Mercury 90 HP Parts Overview

The 90 hp engine is a powerful and efficient choice for various aquatic activities. This model is known for its reliable performance, making it suitable for both recreational and professional use. Understanding the structure and organization of its components can help ensure its longevity and smooth operation.

In order to maintain this type of engine effectively, it is crucial to become familiar with the various elements that contribute to its function. Each element has a specific role, working in harmony to deliver optimal output and ensure a seamless experience on the water.

By exploring the arrangement and connectivity of different mechanisms, users can better grasp how to address maintenance needs and ensure peak performance. This understanding not only aids in routine care but also simplifies troubleshooting, making it easier to identify and resolve potential issues.

Engine Components Overview

The 90 HP motor is built from various crucial elements that ensure its smooth performance and reliable operation. Each part plays a specific role, contributing to the overall efficiency and power output of the engine. Understanding the layout and function of these elements can aid in maintaining and optimizing the motor’s performance.

Key Elements and Their Functions

This engine features several components designed to work together seamlessly. Below is an outline of the primary elements:

- Power Unit: This core component generates the energy required for propulsion, transforming fuel into kinetic energy.

- Cooling System: Helps to regulate the temperature, preventing overheating during extended operation.

- Fuel Delivery System: Ensures the precise mix of fuel and air, providing consistent power and efficiency.

- Electrical System: Manages ignition and ensures proper electrical flow for various controls and sensors.

Maintenance Essentials

Regular upkeep is vital for the longevity of each element within the engine. Here are some tips for maintaining optimal performance:

- Inspect and

Main Elements of a 90 HP Outboard

A 90 horsepower outboard engine is built with several essential components that ensure its reliable performance and smooth operation on the water. Each element is designed to contribute to the overall efficiency, making the engine suitable for various types of watercraft. Understanding these components can help maintain and optimize the engine’s performance.

Engine Block and Cylinders

The core of the outboard’s power lies in its engine block and cylinders. These parts work together to generate the necessary force that drives the propeller. The engine block houses the cylinders, where fuel combustion occurs, translating into the motion that powers the vessel forward. Proper maintenance of these components is crucial for consistent performance.

