Comprehensive Parts Diagram for John Deere AMT 600

In the realm of outdoor machinery, having a clear understanding of the individual elements that make up your equipment is essential for effective maintenance and repair. Each component plays a vital role in ensuring optimal performance, and knowing how they fit together can save time and resources in the long run.

For those who seek to delve deeper into the intricate workings of their machines, visual aids can be invaluable. These graphical representations not only provide clarity but also facilitate the identification of parts that may require attention or replacement. By familiarizing yourself with these illustrations, you empower yourself to tackle repairs with confidence.

Whether you are a seasoned technician or a novice enthusiast, navigating the landscape of machinery components is a skill worth mastering. This exploration not only enhances your understanding but also ensures that your equipment remains in top-notch condition, ready to perform when you need it most.

Understanding the John Deere AMT 600

This section explores the essential aspects of a versatile utility vehicle designed for various tasks. Its robust construction and innovative features make it a popular choice among professionals and enthusiasts alike.

Key characteristics that define this vehicle include:

- Durability: Built to withstand tough environments and heavy loads.

- Versatility: Suitable for numerous applications, from landscaping to agriculture.

- Ease of Maintenance: Designed for straightforward servicing and part replacement.

Understanding the components of this machine is crucial for effective usage and maintenance. Each element plays a significant role in overall performance and reliability.

Notable features that contribute to its functionality are:

- Engine: Offers powerful performance for demanding tasks.

- Transmission: Provides smooth operation and control on various terrains.

- Body Design: Ergonomically crafted for comfort and accessibility.

Comprehending the layout of these features aids users in making informed decisions, ensuring optimal use and longevity of the vehicle.

Key Features of the AMT 600

This vehicle is designed to provide exceptional versatility and efficiency for various tasks. With a robust construction and thoughtful engineering, it stands out in its category, appealing to both casual users and professionals alike.

Durability and Performance

The structure is built to withstand rigorous conditions, ensuring reliability during heavy use. Its powerful engine enhances productivity, making it suitable for a range of applications.

Versatile Applications

This model excels in adaptability, allowing users to customize it for different tasks, from landscaping to hauling materials. Its multifunctionality maximizes utility for owners.

| Feature | Description |

|---|---|

| Engine | High-performance engine for enhanced productivity. |

| Build Quality | Sturdy construction to withstand tough conditions. |

| Customization | Multiple attachments available for varied tasks. |

| Comfort | Ergonomically designed for ease of use. |

Importance of Parts Diagrams

Visual representations of components are essential tools in any mechanical or engineering field. They offer clarity and facilitate understanding of complex assemblies, making maintenance and repairs more efficient.

Enhanced Understanding

- Provides clear visualization of component relationships.

- Helps identify specific elements and their functions.

- Aids in troubleshooting issues effectively.

Streamlined Maintenance

- Enables quick identification of needed components.

- Facilitates ordering and sourcing replacements.

- Improves assembly and disassembly processes.

Common AMT 600 Parts Overview

This section provides an insightful look into the various components essential for the efficient functioning of the vehicle. Understanding these elements is crucial for maintenance and repair, ensuring longevity and optimal performance.

Key Components

Among the significant elements are the engine assembly, transmission system, and suspension setup. Each plays a vital role in enhancing the overall driving experience and reliability. Regular checks and timely replacements can prevent major issues down the line.

Maintenance Essentials

Routine maintenance of filters, belts, and brakes cannot be overstated. Keeping these components in top shape not only boosts performance but also contributes to safety. Investing time in upkeep ensures your vehicle remains robust and ready for any task.

Where to Find Diagrams

Locating detailed illustrations for machinery components can significantly aid in maintenance and repair tasks. Various resources are available, making it easier for enthusiasts and professionals alike to access essential visual guides.

Online Resources

- Manufacturer’s Official Website

- Specialized Machinery Forums

- Online Parts Retailers

Physical Resources

- Local Dealerships

- Automotive Repair Manuals

- Library Archives

Identifying Genuine Parts vs. Aftermarket

When it comes to maintaining machinery, distinguishing between original components and alternatives is crucial for optimal performance and longevity. Understanding the key differences can help in making informed decisions that affect both functionality and cost-effectiveness.

| Criteria | Genuine Components | Aftermarket Options |

|---|---|---|

| Quality | Manufactured to specific standards | Varies widely in quality |

| Warranty | Often comes with a warranty | Limited or no warranty |

| Price | Typically more expensive | Usually cheaper |

| Availability | Readily available through official dealers | Can be found at various retailers |

| Compatibility | Designed for perfect fit | May require adjustments |

Choosing the right option involves weighing these factors against the specific needs of your equipment and the intended usage. Prioritizing quality and compatibility can ultimately lead to better long-term results.

Maintenance Tips for the AMT 600

Regular upkeep is essential to ensure optimal performance and longevity of your utility vehicle. By following a few key practices, you can maintain its efficiency and reduce the risk of unexpected breakdowns. This section highlights essential maintenance strategies to keep your machine in top condition.

