Understanding the Honda HS828 Snowblower Parts Diagram

In the realm of outdoor equipment, a thorough comprehension of individual elements is essential for effective operation and maintenance. Each piece plays a vital role in ensuring optimal performance, and familiarity with these components can significantly enhance user experience. This guide aims to illuminate the intricacies of a particular model, providing insights into its essential features and functionalities.

By examining the various elements that comprise this specific model, users can gain a deeper understanding of how each part interacts within the system. Recognizing the layout and connections among these components facilitates troubleshooting and repairs, ultimately prolonging the lifespan of the equipment. Whether you’re a seasoned operator or a newcomer, this knowledge proves invaluable for efficient usage.

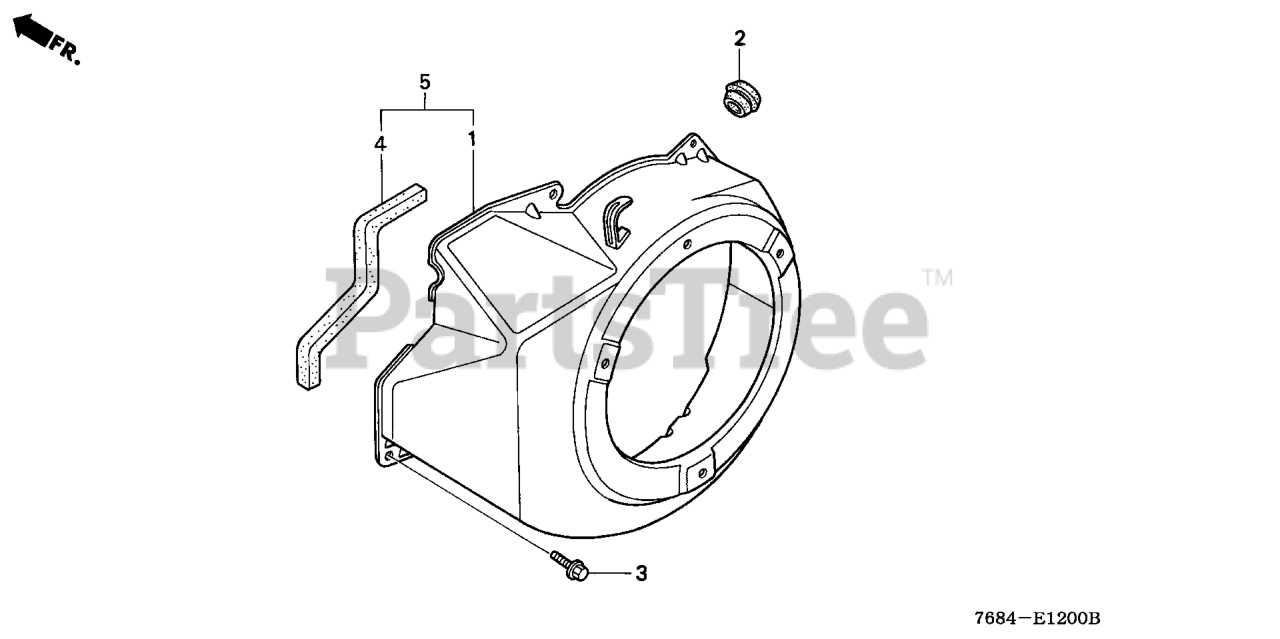

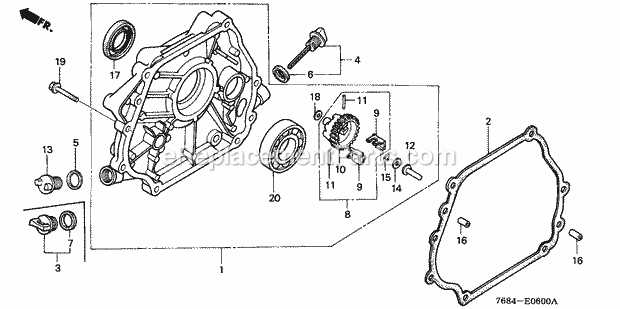

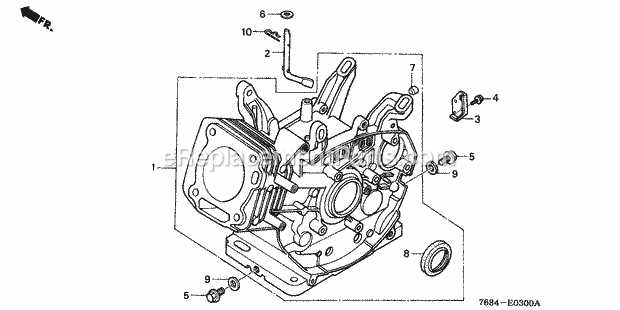

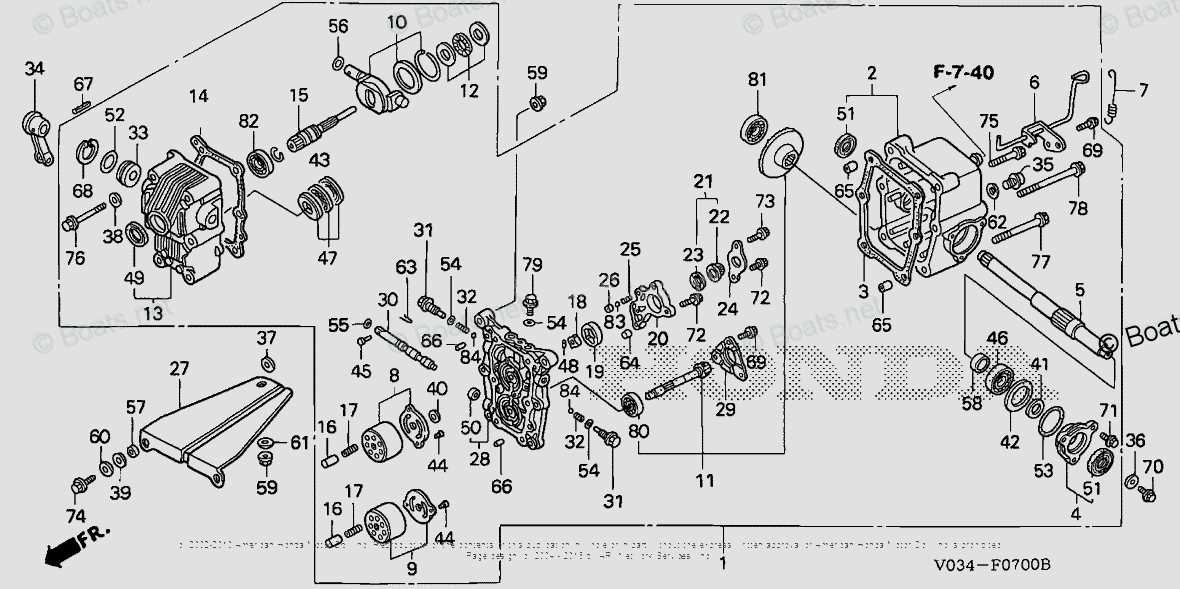

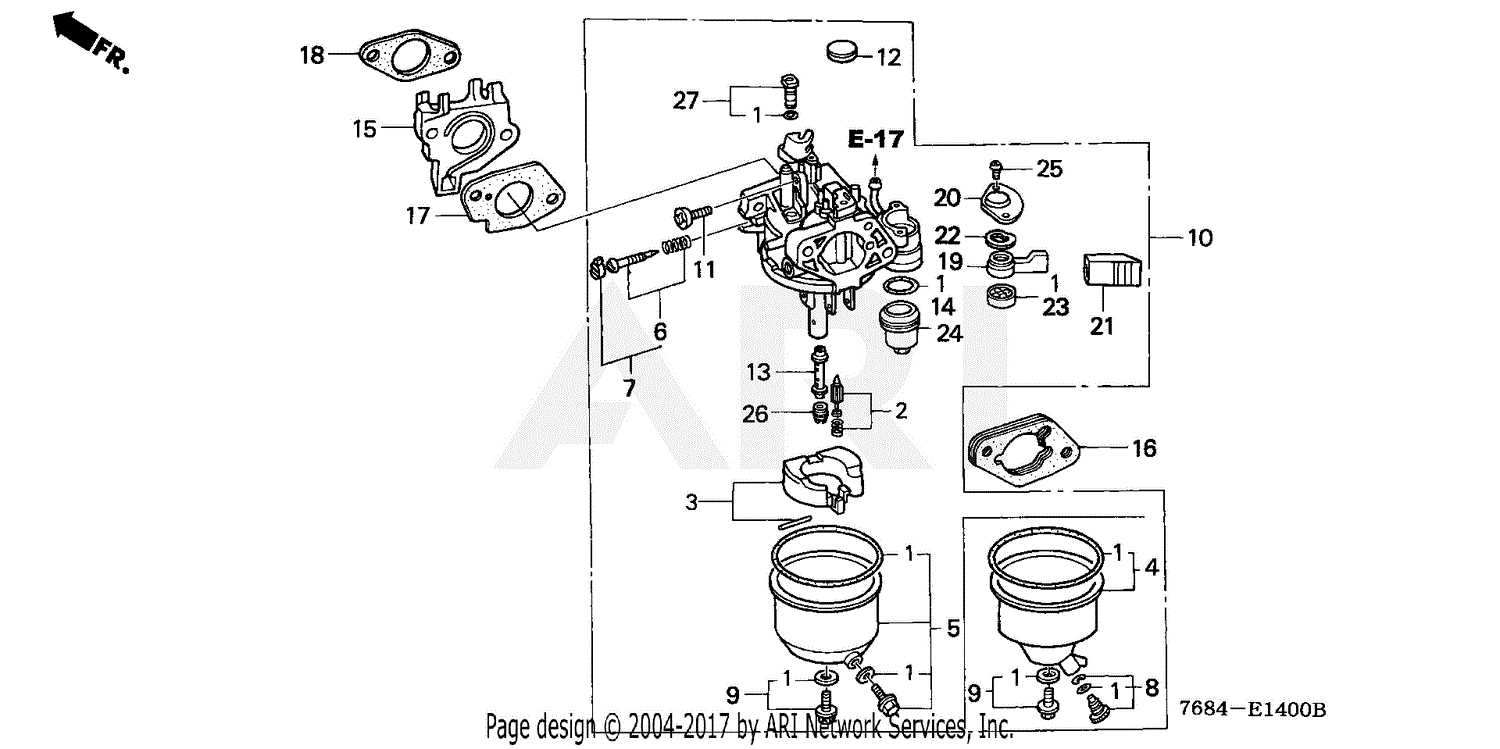

