Understanding the Volvo Penta DP-E Parts Diagram for Optimal Performance

In the world of maritime machinery, a comprehensive grasp of engine assemblies is crucial for effective maintenance and repair. This section delves into the intricate relationships between various elements that constitute a marine propulsion system. By exploring the configuration and function of each component, users can enhance their technical skills and ensure optimal performance.

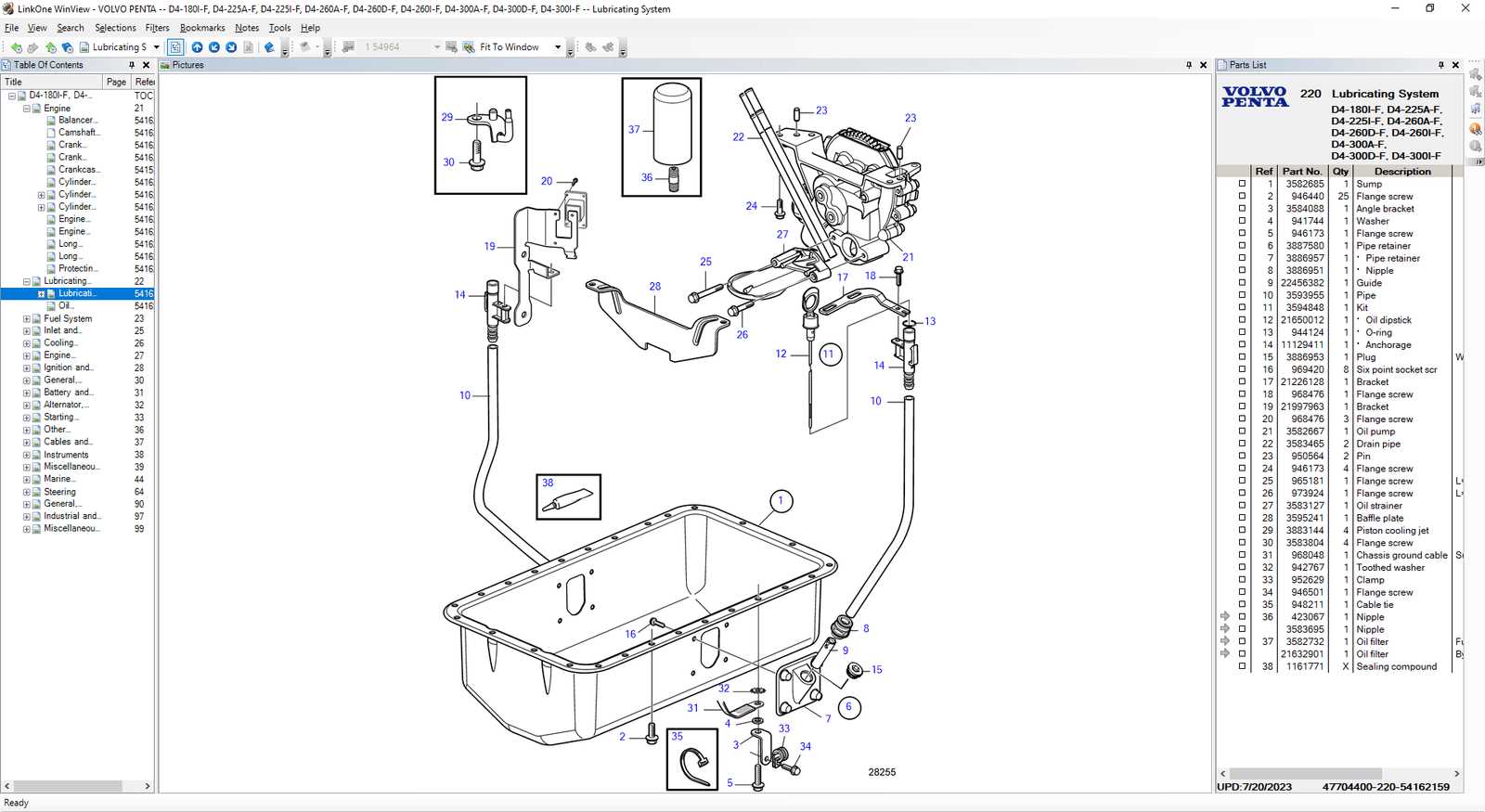

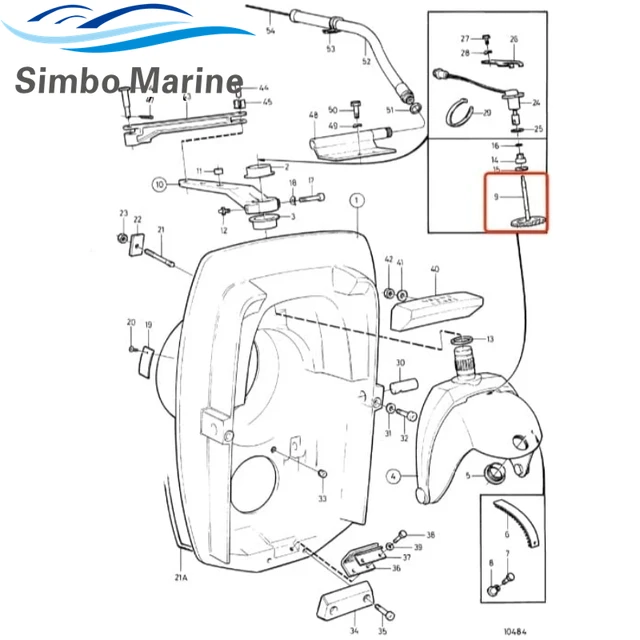

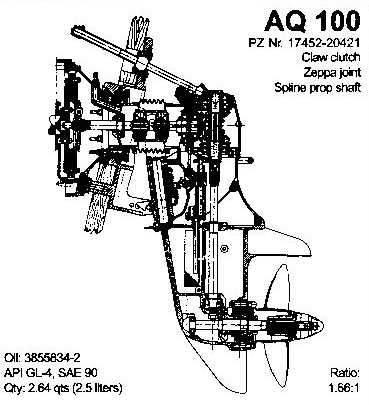

Detailed visual representations serve as invaluable tools for technicians, providing insights into how each part interacts within the overall structure. These illustrations simplify the identification process, allowing for quicker troubleshooting and efficient repairs. Moreover, they facilitate a deeper understanding of how different units contribute to the engine’s functionality.

Familiarity with the layout not only aids in maintenance but also empowers users to make informed decisions when sourcing replacements or upgrades. By grasping the essential components and their arrangements, one can navigate the complexities of marine engineering with confidence and precision.

Understanding Volvo Penta DP-E System

This section explores the intricate mechanism designed for marine propulsion, focusing on its components and functionality. Understanding this system is crucial for optimizing performance and ensuring reliability in various marine conditions.

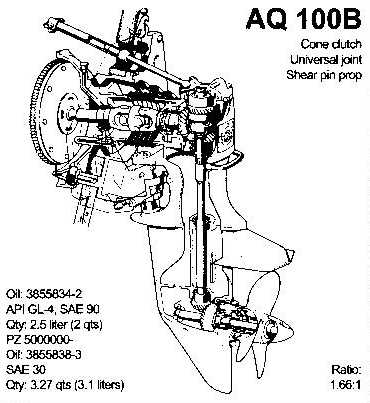

The system comprises several key elements that work together to provide efficient movement through water. Each component plays a specific role, contributing to the overall effectiveness of the unit. Below is a table detailing the primary components involved:

| Component | Description |

|---|---|

| Drive Unit | Enables power transfer from the engine to the propeller. |

| Propeller | Generates thrust by converting rotational energy into forward motion. |

| Hydraulic System | Controls the steering and trim functions for enhanced maneuverability. |

| Control Module | Coordinates operations and ensures optimal performance through various adjustments. |

By examining these components, users can gain insights into maintenance practices and troubleshooting techniques, ultimately enhancing their boating experience.

Components of the DP-E Drive

The drive system encompasses a variety of essential elements that work in harmony to ensure optimal performance and reliability. Understanding these components is crucial for effective maintenance and operation.

- Upper Unit: This section houses the gear mechanisms and provides a pivotal connection to the vessel.

- Lower Unit: Contains the propeller shaft and is responsible for propulsion through water.

- Hydraulic System: Facilitates smooth shifting and provides steering control.

- Cooling System: Ensures that the drive remains at an appropriate temperature during operation.

- Propeller: The ultimate component that interacts with the water to generate thrust.

By examining these key elements, operators can better appreciate the intricate design that contributes to overall marine performance.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations provide crucial information about components and their relationships. By familiarizing yourself with these visuals, you can streamline your troubleshooting and ordering processes.

