Understanding the Yamaha F60 Parts Diagram for Better Maintenance

The intricate world of marine propulsion systems encompasses a wide array of elements that contribute to optimal performance and efficiency. Understanding these components is crucial for maintenance and repair, ensuring that your vessel operates smoothly on the water.

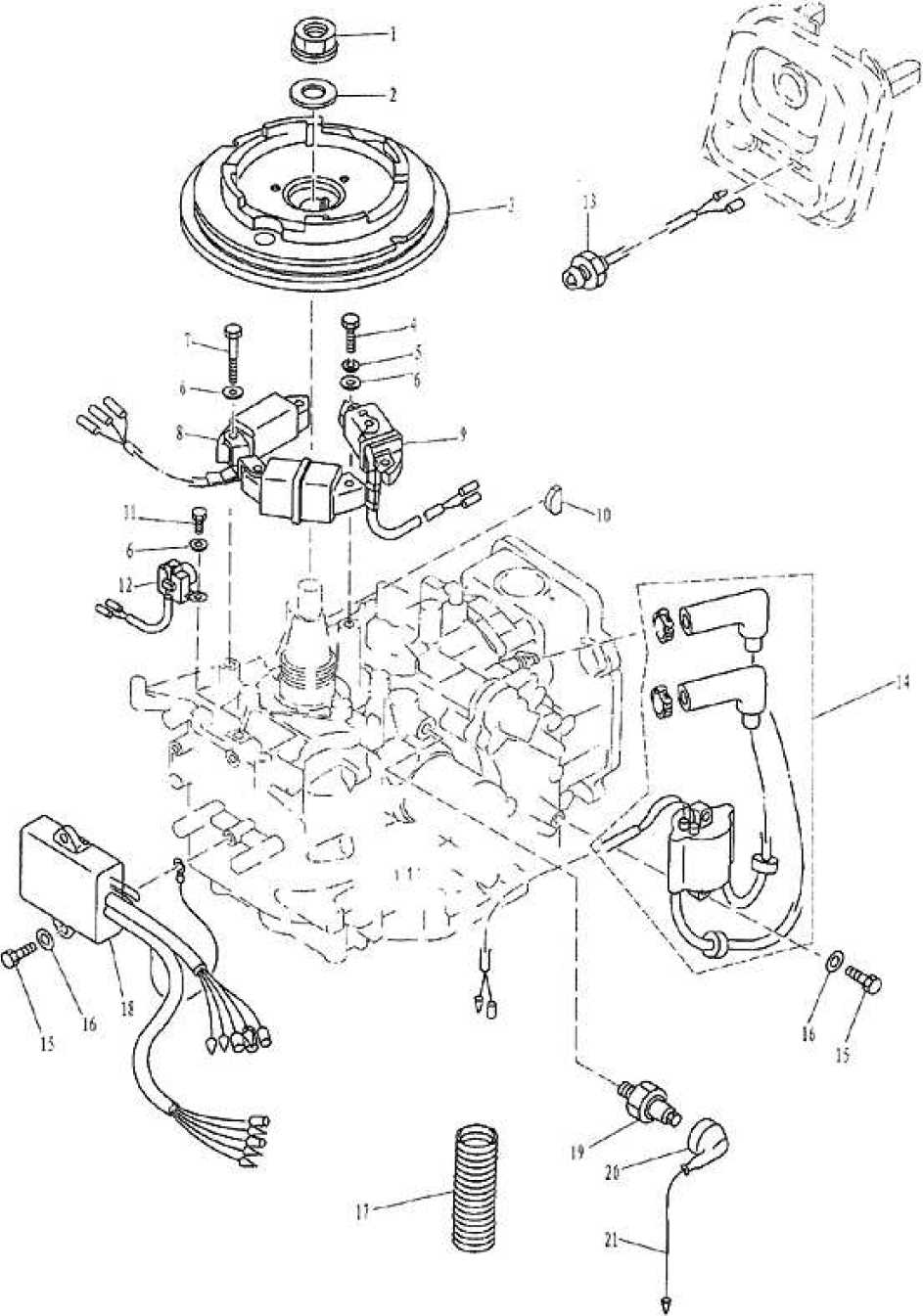

In this section, we will explore the various components of a specific outboard engine, highlighting their functions and interrelationships. By gaining insight into these parts, you can make informed decisions when it comes to upkeep and troubleshooting.