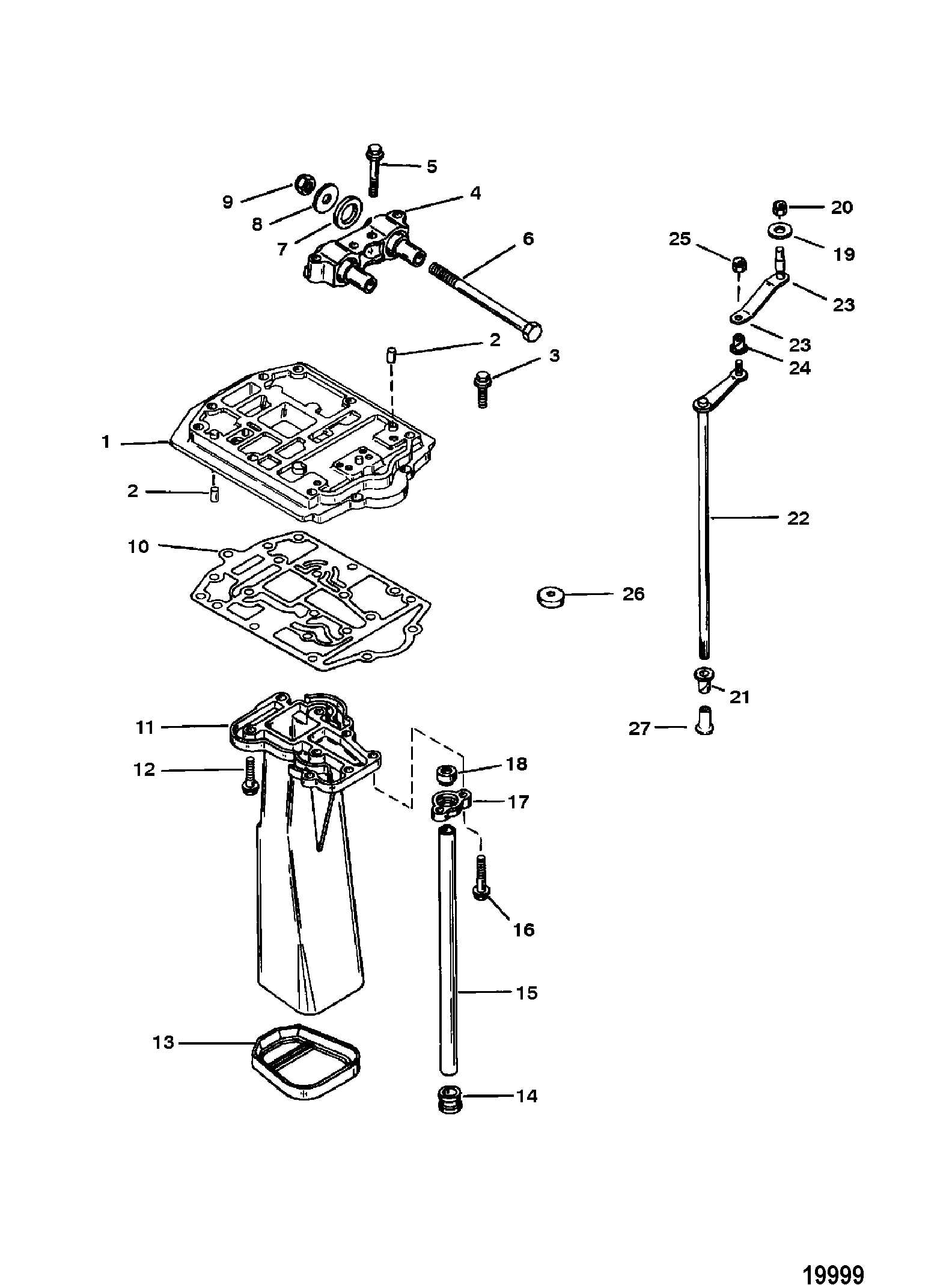

Cooling and Fuel Systems

The cooling system ensures that the engine remains at optimal temperature during operation, preventing overheating. This is typically managed by a water pump that circulates water through the engine. Meanwhile, the fuel system is responsible for delivering the right mixture of fuel and air to the cylinders, allowing for efficient combustion and smooth operation. Regular checks of these systems can enhance the durability and performance

Understanding Marine Engine Components

Operating a marine engine requires a basic grasp of its core elements and how they interact to ensure efficient performance. These mechanisms work together, forming a complex system that powers the vessel through various aquatic environments. By familiarizing oneself with each element, maintaining the engine and diagnosing potential issues becomes much more manageable.

Key Functional Units

Each unit within the engine has a specific role, contributing to the overall functioning of the system. Some provide energy conversion, while others ensure cooling and lubrication. Ignition systems, for instance, initiate the power cycle, while cooling mechanisms keep temperatures stable during operation.

Maintaining Smooth Operation

To keep the system in peak condition, regular checks and replacements of essential components are crucial. Lubrication is a vital part of the process, minimizing wear and ensuring smooth movement. Understanding the purpose of each part helps to perform these tasks more effectively, extending the lifespan of the engine.

Key Components of 90 HP Engine

The 90 horsepower outboard motor is built from various essential elements that ensure smooth and efficient operation. These components work in harmony to deliver optimal performance, durability, and reliability in different conditions. Understanding these elements helps in maintaining and troubleshooting the engine for seamless functionality.

