Kohler SV730 Parts Diagram for Ultimate Maintenance

The intricate world of machinery often demands a deep understanding of its individual components. This section will explore the essential elements that contribute to optimal engine performance and functionality. By grasping the relationships between various parts, one can ensure a well-maintained and efficient operation.

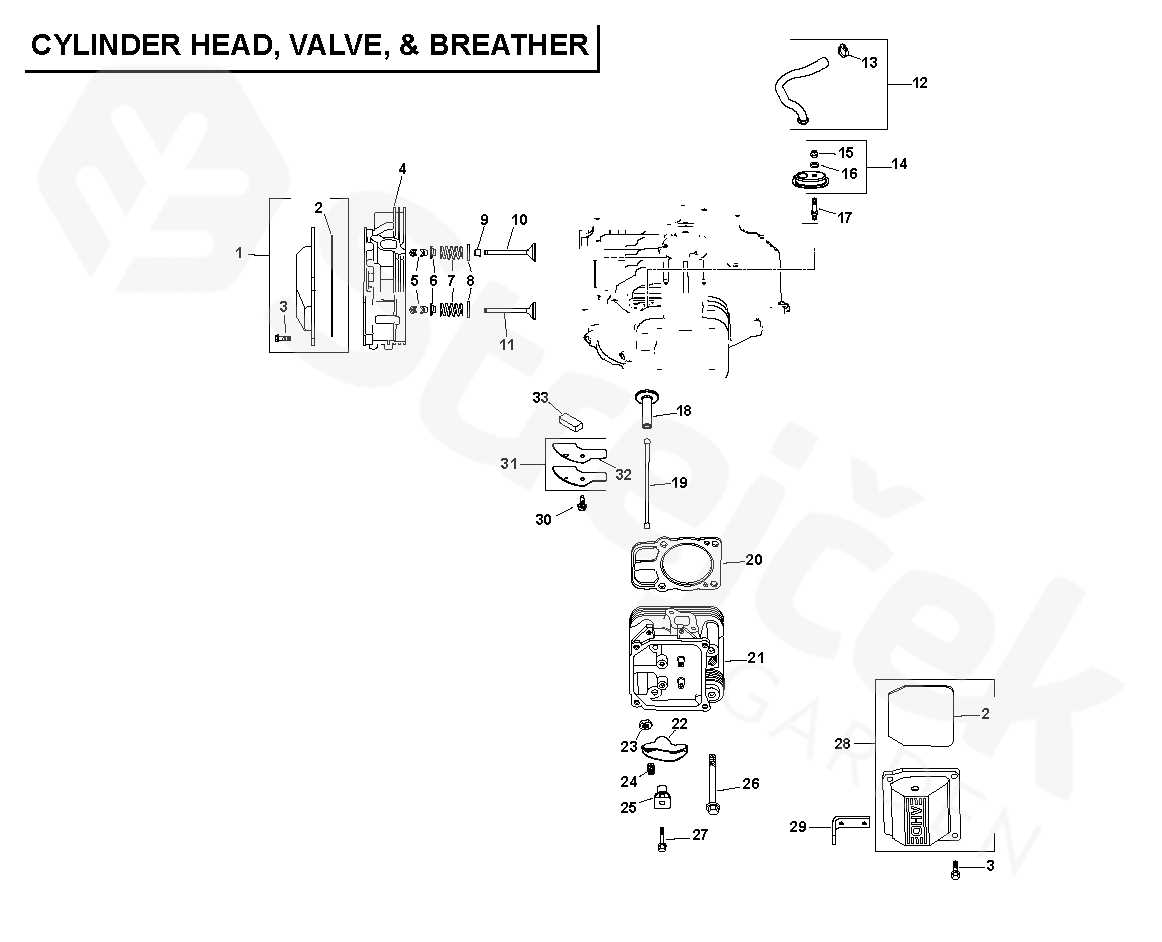

When it comes to maintenance and repairs, having a clear visual representation of the engine’s layout is crucial. Such illustrations not only enhance comprehension but also facilitate smoother troubleshooting. Whether you are a seasoned mechanic or a novice enthusiast, familiarizing yourself with these essential schematics can lead to more informed decisions and actions.

In the quest for ultimate efficiency, understanding the specific functions of each component is vital. This knowledge empowers users to delve into the complexities of engine mechanics, allowing for better upkeep and enhancement of performance. Proper identification of individual pieces can make all the difference in achieving desired results.

