Comprehensive Guide to Honda GCV160 Engine Parts Diagram

When it comes to maintaining and repairing outdoor power equipment, a clear visual representation of its internal mechanisms is invaluable. Such illustrations serve as a comprehensive guide, allowing enthusiasts and professionals alike to identify and comprehend each crucial element that contributes to the overall functionality of these machines. By familiarizing oneself with these components, one can enhance the performance and longevity of their equipment.

In the realm of small motors, knowledge of the specific roles and interactions of each part is essential. From the power generation system to the ignition assembly, every segment plays a pivotal role in ensuring efficient operation. A detailed overview of these components can simplify troubleshooting processes and streamline maintenance efforts.

Exploring the intricacies of these mechanisms not only aids in practical repairs but also deepens one’s appreciation for the engineering involved. With a proper understanding of how each piece fits together, users can confidently approach tasks, whether they are routine check-ups or more extensive refurbishments.

Understanding Honda GCV160 Engine Components

This section aims to provide a comprehensive overview of the essential elements that make up a specific type of power source commonly used in various outdoor equipment. By familiarizing oneself with these components, users can enhance their understanding and maintenance capabilities, ultimately leading to improved performance and longevity.

Key Components Overview

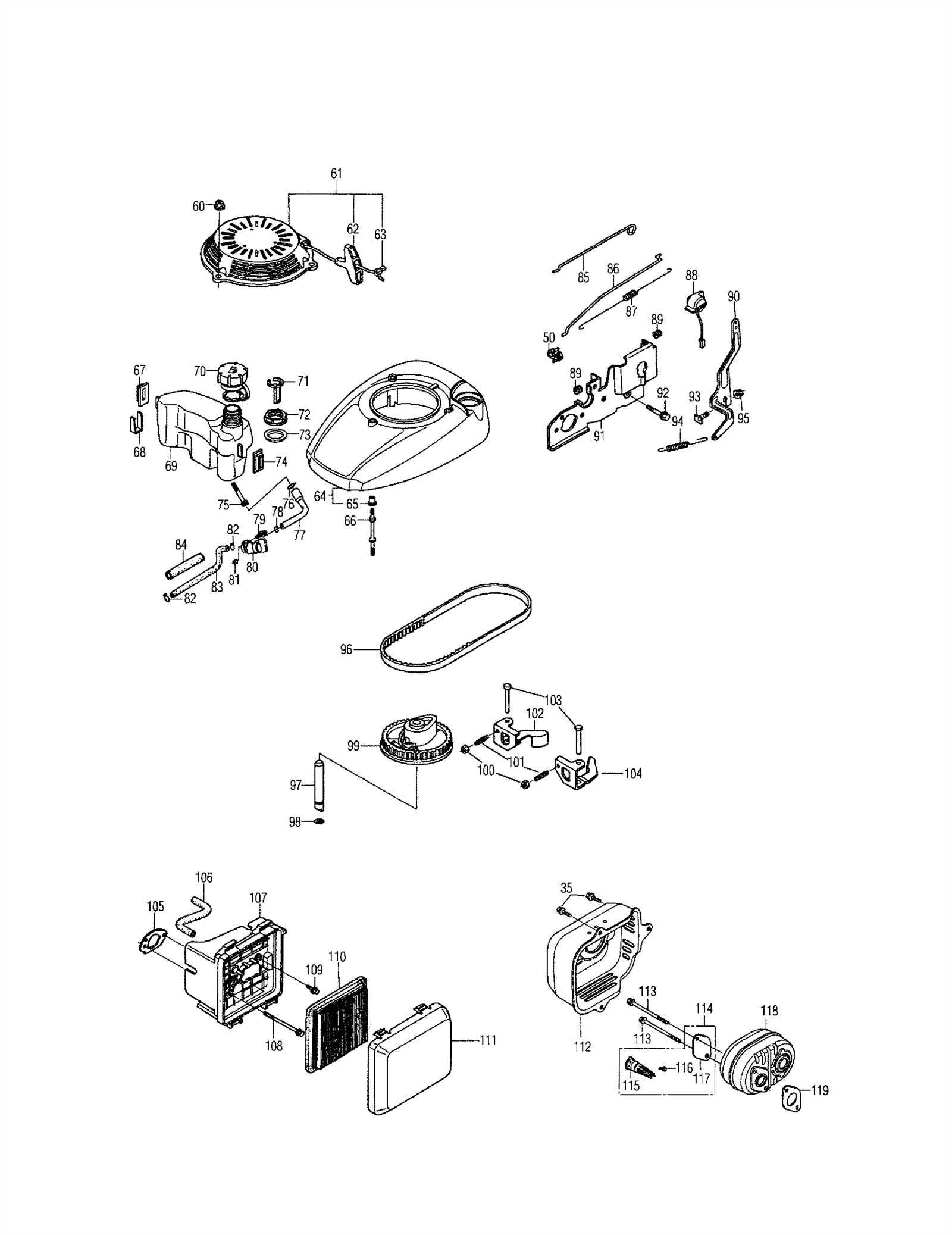

- Fuel System: Responsible for supplying the necessary fuel to the combustion chamber. It includes a fuel tank, carburetor, and fuel lines.