Routine Inspections

Conducting frequent inspections is vital. Check fluid levels, tire pressure, and belts for wear and tear. Pay attention to any unusual noises or vibrations during operation, as these could indicate underlying issues. Addressing small problems early can prevent costly repairs later.

Proper Cleaning

Keeping your vehicle clean not only enhances its appearance but also protects critical components. Regularly wash the exterior to remove dirt and debris, which can cause corrosion over time. Don’t forget to clean under the chassis and around the engine, ensuring that all areas are free from buildup that could hinder performance.

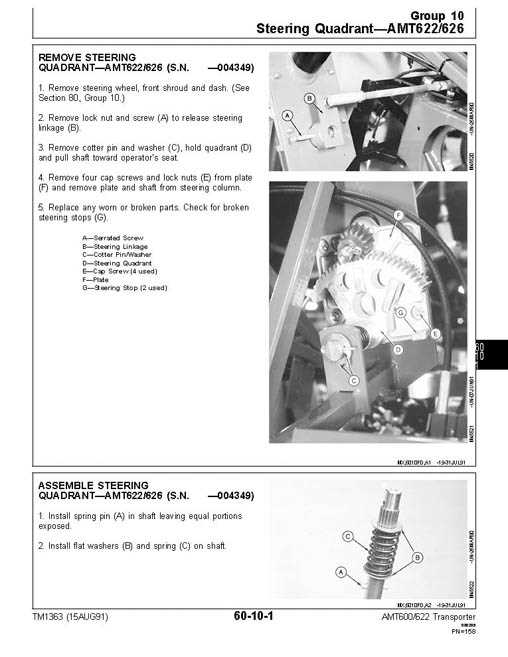

How to Read Parts Diagrams

Understanding schematic illustrations is essential for anyone involved in machinery maintenance or repair. These visual representations provide valuable information about the components and their relationships, helping users identify specific items and understand their function within a system.

Key Elements of Schematic Illustrations

When examining a schematic, it is important to recognize the different features that aid in comprehension. Typically, you will find various symbols and labels that indicate the type of components represented, their connections, and any relevant specifications. Here are some common elements:

| Element | Description |

|---|---|

| Symbols | Graphic representations that signify specific components, such as gears, bolts, or electronic parts. |

| Numbers | Identifiers that correspond to individual items within the accompanying list, facilitating easy reference. |

| Lines | Indicate connections or relationships between various elements, showing how they interact or are assembled. |

Steps to Effectively Interpret Illustrations

To accurately interpret these visual guides, follow these steps:

- Familiarize yourself with common symbols used in the illustration.

- Locate the reference key or legend that explains the symbols and numbers.

- Trace connections to understand how components fit together.

- Cross-reference numbers with the parts list for detailed specifications.

By mastering these techniques, you can navigate schematic illustrations with confidence, enabling efficient repairs and maintenance.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages, particularly in maintenance and repair contexts. These illustrations provide a clear understanding of the arrangement and function of various elements, facilitating efficient troubleshooting and assembly.

- Enhanced Clarity: Visual aids simplify complex structures, making it easier to identify parts and their relationships.

- Time Savings: Quick reference to illustrations can significantly reduce the time spent on repairs and maintenance tasks.

- Improved Accuracy: Detailed depictions help ensure that components are correctly installed, minimizing errors.

- Better Communication: Clear visuals aid in conveying information among team members, leading to more effective collaboration.

Incorporating these resources ultimately leads to increased efficiency and better outcomes in repair and maintenance processes.

Replacing Parts Effectively

Ensuring optimal performance of machinery requires timely and efficient substitution of components. Understanding the intricacies of each element helps in making informed choices when it comes to replacements. A well-planned approach not only enhances functionality but also extends the lifespan of the equipment.

Before initiating the swap, it’s crucial to identify the specific requirements and compatibility of the new component. Referencing reliable resources and manuals can provide clarity and guide the selection process. This knowledge empowers users to choose the right replacements that fit seamlessly and perform effectively.

Once the appropriate item is selected, preparing the workspace and gathering necessary tools is vital. A clean and organized area minimizes errors and promotes safety. Following step-by-step procedures, as outlined in technical documents, ensures a smooth installation, reducing the risk of future issues.

After installation, conducting a thorough inspection and testing the functionality of the new component is essential. Monitoring performance closely during initial operations can help in identifying any discrepancies early on, allowing for prompt adjustments. This proactive approach ultimately leads to sustained efficiency and reliability.

Resources for AMT 600 Owners

For enthusiasts and operators of specialized utility vehicles, accessing reliable resources is crucial for maintenance and upgrades. Whether seeking manuals, aftermarket components, or community advice, various platforms and tools can enhance the ownership experience.

Useful Online Platforms

Numerous websites cater to owners looking for information and support. Some offer forums where users share insights, while others provide downloadable resources such as manuals and guides.

Parts and Support

| Resource | Description |

|---|---|

| Manufacturer’s Website | Official site for manuals and specifications. |

| Online Marketplaces | Platforms to purchase aftermarket components. |

| Community Forums | Discussion boards for tips and troubleshooting. |