Here are some key elements to consider when interpreting these visuals:

| Element | Description |

|---|---|

| Symbols | Each symbol corresponds to a specific component, often standardized across the industry. |

| Labels | Text annotations clarify the function or part number of each element, aiding in identification. |

| Connections | Lines or arrows indicate how components interact or connect, essential for assembly and disassembly. |

| Legend | A legend or key often accompanies the illustration, explaining the symbols and color codes used. |

| Scale | Some visuals include a scale for reference, helping to understand the relative sizes of components. |

By mastering these elements, you can navigate technical illustrations with confidence, ensuring a more efficient repair or replacement process.

Maintenance Tips for DP-E Parts

Regular upkeep of your marine equipment is essential for optimal performance and longevity. By following some key practices, you can ensure that all components function smoothly and efficiently.

Routine Inspection

- Check for wear and tear on all moving parts.

- Inspect seals and gaskets for leaks or damage.

- Examine electrical connections for corrosion or looseness.

Lubrication and Cleaning

- Apply appropriate lubricant to moving components as recommended.

- Clean surfaces regularly to prevent buildup of salt and debris.

- Replace any worn-out components promptly to avoid further issues.

Common Issues with DP-E Units

Marine propulsion systems can face various challenges over time, impacting performance and reliability. Understanding these common problems is essential for maintaining efficiency and ensuring safe operation. Regular inspection and timely repairs can prevent minor issues from escalating into significant malfunctions.

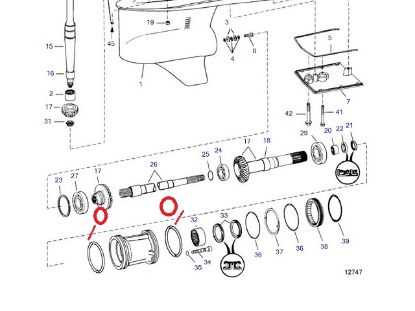

One frequent concern is gear shifting difficulties, which can stem from improper adjustments or wear in the shifting mechanisms. This can lead to unresponsive or harsh engagements, affecting overall maneuverability. Additionally, issues with the hydraulic system, such as leaks or pressure loss, can hinder performance and create safety risks.

Cavitation is another issue that can arise, particularly in high-speed applications. It occurs when low pressure leads to vapor bubbles forming and collapsing, potentially causing damage to propellers and drive components. Monitoring performance and addressing signs of cavitation promptly is crucial to prevent costly repairs.

Corrosion is a persistent challenge in marine environments. Components exposed to saltwater can deteriorate if not properly protected. Regular maintenance, including thorough cleaning and the application of protective coatings, can mitigate these risks and extend the lifespan of the system.

Finally, alignment problems can also impact performance, leading to increased vibration and wear. Ensuring proper alignment during installation and maintenance is vital for optimal operation and longevity of the drive system.

Replacing Worn DP-E Components

Maintaining the efficiency of marine propulsion systems is essential for optimal performance and safety. Over time, certain elements may wear down, leading to reduced functionality. Regular inspection and timely replacement of these components are crucial to ensure a smooth and reliable operation.

Identifying Signs of Wear

Common indicators of deterioration include unusual noises, vibrations, and performance drops. Regular checks can help pinpoint issues before they escalate, ensuring the system operates at its best.

Steps for Replacement

To replace worn elements, first gather the necessary tools and follow a step-by-step guide. Carefully remove the old components, inspect surrounding areas for damage, and install the new parts securely. Finally, conduct thorough testing to confirm proper functionality.

Essential Tools for Repairing DP-E

Effective maintenance and repair of marine propulsion systems require a selection of specialized instruments. Having the right tools on hand not only streamlines the process but also ensures precision and safety during repairs. This section outlines the fundamental implements needed to tackle any necessary service tasks.

Wrenches: A variety of wrenches, including socket and torque types, are crucial for loosening and tightening fasteners with the correct specifications.

Screwdrivers: Both flathead and Phillips screwdrivers are essential for accessing different components within the unit.

Pliers: Needle-nose and adjustable pliers assist in gripping, bending, and cutting wires or other materials.

Multimeter: This device is vital for diagnosing electrical issues, measuring voltage, and ensuring safe operations.

Torque Wrench: This tool guarantees that all bolts and nuts are secured to the manufacturer’s recommended specifications, preventing future failures.

Inspection Mirror: A handy tool for examining hard-to-see areas, ensuring no details are overlooked during maintenance.