Additionally, having access to a visual representation of the assembly not only aids in identifying specific parts but also empowers users to make informed decisions during maintenance tasks. This approach demystifies the machinery and fosters confidence in handling repairs or replacements. By the end of this exploration, you will be better equipped to tackle any challenges that may arise.

Understanding Honda HS828 Snowblower Parts

Maintaining optimal performance of a winter clearing machine requires a solid grasp of its components and their functions. Each element plays a crucial role in ensuring the equipment operates efficiently, providing reliability during heavy snowfall.

To effectively manage and service your machine, it’s essential to familiarize yourself with the key components, including:

- Engine assembly: Powers the unit and is vital for its operation.

- Auger system: Responsible for gathering and displacing the snow.

- Impeller: Aids in propelling the cleared snow away from the path.

- Chassis: The framework that supports all components, ensuring stability.

- Control panel: Allows the operator to adjust settings and monitor performance.

- Skids and shoes: Facilitate smooth movement over various surfaces.

Understanding the interplay between these components can significantly enhance maintenance practices and prolong the lifespan of your equipment. Regular inspection and replacement of worn parts will ensure consistent functionality and prevent unexpected breakdowns.

Furthermore, being aware of each component’s specific function enables users to troubleshoot issues effectively, ensuring swift resolutions and continued operation during winter storms.

Overview of Snowblower Components

Understanding the key elements of a snow-clearing machine is essential for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance, particularly in challenging winter conditions. Familiarity with these components can enhance the user’s experience and extend the lifespan of the equipment.

Engine: The heart of the system, this component provides the necessary power to drive all operations. It converts fuel into mechanical energy, enabling movement and functionality.

Auger: This rotating element is responsible for gathering and breaking up the accumulated snow. Its design allows for efficient collection and transfer of snow towards the discharge chute.

Discharge Chute: Positioned at the front of the machine, this feature directs the expelled snow away from the pathway. Adjustable in direction, it helps control where the snow is thrown.

Drive System: This mechanism connects the engine to the wheels, allowing the machine to move forward or backward. A robust drive system is crucial for navigating through deep snow.

