Kubota L2950 Parts Overview

Exploring the intricate structure of machinery enhances our ability to maintain and repair equipment efficiently. Visual representations serve as essential tools, guiding users through various components and their interactions.

By familiarizing oneself with the arrangement and function of different elements, operators can identify issues more quickly and implement effective solutions. This knowledge not only extends the lifespan of the machinery but also optimizes its performance.

Utilizing detailed illustrations of individual components can greatly aid in understanding their specific roles. With a clear view of how each part contributes to the overall functionality, one can approach maintenance tasks with confidence and precision.

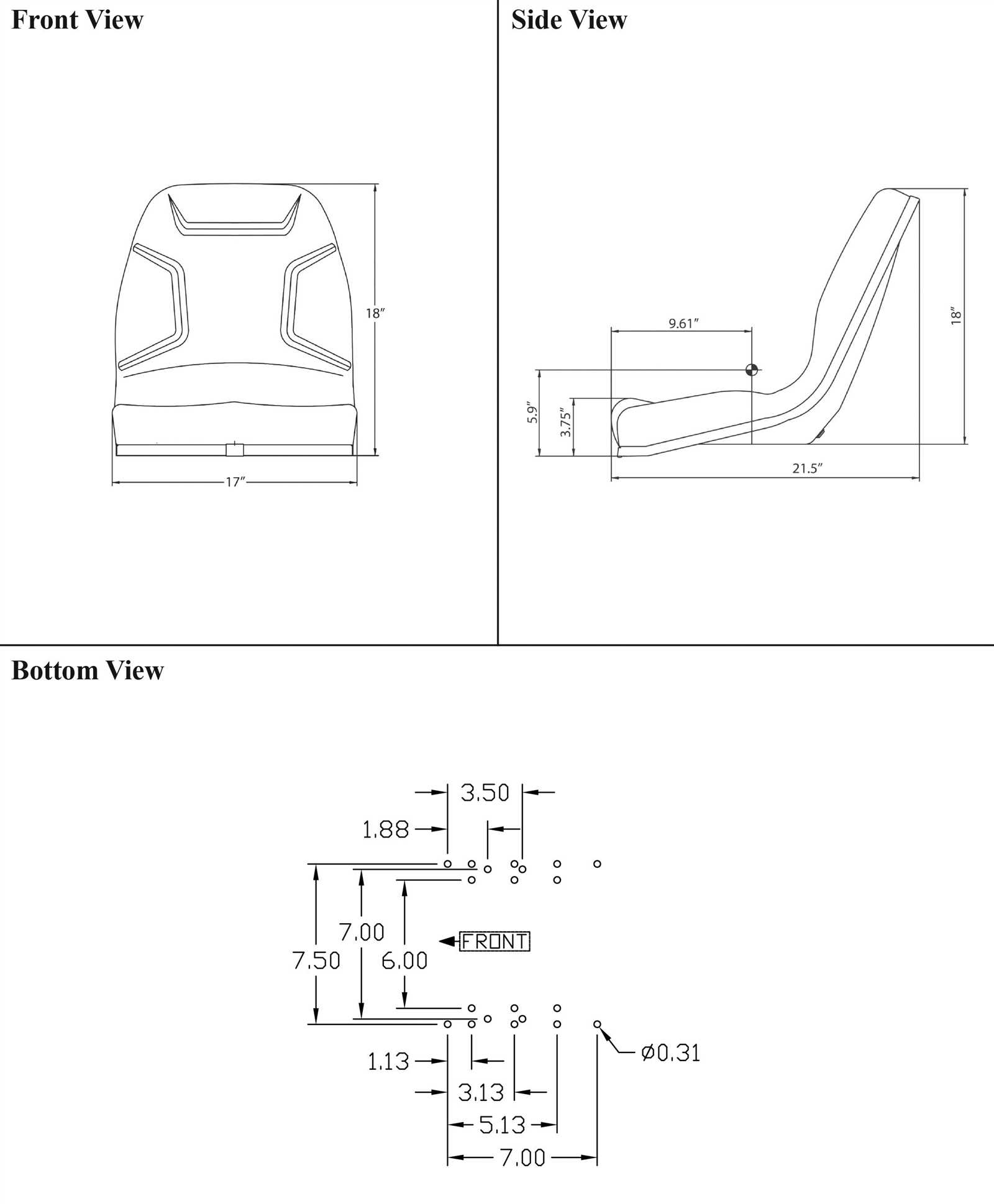

Overview of the Agricultural Machine

This section provides a comprehensive insight into a specific model of agricultural machinery known for its reliability and versatility in various farming tasks. Designed to cater to diverse agricultural needs, it showcases a range of features and specifications that enhance its functionality.

The machine is characterized by:

- Robust construction ensuring durability.

- Advanced engine technology for efficient performance.

- User-friendly controls for ease of operation.

