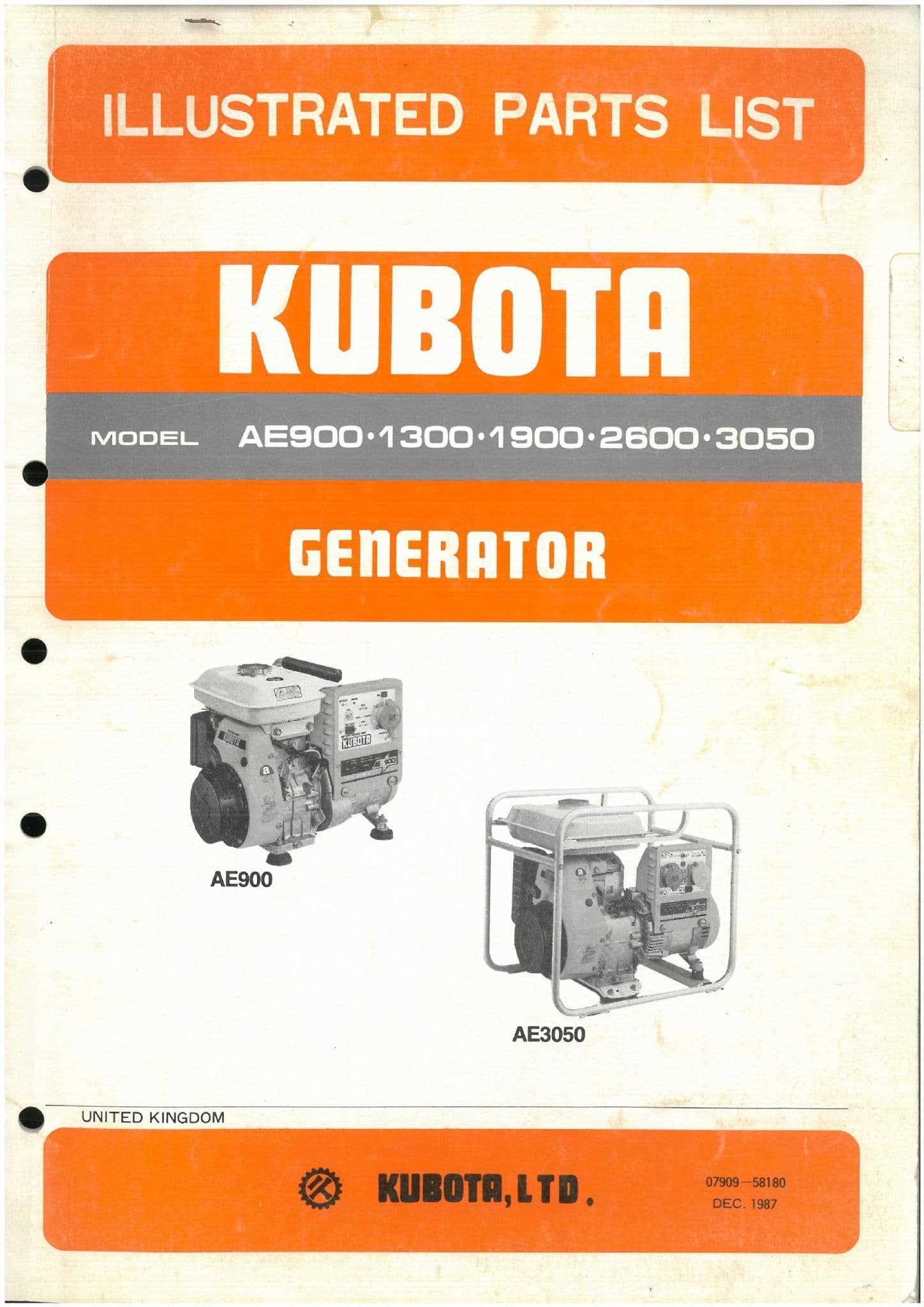

Kubota U17 Parts Diagram Guide

In the realm of compact machinery, having a comprehensive understanding of individual components is crucial for maintenance and efficiency. A well-organized visual representation can greatly enhance the ability to identify and replace necessary elements, ensuring that the equipment operates at peak performance.

Each element plays a vital role in the overall functionality of the machine, and recognizing how they interconnect can prevent potential issues. This exploration offers insights into various sections, aiding operators and technicians in navigating through the intricate assembly.

