Toro 721e Parts Diagram Overview

Maintaining your machinery requires a comprehensive understanding of its individual elements. Each component plays a crucial role in ensuring the overall efficiency and functionality of the device. Knowing how these parts interact can significantly enhance your ability to troubleshoot and repair issues as they arise.

Visual aids can be invaluable in this process, providing clear representations of each element and its placement within the larger assembly. By utilizing these resources, users can delve into the intricacies of their equipment, ensuring that every piece is accounted for and in optimal condition.

Ultimately, a thorough grasp of these components not only simplifies repairs but also prolongs the life of the machinery. Engaging with detailed illustrations fosters a proactive approach to maintenance, empowering users to address potential problems before they escalate.

Overview

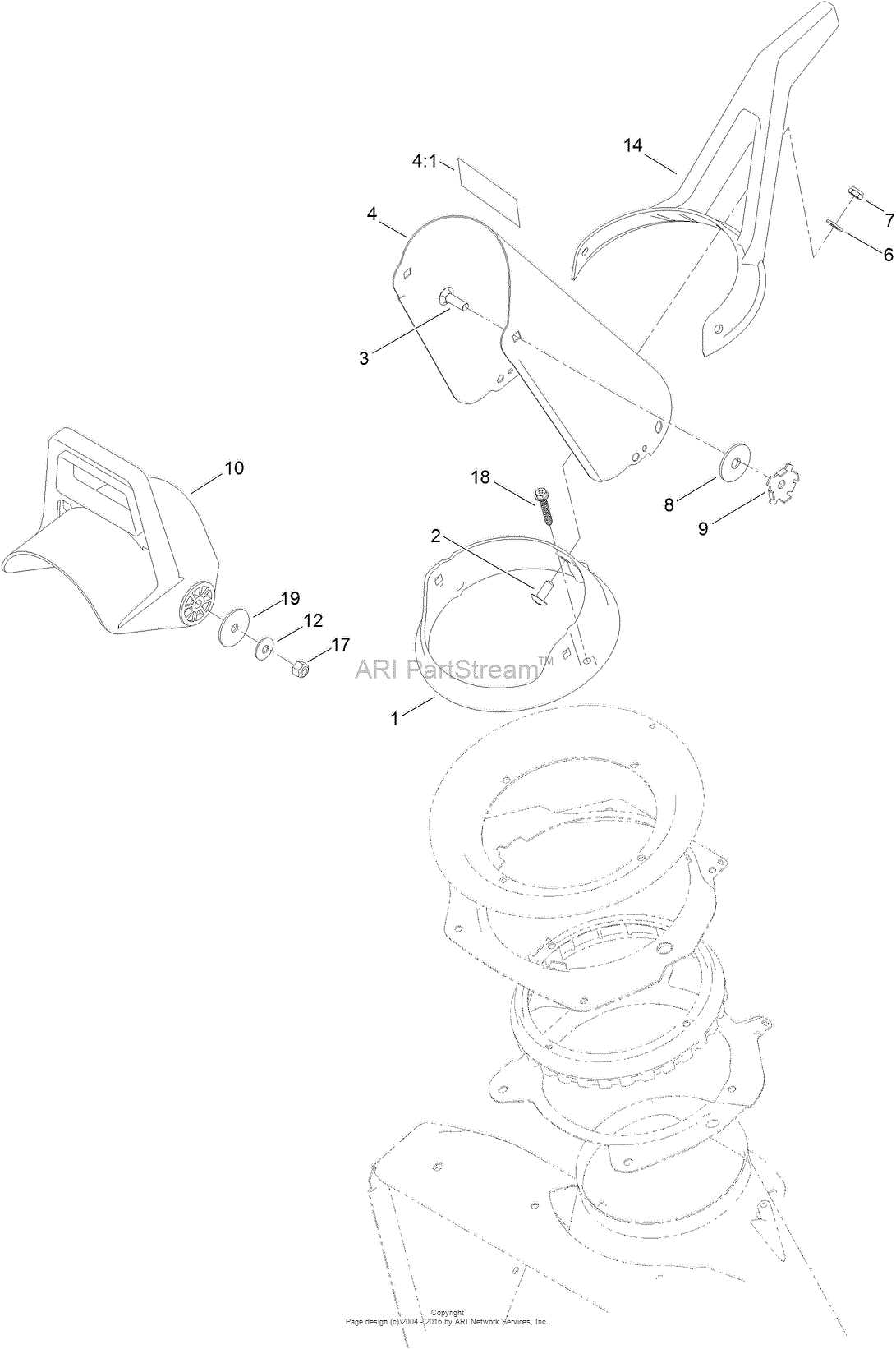

This section provides a comprehensive look at a specific model designed for efficient snow removal. It emphasizes the key features and operational benefits, ensuring users can appreciate its utility and performance in various conditions.

