Parts Diagram for Ford LGT 165

In the realm of vintage agricultural machinery, having a comprehensive grasp of the individual elements that contribute to the overall functionality of these machines is essential. A thorough exploration of these components provides valuable insights into their roles, ensuring that enthusiasts and operators alike can maintain and restore these mechanical marvels effectively.

Exploring the intricate layout of various elements enables a deeper understanding of how each part interacts within the system. This knowledge is crucial for diagnosing issues, performing routine maintenance, and executing successful repairs. By delving into the specifics, users can appreciate the design and engineering that have gone into these robust machines.

Additionally, familiarizing oneself with the various components allows for informed decisions when sourcing replacements or upgrades. Whether one is an avid collector or a dedicated operator, comprehending the intricacies of these machines ensures they continue to operate smoothly and efficiently for years to come.

Understanding Ford LGT 165 Components

This section provides an overview of the essential elements that constitute the machinery in question. Each component plays a critical role in ensuring smooth operation and efficiency, making it crucial to comprehend their functions and interrelationships.

Key Elements of the Machinery

- Engine: The heart of the system, responsible for generating power and facilitating movement.

- Transmission: A vital component that transmits power from the engine to the wheels, allowing for speed variation and torque management.

- Chassis: The structural framework that supports various components and ensures stability during operation.

- Hydraulic System: This mechanism enables lifting and moving heavy loads, enhancing the machine’s functionality.

- Electrical System: Comprising wiring, batteries, and switches, this system powers the electronic components and provides control capabilities.

Functions of Each Component

- Engine: Converts fuel into mechanical energy.

- Transmission: Adjusts the gear ratios to control speed and torque.

- Chassis: Provides a stable base for other components and absorbs shocks.

- Hydraulic System: Uses pressurized fluid to perform work, like lifting or moving attachments.

- Electrical System: Enables ignition, lighting, and electronic control systems.

Key Parts of the LGT 165

This section focuses on the essential components of a well-known compact tractor, highlighting their significance and functionality. Understanding these crucial elements is vital for maintenance and repair, ensuring optimal performance in various agricultural and landscaping tasks.

The engine serves as the heart of the machine, providing the necessary power for all operations. Its robust construction and efficient design contribute to reliable performance, making it suitable for demanding environments.

The transmission system is another critical aspect, facilitating smooth gear shifts and enhancing maneuverability. This feature allows operators to tackle different terrains with ease, adapting to various workloads effectively.

Additionally, the hydraulic system plays a pivotal role in supporting attachments and implements. Its ability to lift and move heavy loads expands the tractor’s versatility, making it a valuable asset for numerous applications.

Lastly, the chassis offers structural integrity and stability, ensuring that all components work harmoniously together. Its design is tailored to withstand stress and provide a solid foundation for the entire unit.