As we delve deeper into the intricate workings, we will uncover the ultimate relationships between these components, highlighting their importance and providing clarity on their maintenance. Gaining this knowledge empowers users to make informed decisions, thereby enhancing the longevity and reliability of their machinery.

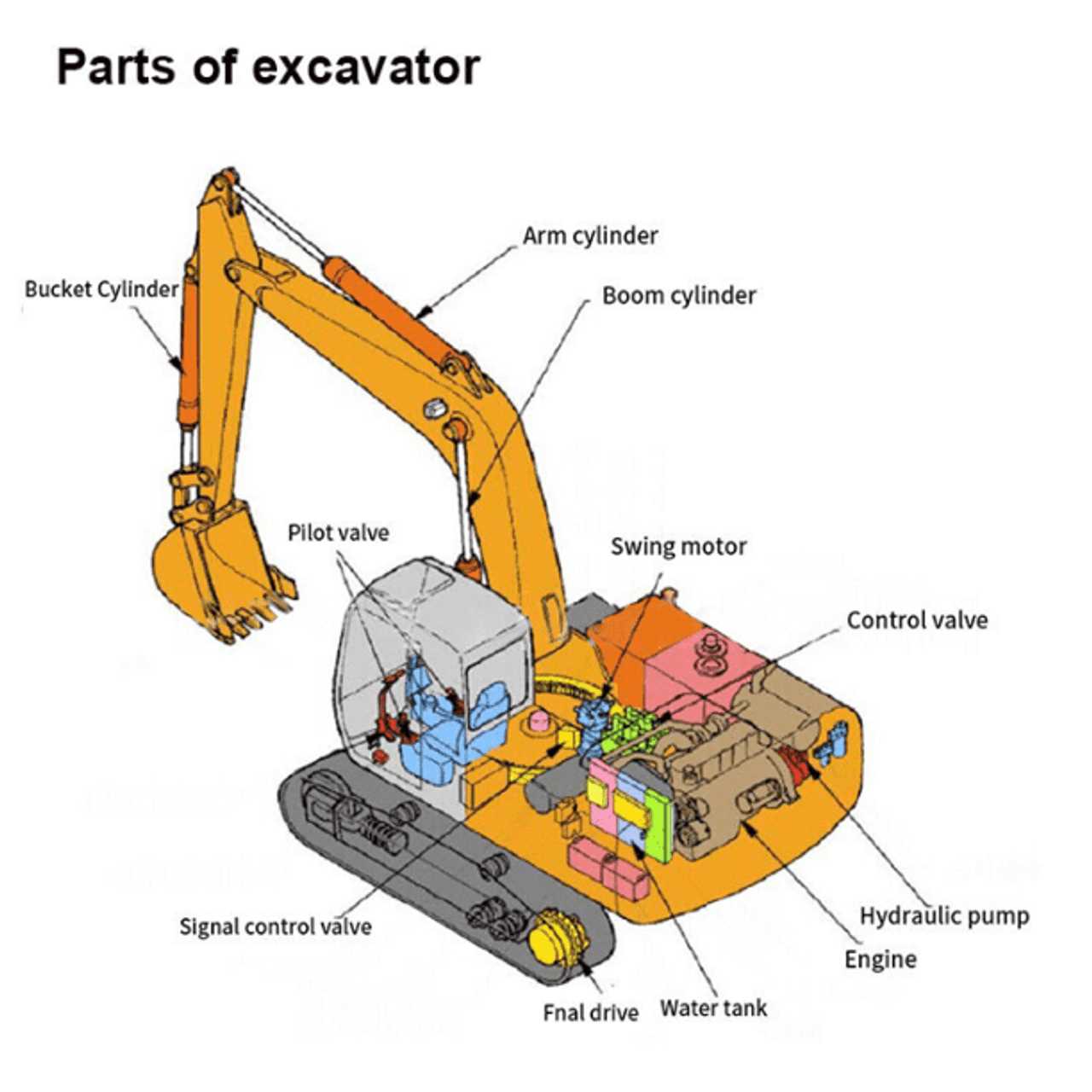

Overview of Compact Excavator

This section provides an insight into a versatile piece of machinery designed for efficient operation in confined spaces. With its robust construction and user-friendly features, this excavator is an essential tool for various construction and landscaping projects. It combines power and precision, making it ideal for tasks that require agility and performance.