Whether you’re a seasoned technician or a boating enthusiast, having a clear visual representation of the engine’s structure will enable you to delve deeper into its mechanics. Ultimately, this knowledge will enhance your ability to manage and service your marine engine effectively.

Understanding Yamaha F60 Parts

Grasping the components of marine engines is essential for optimal performance and maintenance. Each segment plays a crucial role in the overall functionality, ensuring that the vessel operates smoothly and efficiently. A thorough comprehension of these elements can aid in troubleshooting and repairs, enhancing longevity and reliability.

Key Components

Fundamental sections include the power unit, fuel system, and cooling mechanisms. Each element is designed to work in harmony, contributing to the engine’s efficiency and effectiveness. Familiarity with these crucial components allows for informed decisions during service and replacement.

Maintenance Tips

Regular inspections and timely replacements are vital for sustaining performance. Understanding the role of each segment facilitates proactive care, reducing the likelihood of significant issues. Keeping a close eye on wear and tear can significantly extend the lifespan of the engine.

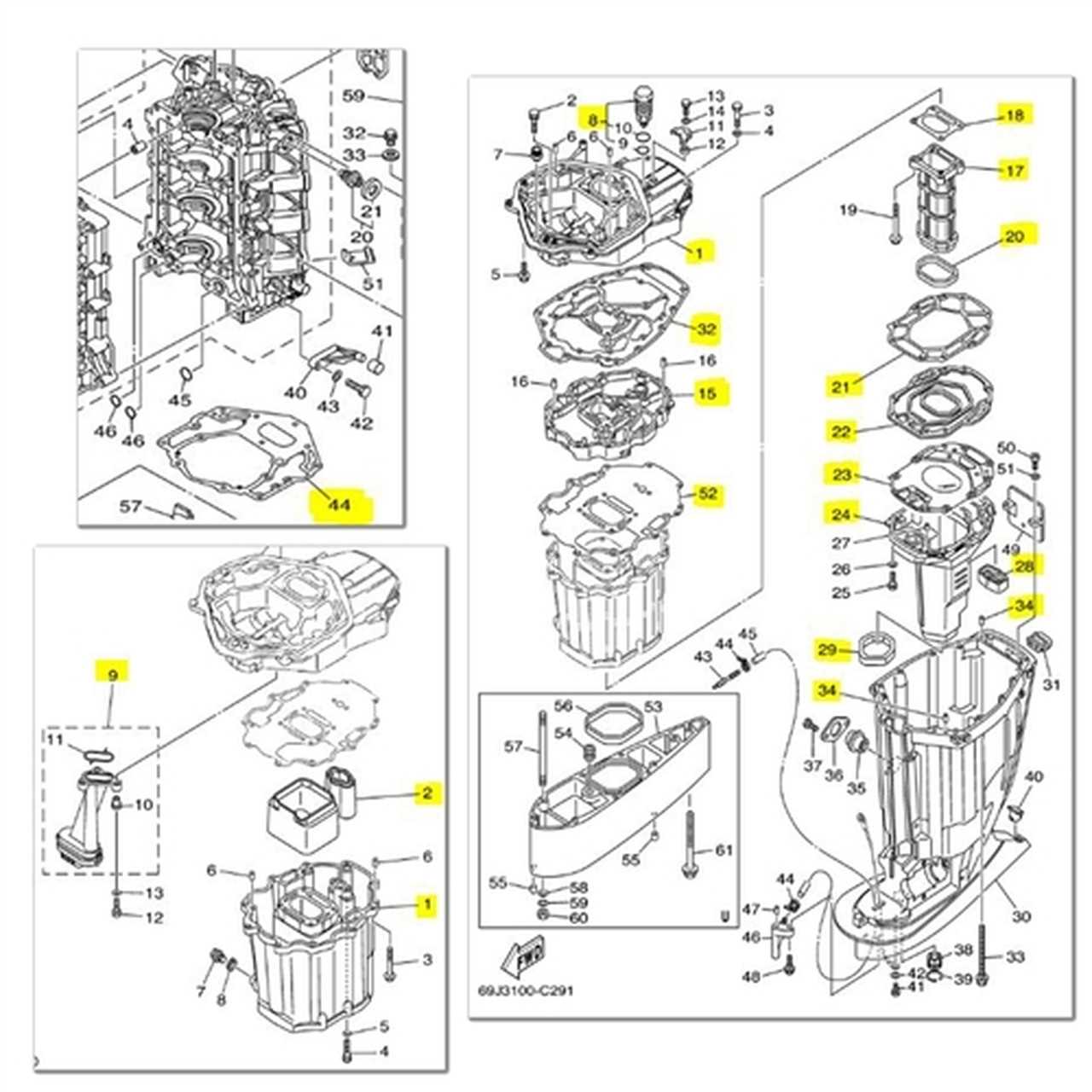

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clear insight into the individual elements that make up complex systems. By showcasing each part’s placement and relationship to others, these illustrations facilitate easier identification and troubleshooting.