- Adaptability to various attachments for different tasks.

In summary, this model is a valuable asset for those seeking to improve productivity in agricultural practices while maintaining ease of use and maintenance.

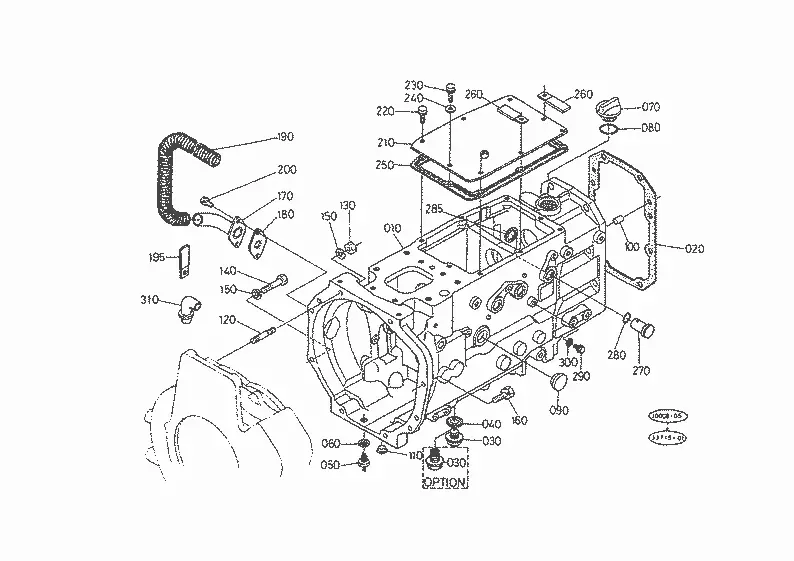

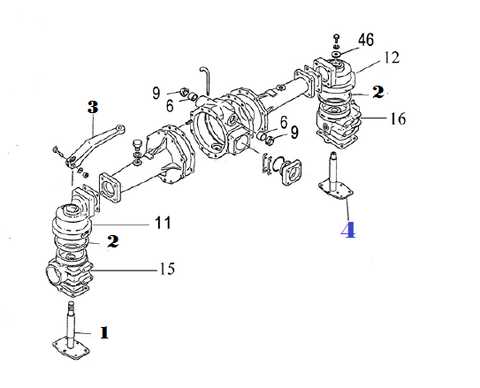

Key Components of L2950

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The powerhouse of the machine, providing the necessary energy for operation.

- Transmission: Responsible for transferring power from the engine to the wheels, enabling movement.

- Hydraulic System: Facilitates the operation of various attachments and enhances lifting capabilities.

- Chassis: The frame that supports all components, ensuring stability and durability.

- Electrical System: Powers the controls and lighting, essential for operation in various conditions.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Each of these elements plays a vital role in ensuring that the equipment operates smoothly and effectively, making it essential for users to be familiar with them.

Importance of Parts Diagrams

Understanding the layout and functionality of components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that guide users in identifying each element’s role and location, ensuring a smoother workflow.

Enhancing Maintenance Efficiency

Clear illustrations facilitate quicker identification of necessary replacements, reducing downtime. This efficiency leads to enhanced operational performance and longevity of the equipment.

Improving Troubleshooting Accuracy

By providing a comprehensive view of various components, these visuals aid technicians in diagnosing issues more accurately. This understanding minimizes guesswork, allowing for targeted interventions.

| Benefit | Description |

|---|---|

| Efficiency | Reduces time spent on repairs and maintenance. |

| Accuracy | Enhances diagnostic capabilities for issues. |

| Guidance | Serves as a reference for correct assembly and disassembly. |

Common Replacement Parts

When maintaining machinery, understanding frequently needed components is essential for ensuring optimal performance and longevity. Many of these essential elements may wear out over time and require replacement to keep the equipment functioning effectively.

Engine Components

Key elements such as filters, gaskets, and belts are vital for the engine’s smooth operation. Regular checks and timely replacements of these items help prevent major failures and enhance efficiency.

Hydraulic System Essentials

In hydraulic systems, components like hoses and seals often need attention. These parts play a crucial role in maintaining pressure and fluid integrity, and their proper functioning is necessary for the overall performance of the machinery.

Identifying Engine Parts

Understanding the various components of an engine is essential for effective maintenance and repairs. Each element plays a crucial role in the overall functionality and performance of the machine.

- Cylinder Head: This component houses the combustion chamber and valves, crucial for the intake and exhaust processes.

- Crankshaft: Converts linear motion from the pistons into rotational motion, driving the machinery.

- Pistons: Move up and down within the cylinders, compressing the fuel-air mixture and transmitting power.

- Oil Pump: Ensures proper lubrication by circulating oil throughout the engine.

- Fuel Injector: Delivers the precise amount of fuel into the combustion chamber for efficient burning.