Skid Shoes: These adjustable parts determine the height of the cutting edge above the ground. Proper adjustment helps prevent damage to surfaces while optimizing snow removal.

Being acquainted with these elements not only aids in troubleshooting but also enhances safety during operation. Regular inspection and understanding of each part’s function can lead to more efficient performance and better handling of winter challenges.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding machinery. It serves as a valuable tool for both novice users and experienced technicians. By illustrating the various elements, such diagrams facilitate easier identification and replacement of worn-out or damaged components.

Furthermore, having a detailed visual aid enhances maintenance efficiency. When users can clearly see how different parts fit together, they can perform repairs with greater confidence, ultimately prolonging the lifespan of the equipment. Additionally, it reduces the likelihood of errors during reassembly.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Provides a clear view of how components interact. |

| Improved Efficiency | Streamlines the repair process, saving time and effort. |

| Reduced Errors | Lowers the chances of mistakes during reassembly. |

| Extended Lifespan | Encourages proper maintenance practices, prolonging usability. |

Key Parts of Honda HS828

This section delves into the essential components that make up a powerful winter machinery unit. Understanding these elements is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and reliability during operation, especially in challenging weather conditions.

Critical Components

Among the vital elements are the engine, which serves as the powerhouse, and the auger assembly, responsible for gathering and propelling snow. The impeller also plays a key role, aiding in the expulsion of snow from the chute. Regular inspection of these components can prevent wear and ensure a smooth operational experience.

Maintenance and Care

Routine upkeep is essential for longevity. Attention should be paid to the belts and cables, which facilitate movement and control. Lubrication of moving parts, along with periodic checks on the fuel system, can greatly enhance performance. Keeping these crucial elements in good condition will ensure reliable operation when it’s needed most.

How to Use the Diagram Effectively

Understanding a visual representation of machinery components can significantly enhance your maintenance and repair tasks. By utilizing this guide, you can streamline the process, ensuring that you locate and identify each element with ease. Here are some practical tips for maximizing the benefits of the illustration.

Steps to Follow

- Begin by familiarizing yourself with the overall layout.

- Identify the key sections that pertain to your specific needs.

- Use a legend or key if available, as it often provides crucial information regarding each part’s function.

- Cross-reference the image with your actual machine to spot any discrepancies.

- Take notes on any components that may need replacement or attention.

Common Mistakes to Avoid

- Ignoring the orientation of the parts, which can lead to misplacement during reassembly.

- Overlooking minor details, such as specific screws or fasteners that may be unique to certain models.

