Understanding the John Deere S180 Parts Diagram for Efficient Maintenance

In the realm of agricultural machinery, comprehending the intricate layout of essential elements is crucial for effective maintenance and repair. A well-organized visual representation not only enhances knowledge but also simplifies the process of identifying and procuring necessary items. This understanding ensures optimal performance and longevity of the equipment.

For operators and technicians alike, having access to a clear blueprint of the various segments is the ultimate resource. It provides insights into how each part interacts with others, paving the way for efficient troubleshooting and replacements. Furthermore, mastering this knowledge empowers users to tackle repairs with confidence, ensuring that their machinery runs smoothly.

Whether you are a seasoned professional or a newcomer, exploring the components of your equipment can yield significant benefits. By delving into the specifics of each element, you can make informed decisions that enhance productivity and reduce downtime.

Overview of John Deere S180

This section provides a comprehensive look at a specific model of outdoor equipment designed for effective lawn care and maintenance. Known for its reliability and performance, this machine serves as a valuable asset for both residential and commercial users.

Key features include:

- Powerful engine options for enhanced performance

- Efficient cutting systems for a clean finish

- Ergonomic controls for user comfort

- Robust construction for durability in various conditions

Maintenance and repairs are essential to ensure longevity. Regular checks and the use of quality components contribute significantly to the upkeep of this model. Users are encouraged to familiarize themselves with the various systems and functionalities for optimal operation.

In summary, this equipment is engineered to meet diverse lawn care needs, combining efficiency with user-friendly features that appeal to a wide range of operators.