Key Features

- Compact design for easy maneuverability.

- Powerful engine for effective snow clearing.

- Adjustable chute for directing snow discharge.

- Durable materials to withstand harsh weather.

Benefits of Use

- Enhances safety by preventing snow buildup.

- Reduces physical effort required for snow removal.

- Promotes efficient workflow, saving time.

- Ideal for residential and light commercial applications.

Key Features of Toro 721e

This model is designed to provide exceptional performance and convenience for users facing winter challenges. Its thoughtful engineering and robust construction make it a reliable choice for clearing snow efficiently.

Compact Size: The unit is lightweight and easy to maneuver, allowing for efficient operation in tight spaces. This feature is particularly advantageous for homeowners with narrow driveways or walkways.

Powerful Engine: Equipped with a high-performance motor, it delivers strong throwing distance and speed, ensuring that snow is removed quickly and effectively, even under challenging conditions.

User-Friendly Controls: Intuitive controls simplify operation, making it accessible for users of all experience levels. This enhances the overall usability and ensures a comfortable experience during extended use.

Durable Construction: Made from high-quality materials, the design promises longevity and resilience against harsh winter elements, ensuring it remains a dependable tool for many seasons.

Efficient Clearing Width: The effective clearing width allows for swift snow removal, minimizing the time spent on winter maintenance and maximizing productivity.

Enhanced Traction: The advanced wheel design provides excellent grip on icy surfaces, preventing slips and ensuring safe operation even in adverse weather conditions.

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the assembly and maintenance of machinery. They serve as a roadmap, guiding users through the intricate relationships and functionalities of each element. Such illustrations enhance clarity and ensure effective troubleshooting, ultimately prolonging the lifespan of equipment.

Benefits of Visual Guides

Utilizing visual aids offers numerous advantages, including improved communication among technicians, reduced errors during repairs, and streamlined inventory management. These tools enable users to quickly identify necessary elements and their respective locations.

Facilitating Maintenance and Repairs

Access to clear visual guides simplifies the maintenance process, allowing users to efficiently locate and replace worn-out or damaged components. This leads to faster repairs and minimized downtime, ensuring optimal performance.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Clarifies the relationship between components. |

| Reduced Errors | Minimizes mistakes during assembly and repairs. |

| Time Efficiency | Accelerates maintenance and troubleshooting processes. |

Common Replacement Parts

When maintaining outdoor equipment, certain components tend to wear out over time and require replacement. Understanding which elements are commonly exchanged can help ensure your machine operates efficiently and reliably.

- Blades: Sharp and effective blades are crucial for optimal performance. Over time, they may become dull or damaged, necessitating replacement.

- Belts: Drive and cutting belts can wear down due to constant use. Regular inspection can prevent unexpected breakdowns.

- Filters: Air and fuel filters play an essential role in maintaining engine efficiency. Clogged filters can lead to reduced performance.

- Batteries: If your equipment relies on a battery, ensuring it is in good condition is vital for reliable operation.

- Wheels: Tires can suffer from wear and tear, impacting mobility. Replacing them when necessary improves functionality.

Being aware of these frequently replaced components can help you keep your machinery in top condition, extending its lifespan and enhancing its performance.

