design. Regular maintenance is straightforward, which contributes to its longevity. Users appreciate the balance between power and efficiency, allowing for extended operation without compromise.

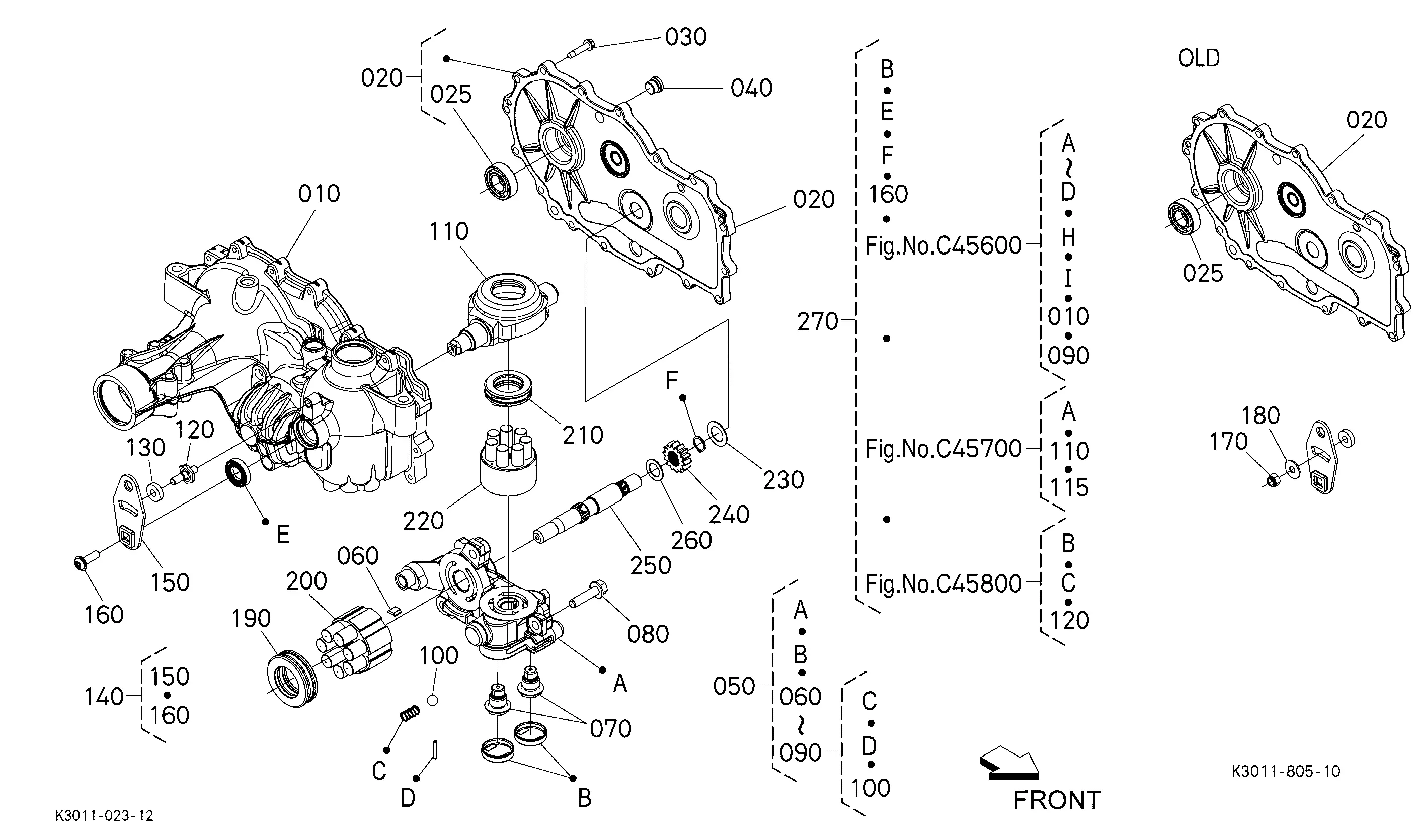

Understanding Parts Diagram Significance

The visual representation of components plays a crucial role in comprehending the assembly and functionality of machinery. By illustrating individual elements and their relationships, these schematics enhance understanding and facilitate maintenance tasks.

These illustrations serve as essential guides for technicians, enabling them to identify specific items and their placements. When one delves into these visuals, it becomes easier to grasp complex mechanisms and perform repairs effectively.

Moreover, accurate depictions assist in ordering replacements, ensuring the right items are sourced quickly. This ultimately streamlines the repair process and minimizes downtime, reinforcing the significance of such representations in the maintenance lifecycle.