Key Features

- Compact design for easy maneuverability

- Powerful engine for enhanced productivity

- Advanced hydraulic system for smooth operation

- Operator-friendly controls for improved efficiency

- Durable construction for long-lasting performance

Applications

- Excavating trenches and foundations

- Landscaping and site preparation

- Utility installations and maintenance

- Demolition of small structures

- Grading and leveling surfaces

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to identify individual elements and their relationships within a system. These illustrations simplify the process of locating specific items, facilitating efficient troubleshooting and replacement procedures.

Enhancing Maintenance Efficiency

Utilizing visual schematics significantly enhances maintenance efficiency. Technicians can quickly reference the necessary components, reducing the time spent searching for parts. This streamlined approach minimizes downtime, allowing for quicker repairs and increased productivity.

Facilitating Accurate Repairs

Visual aids contribute to accurate repairs by providing clear guidance on assembly and disassembly processes. Users can easily comprehend how different elements fit together, reducing the likelihood of errors. Moreover, a comprehensive understanding of the machine’s structure fosters better decision-making when selecting replacements or upgrades.

Key Components of Kubota U17

This section explores the essential elements of a compact excavator, emphasizing their importance for optimal performance and reliability. Understanding these fundamental parts allows operators and technicians to maintain and troubleshoot effectively.

Hydraulic System

The hydraulic system is crucial for the functionality of the machine. It powers various attachments and controls, ensuring precise movements and efficiency during operations. Regular checks on the hydraulic fluid levels and components can prevent potential issues.

Undercarriage

The undercarriage supports the entire structure and facilitates mobility. It includes tracks, rollers, and frames, all designed to provide stability and traction on various terrains. Maintaining these parts is vital for extending the lifespan and improving the overall performance of the equipment.

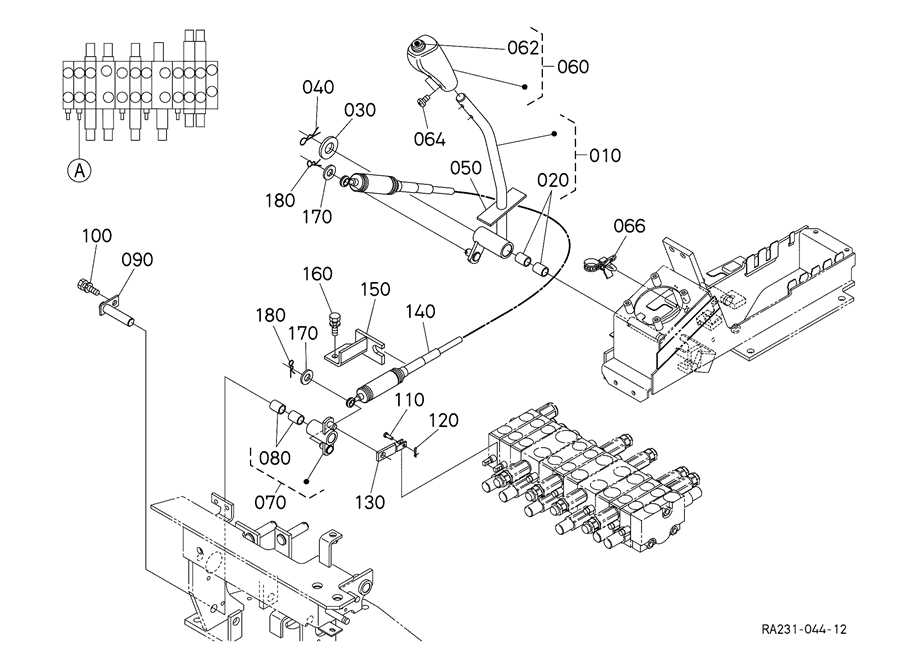

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a detailed overview, allowing users to identify and locate various elements within a machine. Mastering the ability to interpret these images can significantly enhance your troubleshooting skills and streamline your repair processes.

Start by familiarizing yourself with the layout of the visual guide. Typically, these illustrations are divided into sections, each representing a specific area of the equipment. Pay attention to the labeling, as it often includes reference numbers that correlate with a detailed list.

Next, identify the symbols and lines used in the representation. Different shapes may indicate various types of components, while lines often show connections or relationships between parts. Understanding these visual cues is crucial for accurate assembly or disassembly.