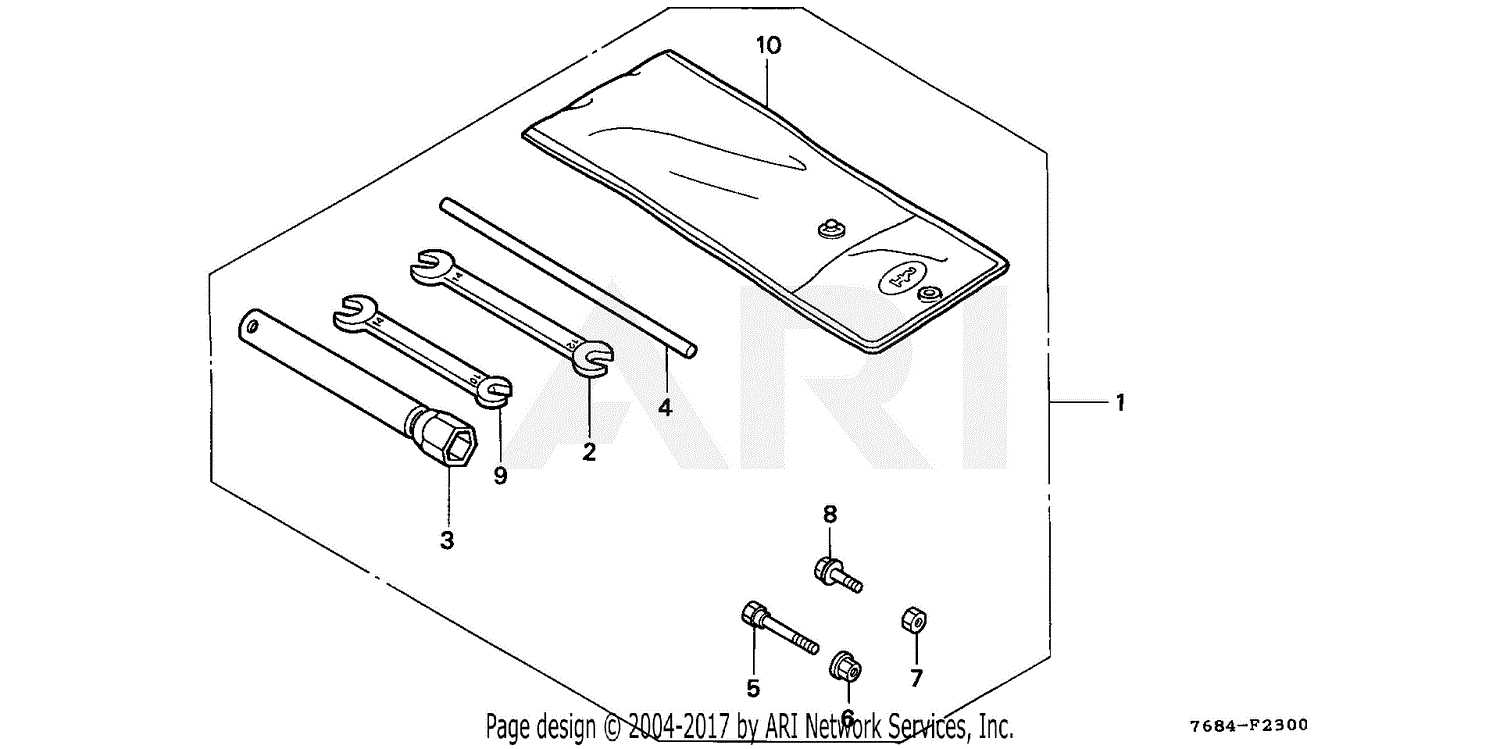

- Neglecting to gather all necessary tools before starting a repair.

- Rushing through the process without proper preparation, which can lead to errors.

By following these guidelines, you can ensure a more efficient and successful maintenance experience, ultimately prolonging the life of your equipment.

Common Repairs and Maintenance Tasks

Proper upkeep and timely repairs are essential for ensuring optimal performance and longevity of your equipment. Regular attention to key components can prevent breakdowns and enhance efficiency, making your winter tasks easier. Below are some of the most common maintenance and repair activities that you may encounter.

Routine Maintenance Tasks

- Oil Change: Regularly replacing the oil helps keep the engine running smoothly. Check the manufacturer’s recommendations for intervals.

- Fuel System Cleaning: Keeping the fuel system clean prevents clogging and ensures efficient operation. Consider using fuel additives or cleaning solutions.

- Check and Replace Belts: Inspect drive belts for wear and tear. Replacing damaged belts promptly can prevent further mechanical issues.