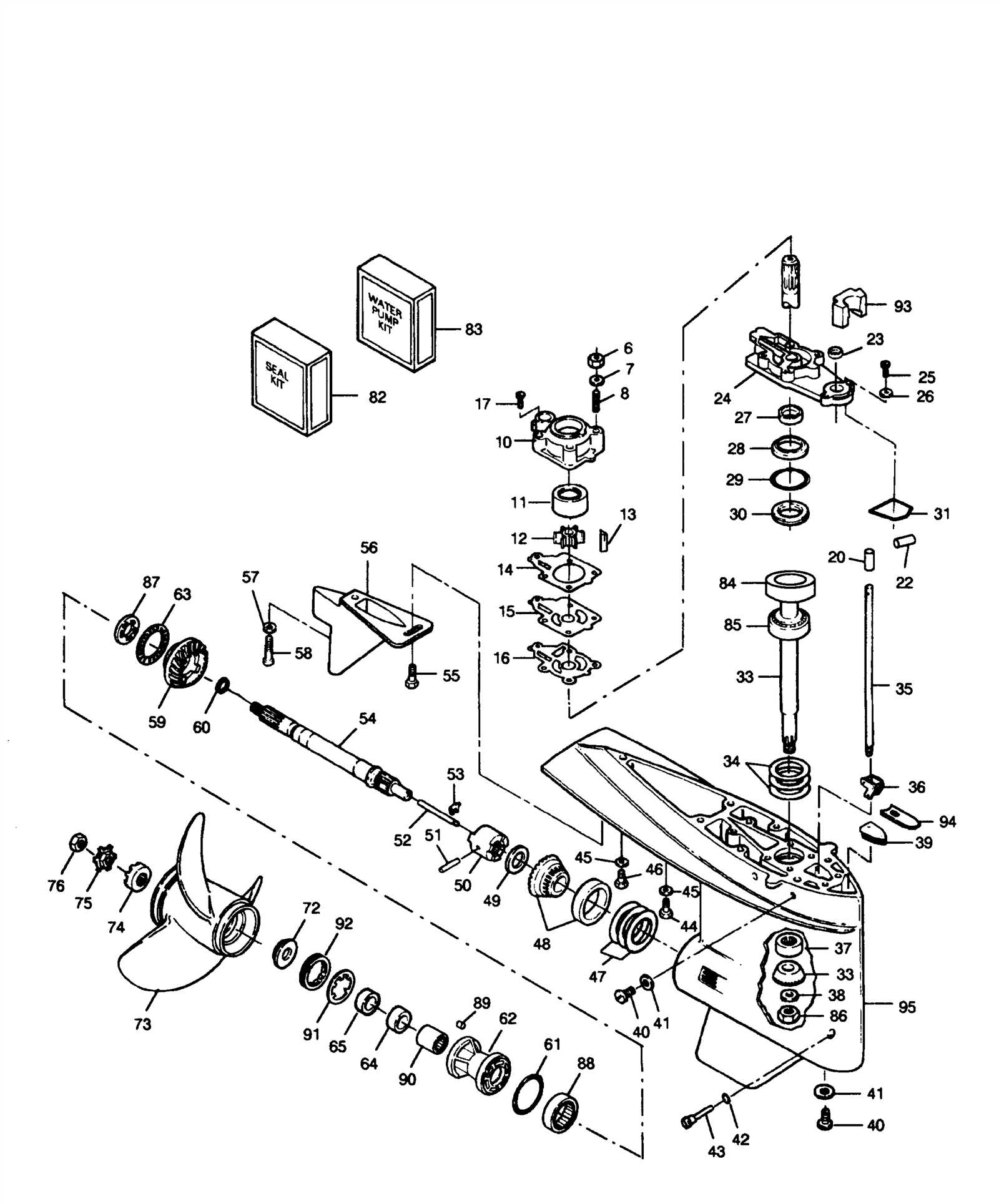

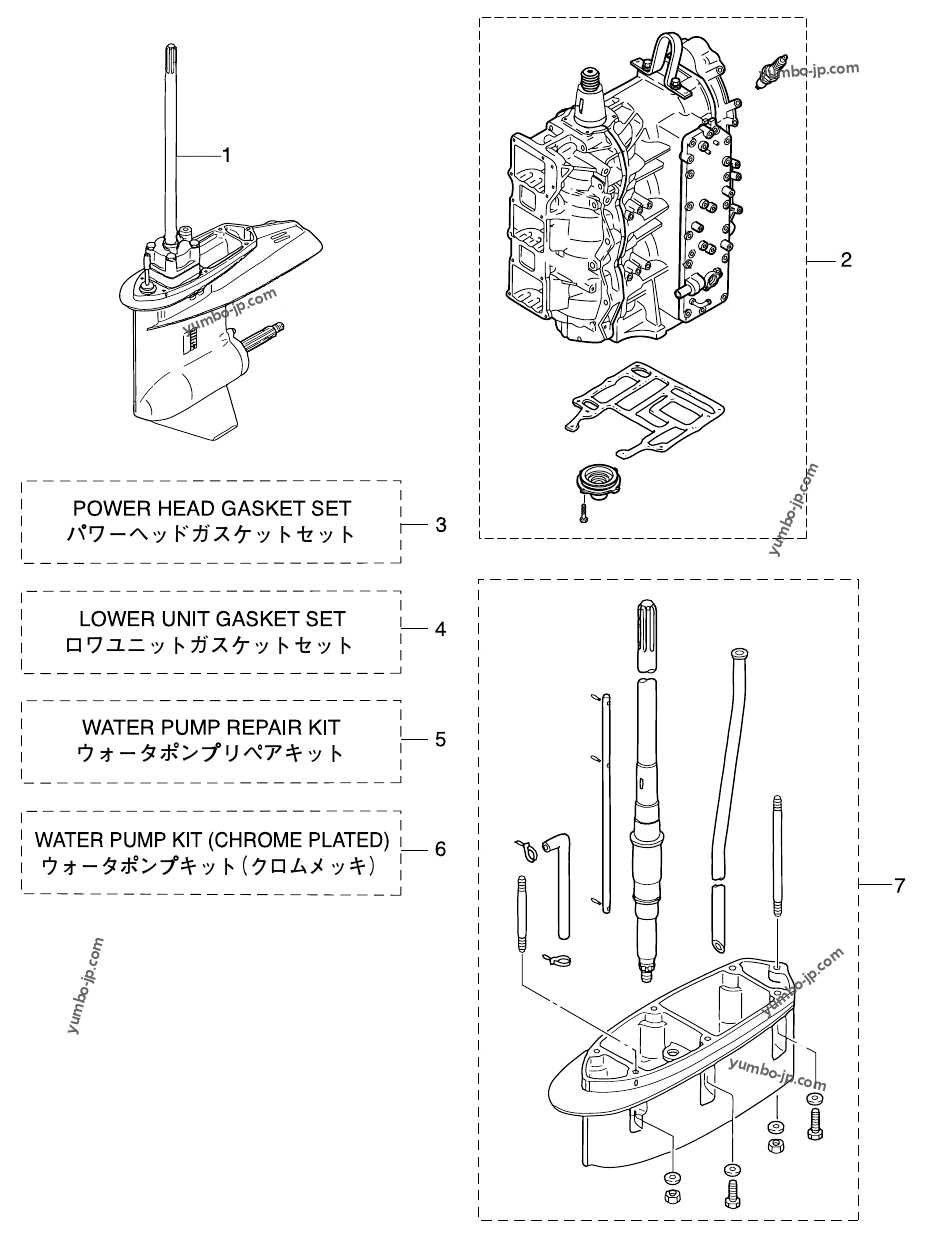

Component Description Powerhead The central unit responsible for generating energy, turning fuel into mechanical power to drive the propeller. Lower Unit Located beneath the main structure, it contains the gears and mechanisms that transfer motion to the propeller. Cooling System Designed to regulate engine temperature, this system prevents overheating by circulating water through key channels. Fuel Delivery Ensures that the right mixture of air and fuel reaches the engine for efficient combustion and smooth power output. Ignition System This component gen Diagram Guide for Outboard Mechanics