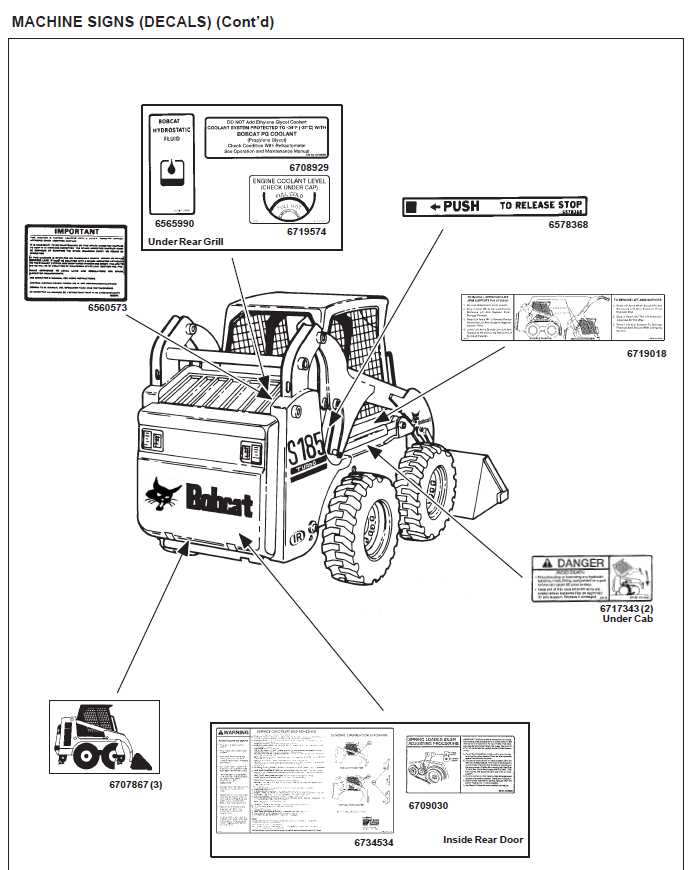

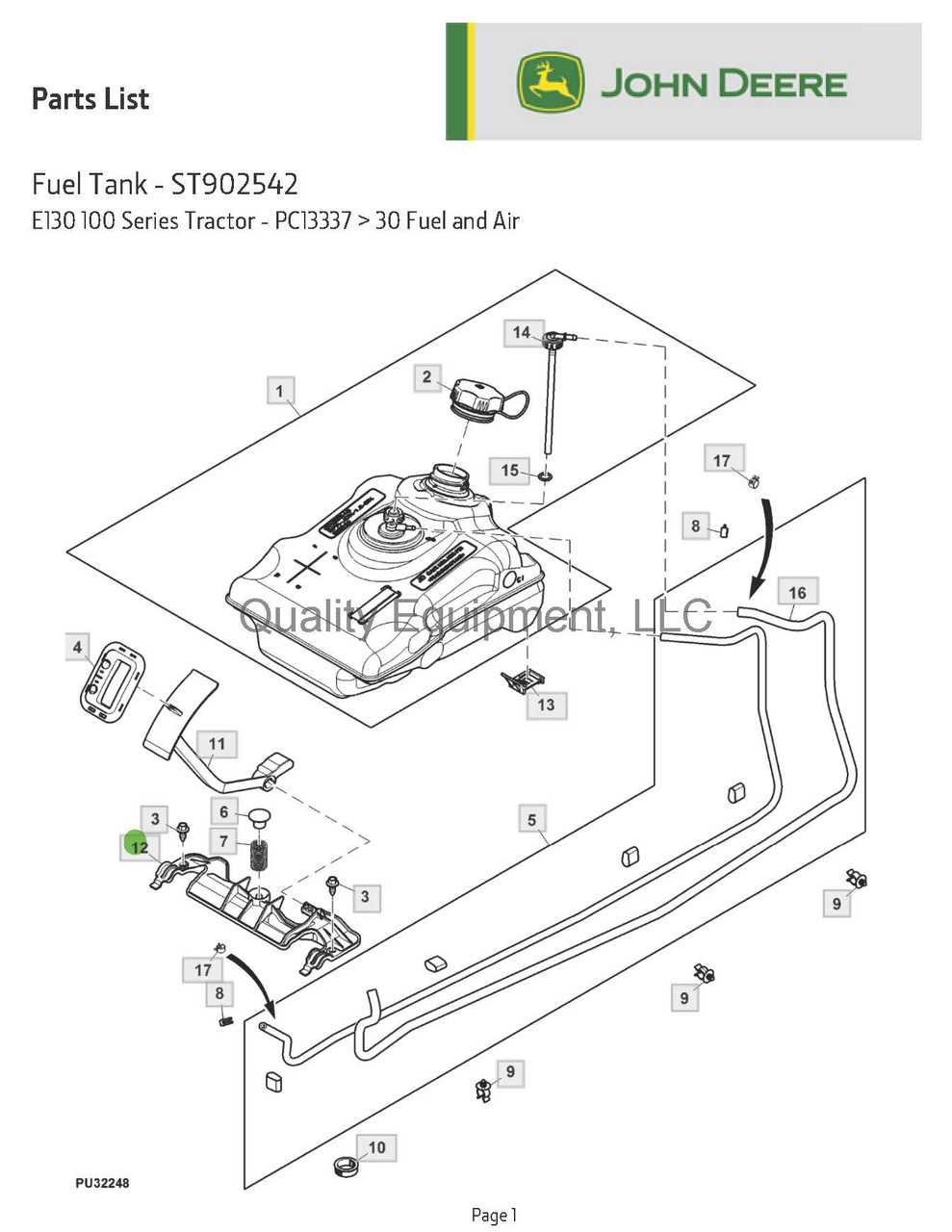

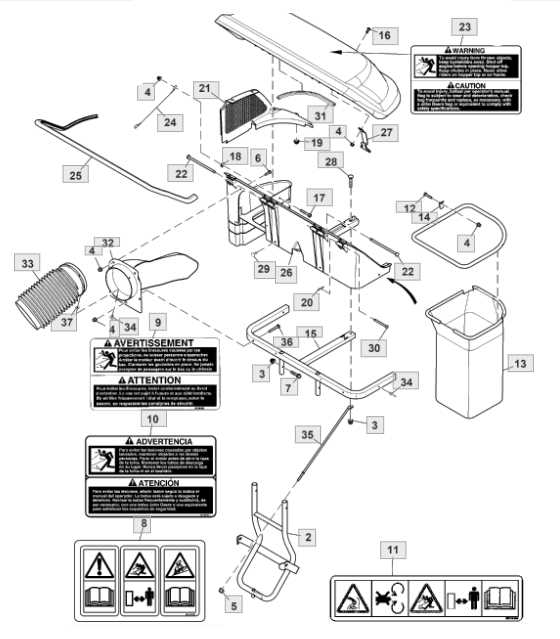

Understanding the Parts Diagram

Grasping the layout of components in machinery is essential for efficient maintenance and repair. A clear visual representation aids in identifying each element and understanding its function within the larger system. This familiarity ultimately enhances the user experience and prolongs the lifespan of the equipment.