Finally, cross-reference with the accompanying documentation. Often, a supplementary list will provide descriptions and specifications for each item represented in the visual. This correlation allows for a deeper understanding and ensures you have the right components for your tasks.

Common Issues and Solutions

In the world of compact machinery, operators often encounter specific challenges that can hinder performance and efficiency. Addressing these issues promptly can save time and prevent costly repairs. This section explores prevalent problems and practical solutions to enhance the reliability of your equipment.

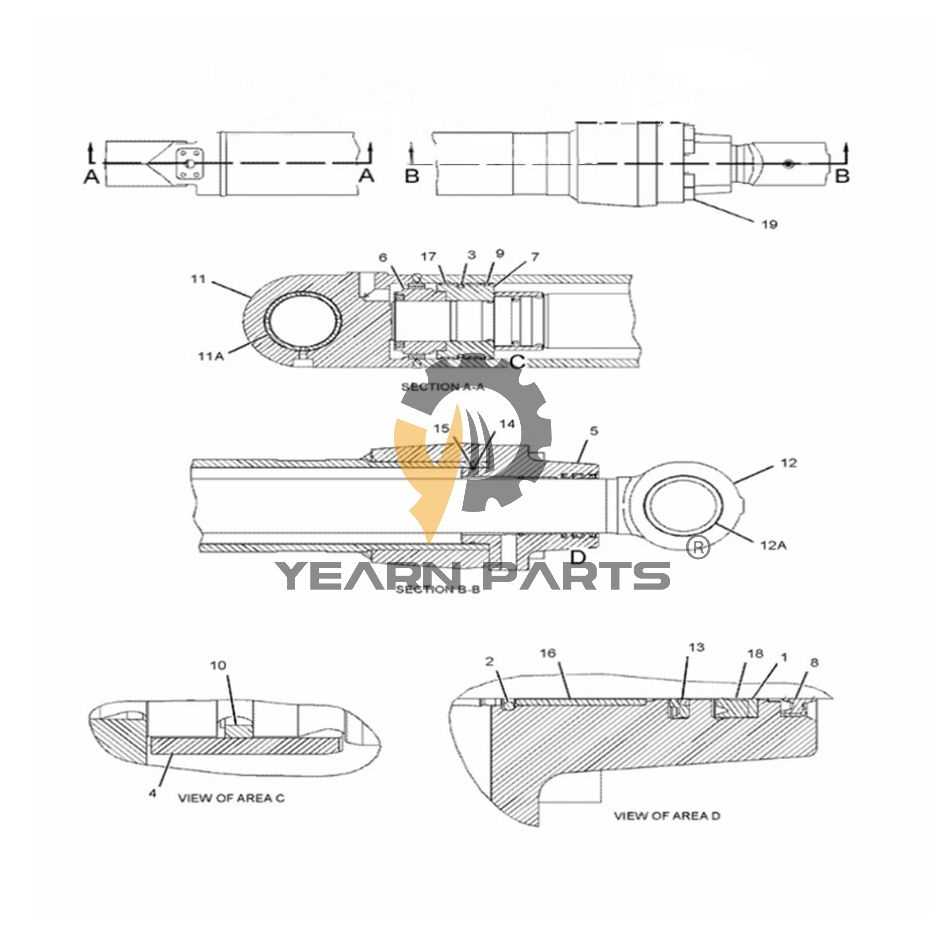

Hydraulic System Failures

One frequent concern is the malfunctioning of the hydraulic system. Symptoms may include sluggish movements or complete unresponsiveness. Regular maintenance is essential. Check for leaks and ensure fluid levels are adequate. Replacing worn seals can significantly improve performance.

Engine Overheating

Another common issue is overheating, which can lead to severe engine damage. Signs include rising temperature gauges and unusual noises. To combat this, ensure that the cooling system is free from debris and the coolant is at the right level. Flushing the radiator regularly can also help maintain optimal temperatures.

Where to Find Genuine Parts

Locating authentic components for machinery is essential for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that meet manufacturer standards, providing peace of mind and functionality.

Authorized Dealers

One of the most dependable ways to acquire genuine components is through authorized dealerships. These establishments offer a wide range of items that are certified for use in your equipment. Benefits include:

- Expert assistance from knowledgeable staff.