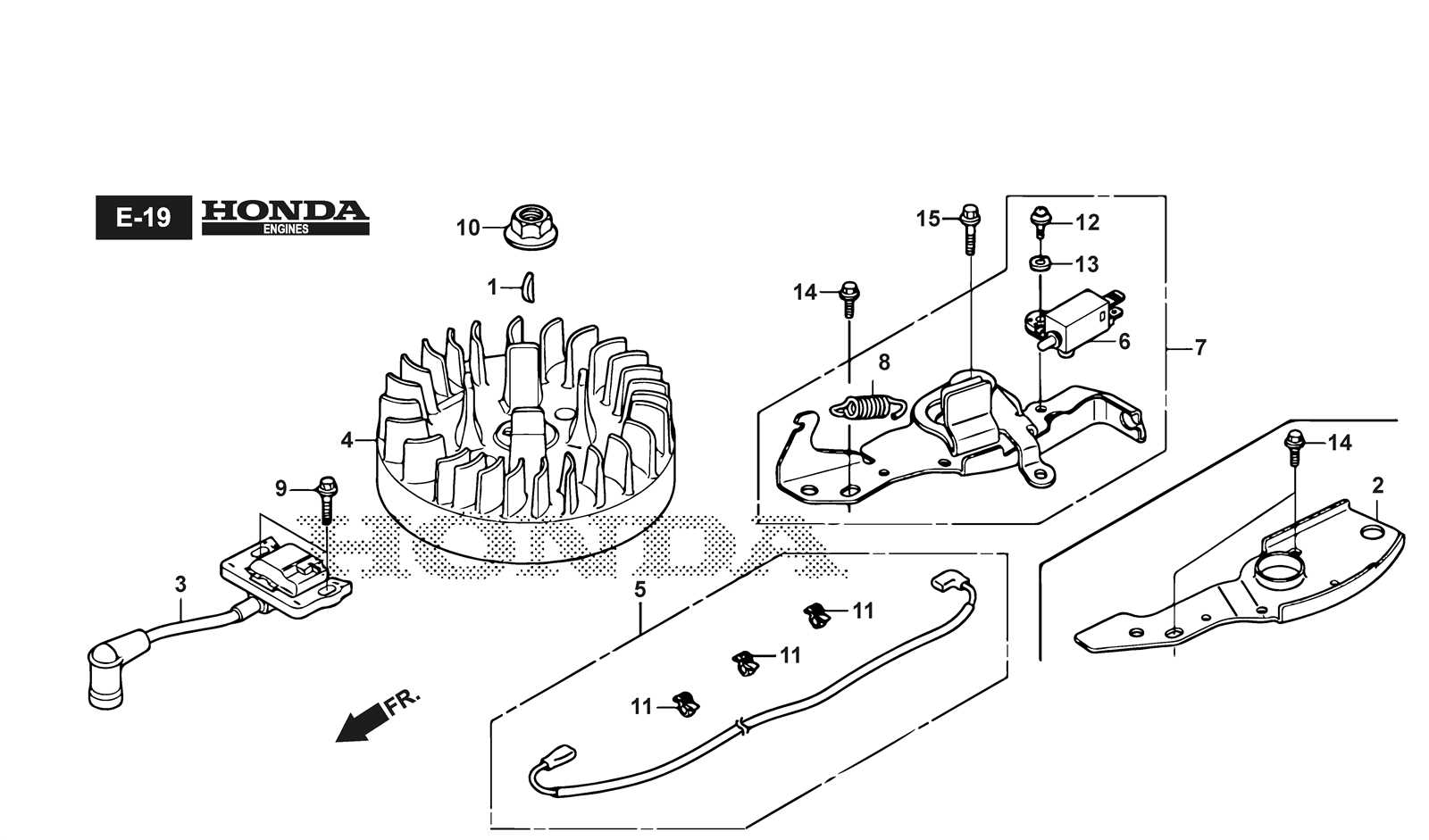

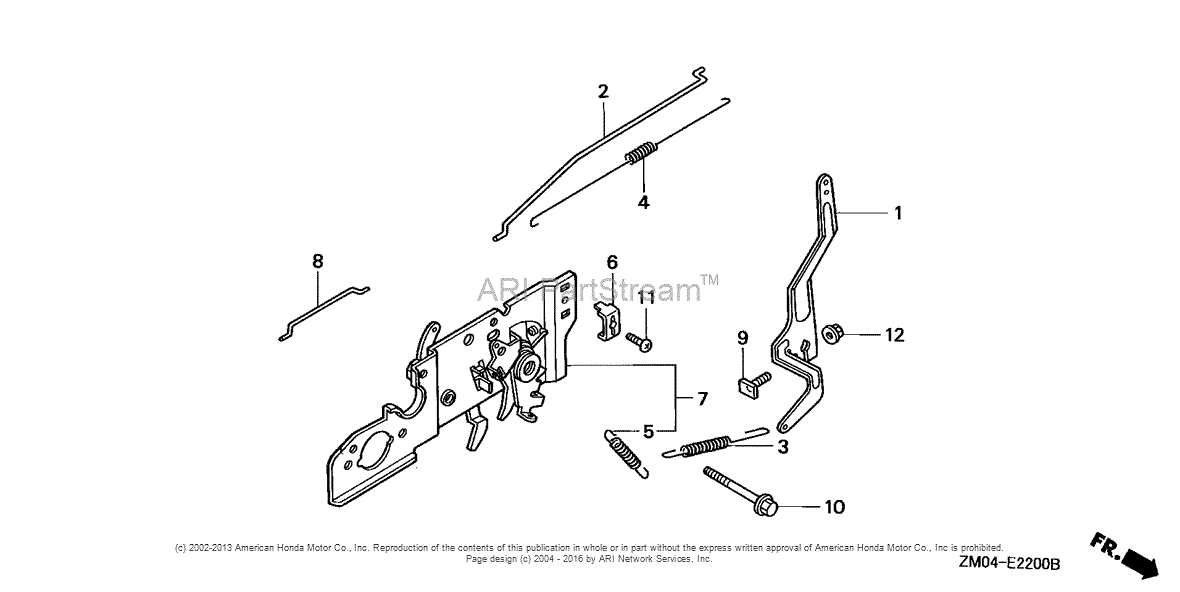

- Ignition System: Ensures the timely spark that ignites the fuel-air mixture. Key elements are the spark plug, ignition coil, and wiring.

- Cooling System: Prevents overheating through airflow and coolant circulation. It consists of a fan, fins, and cooling shrouds.

- Lubrication System: Reduces friction between moving parts. This system includes an oil reservoir, pump, and filter.

Maintenance Considerations

- Regularly check and clean the fuel system to prevent clogs.

- Inspect the ignition components for wear and replace as necessary.

- Ensure the cooling system is free of debris to maintain optimal airflow.

- Monitor oil levels and change it periodically to keep the lubrication system effective.

By understanding these core components, users can perform better maintenance practices, ensuring efficient operation and extending the lifespan of their equipment.

Visual Guide to Engine Parts Diagram

This section provides an insightful overview of essential components typically found in small motor systems. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components Overview

- Power Source: The heart of the machine, responsible for generating motion.

- Fuel System: Comprising elements that store and deliver the necessary fuel for operation.

- Cooling Mechanism: Vital for preventing overheating, consisting of fans and cooling fins.

- Exhaust System: Channels out waste gases, playing a role in efficiency and safety.

- Ignition System: Sparks the combustion process, essential for starting and running smoothly.

Understanding the Layout

Familiarizing yourself with the configuration of these components aids in recognizing their functions and interrelationships. Each section serves a specific purpose, and knowing how they interact enhances overall comprehension.

- Identify the power source and its connection to the fuel system.

- Trace the airflow through the cooling mechanism.