Familiarizing oneself with these components not only aids in troubleshooting issues but also enhances overall mechanical knowledge.

Hydraulic System Components

The hydraulic system is a crucial aspect of many machinery, ensuring efficient operation through fluid power. Understanding the components involved in this system helps in maintaining and optimizing performance. Each part plays a significant role in the overall functionality, contributing to tasks such as lifting, steering, and controlling various attachments.

Main Elements of the Hydraulic System

The primary components include the pump, cylinders, valves, and hoses, all of which work in concert to facilitate fluid movement and pressure regulation. Each element must be in good condition to ensure seamless operation.

Table of Components

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow and pressure for the system |

| Hydraulic Cylinder | Converts hydraulic energy into mechanical force |

| Control Valve | Regulates fluid flow and direction |

| Hoses and Fittings | Connect components and transport fluid |

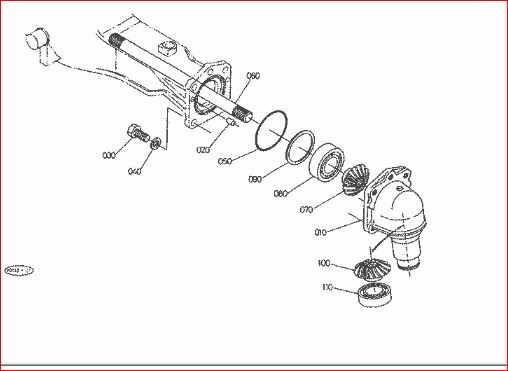

Transmission and Drive Parts

This section focuses on the essential components involved in the movement and control of a vehicle’s power system. Understanding these elements is crucial for maintaining efficiency and performance in machinery.

Key Components

- Gearbox: Responsible for adjusting the torque and speed transmitted from the engine.

- Clutch: Engages and disengages the engine from the transmission system, allowing for smooth gear changes.

- Driveshaft: Transfers power from the transmission to the wheels, ensuring effective movement.

- Axles: Support the vehicle’s weight while allowing for the rotation of the wheels.

- Differential: Distributes power to the wheels, enabling them to rotate at different speeds during turns.

Maintenance Tips

- Regularly check fluid levels in the transmission to ensure smooth operation.

- Inspect the clutch for signs of wear and replace if necessary.

- Examine the driveshaft for any signs of damage or excessive play.

- Keep the differential lubricated to avoid overheating and failure.

Electrical System Overview

The electrical framework of a machinery unit plays a crucial role in ensuring its efficient operation. This system encompasses various components that work together to facilitate power distribution, control functions, and signal transmission, ultimately enhancing performance and reliability.

Main Components

This section outlines the key elements found within the electrical system, including the battery, alternator, wiring harness, and ignition system. Each component contributes uniquely to the overall functionality of the machinery.

| Component | Function |

|---|---|

| Battery | Stores electrical energy and provides power for starting the engine. |

| Alternator | Generates electricity to recharge the battery and power electrical accessories. |

| Wiring Harness | Connects various electrical components and facilitates signal transmission. |

| Ignition System | Ignites the fuel-air mixture, allowing for engine operation. |

Importance of Maintenance

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance practices can significantly extend the lifespan and performance of your equipment.

- Routine Inspections: Conduct regular checks to identify wear and tear early.

- Fluid Levels: Regularly monitor and replace oil, coolant, and hydraulic fluids.

- Filter Replacement: Change air and fuel filters periodically to maintain optimal function.

- Clean Components: Keep external parts free from dirt and debris to prevent damage.

- Check Belts and Hoses: Inspect for cracks or fraying and replace as needed.

By implementing these practices, you can ensure your equipment remains reliable and effective for years to come.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that fit perfectly and function efficiently.

Authorized dealers are among the best options, as they offer original products backed by the manufacturer’s warranty. Additionally, online marketplaces can provide a wide selection, but it’s essential to verify the credibility of the seller to avoid counterfeit goods.

Another effective approach is to consult local repair shops that specialize in your equipment. They often have connections to trusted suppliers and can recommend specific retailers. Networking with fellow operators can also lead to valuable insights on where to obtain genuine components.

Using Diagrams for Repairs

Utilizing visual representations is essential for effective maintenance and troubleshooting of machinery. These illustrations offer a clear overview of components, making it easier to identify parts that require attention or replacement.

Key benefits of using visual aids include:

- Enhanced understanding of complex assemblies.

- Quick identification of specific elements and their functions.

- Facilitated communication among technicians and repair teams.

When engaging in repair tasks, following these steps can improve efficiency:

- Consult the visual representation to familiarize yourself with the layout.

- Locate the component in question based on the illustration.

- Proceed with the repair or replacement using the guidance provided.

Incorporating these visual tools into repair workflows not only streamlines the process but also reduces the likelihood of errors, ensuring machinery operates at optimal levels.