Cub Cadet GT2554 Parts Diagram for Easy Maintenance

In the realm of outdoor equipment, understanding the intricate assembly of machinery is crucial for optimal performance and maintenance. An in-depth exploration of the various elements that comprise these powerful machines not only enhances functionality but also ensures longevity. Each component plays a significant role in the overall efficiency and effectiveness of the equipment.

For enthusiasts and operators alike, having access to a comprehensive visual guide can be the ultimate resource. It simplifies the identification of individual pieces, making it easier to manage repairs and replacements. This knowledge empowers users to delve into the mechanics of their machines with confidence.

By familiarizing oneself with the specific arrangements and connections of the various components, operators can significantly improve their operational experience. This understanding leads to more informed decisions regarding maintenance and upgrades, ultimately contributing to the equipment’s performance and durability.

Overview of the Lawn Tractor

This section provides a comprehensive insight into a specific model of riding mower designed for efficiency and versatility in lawn maintenance. With a focus on performance and user-friendly features, this machine stands out in its class.

Key Features

- Powerful engine for robust performance

- Comfortable seating for extended use

- Durable construction ensuring longevity

- Advanced cutting system for a precise finish

Benefits of Ownership

- Enhances lawn care efficiency

- Reduces physical strain with ergonomic design

- Offers versatility for various yard tasks

- Provides reliable support and maintenance options

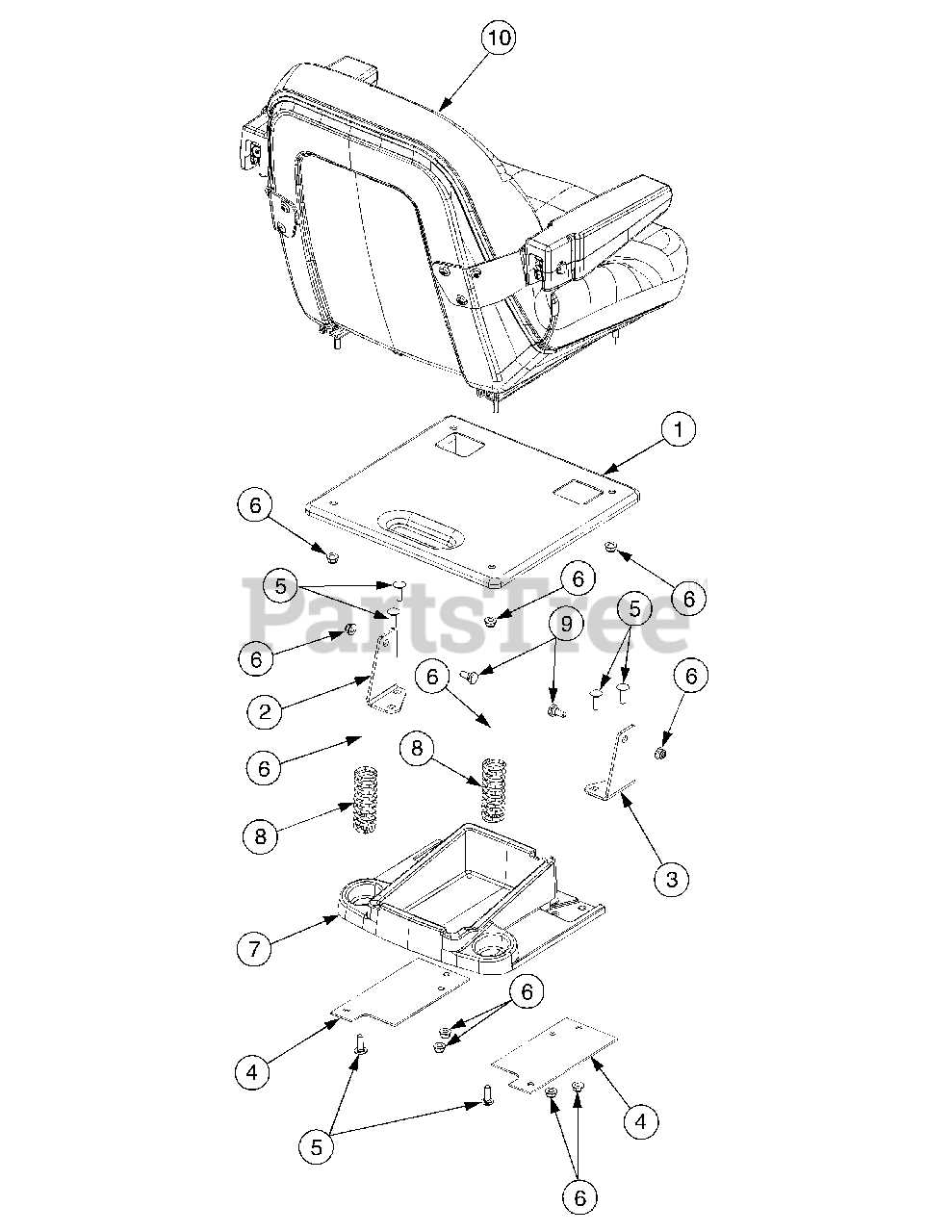

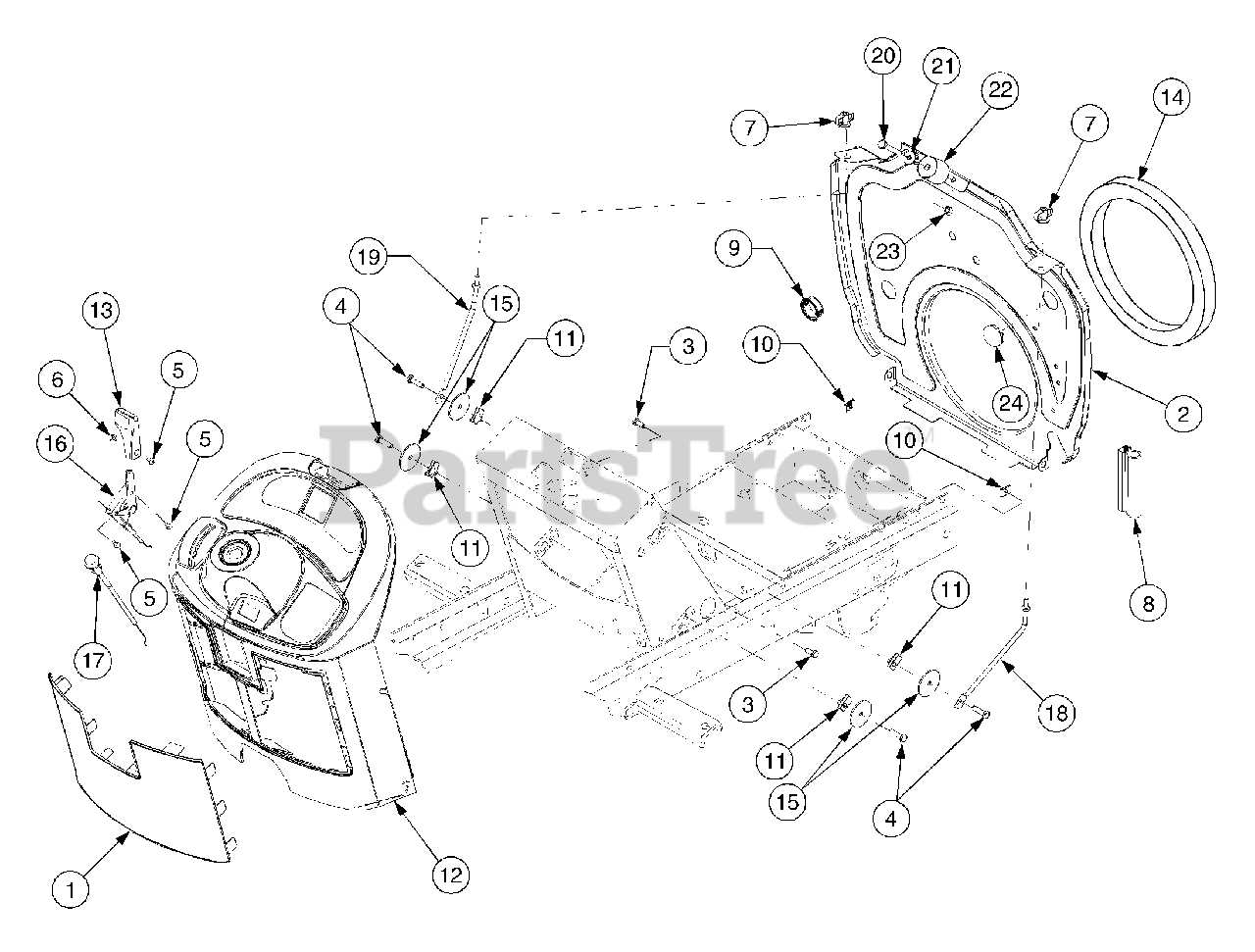

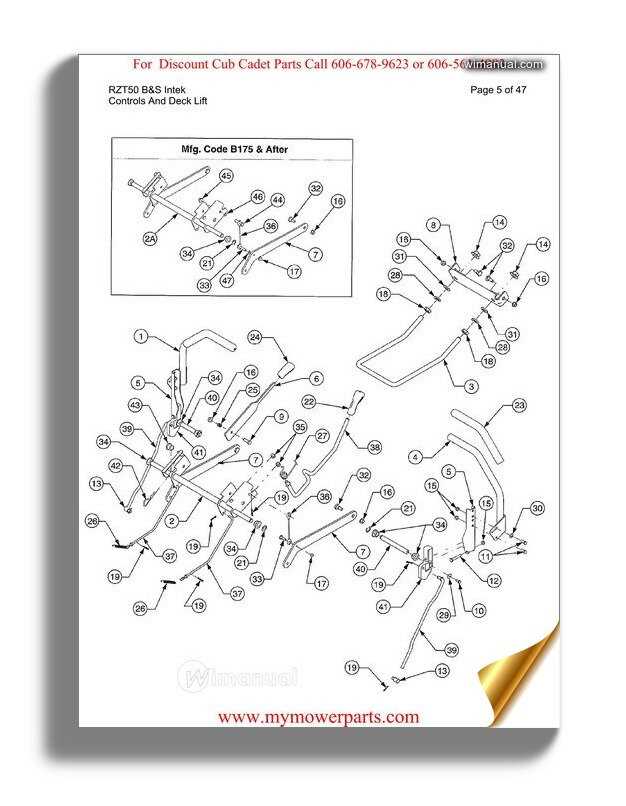

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair. This visual representation serves as a guide, enabling users to identify each section and piece efficiently.

Key benefits of utilizing this visual guide include:

- Enhanced clarity in locating specific items.

- Streamlined repair processes through systematic identification.

- Increased understanding of the overall system functionality.

When examining the layout, consider the following steps:

- Familiarize yourself with the categories and classifications.

- Identify any unique identifiers for each component.

- Refer back to the visual for troubleshooting issues effectively.

Ultimately, a thorough understanding of this visual tool empowers users to engage with their equipment more confidently.

Key Components of GT2554

This section highlights essential elements that contribute to the functionality and performance of the machine. Understanding these components is crucial for maintenance and repair, ensuring optimal operation over time.

| Component | Description |

|---|---|

| Engine | Drives the entire system, providing necessary power for various tasks. |

| Transmission | Facilitates speed control and power transfer from the engine to the wheels. |

| Deck | Houses cutting mechanisms and ensures effective grass management. |