To effectively utilize this visual guide, it’s important to recognize key sections and how they interconnect. Below is a simplified overview that outlines major components.

| Component | Description |

|---|---|

| Engine | Powers the machine, providing necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels, affecting speed and torque. |

| Chassis | The frame that supports all other elements, ensuring stability and durability. |

| Hydraulics | Facilitates movement and operation of attachments through fluid pressure. |

| Control System | Enables user input for various functions and settings during operation. |

Key Components of the S180 Model

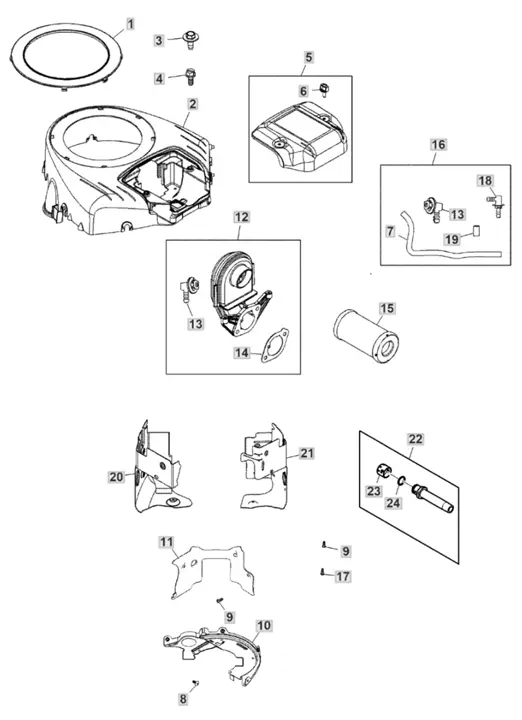

The efficient operation of this machine relies on several essential elements that work harmoniously together. Understanding these fundamental parts is crucial for maintenance and optimal performance.

Engine: The powerhouse of the unit, delivering the necessary torque and horsepower for various tasks.

Transmission: This system facilitates smooth shifting between gears, enhancing maneuverability and speed control.

Deck: A vital component for cutting, designed to provide a precise and even trim across different terrains.

Wheels: Engineered for stability and traction, they ensure reliable navigation over diverse surfaces.

Control Panel: The user interface that allows operators to manage functions and monitor performance effectively.

Familiarity with these key components empowers users to delve deeper into maintenance practices, ultimately enhancing the lifespan and efficiency of the machine.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of machinery. They serve as essential references that provide clear visual guidance, enabling users to identify components and their relationships within a system. When accuracy is prioritized, it enhances understanding and facilitates effective troubleshooting, ultimately leading to improved efficiency in repairs.

Enhancing Efficiency

Accurate visuals streamline the repair process by reducing the time spent on identifying parts and their functions. When users can easily interpret the illustrations, they are less likely to make errors that could lead to costly mistakes. This efficiency not only saves time but also minimizes downtime for the equipment, ensuring that operations continue smoothly.

Improving Safety

In addition to efficiency, well-crafted illustrations contribute significantly to safety. By clearly outlining the correct assembly and disassembly procedures, they help prevent accidents that could arise from incorrect handling of machinery. Understanding the layout and function of each component is vital for safe operation, and accurate visuals are a key element in achieving this goal.

Common Issues with S180 Parts

In the realm of lawn care machinery, certain components often encounter frequent problems that can hinder performance. Understanding these common issues can help owners maintain their equipment more effectively, ensuring longevity and optimal functionality.