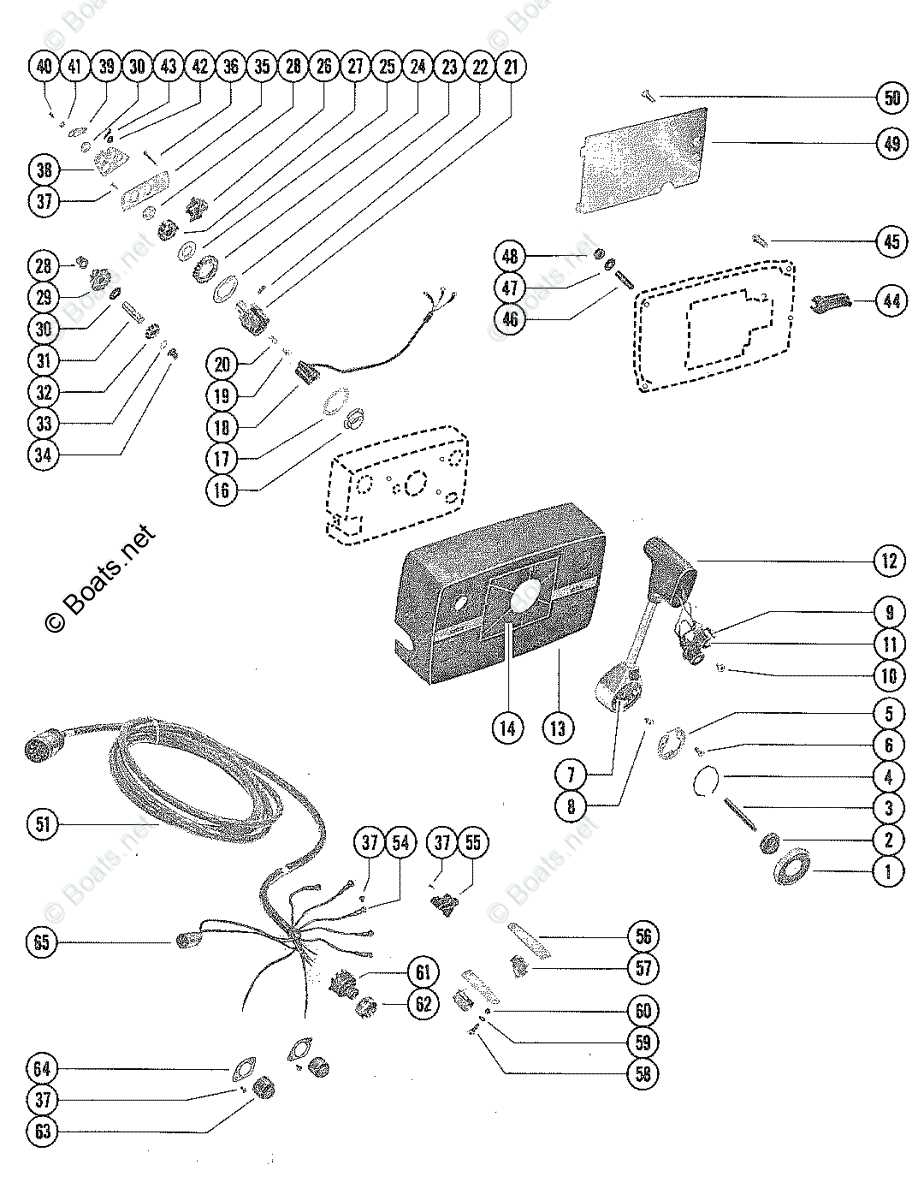

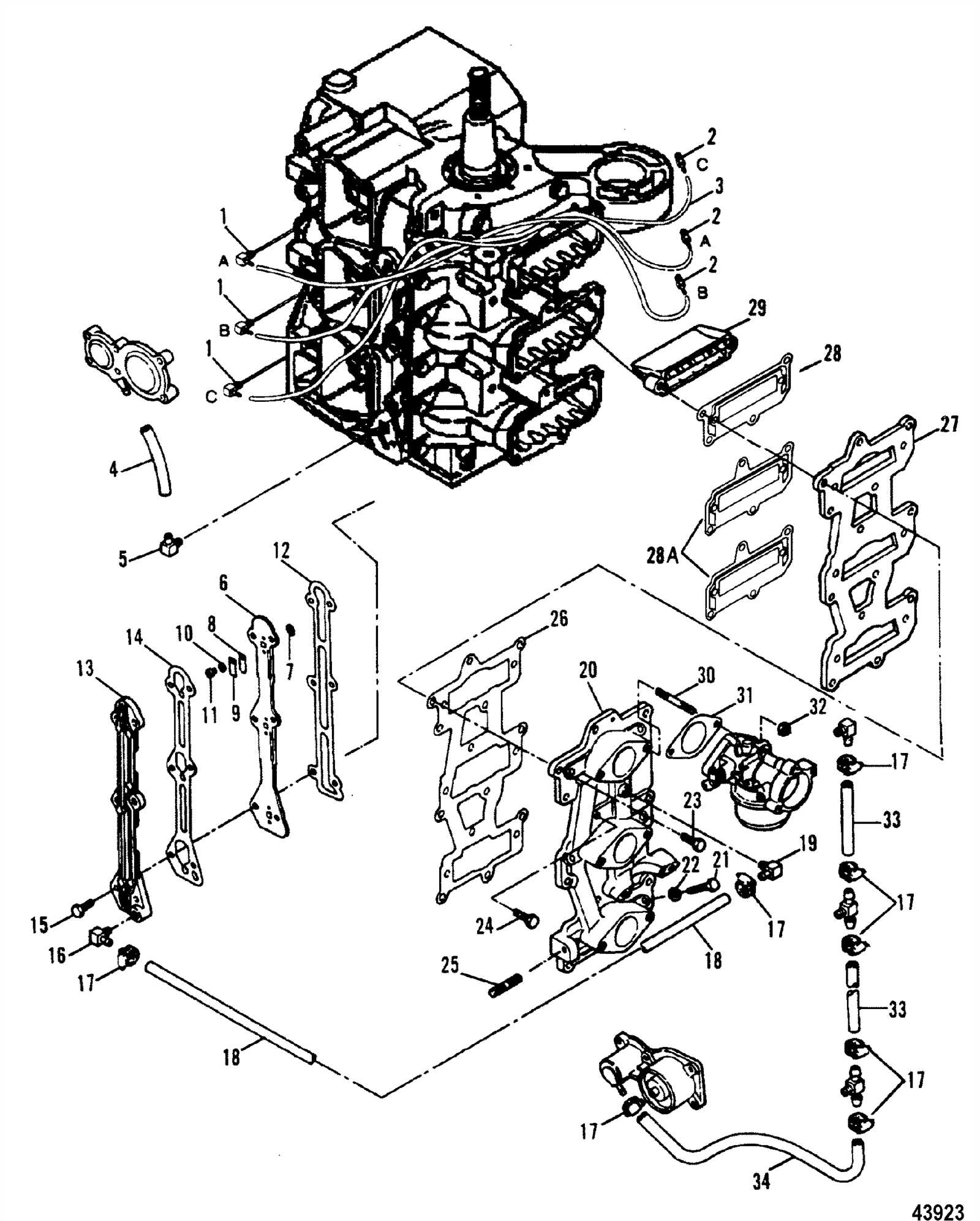

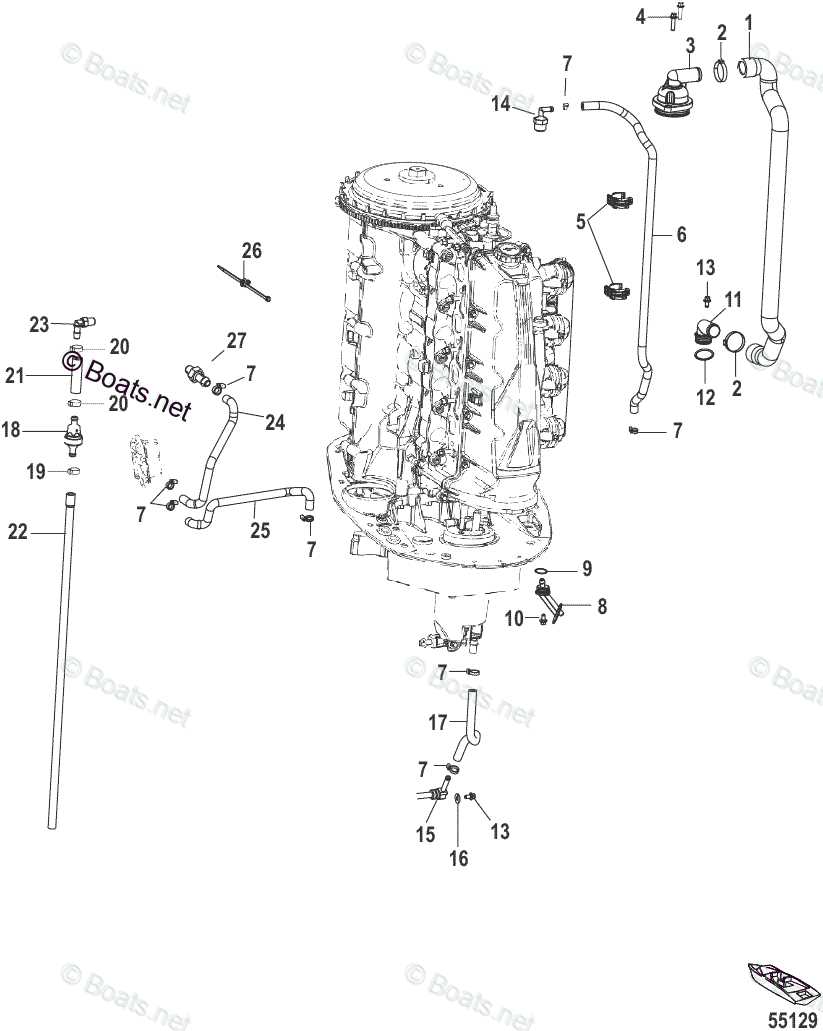

Understanding the layout and structure of marine engines is crucial for anyone involved in watercraft maintenance. A well-illustrated guide provides clarity on how each component fits together, making repairs and routine checks more efficient. By visualizing the entire system, technicians can identify potential issues and streamline the assembly or replacement process.

Visualizing Engine Components

A detailed illustration offers a clear view of the intricate elements of watercraft engines. This helps to understand the positioning and connection of each element, allowing mechanics to pinpoint the necessary adjustments. It simplifies complex mechanical systems, aiding in identifying and resolving mechanical challenges swiftly.

Improving Maintenance Efficiency

Using a graphical reference is key to improving maintenance routines. It allows technicians to familiarize themselves with the layout, ensuring precision during both minor adjustments and more extensive repairs. A comprehensive visual tool enhances the overall workflow, reducing time spent on troubleshooting and enhancing the performance of marine engines.

Breakdown of Essential Engine Sections

Understanding the fundamental components of a marine propulsion system is crucial for effective maintenance and troubleshooting. Each section plays a vital role in the overall functionality and efficiency of the motor. By analyzing these key areas, one can ensure optimal performance and longevity.

Power Generation and Transmission