Enhanced Clarity: A well-structured visual guide eliminates confusion, enabling technicians to navigate intricate assemblies with confidence. This clarity is vital for both seasoned professionals and newcomers, ensuring that everyone can effectively interpret the information.

Efficiency in Repairs: Having a detailed reference at hand significantly speeds up the repair process. When individuals can quickly locate components and understand their functions, the likelihood of errors diminishes, leading to faster and more accurate repairs.

Cost-Effectiveness: By minimizing the time spent on diagnostics and assembly, these visual aids contribute to overall cost savings. Quick resolution of issues reduces downtime, allowing for more efficient use of resources and finances.

In conclusion, visual aids play a pivotal role in maintenance, enhancing understanding, efficiency, and cost-effectiveness. They empower users to engage with their equipment more effectively, ensuring longevity and optimal performance.

Common Yamaha F60 Components

This section explores essential elements found in a popular marine engine model, highlighting their significance and functionality. Understanding these components can enhance maintenance practices and improve overall performance.

Key Components

- Powerhead: The heart of the engine, responsible for converting fuel into mechanical energy.

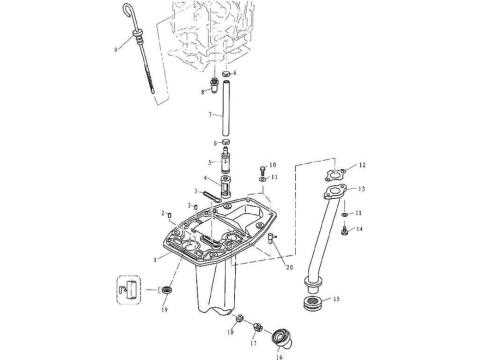

- Lower Unit: Houses the gear system and propeller, essential for propulsion.

- Fuel System: Includes the tank, pump, and injectors, ensuring efficient fuel delivery.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

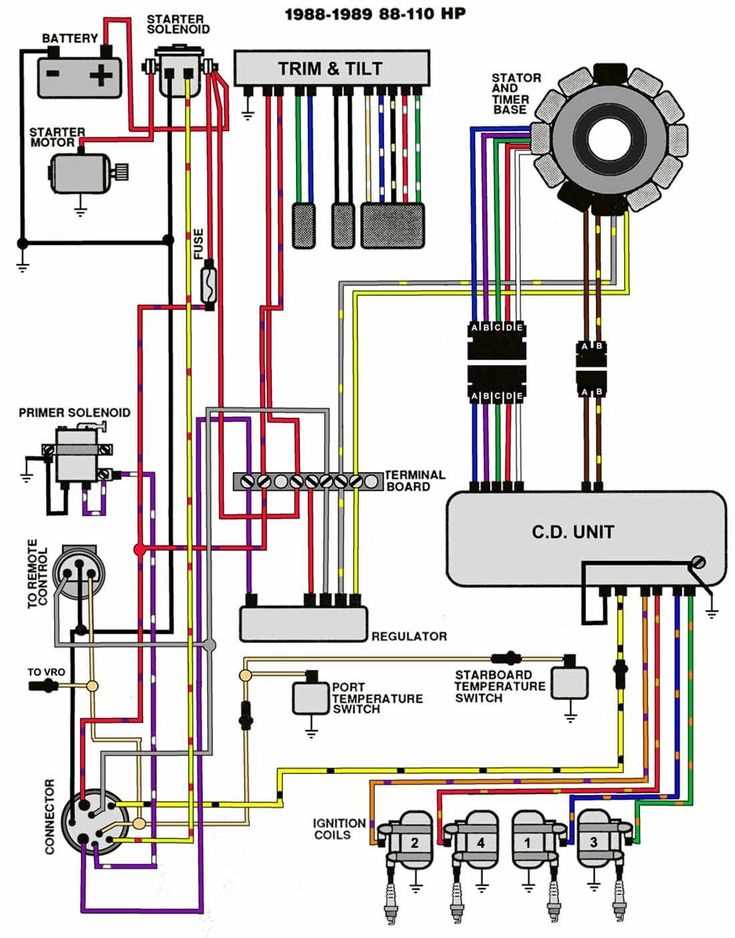

- Electrical System: Comprises batteries, wiring, and ignition components, crucial for starting and running the engine.