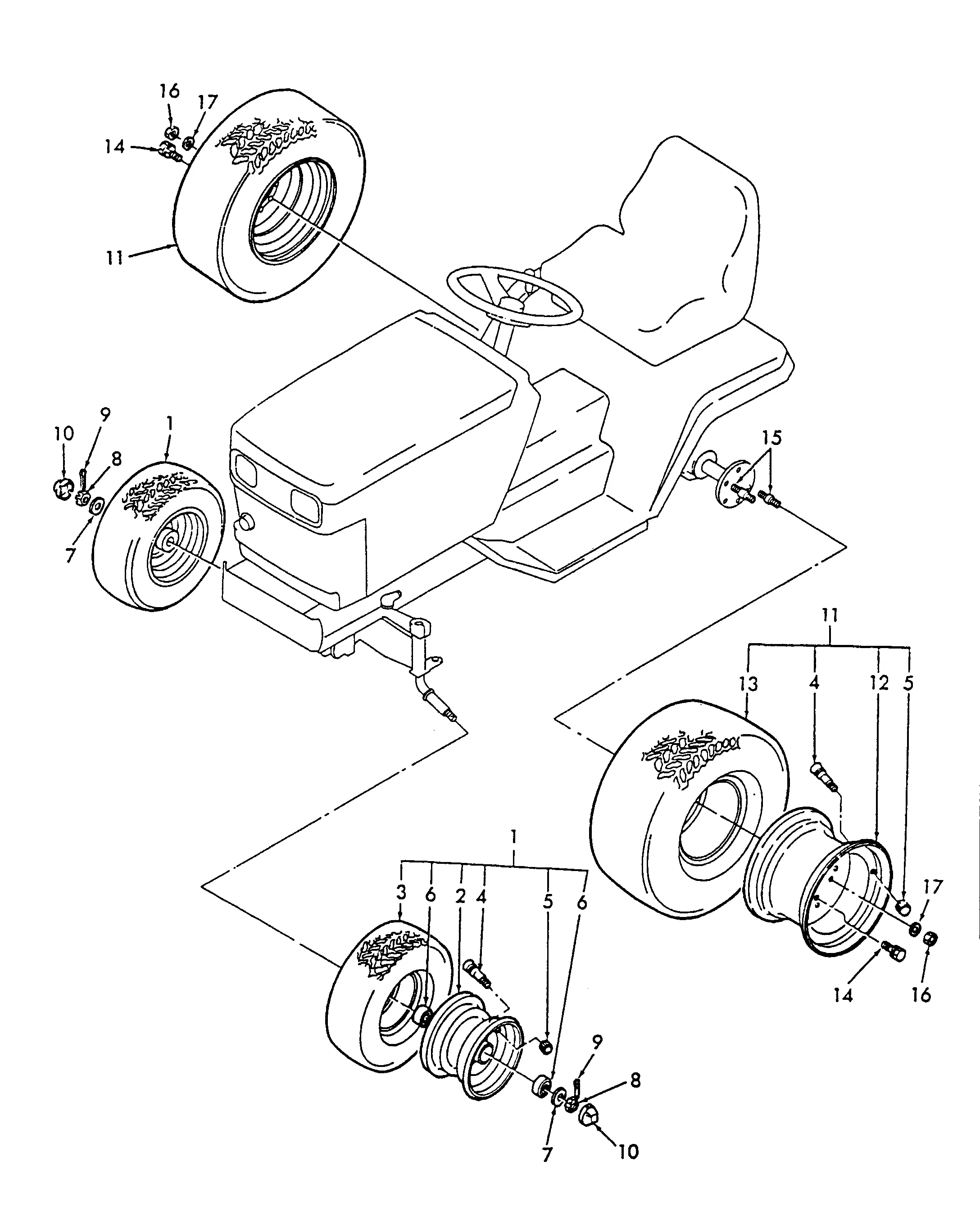

Importance of the Parts Diagram

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. A visual representation of the various elements allows users to identify individual components quickly, facilitating efficient troubleshooting and replacement processes. This kind of illustration serves as an essential reference for both professionals and enthusiasts alike.

Moreover, a well-structured visual guide enhances communication among technicians, ensuring that everyone is on the same page regarding the specifics of the equipment. This clarity helps in reducing errors during repairs and can save time, ultimately improving overall productivity.

Additionally, having access to such a schematic can aid in sourcing replacement components accurately. It allows users to verify compatibility and specifications, minimizing the risk of acquiring incorrect parts that could lead to further complications.

| Component | Description | Function |

|---|---|---|

| Engine | The main power source of the machinery. | Converts fuel into mechanical energy. |

| Transmission | System that transfers power from the engine to the wheels. | Regulates speed and torque. |

| Chassis | The framework supporting the entire structure. | Provides stability and strength. |