The power generation segment is responsible for converting fuel into mechanical energy. This section includes various mechanisms that work in harmony to transmit power to the propeller. Efficient energy transfer is essential for achieving desired speed and handling capabilities.

Cooling and Lubrication Systems

Proper cooling and lubrication are critical for preventing overheating and reducing friction between moving parts. The cooling system circulates a fluid to dissipate heat, while the lubrication system ensures that all components function smoothly. Regular checks and maintenance of these systems can significantly enhance the reliability of the engine.

How to Identify Engine Parts Easily

Recognizing various components of a motor can be a straightforward task when approached systematically. Familiarizing yourself with the different sections of the machinery and understanding their functions is essential for effective identification. This knowledge not only aids in maintenance but also enhances overall efficiency.

To assist in the identification process, refer to a structured overview that highlights key elements and their respective roles. Below is a table that outlines common components and their characteristics:

Component Description Cylinder Head Top section of the engine that houses the combustion chamber. Crankshaft Converts linear motion from pistons into rotational motion. Timing Belt Synchronizes the rotation of the crankshaft and camshaft. Oil Filter Removes contaminants from engine oil to ensure smooth operation. Fuel Injector Delivers fuel into the combustion chamber for efficient combustion. By utilizing this guide, one can easily navigate through the complexities of a motor’s construction, ensuring better care and maintenance of the machinery.