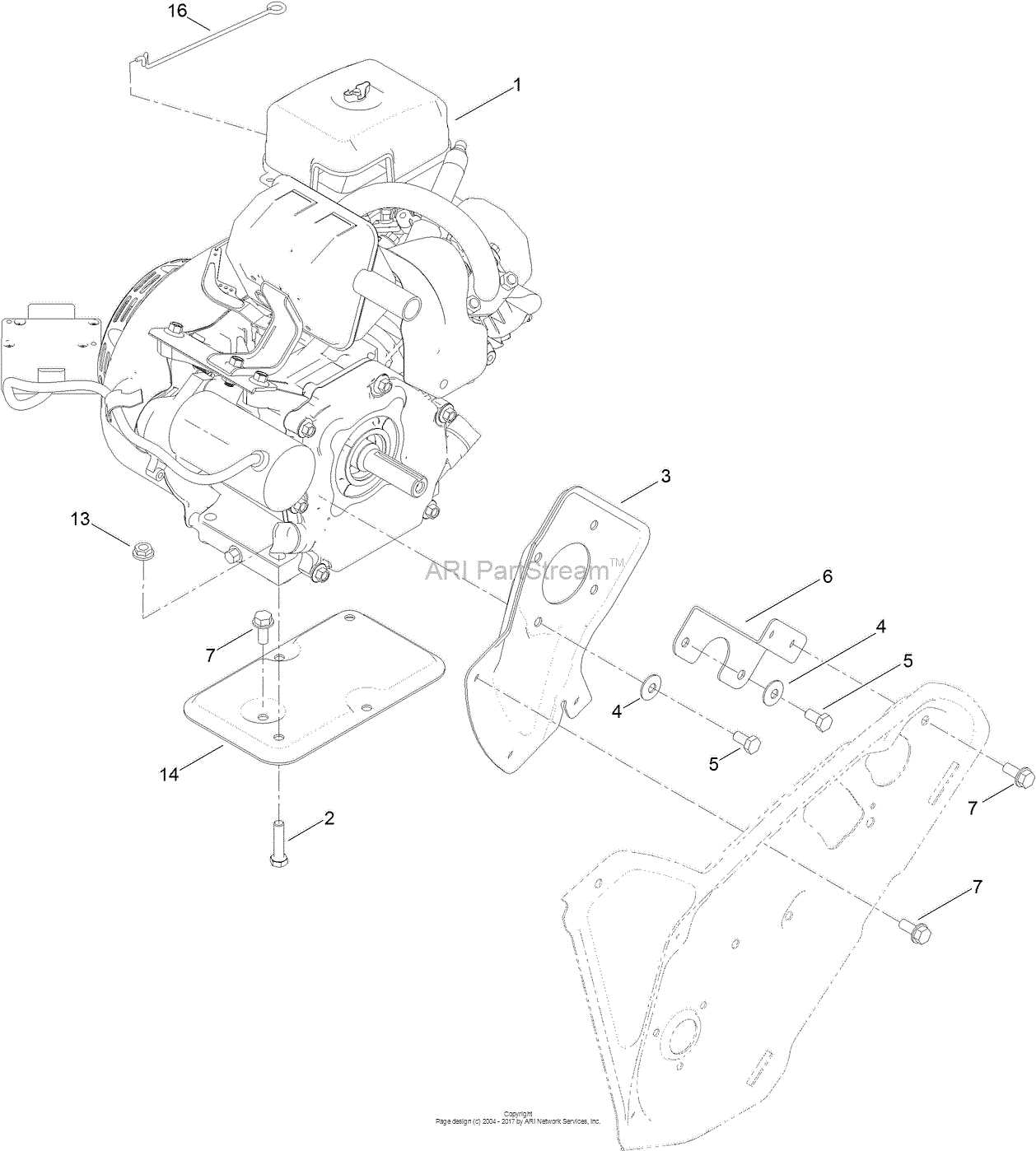

Understanding the Engine Components

Engine assemblies comprise various critical elements that work in harmony to ensure optimal performance. Each part plays a vital role in the overall functionality, contributing to efficiency and reliability in operation.

Key Elements of the Engine

Among the essential components, several stand out due to their significant impact on engine operation. Recognizing these parts helps in grasping the mechanics behind power generation and movement.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and allows combustion. |

| Piston | Converts fuel combustion into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of the engine valves. |

| Fuel Injector | Delivers fuel into the combustion chamber. |

Conclusion

Understanding these critical components provides insights into the intricate workings of an engine. Each element’s performance directly influences the overall effectiveness, making knowledge of these parts essential for maintenance and troubleshooting.