Kohler SV730 Overview

This section provides a comprehensive insight into a specific engine model, renowned for its reliability and efficiency in various applications. Designed to meet demanding performance standards, it serves as a popular choice among enthusiasts and professionals alike.

Key Features

The engine boasts robust construction, ensuring durability and longevity. With an innovative design, it offers impressive torque and power output, making it suitable for diverse tasks. The user-friendly maintenance features facilitate easy servicing, allowing operators to keep the engine in optimal condition.

Applications

Commonly utilized in lawn care equipment and other outdoor machinery, this model excels in both residential and commercial settings. Its versatility and performance capabilities make it an ultimate option for those seeking dependable power sources.

Understanding Engine Components

Engine functionality relies on a variety of interrelated elements that work harmoniously to generate power. Each component plays a vital role in ensuring optimal performance and efficiency.

- Crankshaft: Converts linear motion into rotational energy.

- Piston: Moves within the cylinder, creating pressure from fuel combustion.

- Camshaft: Controls the timing of valve openings and closings.

- Valves: Regulate the intake of air and fuel and the exhaust of gases.

- Ignition System: Initiates the combustion process.

Understanding these elements provides insight into how engines operate and the importance of each part in maintaining overall functionality.

Importance of Parts Diagrams

Understanding the structure of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools for identifying components and their relationships, ultimately enhancing the repair process.

- Clarity: These visuals provide clear insights into each element, making it easier to recognize and locate specific pieces.

- Efficiency: Quick reference aids in speeding up the troubleshooting and assembly process.

- Communication: Shared visuals foster better collaboration among technicians and support staff.

- Training: New team members benefit from guided learning, allowing them to grasp complex systems more effectively.

By delving into these resources, users can ensure accurate repairs and maintain optimal performance in their equipment.

Common Issues with SV730 Engines

Engines of this type are widely used in various applications, making it essential to understand the typical problems that can arise during their operation. Identifying these issues early can help in maintaining performance and extending the lifespan of the machinery.

Overheating Problems

One frequent issue is overheating, which can lead to significant damage if not addressed promptly. This often occurs due to a malfunctioning cooling system, whether from clogged passages, low coolant levels, or a failing thermostat. Regular checks and maintenance of the cooling components can prevent this situation.

Fuel System Complications

Another common concern involves the fuel system. Blockages in the fuel lines, clogged filters, or malfunctioning injectors can lead to poor engine performance or failure to start. It is crucial to ensure that the fuel system is clean and that quality fuel is being used to minimize these risks.

Regular maintenance and timely inspections are vital in keeping these engines running smoothly and efficiently. Being aware of these common issues can help operators take proactive measures to avoid costly repairs.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair tasks. This guide will help you navigate the layout, allowing for quick identification and access to necessary elements, ensuring optimal functionality of your machinery.

Familiarize Yourself with the Layout

Begin by examining the overall structure presented in the visual aid. Take note of the sections and how different pieces are grouped. This familiarity will enable you to quickly locate specific items when needed.

Identify and Reference Components

Once you understand the layout, use the illustration to pinpoint individual parts. Each section typically includes labels and numbers that correspond to a list of items. Make sure to cross-reference these details for precise ordering and replacement.

Finding Replacement Parts

Locating suitable components for your machinery can be a straightforward process when you know where to look. Understanding the essentials can save time and ensure optimal performance. Whether you are tackling maintenance or repairs, being informed about your options is crucial.

Where to Search

Start by exploring local hardware stores, online retailers, or authorized dealers. Each option has its own benefits, such as immediate availability or the convenience of home delivery.

Tips for Selection

When selecting components, ensure compatibility with your equipment. Checking model numbers and specifications can prevent unnecessary returns and ensure proper function.

| Source | Advantages |

|---|---|

| Local Stores | Immediate availability |

| Online Retailers | Convenience and wider selection |

| Authorized Dealers | Guaranteed compatibility |

Maintenance Tips for SV730

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a structured maintenance routine, you can prevent common issues and enhance efficiency. Here are some effective strategies to keep in mind.

Routine Checks

- Inspect the air filter regularly and replace it if dirty.

- Check the oil level and change it according to the manufacturer’s guidelines.

- Examine the fuel system for leaks or blockages.