- Observe how the exhaust system routes away from the main unit.

- Examine the ignition system’s placement relative to the fuel delivery.

This visual guide equips you with the knowledge to effectively engage with the machinery, leading to informed decisions during maintenance or repairs.

Common Issues with GCV160 Engines

When dealing with small power units, several typical challenges can arise that may affect performance and reliability. Understanding these common problems can aid in troubleshooting and maintenance, ensuring smoother operation and prolonged lifespan.

Starting Difficulties

One frequent issue encountered is difficulty in initiating the unit. This may stem from various factors, including fuel quality, spark plug condition, or carburetor blockages. Ensuring that the fuel is fresh and that the ignition components are in good shape can often resolve these starting troubles.

Overheating Problems

Another significant concern is overheating, which can lead to severe damage if not addressed promptly. This condition may arise from inadequate cooling, dirty air filters, or oil level inconsistencies. Regular maintenance, such as cleaning air intake areas and checking oil levels, can help mitigate this risk and maintain optimal temperatures during operation.

How to Identify Engine Parts

Recognizing various components of a power unit is essential for effective maintenance and repairs. By familiarizing yourself with the different elements and their functions, you can troubleshoot issues more efficiently and ensure optimal performance. This guide will help you distinguish between essential segments, enabling you to take the right steps in your maintenance routine.

Start by observing the structure and layout of the unit. Each component has a specific role, and knowing these can aid in identification. Below is a table that highlights common elements, their descriptions, and their functions.

| Component | Description | Function |

|---|---|---|

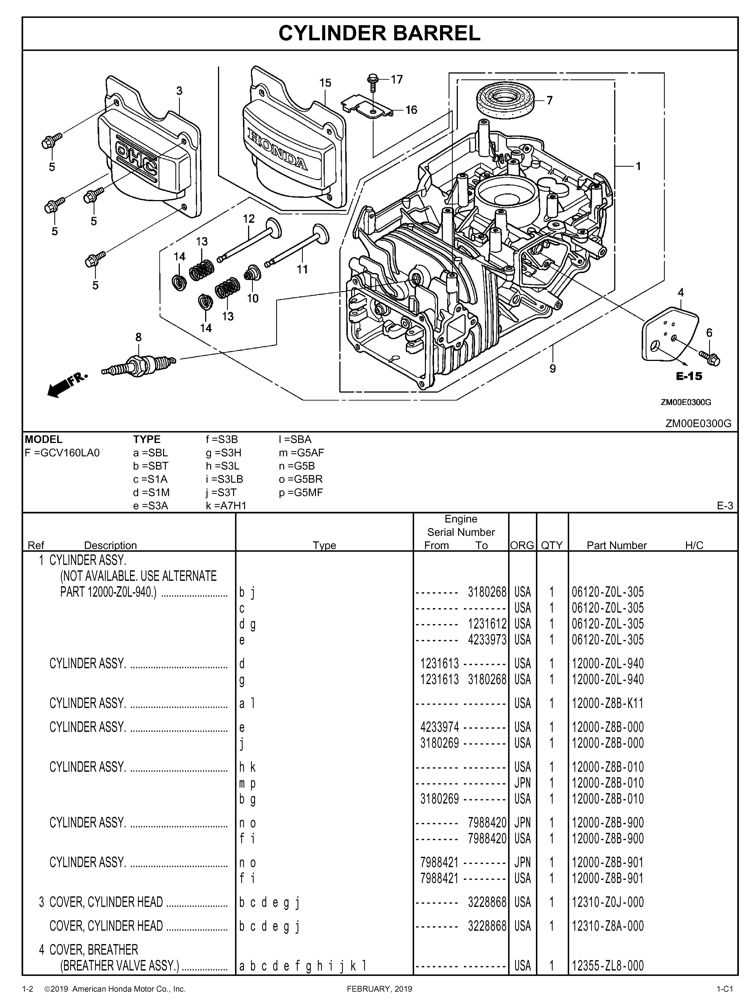

| Cylinder | A metal casing housing the piston | Contains combustion process |

| Piston | A cylindrical piece that moves within the cylinder | Transforms pressure from combustion into mechanical energy |

| Crankshaft | A shaft that converts linear motion into rotational motion | Transmits power to the output |

| Carburetor | A device that mixes air and fuel | Ensures optimal fuel-air mixture for combustion |

| Ignition System | A collection of components that create a spark | Ignites the fuel-air mixture for combustion |

Understanding these elements not only aids in identification but also empowers you to conduct repairs and adjustments confidently. Regular inspection and familiarity with each part can lead to more informed decisions regarding maintenance and performance improvements.