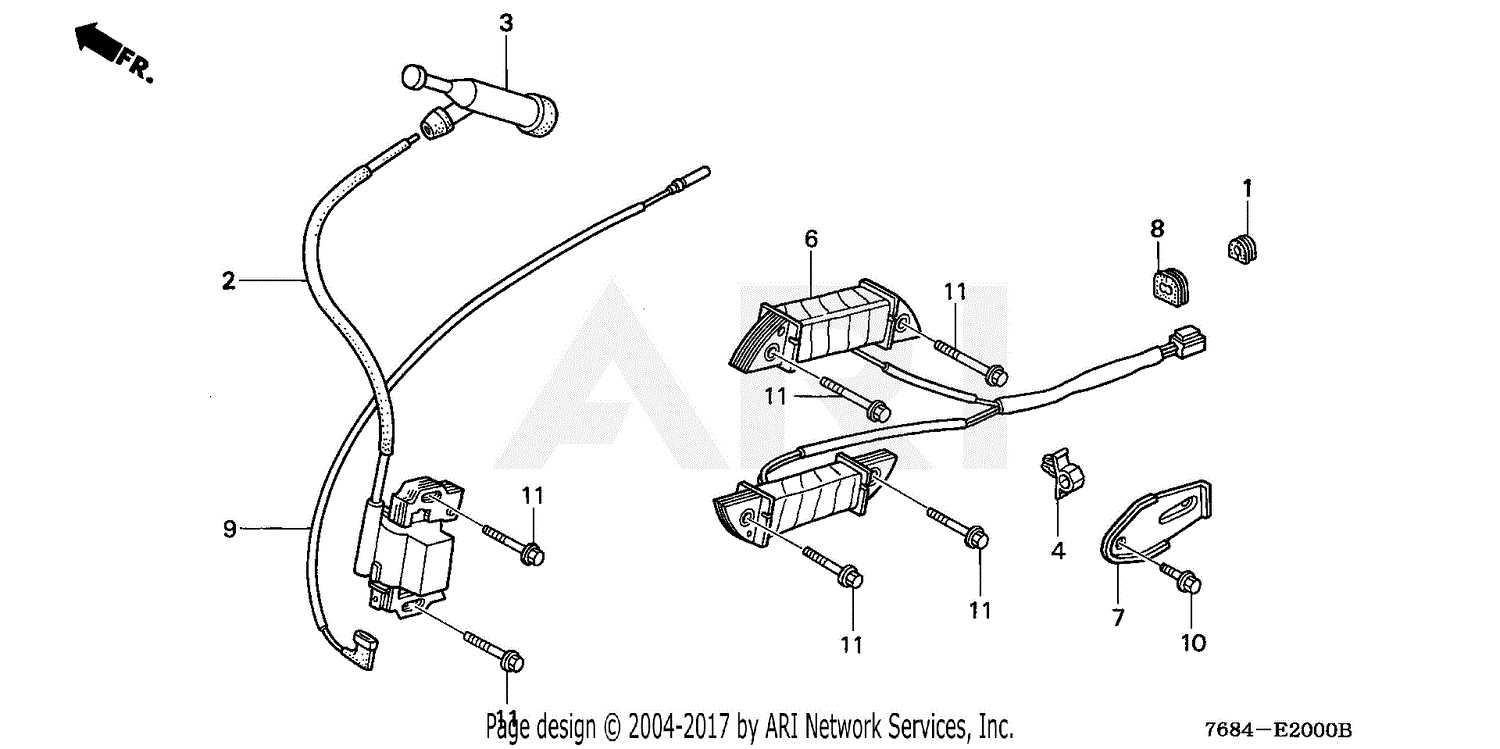

- Inspecting Spark Plugs: Clean or replace spark plugs as needed to ensure reliable starting and performance.

Common Repairs

- Auger Repair: If the auger is not functioning properly, check for blockages or damage. Replacement parts may be necessary for effective operation.

- Chassis Alignment: Ensure that all components are aligned correctly to avoid excessive wear and potential failure.

- Throttle Cable Replacement: If the throttle is unresponsive, replacing the cable can restore control over the engine speed.

- Clearing Blockages: Regularly check and clear any snow or debris buildup around the intake area to maintain optimal airflow.

By regularly performing these tasks, you can maintain high efficiency and extend the lifespan of your machinery, ensuring it remains ready for action throughout the winter season.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources that make finding the right items easy and efficient. Here are some strategies to ensure a successful search:

- Official Manufacturer Websites: Start by visiting the official site of the brand. They often provide comprehensive catalogs and manuals that can guide you in identifying the correct items.

- Online Retailers: Major e-commerce platforms typically carry a wide range of products. Utilize their search features to filter results based on model numbers or specific needs.

- Specialty Stores: Look for websites dedicated to specific machinery or tools. These platforms may offer a more focused selection and knowledgeable customer support.

- Forums and Communities: Engage with online groups or forums related to your equipment. Other users can provide recommendations on where to find reliable components.

When searching, it’s important to keep a few tips in mind:

- Check Compatibility: Always verify that the items you find are compatible with your specific model to avoid future issues.

- Read Reviews: Before making a purchase, check customer reviews to ensure the quality and reliability of the products.

- Compare Prices: Take the time to compare prices across different platforms to ensure you’re getting the best deal.

- Return Policies: Familiarize yourself with return policies in case the components do not meet your expectations.

By utilizing these resources and strategies, you can efficiently find the necessary components to keep your equipment running smoothly.

Tips for Identifying Compatible Parts

Ensuring the right components are used in your equipment can significantly enhance its performance and longevity. Identifying suitable replacements requires attention to detail and a solid understanding of the various factors that contribute to compatibility. Below are some effective strategies to help you make informed decisions when selecting components for your machine.