Maintenance Considerations

- Regularly inspect the powerhead for any signs of wear or damage.

- Ensure the lower unit is free from leaks and properly lubricated.

- Check the fuel system for clogs or deterioration to avoid performance issues.

- Monitor the cooling system to ensure it functions efficiently and replace any worn parts.

- Maintain the electrical system by checking connections and battery health regularly.

Where to Find Diagrams Online

Locating visual guides for machinery components can significantly enhance your understanding of assembly and maintenance. Various online resources cater to this need, providing detailed illustrations and specifications that assist in repairs and upgrades.

1. Manufacturer Websites

Official websites often host a repository of resources, including schematics and technical documents. Visiting these sites can yield accurate and reliable information directly from the source.

2. Online Forums and Communities

Engaging with enthusiast communities can provide valuable insights. Members frequently share links and documents that may not be readily available elsewhere, fostering collaboration and knowledge sharing.

| Resource Type | Benefits |

|---|---|

| Manufacturer Websites | Direct access to official resources, high reliability |

| Online Forums | Community support, diverse user experiences |

| Specialized Websites | Comprehensive collections, user-friendly navigation |

Identifying Parts by Model Number

Understanding components through their unique identifiers is essential for effective maintenance and repair. Each identifier corresponds to specific attributes, making it easier to locate and distinguish between various elements within a system.

Why Model Numbers Matter

Model numbers provide crucial insights into the specifications and compatibility of components. They help streamline the selection process, ensuring that the correct items are sourced for repairs or replacements.

How to Locate Model Numbers

Typically, model numbers can be found on the component itself, in manuals, or on manufacturer websites. Familiarizing yourself with where to look can save time and reduce errors in identification.

| Component Type | Typical Location of Model Number |

|---|---|

| Engine | On the casing or near the mounting points |

| Propeller | Stamped on the blade or hub |

| Control Unit | Inside the access panel or on the back |

Maintenance Tips for Yamaha F60

Regular upkeep is essential for ensuring optimal performance and longevity of your marine engine. Adopting a systematic approach to maintenance can prevent costly repairs and enhance reliability during your outings. Below are some key suggestions to help keep your engine in top condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 100 hours or annually | Replace with high-quality oil to maintain smooth operation and reduce wear. |

| Fuel System Check | Every season | Inspect filters and lines for leaks or blockages to ensure proper fuel flow. |

| Cooling System Inspection | Every 50 hours | Check for any debris in the cooling passages and ensure water intake is clear. |

| Battery Maintenance | Monthly | Clean terminals and ensure proper charge levels to avoid starting issues. |

| Propeller Inspection | Every outing | Look for signs of damage or debris that may affect performance. |

By following these guidelines and maintaining a consistent schedule, you can ensure your engine remains reliable and efficient for many adventures ahead.

Replacement Parts Overview

This section explores the essentials of sourcing components for marine engines, focusing on the need for reliable replacements to ensure optimal performance and longevity. Understanding the various options available can aid in maintaining functionality and preventing potential issues.

Types of Components

Several categories of elements are crucial for the efficient operation of any engine. Engine internals, such as pistons and valves, must be selected carefully for durability. Additionally, external accessories, including filters and gaskets, play vital roles in maintaining operational integrity.

Importance of Quality

Choosing high-quality replacements is essential for performance. Subpar components can lead to significant malfunctions, reducing efficiency and increasing maintenance costs. Investing in superior alternatives ensures that the engine runs smoothly and extends its lifespan.

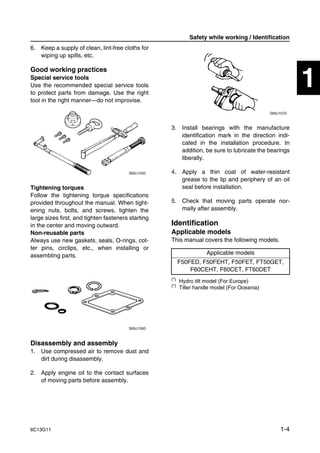

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for comprehending complex systems. These illustrations provide a clear framework for identifying components and their relationships, enhancing your ability to troubleshoot and repair effectively.