Frequent Mechanical Failures

Mechanical failures can arise from wear and tear, inadequate maintenance, or manufacturing defects. Commonly observed issues include:

| Issue | Description |

|---|---|

| Blade Dullness | Blades can become dull over time, leading to uneven cuts and increased strain on the engine. |

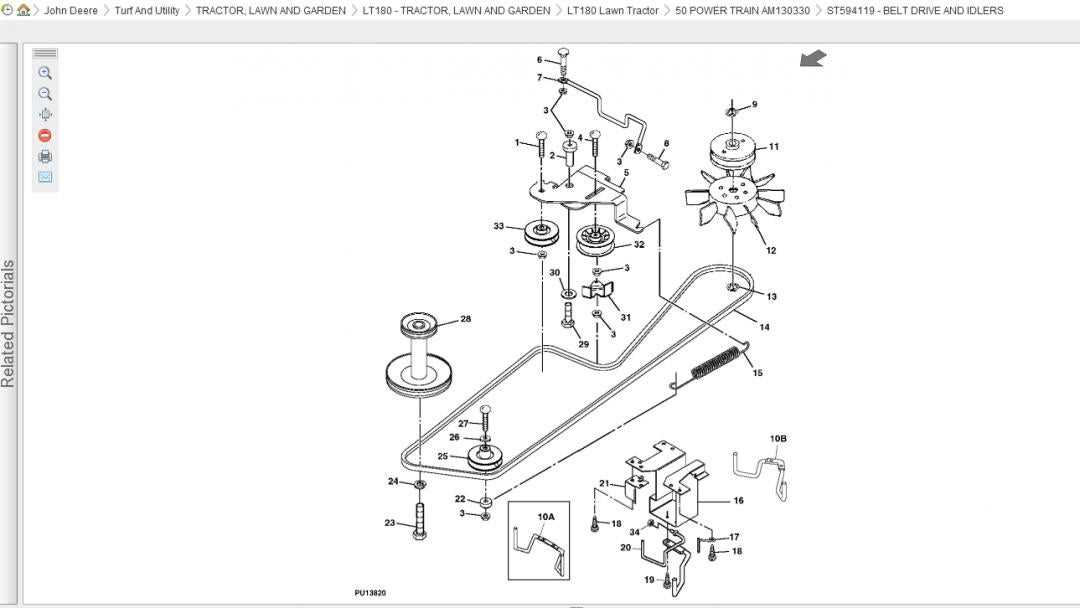

| Belt Wear | Belts may wear out or fray, affecting power transfer and efficiency. |

| Battery Failure | Batteries can lose charge or fail completely, preventing the machine from starting. |

Electrical and Connectivity Issues

Electrical components are susceptible to faults that can disrupt operation. Common electrical problems include:

| Issue | Description |

|---|---|

| Faulty Wiring | Wiring can become damaged or corroded, leading to short circuits or loss of power. |

| Sensor Malfunctions | Sensors may fail to provide accurate readings, affecting overall performance. |

| Starter Problems | The starter motor can fail, making it difficult to initiate the machine. |

Maintenance Tips for S180 Owners

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a systematic approach to maintenance not only enhances efficiency but also helps in preventing costly repairs down the line. By following these guidelines, owners can enjoy a seamless experience and keep their machinery in prime condition.

Start with routine inspections to identify any signs of wear or damage. Checking fluid levels, filters, and belts regularly can prevent potential issues from escalating. Ensure that all moving parts are adequately lubricated to minimize friction and extend their lifespan.

Cleaning is another vital aspect of maintenance. Remove debris, grass clippings, and dirt from surfaces to prevent clogs and overheating. Pay special attention to the undercarriage and cooling systems, as they are prone to accumulation of materials that can impede performance.

Additionally, seasonal preparations are important. Before heavy use in the spring, conduct a thorough check-up, including sharpening blades and adjusting tire pressure. After the season, winterizing your machine can protect it from harsh conditions, ensuring it starts smoothly when needed.

Lastly, always refer to the manufacturer’s guidelines for specific maintenance schedules and recommended practices. Staying proactive will ultimately lead to a more reliable and efficient machine, giving you peace of mind as you tackle your tasks.

Where to Find Replacement Parts

Locating quality components for machinery can enhance performance and extend the lifespan of your equipment. Various resources are available to ensure you find the right items for maintenance and repairs.

Authorized Dealers

One of the most reliable sources is authorized dealers, who offer original equipment and have in-depth knowledge about your model. Their expertise ensures you get authentic replacements that match specifications.

Online Retailers

Numerous online platforms specialize in selling aftermarket and genuine components. Websites often feature user reviews and detailed descriptions, allowing you to make informed choices. Always check the return policy before purchasing to ensure satisfaction.