- Access to the latest models and updates.

- Warranty coverage on purchased items.

Online Retailers

The internet provides a plethora of options for sourcing authentic components. However, it’s crucial to ensure the credibility of the online platform. Consider the following:

- Check for customer reviews and ratings.

- Look for a secure payment method.

- Verify the return policy.

Utilizing these resources will help you find the right components to keep your machinery running smoothly.

Benefits of OEM vs Aftermarket Parts

When it comes to equipment maintenance, choosing between original and alternative components can significantly impact performance and longevity. Understanding the nuances of each option is essential for making informed decisions that affect efficiency and overall functionality.

Original components often guarantee compatibility and reliability, as they are specifically designed for the machinery in question. This means that users can expect optimal performance and reduced risk of malfunction.

On the other hand, alternative components can offer cost savings and increased availability, making them appealing for budget-conscious operators. However, quality can vary, and it is crucial to research the supplier to ensure that these alternatives meet necessary standards.

Ultimately, the choice between these two categories hinges on individual priorities–whether that be performance assurance or economic efficiency. Making an informed choice can lead to better outcomes in equipment management.

Maintenance Tips for Kubota U17

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By following a structured maintenance routine, you can prevent potential issues and enhance performance. Here are some key recommendations to keep in mind.

1. Regular Inspections: Conduct frequent checks on all components to identify wear and tear early. Look for any signs of leaks, cracks, or unusual noises.

2. Fluid Levels: Maintain optimal levels of hydraulic fluid, oil, and coolant. Regularly change these fluids as per the manufacturer’s guidelines to ensure smooth operation.

3. Cleaning: Keep the machine clean by removing dirt and debris, especially around filters and vents. This practice prevents overheating and ensures efficient performance.

4. Filter Replacement: Replace air and fuel filters at recommended intervals. Clean filters enhance airflow and fuel efficiency, which are crucial for optimal functioning.

5. Track Wear Parts: Monitor components that experience high levels of stress and may require more frequent replacement. Staying proactive can save time and costs in the long run.

6. Battery Maintenance: Regularly check the battery terminals for corrosion and ensure that connections are tight. A well-maintained battery is vital for reliable starts.

7. Consult the Manual: Always refer to the operation manual for specific maintenance schedules and procedures. Adhering to manufacturer recommendations is the best way to ensure your equipment operates effectively.