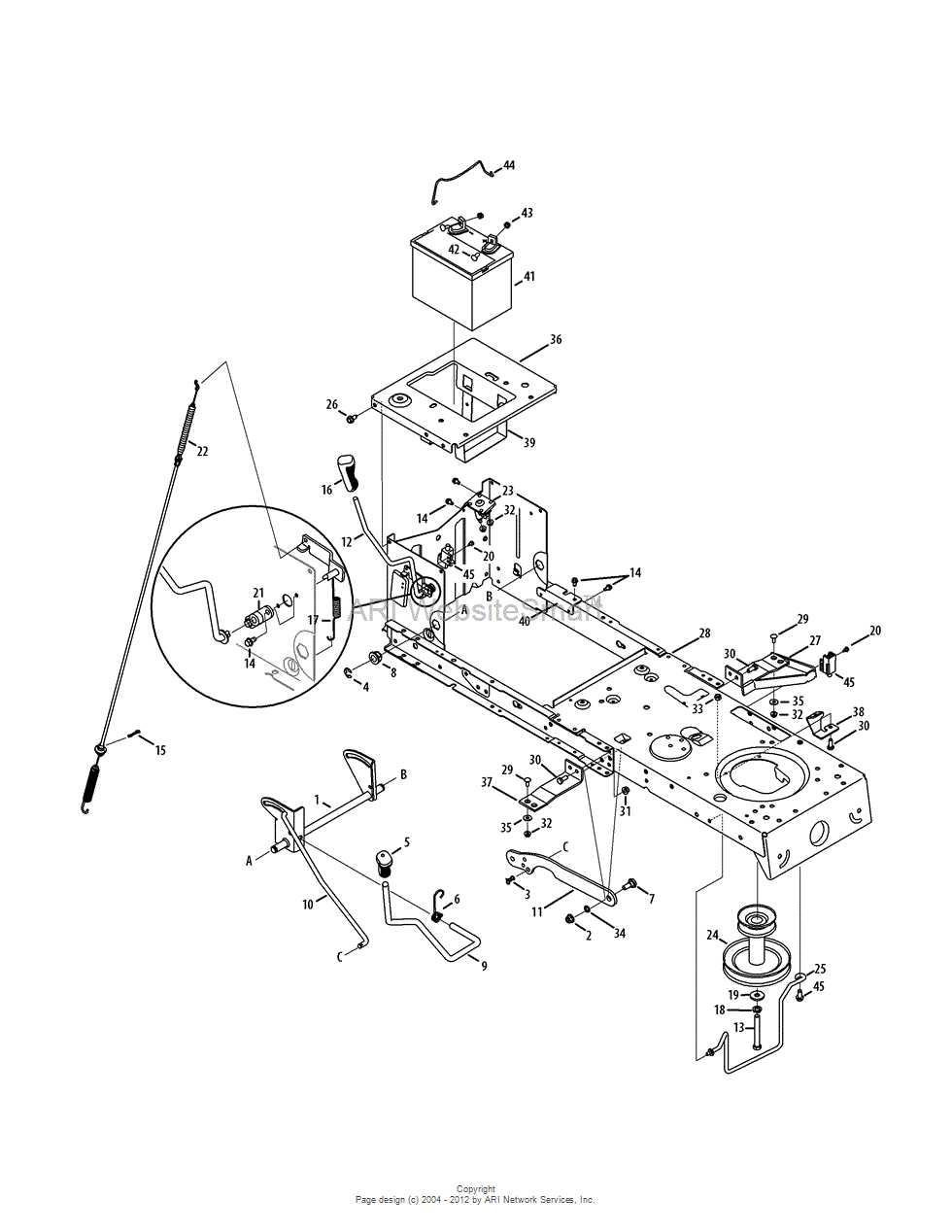

Transmission and Drive System Parts

The efficiency of any machinery heavily relies on its propulsion mechanism. This section explores the essential components that facilitate movement and control, ensuring optimal performance and reliability.

Key Components

Critical elements include gears, belts, and pulleys, which work in harmony to transmit power from the engine to the wheels. These components must be robust to withstand wear and tear while maintaining precision in operation.

Maintenance and Upgrades

Regular inspection and timely replacements are vital for longevity. Upgrading specific elements can enhance efficiency, providing an ultimate boost to performance. Investing in high-quality replacements ensures the system functions at its best, contributing to overall durability.

Fuel System Components Explained

The efficiency and performance of any engine rely heavily on its fuel delivery system. This intricate assembly ensures that the correct mixture of fuel and air reaches the combustion chamber, optimizing power and minimizing emissions. Understanding the individual elements that comprise this system is crucial for maintenance and troubleshooting.

| Component | Description |

|---|---|

| Fuel Tank | The reservoir that holds the fuel, designed to prevent leaks and ensure safe storage. |

| Fuel Pump | This device transports fuel from the tank to the engine, maintaining the necessary pressure for optimal performance. |

| Fuel Filter | A critical component that removes impurities and debris from the fuel before it reaches the engine, protecting internal parts. |

| Carburetor/Fuel Injector | These elements mix air and fuel in the correct proportions; carburetors use mechanical means while fuel injectors operate electronically. |

| Fuel Lines | Hoses or pipes that transport fuel between the tank, pump, filter, and engine, designed to withstand pressure and prevent leaks. |

| Air Filter | This component ensures that only clean air enters the combustion chamber, enhancing fuel efficiency and engine longevity. |

Each part of the fuel delivery system plays a vital role in ensuring the engine operates smoothly and efficiently. Regular inspection and maintenance of these components can lead to improved performance and extended lifespan of the engine.