Maintenance Tips for GCV160 Engines

Regular upkeep is essential for ensuring optimal performance and longevity of small power units. Implementing a systematic maintenance routine not only enhances efficiency but also prevents unexpected breakdowns. Here are some key recommendations to keep your machinery running smoothly.

1. Check the Oil Level

Regularly inspect the lubricant level and quality. Clean oil is crucial for reducing friction and preventing wear. Replace it according to the manufacturer’s guidelines to ensure optimal performance.

2. Clean or Replace the Air Filter

A clean air filter allows for proper airflow, which is vital for efficient operation. Periodically check and clean or replace the filter to prevent dirt accumulation that can hinder performance.

3. Inspect the Spark Plug

The spark plug plays a crucial role in the ignition process. Examine it for wear or carbon buildup, and replace it if necessary to ensure a reliable start and smooth operation.

4. Fuel Quality Matters

Always use fresh, high-quality fuel to prevent engine issues. Stale or contaminated fuel can lead to poor performance and starting difficulties. Consider using fuel stabilizers for extended storage periods.

5. Check Belts and Cables

Inspect belts for signs of wear or fraying, and ensure cables are securely connected. Replace any damaged components to avoid disruptions in operation.

6. Regular Cleaning

Keep the exterior of the unit clean. Remove debris and dirt to prevent overheating and to maintain clear airflow. A clean machine operates more efficiently and lasts longer.

7. Follow the Service Schedule

Adhering to a predetermined maintenance schedule is crucial. Refer to the owner’s manual for specific intervals for checks and replacements to keep your machinery in top shape.

By following these maintenance tips, you can enhance the performance and extend the life of your equipment, ensuring it remains reliable for all your tasks.

Replacement Parts for Honda GCV160

Maintaining optimal performance in small machinery often requires timely updates and substitutions of certain components. Knowing the key elements that need replacement can enhance efficiency and prolong the lifespan of the unit. This section outlines the essential replacements to consider for seamless operation.

- Air Filter

- Oil Filter

- Fuel Filter

- Spark Plug

- Cylinder Head Gasket

- Piston Ring Set

Each of these components plays a vital role in ensuring smooth functionality and reliability. Regular checks and timely replacements can prevent potential issues and keep your machinery running effectively.

- Air Filter: Regularly replacing the air filter prevents dirt and debris from entering the combustion chamber, ensuring cleaner performance.

- Oil Filter: An efficient oil filter is crucial for maintaining proper lubrication and reducing wear on internal mechanisms.

- Fuel Filter: This component is essential for keeping the fuel system clean and preventing clogs that can disrupt operation.

- Spark Plug: A new spark plug enhances ignition efficiency, contributing to better fuel economy and performance.

- Cylinder Head Gasket: This ensures a tight seal and prevents leaks that can lead to loss of compression.

- Piston Ring Set: Replacing worn piston rings helps maintain compression and efficiency, minimizing exhaust emissions.

Prioritizing the replacement of these components will ensure that your machinery operates at its best, avoiding unnecessary downtime and repairs.

Tools Needed for Engine Repairs

When undertaking mechanical maintenance, having the right implements at hand is essential for achieving optimal results. Whether addressing minor adjustments or comprehensive overhauls, an organized toolkit can make the process smoother and more efficient. Below are key items that should be included in any repair arsenal.

Essential Hand Tools

Wrenches and screwdrivers are fundamental for loosening and tightening components. Various sizes and types ensure compatibility with different fasteners, enabling precise adjustments. Additionally, pliers can assist with gripping, twisting, and cutting tasks, making them invaluable during repairs.

Specialized Equipment

In certain situations, specialized tools are necessary. A compression tester helps evaluate the internal condition of components, while a torque wrench ensures that fasteners are tightened to the correct specifications, preventing damage. Moreover, having a reliable multimeter allows for electrical diagnostics, essential for troubleshooting issues.

Step-by-Step Disassembly Process

Disassembling a small motor requires careful attention to detail and a systematic approach. This guide will help you navigate the disassembly procedure, ensuring that each component is properly handled and organized. By following these steps, you can effectively break down the assembly, making maintenance or repairs more manageable.