Comparing S180 Parts with Other Models

When examining the components of various models within a similar range, it becomes evident that there are both shared elements and distinct differences. These variations can significantly impact performance, maintenance, and user experience. Understanding these nuances is crucial for making informed decisions about equipment and repairs.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | V-Twin | Single Cylinder | V-Twin |

| Transmission | Hydrostatic | Gear Driven | Hydrostatic |

| Cutting Width | 42 inches | 38 inches | 48 inches |

| Fuel Capacity | 3 gallons | 2.5 gallons | 3 gallons |

| Weight | 450 lbs | 400 lbs | 500 lbs |

By comparing these models, one can identify which specific features align best with individual needs, thus facilitating better choices in both purchase and repair processes. The interplay of various characteristics highlights the importance of thorough research and understanding of equipment specifications.

DIY Repairs Using the Diagram

Understanding the layout of components is essential for effective maintenance and repair. By utilizing a clear visual reference, you can confidently tackle various issues that may arise.

Here are some key benefits of using a visual reference for your repairs:

- Enhanced clarity in identifying parts.

- Streamlined repair processes.

- Reduced chances of error during reassembly.

To get started, follow these steps:

- Gather necessary tools and materials.

- Refer to the visual reference for component identification.

- Carefully remove the damaged parts, taking notes as you go.

- Replace with new components, ensuring proper fit.

- Double-check your work against the visual reference.

With a methodical approach, you’ll find that DIY repairs become much more manageable and rewarding.

Wiring and Electrical Components

This section explores the intricate network of wiring and electrical elements that play a crucial role in machinery operation. Understanding these components is essential for effective maintenance and troubleshooting. Each connection and circuit contributes to the overall functionality, ensuring that the equipment performs optimally under various conditions.

Key elements include fuses, relays, switches, and connectors, which facilitate the flow of electricity and control different functions. Proper wiring not only enhances performance but also prevents potential hazards, making it vital to adhere to manufacturer specifications during repairs or modifications.

Regular inspection of these electrical components can help identify wear and tear, allowing for timely replacements. This proactive approach minimizes downtime and extends the lifespan of the equipment, ultimately ensuring efficient operation in the field.

Hydraulic System Overview

The hydraulic system plays a crucial role in the functionality of various machinery, allowing for efficient movement and control of components through fluid power. This system converts mechanical energy into hydraulic energy, enabling operators to perform tasks with precision and ease.

Key Components

Understanding the main components of a hydraulic system is essential for maintaining optimal performance. The primary elements include the pump, actuators, valves, and fluid reservoirs, each serving a specific purpose in the overall operation.

Functionality

The effectiveness of the hydraulic system relies on the principles of fluid mechanics. When the pump generates pressure, it pushes fluid through the system, allowing actuators to move and perform tasks. This seamless operation is vital for tasks requiring significant force and control.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure |

| Actuator | Converts hydraulic energy to mechanical motion |

| Valve | Controls fluid flow and direction |

| Reservoir | Stores hydraulic fluid |

Customer Reviews of S180 Parts

This section explores the feedback from users regarding components for a popular lawn care machine. Insights gathered from various experiences highlight the quality, reliability, and overall satisfaction with the items available.

- Quality: Many users emphasize the durability of the components, noting they withstand heavy use.

- Performance: Customers report improved functionality after replacing older items with newer options.

- Value for Money: Several reviews mention that while prices vary, the investment is justified by the longevity of the products.

Overall, feedback indicates a strong endorsement for these essential components, suggesting they significantly enhance the user’s experience.

Upgrades and Modifications Available

Enhancing the functionality and performance of your equipment can significantly improve its efficiency and durability. Numerous upgrades and modifications are available to tailor the machine to specific needs, ensuring optimal operation for various tasks. These enhancements can range from simple attachments to comprehensive system overhauls.

Common Upgrades

- Engine Enhancements

- Advanced Cutting Decks

- Improved Tire Options

- Ergonomic Seat Upgrades

- Additional Lighting Kits

Custom Modifications

- Custom Storage Solutions

- Performance Tuners for Enhanced Power

- Enhanced Suspension Systems

- Aftermarket Attachment Compatibility

- Precision Guidance Systems

Investing in these modifications not only boosts productivity but also extends the lifespan of your machine, providing greater value in the long run.