1. Consult the Owner’s Manual

Your first step should be to refer to the owner’s manual, which typically contains essential specifications and part numbers. This document serves as a valuable resource, providing insights into the recommended components and their compatibility.

2. Verify Specifications

Cross-checking measurements and specifications is crucial. Dimensions, materials, and design features can vary significantly between components, even if they appear similar at first glance. Make sure to measure key aspects such as:

| Specification | Importance |

|---|---|

| Dimensions | Ensures a proper fit |

| Material Type | Affects durability and performance |

| Attachment Points | Guarantees secure installation |

| Functionality | Ensures the part performs as intended |

By following these guidelines, you can confidently identify compatible components, ensuring your equipment operates efficiently and effectively.

Preventive Maintenance for Longevity

Regular upkeep is essential to ensure optimal performance and extend the lifespan of your equipment. Implementing a routine maintenance schedule can prevent unexpected breakdowns and costly repairs, allowing for smooth operation during peak usage periods. By dedicating time to care for your machinery, you can enhance its efficiency and reliability.

Key Maintenance Tasks

- Check and replace fluids regularly to maintain optimal functioning.

- Inspect moving components for wear and tear, ensuring they are well-lubricated.

- Clean air filters and intake areas to promote efficient airflow.

- Examine belts and cables for signs of damage or fraying.

- Ensure that all fasteners are secure to prevent parts from loosening during operation.

Seasonal Preparation

- Before the start of the season, conduct a comprehensive inspection to identify any potential issues.

- Store equipment in a dry, sheltered location to protect it from the elements.

- Run the machinery briefly after long periods of inactivity to keep components lubricated.

- Keep a log of maintenance activities to track performance and plan future upkeep.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality. Understanding the intricacies of these elements can enhance both maintenance and operational efficiency.

What should I do if a component is damaged? It is essential to assess the extent of the damage. Minor issues may be repairable, while significant damage may necessitate a complete replacement. Always refer to the manufacturer’s guidelines for specific recommendations.

How can I identify the correct component for my machine? Identifying the right element involves checking model numbers and specifications. Consult the user manual or reach out to a certified dealer for accurate assistance.

Are aftermarket options reliable? Aftermarket alternatives can vary in quality. It’s crucial to research brands and read reviews to ensure that the replacement will meet your performance expectations.

How often should I replace certain components? The lifespan of each part depends on usage and maintenance. Regular inspections can help determine when a replacement is necessary, ensuring optimal operation.

Where can I find detailed information about components? Manufacturer websites often provide resources, including technical documentation and support services. Online forums and communities can also be valuable for shared experiences and advice.

Resources for Repair Manuals

Finding reliable resources for repair manuals is essential for maintaining and fixing your equipment effectively. These guides provide detailed instructions and illustrations that can simplify the troubleshooting process, helping you save time and money. Here are some valuable sources to consider when seeking out these manuals.

Online Databases

- Manufacturer Websites: Many brands offer downloadable manuals directly on their official sites.

- Specialty Forums: Communities of enthusiasts often share resources, including links to repair manuals.

- Document Repositories: Websites dedicated to user-generated content may host a variety of repair guides.

Physical Resources

- Local Libraries: Many libraries maintain a collection of manuals that can be borrowed or accessed on-site.

- Automotive or Equipment Retailers: Some stores may offer printed manuals for purchase or provide access to them in-store.

- Trade Shows: Attending industry events can provide access to vendors who distribute repair literature.

Where to Get Professional Help

When dealing with equipment maintenance or repair, seeking assistance from qualified professionals can save time and ensure proper functionality. Experts possess the necessary skills and tools to diagnose issues accurately, providing reliable solutions that can enhance performance and longevity.

Authorized Service Centers

Visiting authorized service centers is one of the best options for receiving specialized care. These facilities are staffed with trained technicians who have extensive knowledge of the specific machinery. They utilize genuine components and adhere to manufacturer guidelines, ensuring that any work done is of the highest standard.

Online Resources and Forums

For those who prefer a more hands-on approach or wish to gain additional insights, numerous online platforms offer valuable information. Forums and community websites provide a space for users to share their experiences and solutions. Engaging with these communities can lead to useful tips and direct recommendations for reputable service providers.