Exploring the Structure of 90 HP Motor

Understanding the composition of a 90-horsepower engine is essential for anyone involved in marine mechanics or boat maintenance. This section delves into the various components that contribute to the motor’s overall functionality, performance, and durability. Each element plays a crucial role in ensuring smooth operation and efficient power delivery.

Key Components of the Engine

The engine is comprised of multiple vital parts, each designed to fulfill specific tasks. These include the cylinder block, crankshaft, pistons, and various other assemblies that work in unison to generate thrust. Every component’s design and materials are tailored to withstand the rigors of operation in a marine environment.

Understanding the Assembly

The assembly of this motor is meticulously crafted to optimize performance. Attention to detail in the arrangement of components ensures reliability and efficiency. Regular inspections and maintenance of these parts can significantly extend the lifespan of the engine, making it a valuable investment for any vessel owner.

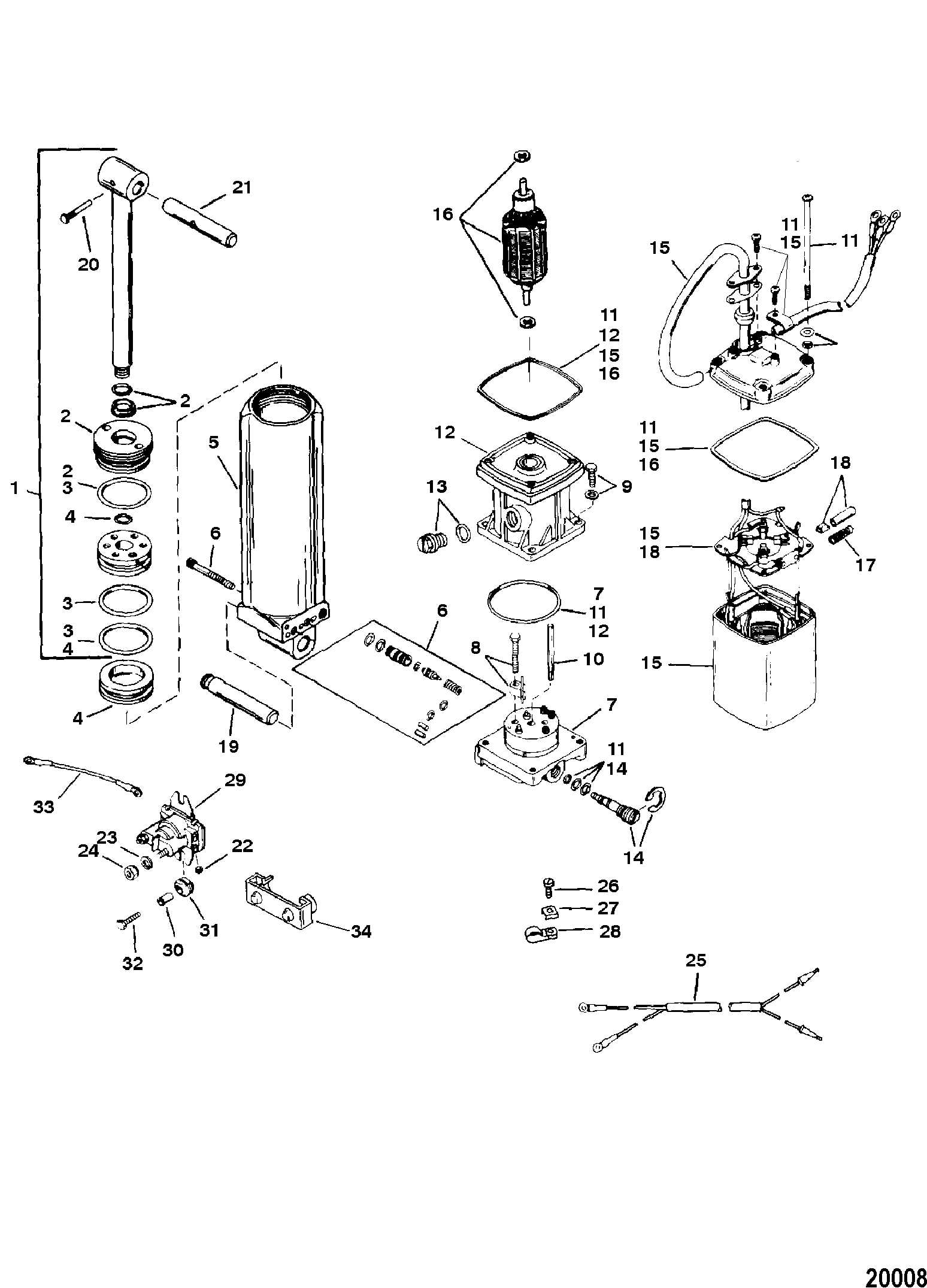

Detailed Look at Marine Engine Systems

Understanding the intricacies of marine propulsion units is essential for effective maintenance and operation. These systems are engineered to provide reliable performance in challenging aquatic environments. A comprehensive examination of the components reveals how each part contributes to overall functionality and efficiency.