Seasonal Maintenance

- Before the season starts, clean the cooling fins and ensure proper airflow.

- Sharpen or replace the blades to maintain cutting efficiency.

- Test the battery and connections, especially before heavy usage periods.

Comparing SV730 with Other Models

This section explores the distinctions and similarities between a specific engine model and its counterparts, focusing on performance, efficiency, and design. Understanding these differences can help users make informed decisions based on their specific needs and applications.

Performance Overview

In terms of power output and torque, this engine type often demonstrates robust performance, making it suitable for various applications. However, other models may excel in certain areas, such as fuel efficiency or operational longevity.

Design Features

The structural design of the engine plays a critical role in its functionality. Comparing design elements reveals how different models cater to diverse operational environments and user requirements.

| Feature | Engine Model A | Engine Model B | Current Model |

|---|---|---|---|

| Power Output | 25 HP | 27 HP | 26 HP |

| Torque | 45 lb-ft | 50 lb-ft | 48 lb-ft |

| Fuel Efficiency | 20 MPG | 18 MPG | 19 MPG |

| Weight | 150 lbs | 160 lbs | 155 lbs |

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures necessary for the assembly and disassembly of the equipment components. Understanding these processes is essential for maintenance and ensuring optimal performance. Following proper steps minimizes the risk of damage and facilitates efficient repairs.

Preparation Steps

Before starting the disassembly process, gather all required tools and ensure a clean workspace. Familiarize yourself with the specific components and their connections to prevent confusion during reassembly. It is also advisable to take photographs or notes of each step for reference.

Disassembly Process

Begin by carefully removing any protective covers or shields. Proceed to disconnect components systematically, ensuring that you keep track of fasteners and small parts. Take your time to avoid any unnecessary force, which could lead to damage. Once fully disassembled, store the parts in an organized manner for easy access during assembly.

Essential Tools for Repairing SV730

When undertaking maintenance on your equipment, having the right set of tools is crucial for effective and efficient repairs. These instruments not only facilitate the process but also ensure that tasks are completed safely and accurately. Below, we explore the indispensable tools that will assist you in your repair endeavors.

Basic Hand Tools

At the foundation of any repair project are basic hand tools. A set of wrenches, screwdrivers, and pliers will cover most tasks you’ll encounter. Socket sets are particularly useful for removing and installing various components, while torque wrenches ensure that fasteners are tightened to the correct specifications.

Specialized Equipment

In addition to hand tools, specialized equipment is often necessary for more intricate repairs. Multimeters can help diagnose electrical issues, while compression testers are essential for assessing engine performance. Having a well-rounded toolkit can greatly enhance your ability to delve into repairs effectively.

Cost Considerations for Replacement Parts

When it comes to maintaining outdoor equipment, understanding the financial implications of sourcing components is essential. Replacement items can vary significantly in price based on several factors, including quality, brand reputation, and availability. This section aims to provide insights into how these aspects can influence overall expenditure and ensure you make informed decisions when it comes to upkeep.

One of the primary considerations is the quality of the replacement components. High-quality options often come with a higher initial cost but may offer better performance and durability, ultimately leading to savings on future repairs or replacements. Conversely, lower-priced alternatives might be tempting, but they could result in more frequent failures, escalating long-term costs.

Brand reputation also plays a crucial role in pricing. Established manufacturers may charge a premium due to their reliability and support. In contrast, lesser-known brands may provide similar products at a reduced cost, but the risk of inadequate performance should be evaluated carefully.

Availability is another factor that can impact pricing. Parts that are in high demand or are specific to certain models may command higher prices due to scarcity. Planning ahead and researching options can help mitigate these costs, allowing for smarter purchasing decisions.

Where to Buy Kohler Parts

Finding components for outdoor equipment can often be a daunting task, but numerous options are available for those in search of high-quality replacements. From online marketplaces to local suppliers, understanding where to look can make the process smoother and more efficient.

Online Retailers

Many enthusiasts turn to online platforms for their convenience and extensive selection. Websites like Amazon and specialized e-commerce stores offer a wide range of components, often with customer reviews to guide your choices. Always ensure the seller has a good reputation to avoid potential pitfalls.

Local Dealers

Visiting nearby dealerships can provide personal assistance and immediate access to necessary items. These locations typically have knowledgeable staff who can help identify the correct components you need. Additionally, supporting local businesses fosters community relationships.