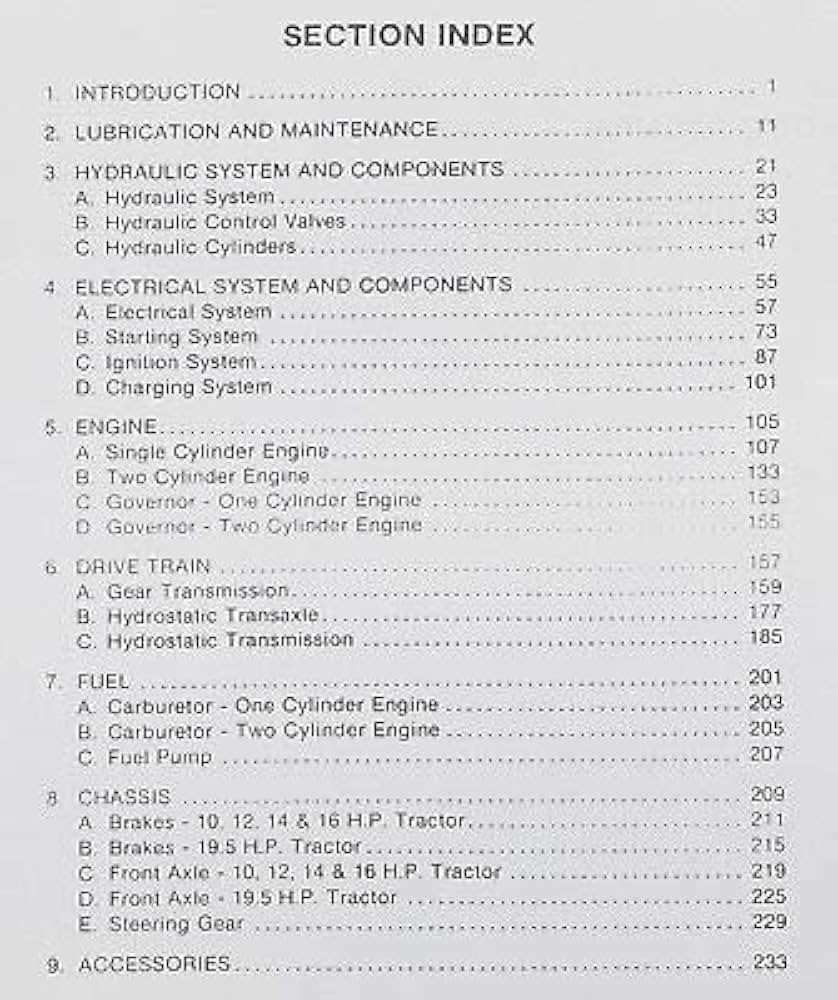

How to Read the Diagram

Understanding a technical schematic is essential for anyone looking to perform repairs or maintenance. These visuals contain key information that helps identify connections and relationships between components. With a structured approach, it’s easier to follow the logic of the layout and ensure everything is correctly aligned.

Here are a few steps to guide you through reading a schematic:

- Familiarize with symbols: Every component in the diagram is represented by a specific symbol. It’s important to recognize these icons to understand what they represent.

- Follow the lines: Lines in the schematic show the

Common Replacement Parts for LGT 165

Routine maintenance often involves replacing specific components to ensure the machine continues to operate at its best. Various mechanical and electrical elements are prone to wear and tear over time, requiring attention to maintain performance and safety.

Key components that frequently need replacement include engine belts, blades, and the air filter. These elements are essential for ensuring optimal

Maintaining Your Equipment for Optimal Performance

Regular upkeep of your machine is essential to ensure its longevity and efficient operation. By following a consistent maintenance schedule, you can prevent potential issues and keep the system running smoothly. Proper care not only extends the life of your equipment but also ensures reliable performance during use.

Inspecting the Moving Components: It is important to regularly check the key mechanisms of the machine. This includes looking for signs of wear or damage and addressing any issues before they escalate. Lubricating essential parts and tightening loose connections can significantly

Troubleshooting Common Issues

When dealing with machinery, various operational problems can arise over time, often related to wear or improper maintenance. Understanding the root cause of these issues is crucial for restoring functionality and ensuring long-term reliability. Below, we outline some frequent complications and steps to address them.

- Engine Stalling: This can be caused by fuel delivery problems, a clogged filter, or faulty spark plugs. Regularly inspect the fuel system and ignition components to ensure smooth operation.

- Transmission Slipping: If you notice inconsistent power delivery, check the drive belts and transmission fluid levels. Replacing worn belts or refilling fluids may resolve the issue.

- Overheating: Overheating can result from a malfunctioning cooling system. Ensure the coolant is at the correct level, and inspect the radiator for blockages or leaks.

- Electrical Fail

Where to Find Replacement Parts

When it comes to maintaining or restoring your equipment, sourcing the right components is crucial for ensuring long-term functionality. Whether you are dealing with general wear and tear or addressing more specific issues, knowing where to look for appropriate replacements can save time and effort.