Electrical System Overview

The electrical framework of a machinery unit is crucial for its efficient operation and overall functionality. This system encompasses various components that work in harmony to ensure seamless performance and reliable energy distribution.

- Power Source: The origin of energy supply that powers the entire mechanism.

- Wiring Harness: A network of cables that connects different parts, facilitating communication and energy transfer.

- Control Module: The brain of the system, managing various functions and ensuring the device operates correctly.

- Battery: A storage unit that provides energy when needed, particularly during start-up or when the primary source is unavailable.

Each component plays a vital role in maintaining the machine’s efficiency and reliability. Understanding this system is essential for effective troubleshooting and maintenance.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires a strategic approach to upkeep and care. By adhering to regular maintenance routines, you can significantly enhance the lifespan and efficiency of your machinery. This section offers key practices to help you achieve optimal results over time.

Regular Cleaning

Keeping your machinery clean is essential. Accumulated dirt and debris can hinder performance and lead to wear and tear. Make it a habit to inspect and clean after each use.

Lubrication and Inspection

Routine lubrication of moving parts prevents friction and prolongs service life. Additionally, conducting periodic inspections for signs of wear helps identify potential issues before they escalate.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | After each use | Prevents buildup and damage |

| Lubrication | Monthly | Reduces friction |

| Inspection | Quarterly | Identifies wear and tear |

Where to Find Toro Parts

Locating components for lawn maintenance equipment can be streamlined with the right resources. Numerous avenues exist for acquiring necessary items, ranging from local retailers to online marketplaces.

Local authorized dealers often provide the best selection and expertise, ensuring you receive quality replacements tailored to your specific model. Additionally, big-box stores may carry compatible items, making it convenient for quick fixes.

Online platforms offer vast inventories, allowing you to compare prices and find rare components. Websites dedicated to equipment parts often feature user-friendly search tools, enabling you to pinpoint exactly what you need. Forums and communities can also serve as valuable resources, where enthusiasts share recommendations and experiences.

For those who prefer a hands-on approach, salvage yards can be treasure troves of functional items at a fraction of the cost. Exploring these various options will ultimately enhance your ability to maintain and repair your machinery efficiently.

Aftermarket vs. OEM Parts

When maintaining machinery, users often face the choice between factory-manufactured components and those produced by third-party suppliers. Each option presents distinct advantages and disadvantages that can impact performance, longevity, and cost-effectiveness.

Factory-manufactured components are crafted by the original equipment manufacturer and are typically designed to meet specific standards. This ensures compatibility and reliability, making them a preferred choice for those seeking to maintain optimal functionality. They often come with warranties, providing peace of mind regarding their quality.

On the other hand, third-party alternatives can offer significant savings and a broader variety of choices. These components may be designed to perform similarly to their factory counterparts, but variations in quality and performance can exist. Consumers should conduct thorough research to ensure that these options meet their needs without compromising safety or efficiency.

Ultimately, the decision between these two types of components should be guided by individual requirements, budget considerations, and the specific context of use.