| Wheels | Support movement and stability across different terrains. |

| Controls | Allow the operator to navigate and manage the machine efficiently. |

Importance of Maintenance

Regular upkeep is crucial for ensuring the longevity and efficiency of any machinery. Proper care not only enhances performance but also prevents unexpected breakdowns, leading to a more productive experience.

Key reasons for maintenance include:

- Prolongs lifespan of equipment.

- Enhances operational efficiency.

- Reduces repair costs over time.

- Ensures safety for users.

- Maintains resale value.

By implementing a consistent maintenance schedule, users can delve into proactive measures that contribute to the ultimate performance of their machinery.

Common Issues and Repairs

In any mechanical system, wear and tear can lead to various complications that may require attention. Understanding these frequent problems can help owners maintain their equipment effectively and address issues promptly to avoid further damage.

Typical Problems Encountered

- Engine not starting

- Cutting blades not engaging

- Fuel system blockages

- Electrical failures

- Excessive vibrations during operation

Repair Strategies

- Engine Troubles: Check the battery, ignition system, and fuel supply.

- Blade Engagement Issues: Inspect the engagement mechanism for wear and ensure proper linkage.

- Fuel System Blockages: Clean or replace fuel filters and ensure proper fuel flow.

- Electrical Failures: Examine wiring for shorts and test electrical components for functionality.