Central to the operation are several key elements, including the power source, transmission mechanisms, and cooling systems. Each component plays a pivotal role in ensuring smooth performance and longevity.

Component Description Function Engine Block The main structure housing the engine components. Provides structural integrity and houses the cylinders. Piston A cylindrical component that moves up and down within the cylinder. Converts fuel energy into mechanical energy. Crankshaft A rotating shaft that converts linear motion into rotational motion. Drives the propeller through the transmission. Cooling System A system designed to dissipate heat generated by the engine. Prevents overheating and maintains optimal operating temperature. Fuel System Includes components that store and supply fuel to the engine. Ensures proper fuel delivery for efficient combustion. A deep dive into these systems not only enhances understanding but also assists in diagnosing issues and implementing effective repairs, ultimately leading to improved reliability on the water.

Guide to Understanding Component Placement

Understanding the arrangement of various elements within an outboard motor is crucial for efficient operation and maintenance. This section provides insights into how different components interact and their respective locations, ensuring optimal performance and accessibility for repairs.

Effective Organization of parts allows for smoother functionality and ease of access when addressing issues. Each segment serves a specific role, contributing to the overall efficiency of the engine. By familiarizing oneself with the layout, users can quickly identify areas needing attention.

Furthermore, knowing the placement of crucial elements aids in troubleshooting and enhances the ability to make informed decisions during maintenance. It is essential to regularly consult the layout to ensure that all components are functioning harmoniously.

Inside the Outboard Mechanism

The internal structure of an outboard engine is a fascinating blend of precision engineering and innovative design. Understanding how these components interact is essential for anyone looking to maintain or repair their marine propulsion system.

At the heart of the engine lies the power unit, which is responsible for converting fuel into motion. This process involves several critical elements:

- Combustion Chamber: Where fuel and air mix to create energy.

- Piston: Converts the explosive force into mechanical energy.

- Cylinder: Houses the piston, allowing for smooth movement.

- Crankshaft: Transforms the linear motion of the piston into rotational force.

Additionally, the cooling system plays a vital role in maintaining optimal operating temperatures. It prevents overheating and ensures longevity by circulating coolant throughout the engine. Key components include:

- Water Pump: Draws in water from the surrounding environment.

- Heat Exchanger: Transfers heat from the engine to the water.

- Thermostat: Regulates the flow of coolant based on temperature.

Lastly, the ignition system is crucial for starting and running the engine efficiently. It consists of:

- Spark Plugs: Ignite the fuel-air mixture.

- Ignition Coil: Generates the high voltage needed for the spark.

- Battery: Provides the necessary power for the ignition process.

By understanding these components and their functions, users can better appreciate the complexity and performance of their outboard motor.

Replacing and Maintaining Engine Parts

Regular upkeep and timely replacement of components are crucial for ensuring optimal performance and longevity of any propulsion system. This section provides insights into the essential practices for maintaining and swapping out engine elements, highlighting the importance of proactive care and attention.

Importance of Regular Maintenance

Consistent maintenance helps in identifying potential issues before they escalate. Key benefits include:

- Improved efficiency and fuel consumption.

- Enhanced safety and reliability during operation.

- Prolonged lifespan of the engine and its components.

Steps for Component Replacement

When it becomes necessary to replace specific components, follow these general steps:

- Gather the required tools and new components.

- Disconnect the power source to ensure safety.

- Remove the old component carefully, taking note of its placement.

- Install the new component, ensuring it fits securely.

- Reconnect the power source and perform a test to confirm functionality.

Adhering to these guidelines will help maintain the system’s integrity and ensure smooth operation over time.

Troubleshooting Common Parts Issues

Addressing frequent challenges with components is essential for ensuring optimal functionality and longevity of the equipment. Identifying symptoms early can prevent more significant problems and costly repairs. This section outlines common issues encountered with various elements and offers guidance on diagnosing and resolving them effectively.

Identifying Symptoms

Recognizing the signs of malfunction is the first step in troubleshooting. Common indicators may include:

- Unusual noises during operation

- Inconsistent performance or power loss

- Visible wear or damage on external surfaces

- Leaks or fluid accumulation

Steps to Resolve Issues

Once symptoms are identified, follow these steps for effective troubleshooting:

- Inspect the affected component for visible damage or wear.

- Check connections and wiring for secure attachments.

- Consult the manufacturer’s guidelines for specific diagnostics.

- Replace any faulty or worn elements as necessary.

- Test the system after adjustments to ensure proper operation.

Regular maintenance and attention to detail can significantly reduce the occurrence of these issues, leading to a more reliable and efficient experience.