Preparation and Safety

Before beginning the disassembly, gather all necessary tools and ensure a clean workspace. Disconnect the power source to prevent accidents. Wear protective gear, such as gloves and goggles, to safeguard against debris and sharp edges. Organizing screws and small components in labeled containers will streamline reassembly.

Step-by-Step Disassembly

Start by removing any outer casing to expose the inner components. Take note of the order in which parts are removed, as this will assist during reassembly. Proceed to detach the main components methodically, ensuring that any connected wires or hoses are carefully unplugged or disconnected. Pay close attention to the position and orientation of each part, as this knowledge will be invaluable when putting everything back together.

Reassembly Tips for GCV160 Engines

Reassembling small machinery components requires attention to detail and a systematic approach. Ensuring each element is correctly placed and secured will enhance performance and longevity. This guide outlines essential tips to facilitate a smooth reassembly process, minimizing the risk of errors and promoting efficiency.

Before starting the reassembly, gather all necessary tools and components. Organizing parts and referring to a clear reference will streamline the process. Here are some key suggestions:

| Tip | Description |

|---|---|

| Cleanliness | Ensure all components are clean and free from debris. Use compressed air or a soft brush to remove any residue. |

| Follow Sequence | Adhere to the original disassembly sequence. This helps in maintaining the integrity of the structure and avoiding confusion. |

| Use Lubricants | Apply appropriate lubricants to moving parts to reduce friction and ensure smooth operation. Refer to the manufacturer’s guidelines for the correct type. |

| Torque Specifications | Use a torque wrench to tighten fasteners to the specified settings. This prevents damage and ensures proper function. |

| Double-check Connections | Verify that all connections, including hoses and electrical links, are secure and correctly aligned. |

By following these tips, you can ensure a successful reassembly that promotes the efficiency and reliability of your machinery. Take your time, stay organized, and refer to documentation when necessary for optimal results.

Upgrades and Performance Enhancements

Improving the efficiency and power of small machinery can lead to significant benefits in performance and longevity. By exploring various modifications and enhancements, enthusiasts can unlock the full potential of their equipment. These upgrades often involve changes to airflow, fuel delivery, and ignition systems, ensuring that the unit runs smoother and with greater output.

Airflow Modifications: Enhancing the intake and exhaust systems is crucial for optimal performance. Upgrading to a high-flow air filter can increase airflow, resulting in better combustion. Additionally, installing a performance exhaust can reduce back pressure, allowing for a more efficient exit of gases.

Fuel System Improvements: Tweaking the fuel delivery mechanism can also lead to marked improvements. Using higher quality fuel or adjusting the carburetion settings can optimize fuel mixture ratios, enhancing power and efficiency. Fuel additives may also help in achieving cleaner combustion.

Ignition Upgrades: A more robust ignition system can greatly impact performance. Upgrading spark plugs and ignition coils can lead to more reliable starts and smoother operation. Ensuring that the timing is properly adjusted further maximizes power output and fuel efficiency.

Implementing these upgrades not only boosts performance but can also extend the lifespan of the machinery. Careful selection and installation of these enhancements will lead to a more enjoyable and effective experience.

Frequently Asked Questions about GCV160

This section addresses common inquiries related to a popular small power unit known for its efficiency and reliability. Users often seek clarification on various aspects, from maintenance to troubleshooting, ensuring optimal performance and longevity of the device.

What type of fuel is recommended for optimal performance?

It is advisable to use unleaded gasoline with an octane rating of 87 or higher. Avoid using fuel containing more than 10% ethanol, as it can cause damage over time.

How often should I change the oil?

Regular oil changes are crucial for maintaining the unit’s health. It is recommended to change the oil every 50 hours of operation or at least once a year, whichever comes first.

What maintenance tasks should I perform regularly?

Key maintenance tasks include checking and replacing the air filter, cleaning the spark plug, and inspecting the fuel system. Regular checks can prevent potential issues.

How can I troubleshoot starting problems?

If the unit fails to start, check the fuel level, ensure the spark plug is clean and properly connected, and confirm that the air filter is not clogged. These are common areas that can affect starting.

Where can I find replacement components?

Replacement components can typically be found at authorized dealers or online retailers specializing in small machinery parts. Always ensure you are purchasing compatible items for the best fit.