- Vibration Problems: Check for loose parts or damaged blades and tighten or replace as necessary.

Regular maintenance and timely repairs can significantly enhance the longevity and performance of your equipment. Keeping an eye on these common issues will help you address them before they escalate into more serious problems.

Where to Find Replacement Parts

Locating suitable components for your lawn equipment can enhance its performance and longevity. There are various avenues to explore for sourcing these necessary items, each offering unique benefits.

| Source | Description |

|---|---|

| Authorized Dealers | Visit certified retailers that specialize in specific brands. They often carry genuine replacements and provide expert advice. |

| Online Marketplaces | Websites like Amazon or eBay feature a wide selection of components, often at competitive prices. Ensure to verify seller ratings. |

| Local Repair Shops | Neighborhood repair centers can be a great resource for finding both new and refurbished items, along with professional installation services. |

| Manufacturer’s Website | Official sites typically offer direct purchasing options for original items and detailed specifications. |

Step-by-Step Assembly Guide

This section aims to provide a comprehensive walkthrough for assembling your equipment effectively. Following a structured approach ensures that each component is fitted correctly, resulting in optimal performance and longevity.

Step 1: Begin by gathering all necessary components and tools. Familiarize yourself with each part to understand its function within the overall system.

Step 2: Start with the base unit. Securely attach the frame components, ensuring they align properly. Use the appropriate fasteners to prevent any wobbling.

Step 3: Next, install the drive mechanism. This is crucial for the efficient operation of your machinery. Refer to the specifications for torque settings and alignment details.

Step 4: Assemble the control system. Pay close attention to the wiring and connections, as these are essential for functionality. Double-check each link to ensure reliability.

Step 5: Finally, review the assembly to confirm that all parts are correctly secured and aligned. Conduct a thorough inspection before the initial operation to prevent any issues.

By following these steps diligently, you can achieve a seamless assembly process, setting the stage for the ultimate performance of your machine.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures a high level of quality and compatibility. These parts are specifically designed for particular machinery, which enhances performance and longevity. Here are some key advantages of choosing OEM components over aftermarket alternatives.

Quality Assurance

OEM components undergo rigorous testing and quality control. This guarantees that each item meets the manufacturer’s standards, leading to:

- Improved durability

- Enhanced functionality

- Reduced risk of failure

Perfect Fit and Compatibility

Original parts are engineered to match the specifications of your equipment precisely. This results in:

- Seamless installation

- Optimal performance

- Fewer maintenance issues

In conclusion, selecting original components not only promotes efficiency but also contributes to the overall reliability of your machinery. Investing in these high-quality items is a wise decision for long-term success.

Upgrading Your GT2554 Model

Enhancing your lawn tractor can significantly improve its performance and extend its lifespan. By implementing thoughtful modifications, you can achieve better efficiency, increased power, and a more comfortable operating experience. This journey not only involves upgrading components but also tailoring the machine to better suit your specific needs.

Consider Engine Improvements: Upgrading the engine can provide a notable boost in power and efficiency. Look for high-performance options that offer better fuel economy and increased torque.

Transmission Enhancements: Optimizing the transmission system can enhance speed and control. Consider adding a more advanced transmission or upgrading existing components to improve responsiveness.

Attachment Compatibility: Ensure your machine is equipped to handle various attachments. Upgrading the hitch or adding adapters can expand functionality, making tasks easier and more efficient.

Comfort and Ergonomics: Improving the operator’s comfort can greatly enhance the experience. Consider upgrading the seat to one with better cushioning or adding ergonomic controls for ease of use.

Maintenance and Care: Regularly upgrading and maintaining critical systems ensures long-lasting performance. Invest in high-quality filters and fluids to keep the engine running smoothly.

By focusing on these key areas, you can elevate your tractor’s capabilities and ensure it remains a reliable partner for years to come.

Safety Tips for Operation

Ensuring safe operation of machinery is crucial for both the operator and those nearby. Adhering to essential safety practices can prevent accidents and promote a secure working environment.

Pre-Operation Checks

Before beginning any task, perform a thorough inspection of the equipment. Check for any signs of wear or damage, and ensure all safety features are functioning properly. Familiarize yourself with the user manual to understand specific operational guidelines.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This gear helps shield you from potential hazards and enhances overall safety during operation. Never underestimate the importance of being properly equipped.