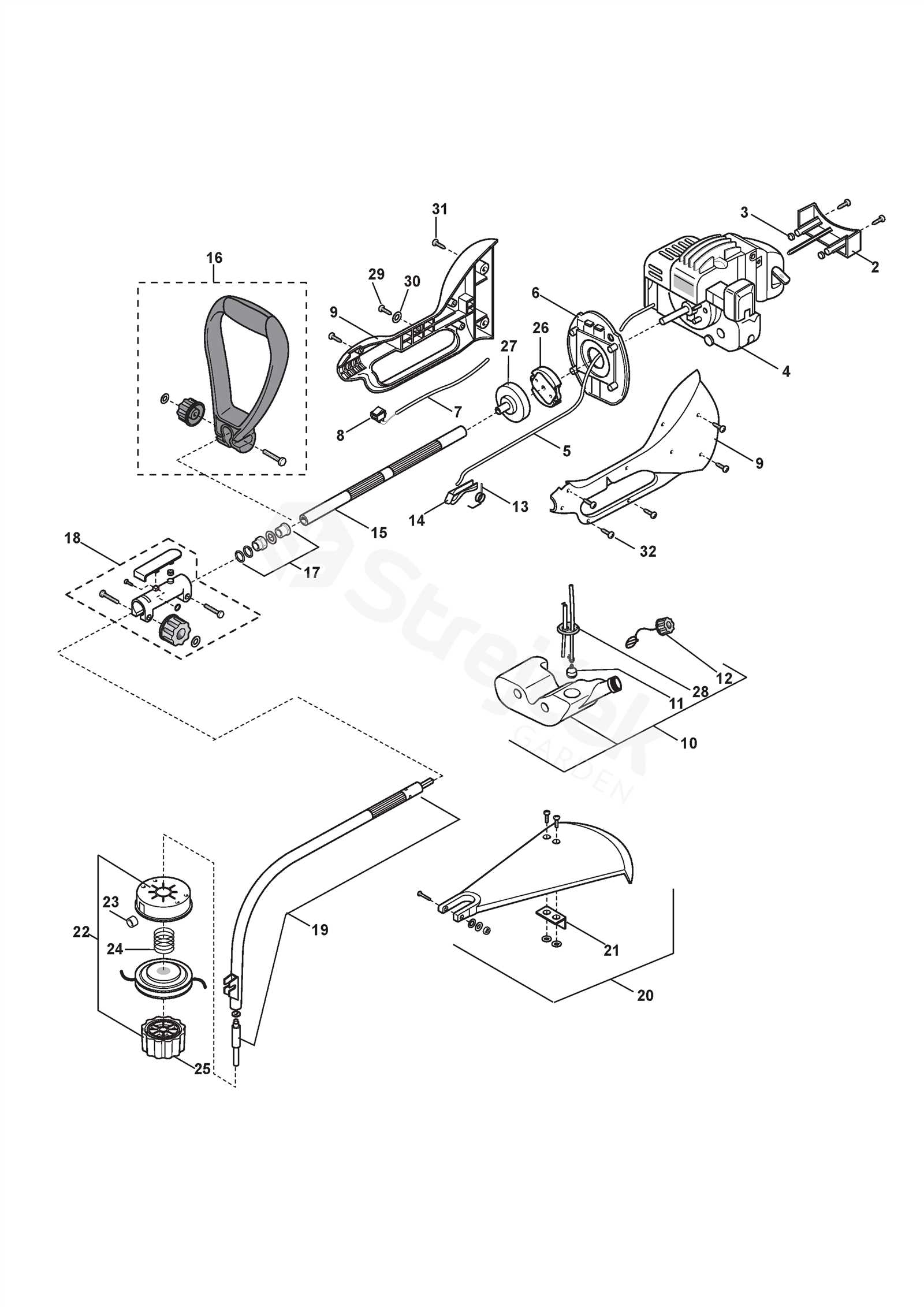

Assembly Instructions and Safety

This section provides essential guidance on the proper assembly of equipment, emphasizing the importance of safety throughout the process. Following these instructions will ensure that the machine functions correctly while minimizing the risk of accidents or injuries.

Assembly Steps

Begin by gathering all necessary components and tools. Carefully examine each part to confirm it is in good condition before proceeding. Follow the step-by-step instructions outlined in the manual, ensuring that each component is securely attached. Pay close attention to alignment and fastening requirements, as improper assembly can lead to malfunctions.

Safety Precautions

Always prioritize safety while assembling. Wear appropriate personal protective equipment, such as gloves and safety goggles. Keep the workspace clean and organized to prevent hazards. Be mindful of sharp edges and moving parts during assembly. If assistance is needed, do not hesitate to seek help to avoid mishandling any components.

By adhering to these assembly instructions and safety measures, users can ensure both a successful setup and a safe working environment.

Frequently Asked Questions

This section aims to address common inquiries related to equipment maintenance and component identification. Here, users can find answers to typical concerns, ensuring a better understanding of their machinery.

- What should I do if a part is missing?

If you notice a component is absent, first check the packaging thoroughly. If it’s still missing, contact your supplier for assistance.

- How can I identify the right replacement for a broken piece?

Refer to the user manual for specifications and part numbers. It’s also helpful to consult with customer service for guidance.

- Are there any maintenance tips for prolonging the life of my equipment?

Regularly clean and inspect your machinery, lubricate moving parts, and store it in a dry place to prevent rust and wear.

- Where can I find reliable sources for purchasing components?

Consider authorized dealers or reputable online retailers that specialize in machinery accessories.

- How often should I replace specific components?

The frequency of replacement varies by usage. Check the manual for recommended schedules, or replace parts that show signs of significant wear.