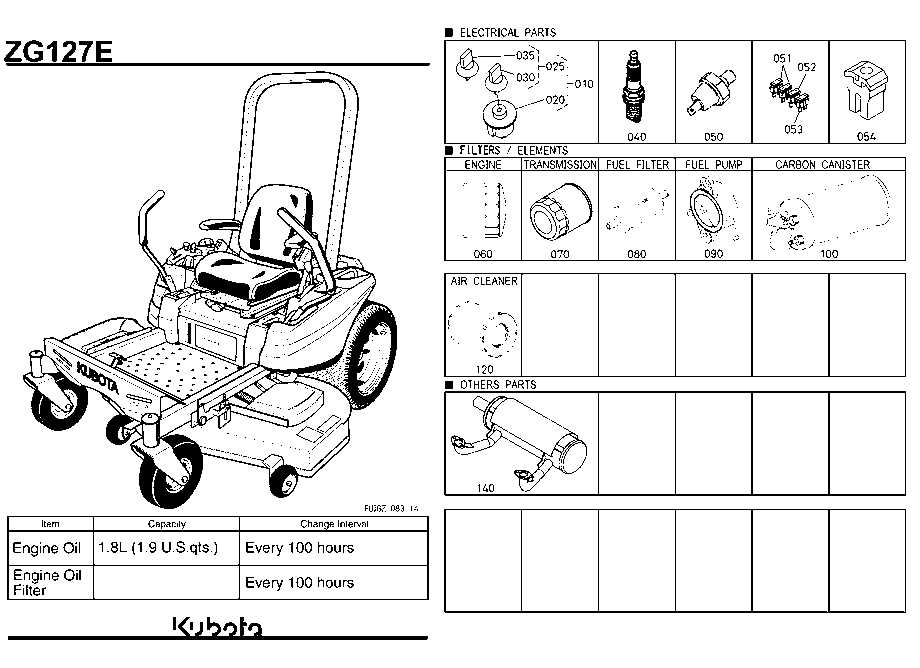

Key Components of ZG127E

This section delves into the essential elements that make up a high-performance mowing machine. Understanding these critical parts can enhance maintenance practices and ensure optimal operation.

Power System

The power system serves as the heart of the equipment, driving its performance. It typically consists of a robust engine designed for efficiency and longevity. This element is crucial for achieving high cutting speeds and ensuring reliability during operation.

Cutting Mechanism

The cutting mechanism is another vital aspect, featuring sharp blades that are engineered for precision. These blades are designed to provide a clean cut, promoting healthy grass growth. Regular inspection and maintenance of this system can significantly impact the overall effectiveness of the machine.

By focusing on these fundamental components, operators can better appreciate the engineering behind the equipment and maintain it for superior performance.

How to Read Parts Diagrams

Understanding the visual representation of components is essential for efficient maintenance and repair. These illustrations offer a clear view of how various elements fit together and function as a whole. Familiarity with these representations can significantly enhance your ability to identify necessary items and their locations.

Identifying Components

Start by familiarizing yourself with the symbols and labels used in the illustrations. Each item is usually numbered or labeled, corresponding to a list or key. Recognizing these markings helps you pinpoint what you need for repairs or replacements.

Understanding Relationships

Pay attention to how different parts are connected. Lines or arrows often indicate relationships and functionality between components. This insight allows for a better understanding of the overall system and can aid in troubleshooting.

| Component | Description | Reference Number |

|---|---|---|

| Element A | Main structural component | 1 |

| Element B | Connecting link | 2 |

| Element C | Control mechanism | 3 |

Common Issues with Kubota ZG127E

When operating a high-performance mower, users may encounter several challenges that can affect efficiency and reliability. Understanding these common problems can help in timely maintenance and repairs, ensuring optimal performance and longevity of the machine.

- Engine Difficulties:

Starting issues or irregular engine performance can stem from various sources, including:

- Fuel system blockages

- Worn spark plugs

- Electrical faults

- Blade Malfunctions:

Uneven cutting or reduced effectiveness may be due to:

- Dull or damaged blades

- Improper blade height adjustment

- Debris buildup around the cutting deck

- Hydraulic System Issues:

Hydraulic problems can lead to poor maneuverability or power loss, often caused by:

- Fluid leaks

- Contaminated hydraulic fluid

- Worn seals or hoses

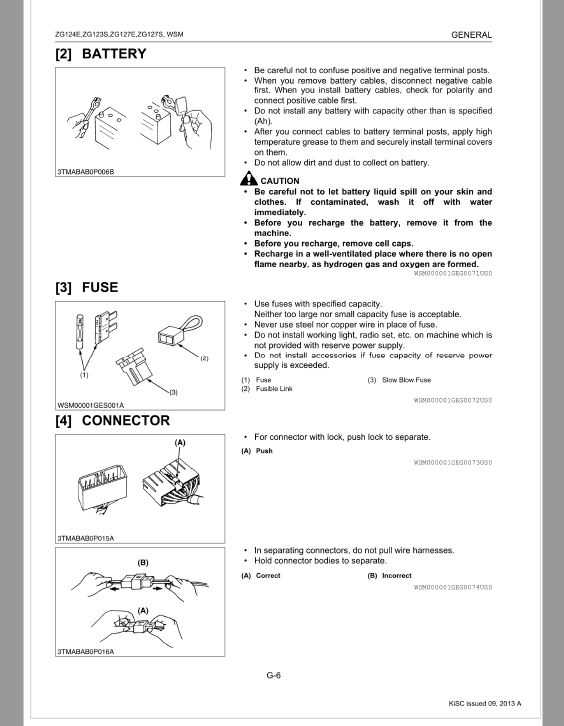

- Electrical System Failures:

Faulty wiring or components can lead to malfunctioning systems, including:

- Battery drainage

- Malfunctioning lights or indicators

- Starter motor issues

- Transmission Problems:

Issues with the transmission can cause difficulty in speed control and responsiveness, often resulting from:

- Low transmission fluid levels

- Worn belts or chains

- Clutch-related issues

Regular maintenance and addressing these concerns promptly can enhance performance and extend the lifespan of your mower.

Finding Replacement Parts Effectively

Locating suitable components for machinery can be a straightforward task with the right approach. Understanding how to navigate available resources and using specific strategies can streamline the process and save time and money. This section explores practical steps to ensure you acquire the necessary items efficiently.

Utilizing Online Resources

The internet offers a wealth of information, making it easier to find what you need. Websites dedicated to equipment and tools often provide comprehensive catalogs. Searching for your equipment’s model number can yield specific results, helping you pinpoint exact components.

Consulting Local Suppliers

Engaging with local dealers can enhance your search. These suppliers may have valuable insights and can often order parts directly for you. Building a relationship with these experts can lead to better service and timely updates on availability.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Wide selection, convenience, often lower prices |

| Local Dealers | Personalized service, immediate access, expert advice |

| Manufacturer’s Website | Authentic parts, specific details, warranty information |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. Regular attention can significantly enhance functionality and prevent costly repairs. Following a systematic maintenance routine will ultimately yield better efficiency and reliability.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct thorough checks for wear and tear to identify issues early. |

| Clean Components | Remove debris and dirt to maintain optimal performance. |

| Check Fluid Levels | Ensure that oils and fluids are at appropriate levels for smooth operation. |

| Follow Manufacturer Guidelines | Adhere to recommended schedules for servicing and part replacements. |

| Store Properly | Keep equipment in a sheltered environment to protect against weather elements. |

Resources for ZG127E Owners

For enthusiasts and operators, having access to comprehensive materials is essential for maintaining and optimizing equipment performance. Various resources can enhance understanding and provide assistance when it comes to upkeep and repairs.

| Resource Type | Description |

|---|---|

| User Manuals | Detailed guides that offer insights into operation and maintenance procedures. |

| Online Forums | Communities where users can share experiences, troubleshoot issues, and exchange tips. |

| Videos | Tutorials demonstrating various tasks such as routine maintenance and repairs. |

| Retailers | Trusted suppliers for sourcing quality components and accessories. |

Upgrades for Improved Performance

Enhancing the efficiency and power of your machinery can significantly impact its overall effectiveness. By implementing certain modifications, operators can achieve smoother operation, better fuel efficiency, and increased durability. Focusing on key components and integrating advanced technologies will ultimately lead to a more productive experience.

Engine Enhancements

Upgrading the engine with high-performance filters and tuning kits can provide a notable boost in horsepower and torque. Aftermarket exhaust systems can also improve airflow, enhancing combustion efficiency and reducing emissions. Investing in quality fuel injectors ensures optimal fuel delivery, further maximizing performance.

Suspension and Handling Improvements

Improving the suspension system with upgraded shock absorbers and springs can lead to better handling and ride comfort. Adding high-traction tires can significantly enhance grip and stability, especially in challenging terrain. These enhancements not only improve performance but also prolong the lifespan of critical components.

Expert Recommendations for Parts Selection

Choosing the right components for your machinery is crucial for optimal performance and longevity. Understanding the intricacies of each element can significantly impact efficiency and maintenance. Below are key considerations to help you make informed decisions.

Quality over Cost

Investing in high-quality components can save you money in the long run by reducing the frequency of replacements and repairs. It’s advisable to source from reputable manufacturers that ensure durability and reliability.

Compatibility Matters

Always verify that the selected components are compatible with your equipment. Mismatched elements can lead to operational issues and costly damages. Consult your user manual or a professional if you are uncertain.

| Criteria | Recommendation |

|---|---|

| Material Quality | Choose durable materials like steel or high-grade composites. |

| Brand Reputation | Select components from established brands with positive reviews. |

| Warranty Options | Look for products with solid warranty terms for added assurance. |

| Technical Support | Prefer suppliers offering comprehensive support and guidance. |