Online Retailers

One of the most convenient places to search for replacements is through various online platforms. Numerous retailers offer a wide selection of components suited for various models, making it easy to find the exact fit you need. These platforms often provide detailed descriptions and compatibility information to guide your purchase.

Specialized Stores

For those who prefer in-person shopping or need expert advice, specialized stores focusing on machinery components can be a valuable resource. These shops typically offer a range of solutions and may even have rare or harder-to-find items in stock. Consulting with knowledgeable staff can also help ensure that you get the right part for your specific

Comparison with Other Ford Models

When exploring various machines from this manufacturer, it’s important to analyze the distinctions and similarities between different units. Each version offers its own unique blend of capabilities, engine performance, and functional features, which cater to specific needs and preferences. This comparison provides insight into how design choices and mechanical improvements have evolved across several machines.

Performance and Power

The main difference between these models lies in their power output and engine capabilities. Some machines are designed for heavier tasks and are equipped with larger engines to handle more demanding workloads. In contrast, other units focus on agility and efficiency, offering more compact designs for smaller spaces or lighter tasks.

Design and Features

Aside from engine differences, the design and included features also vary significantly. Some models are built for more rugged terrain and come with enhanced durability, while others prioritize comfort and ease of use for operators, featuring more ergonomic controls and user-friendly interfaces. These variations ensure that

Upgrading Components for Better Performance

Improving the efficiency and durability of your equipment can be achieved by upgrading its essential parts. Modernizing certain elements ensures smoother operation and enhanced longevity, especially when dealing with older or heavily used machinery. Key areas for improvement can range from power systems to mechanical components, depending on the intended use and operating conditions.

One of the primary focuses in performance upgrades is increasing the power output, which can lead to better functionality under heavy loads. Replacing worn-out or outdated pieces with newer, high-performance alternatives can greatly enhance overall reliability and efficiency. Additionally, upgrading various controls and settings can provide more precise handling and ease of operation.

Lastly, addressing safety concerns through upgraded parts can also be a critical factor. Stronger materials, better alignment, and improved

Safety Tips During Repairs

When working on any mechanical equipment, it’s essential to prioritize safety. Taking the necessary precautions can prevent accidents and ensure a smooth repair process. Whether you are an experienced technician or a beginner, following basic safety guidelines is crucial to avoid potential hazards.

Proper Use of Tools

Always ensure that you are using the correct tools for the task at hand. Misusing equipment or tools that are not suited for the job can lead to injuries or damage to the machine. Regularly inspect your tools for wear and tear, and replace any that are damaged to maintain their effectiveness and safety.

Protective Gear

Wearing appropriate protective gear is a fundamental step in personal safety. Gloves, safety glasses, and proper footwear can shield you from sharp objects, flying debris, and other potential dangers. Additionally, working in a well-ventilated space can prevent exposure

Resources for Ford LGT Owners

Finding the right tools and references is essential for keeping your equipment in top condition. Whether you need guidance for maintenance, repairs, or upgrades, there are numerous platforms offering valuable insights and expert advice. From detailed guides to community forums, these resources can significantly enhance your understanding and ease the process of upkeep.

Online manuals provide step-by-step instructions, covering a wide range of technical aspects. Additionally, specialized communities often share tips, allowing enthusiasts to troubleshoot issues together and exchange recommendations on the best practices for different models. Leveraging these platforms ensures efficient problem-solving and ongoing support for any challenges that may arise.

Expert Advice on Part Selection

Choosing the right components for your equipment requires a thorough understanding of compatibility and functionality. It’s essential to select elements that not only fit perfectly but also ensure optimal performance and durability. Below are practical tips to guide you through this process, helping to make informed decisions for long-term reliability.

Identifying Key Features

- Ensure compatibility by cross-referencing model numbers and technical specifications.

- Look for high-quality materials that withstand wear and tear over time.

- Consider maintenance needs, as some components require regular upkeep.

Quality Over Cost

While price is always a consideration, prioritize quality to avoid frequent replacements. Cheaper alternatives may save money upfront, but investing in well-made components can save time and money in