Familiarize Yourself with Symbols

Each illustration uses specific symbols to represent various elements. Take time to learn these icons, as they serve as a universal language that simplifies communication and understanding of the layout.

Follow the Flow of Information

Pay attention to the connections and flow between elements. Recognizing how components interact will help you grasp the overall function, making it easier to identify any issues that may arise during maintenance.

Tools Required for Repairs

Proper maintenance and repair of equipment demand a specific set of instruments to ensure efficiency and safety. Understanding which tools are essential can make the process smoother and more effective, allowing for precise adjustments and replacements.

Essential Instruments

Here is a list of vital tools commonly needed for repairs:

| Tool | Purpose |

|---|---|

| Socket Wrench | Used for tightening and loosening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws of various sizes. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

Safety Gear

In addition to standard tools, safety equipment is crucial for protecting oneself during repairs. Always use gloves and safety glasses to prevent injuries while working.

Frequently Replaced Components

In any engine system, certain elements are prone to wear and tear over time, necessitating their replacement. Understanding which components commonly need attention can enhance maintenance efficiency and prolong the overall lifespan of the machinery.

- Propeller Shaft: Often subject to stress, it requires regular inspections.

- Fuel Filter: Essential for maintaining optimal performance, it should be replaced periodically.

- Spark Plugs: Crucial for ignition, these components need replacement to ensure smooth operation.

- Water Pump: A vital part for cooling, its failure can lead to serious issues.

- Battery: Regular checks and replacements can prevent starting problems.

By keeping an eye on these frequently changed components, users can ensure their systems run efficiently and effectively.

Understanding Engine Assembly

The assembly of a marine engine involves a complex interplay of various components working in harmony to ensure optimal performance and efficiency. Each element plays a critical role in the overall functionality, contributing to the power generation and operational stability of the vessel.

At the heart of the engine assembly is the crankshaft, which converts linear motion into rotational power. Connected to it are pistons that move within the cylinders, creating the necessary compression for combustion. The synchronization of these parts is vital, as even minor misalignments can lead to significant issues in operation.

Supporting the moving components are various systems, including lubrication and cooling, which prevent overheating and ensure smooth operation. Gaskets and seals are also essential, as they maintain pressure and prevent leaks that could compromise engine performance.

Understanding the intricate relationships between these components allows for better maintenance practices and troubleshooting, ensuring the longevity and reliability of the engine assembly. Knowledge of these systems not only aids in repairs but also enhances overall efficiency and safety on the water.

Common Issues and Solutions

When dealing with marine engines, it’s essential to understand frequent challenges that may arise during operation and maintenance. Identifying these issues early can lead to effective solutions, ensuring optimal performance and longevity.

-

Starting Difficulties:

This can often be attributed to fuel delivery problems or battery issues. Check fuel lines for clogs and ensure the battery is fully charged.

-

Overheating:

This may be caused by blocked cooling passages. Regularly inspect and clean the cooling system to prevent this issue.

-

Unusual Noises:

Grinding or rattling sounds can indicate mechanical problems. Examine components for wear and replace as necessary.

-

Fuel Leaks:

Leaks can compromise safety and efficiency. Inspect fuel lines and connections regularly for any signs of damage.

By proactively addressing these common issues, users can enhance their experience and ensure smooth operation.

Best Practices for Parts Ordering

Efficient procurement of components is essential for maintaining performance and reliability. Adhering to a systematic approach can streamline the process, minimize delays, and reduce costs. Here are some strategies to enhance your ordering experience.

1. Identify Your Needs

Before placing an order, assess the specific requirements based on your machinery’s performance and maintenance history. This ensures that you acquire the correct items, thus avoiding unnecessary returns or exchanges.

2. Choose Reputable Suppliers

Selecting trustworthy vendors is crucial for quality assurance. Research potential suppliers and read reviews to gauge their reliability. Consider the following factors when evaluating them:

| Criteria | Description |

|---|---|

| Quality Assurance | Check for certifications and product guarantees. |

| Delivery Times | Understand shipping times and any potential delays. |

| Customer Support | Evaluate the availability and responsiveness of support teams. |

| Return Policy | Review the terms for exchanges and refunds. |

By implementing these best practices, you can enhance the efficiency of your procurement process, ensuring that you always have the right components on hand when you need them.