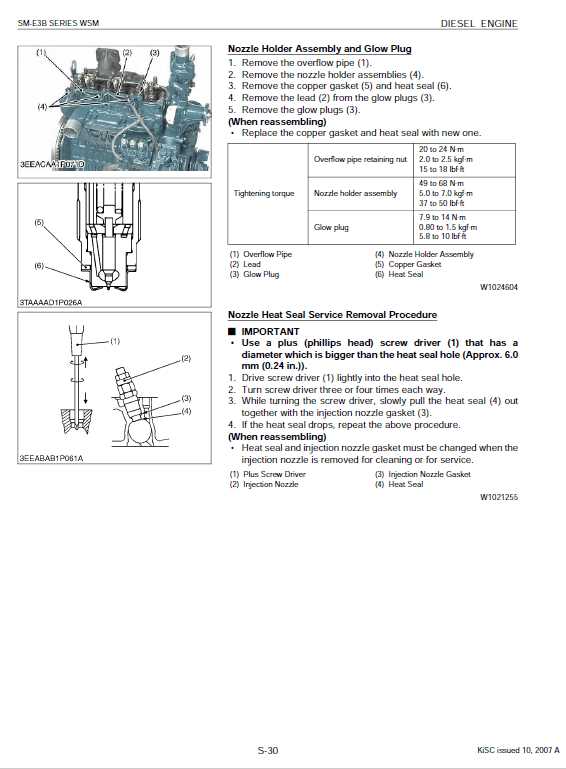

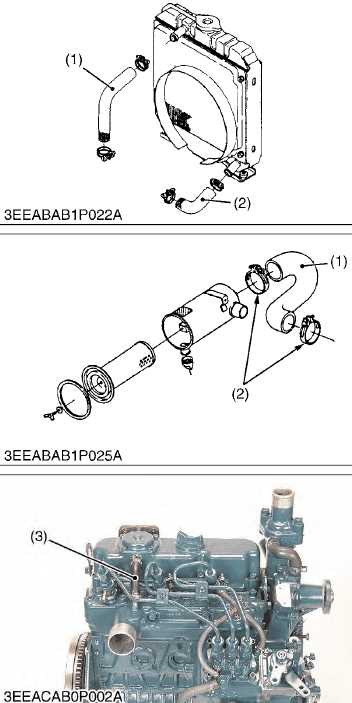

Understanding Hydraulic System Components

Hydraulic systems are essential for the efficient operation of various machinery, utilizing fluid power to perform tasks that would otherwise require significant mechanical effort. By examining the individual elements of these systems, one can gain insights into their functionality and importance in enhancing operational performance.

Key Elements of Hydraulic Systems

At the core of hydraulic systems are components such as pumps, cylinders, and valves. Pumps serve to generate the necessary pressure, while cylinders convert hydraulic energy into linear motion. Valves regulate the flow and direction of the fluid, ensuring precise control over the system’s operations.

Importance of Maintenance

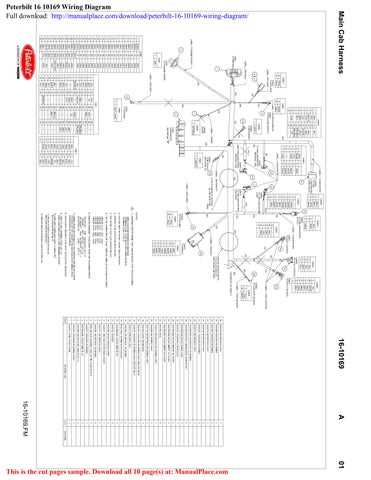

Electrical System Breakdown

The electrical system of a compact excavator is a complex network that ensures optimal operation of various components. This section provides an overview of its primary elements, focusing on functionality and interconnections. Understanding these components is crucial for effective troubleshooting and maintenance, ensuring the machinery operates smoothly.

Key Components

Each part of the electrical assembly plays a vital role in the overall performance. The main components include the battery, alternator, starter motor, and wiring harness, which work together to supply power and facilitate control over the machine’s operations.

Wiring Connections

Proper wiring is essential for reliable electrical flow. Each connection must be secure and insulated to prevent shorts and ensure longevity. Below is a summary of the essential wiring connections within the system:

| Component | Connection Type | Purpose |

|---|---|---|

| Battery | Positive/Negative | Power supply |

| Alternator | Output Lead | Charging battery |

| Starter Motor | Solenoid Connection | Engine ignition |

| Wiring Harness | Multi-pin Connectors | Signal transmission |

Replacement Procedures for Major Parts

Maintaining optimal performance of machinery involves understanding the necessary steps for replacing key components. This section outlines essential procedures to ensure effective replacements, minimizing downtime and maximizing efficiency.

1. Preparation: Begin by gathering the required tools and replacement components. Refer to the service manual for specific instructions and safety precautions. Ensuring a clean workspace is crucial for preventing contamination during the replacement process.

2. Disassembly: Carefully remove any coverings or guards that obstruct access to the components. Document the arrangement of parts, using diagrams or photos if necessary, to aid reassembly later.

3. Component Removal: Follow the outlined steps to detach the old part, paying attention to any fasteners or connectors. Utilize appropriate techniques to avoid damaging surrounding areas.

4. Installation: Position the new component in place, ensuring it aligns correctly with any connecting parts. Secure it using the specified fasteners, and double-check for proper fit and functionality.

5. Final Checks: Reassemble any removed parts and covers. Conduct a thorough inspection to confirm everything is correctly installed. Test the machinery to ensure all components are functioning as intended.

Following these procedures will not only facilitate a smooth replacement process but also enhance the longevity and performance of the equipment.

Resources for Kubota U17 Owners

For those who own this compact machinery, having access to reliable resources is essential for maintenance and repair. Various platforms offer manuals, schematics, and community support to ensure optimal performance and longevity of your equipment.

Online forums and discussion groups provide a wealth of knowledge from fellow enthusiasts and professionals, allowing users to share experiences and solutions. Additionally, manufacturers often supply downloadable manuals that cover maintenance schedules and troubleshooting techniques.

Local dealers can be invaluable, offering not only parts but also expertise and advice tailored to specific models. Furthermore, instructional videos on platforms like YouTube can guide users through common repairs and enhancements.