Having these essential tools readily available will facilitate efficient and thorough repairs, ultimately extending the lifespan of your marine equipment.

Where to Find Genuine Parts

Finding authentic components for your marine equipment is essential for ensuring optimal performance and longevity. It is crucial to source these items from reliable suppliers to avoid complications and maintain safety standards.

Authorized Dealers

One of the best ways to acquire genuine components is through authorized dealers. These establishments are recognized by the manufacturer and offer certified products that meet quality standards. Always check for their credentials to ensure you are receiving the best.

Online Marketplaces

Reputable online platforms can also provide access to original items. Look for sellers with high ratings and positive feedback. Additionally, verify that the listings specify authenticity to avoid counterfeit products that may jeopardize your equipment.

Upgrading Your DP-E System

Enhancing your propulsion system can significantly improve performance and efficiency. By focusing on modern components and advanced technologies, you can ensure a smoother operation and extend the lifespan of your equipment. This section explores key aspects to consider when making upgrades.

Key Considerations for Upgrades

When planning enhancements, evaluate the compatibility of new parts with existing setups. Prioritize high-quality materials that can withstand marine environments. Additionally, consider software updates that can optimize functionality and enhance user experience.

Recommended Components for Upgrade

| Component | Benefits |

|---|---|

| New Propeller | Improved thrust and fuel efficiency |

| Advanced Gearbox | Smoother shifting and greater reliability |

| Enhanced Control System | Better responsiveness and user interface |

By carefully selecting and implementing these upgrades, you can achieve the ultimate performance boost for your system.

Benefits of Proper Maintenance

Regular upkeep of marine equipment is essential for ensuring optimal performance and longevity. Neglecting this aspect can lead to costly repairs and decreased efficiency. Proper care not only enhances the lifespan of the machinery but also ensures safety and reliability on the water.

Enhanced Performance

When equipment is well-maintained, it operates at peak efficiency. Key benefits include:

- Smoother operation and improved responsiveness.

- Higher fuel efficiency, reducing operating costs.

- Minimized risk of breakdowns, allowing for uninterrupted use.

Increased Safety

Regular maintenance checks contribute significantly to the safety of both the vessel and its occupants. Important points include:

- Early detection of potential issues that could lead to accidents.

- Assurance that safety systems are functioning correctly.

- Reduced likelihood of emergencies caused by mechanical failures.

Compatibility with Other Volvo Models

Understanding the interchangeability between various marine systems can enhance functionality and maintenance efficiency. This section explores how different models share components, ensuring seamless integration and optimal performance.

Interchangeable Components

Many elements from various series are designed with common specifications, allowing for easier upgrades and repairs. This compatibility reduces downtime and enhances the overall experience for users.

Benefits of Compatibility

Utilizing interchangeable parts leads to cost savings and simplifies sourcing replacements. It also fosters a more extensive support network, making it easier to find solutions and enhance system longevity.

Frequently Asked Questions about DP-E

This section addresses common inquiries regarding a specific marine propulsion system. It aims to provide clarity on various aspects, including functionality, maintenance, and compatibility. Understanding these elements can enhance user experience and ensure optimal performance of the equipment.

What maintenance is required for optimal performance?

Regular maintenance is crucial for longevity and efficiency. Users should perform routine checks on the seals, lubricants, and overall condition of the system. Additionally, periodic inspections of the hydraulic components are recommended to prevent potential failures.

How can I identify compatible components?

Compatibility is essential when sourcing components for replacement or upgrades. It’s advisable to consult the manufacturer’s specifications and guidelines. Utilizing a trusted dealer or service center can also ensure that the selected parts meet the necessary standards for integration with the existing system.

Cost Considerations for Repairs

When addressing the financial aspects of maintenance and restoration, several factors come into play that can significantly influence the overall expenses. Understanding these components is essential for making informed decisions that align with your budget and operational needs.

Key Factors Affecting Repair Costs

- Type of Damage: The severity and nature of the issue can greatly vary costs. Minor adjustments are typically less expensive than major overhauls.

- Labor Rates: The expertise required and local labor costs will impact the total expenditure.

- Component Quality: Choosing between original and aftermarket parts can lead to substantial price differences.

- Timeframe: Urgent repairs may incur additional fees, making it crucial to weigh the urgency against costs.

Strategies to Minimize Expenses

- Conduct regular inspections to identify issues early.

- Compare quotes from multiple service providers.

- Invest in preventative maintenance to reduce the likelihood of costly repairs.