Ford 5610 Parts Diagram for Easy Maintenance and Repairs

Understanding the layout of crucial mechanical elements is essential for anyone working with agricultural equipment. These elements ensure smooth operation and contribute to overall machine efficiency. Having a clear visual representation of each part’s placement and function helps in troubleshooting and maintenance, making it easier to handle repairs and adjustments.

In this section, we will explore how various mechanical parts interact within a typical agricultural machine. By examining the connections between the major systems, you can gain a deeper understanding of the equipment’s functionality and longevity. Whether dealing with the hydraulic system, engine components, or transmission, knowing how these elements work together is key to optimal performance.

By the end of this overview, you will have a more structured insight into the assembly of important mechanical parts and how they contribute to the reliable operation of the machine. This knowledge is invaluable for both regular maintenance and unexpected repairs.

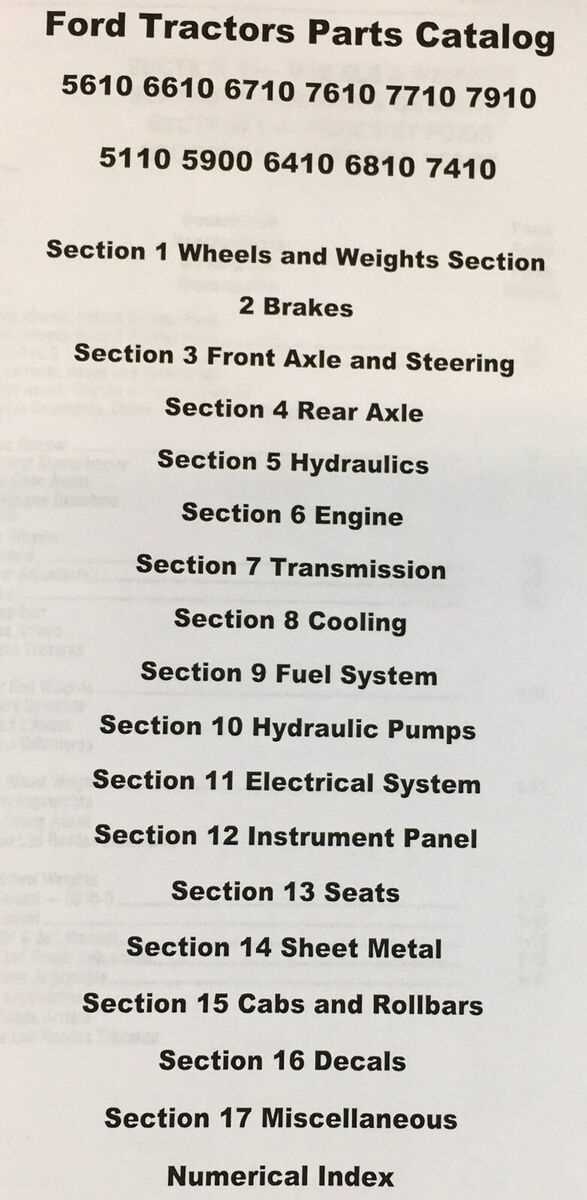

Ford 5610 Parts Diagram Overview

Understanding the layout and structure of various components in agricultural machinery is essential for efficient maintenance and repair. A clear and well-organized visual representation of mechanical elements allows users to identify and manage various sections with ease. Such guides are invaluable for those aiming to ensure smooth operation and address any technical issues promptly.

Main Sections and Components

Machinery of this type typically consists of multiple sections, each responsible for specific functions. The core systems include power transmission, hydraulic operations, and the engine mechanism. Each of these plays a crucial role in the overall performance, and having a clear visual guide helps in locating and understanding them better.

Detailed Component Table

The table below outlines key sections, offering a brief description of each area for a clearer understanding:

| Component | Description | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Transmission System | Responsible for power distribution, ensuring proper movement and operation. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hydraulics | Controls lifting mechanisms, vital for handling attachments and heavy loads. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Engine Block | The central power source, driving all operations and ensuring efficient functionality. |

| Component | Description |

|---|---|

| Gearbox | Facilitates the adjustment of power and speed. |

| Clutch | Engages and disengages the engine from the transmission. |

| Driveshaft | Transmits torque from the transmission to the wheels. |

| Transmission Fluid | Lubricates and cools the system for optimal performance. |

System Functionality

Understanding how each component interacts allows for better maintenance and troubleshooting. A well-maintained layout not only enhances performance but also prolongs the lifespan of the machinery.

Hydraulic Parts Breakdown

This section provides a comprehensive overview of the essential components involved in the hydraulic system, detailing their functions and interconnections. Understanding these elements is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Pump | Responsible for circulating hydraulic fluid throughout the system, generating the necessary pressure. |

| Actuator | Converts hydraulic energy into mechanical motion, enabling various tasks. |

| Valve | Controls the flow and direction of the hydraulic fluid, ensuring the system operates efficiently. |

| Reservoir | Stores hydraulic fluid, allowing for system expansion and maintaining fluid levels. |

| Filter | Removes contaminants from the hydraulic fluid, protecting components from damage. |

Exploring the Electrical System

The electrical system of any agricultural machinery plays a crucial role in its overall functionality. It serves as the backbone for various components, ensuring efficient operation and communication between systems. Understanding its intricacies is essential for optimal performance and troubleshooting.

Key Components

Several vital elements contribute to the efficacy of the electrical framework. These components include batteries, alternators, and wiring harnesses, each serving a specific purpose in maintaining the machinery’s operation.

| Component | Description |

|---|---|

| Battery | Stores electrical energy for starting and powering systems. |

| Alternator | Generates electricity to recharge the battery and power components. |

| Wiring Harness | Connects various electrical parts, facilitating communication and power distribution. |

Troubleshooting Tips

Identifying issues within the electrical system can be challenging. Regular inspections and testing of components can prevent malfunctions and enhance longevity. Using proper tools for diagnosis is paramount to ensure accurate troubleshooting.

Steering and Suspension Components

The steering and suspension systems play a crucial role in ensuring smooth maneuverability and stability of vehicles. These components work in harmony to provide control and comfort, allowing the driver to navigate various terrains with ease.

| Component | Function |

|---|---|

| Steering Wheel | Controls the direction of the vehicle. |

| Steering Column | Connects the steering wheel to the mechanism that directs the wheels. |

| Ball Joints | Facilitate movement between steering and suspension components. |

| Shock Absorbers | Dampen the impact of bumps, ensuring a smooth ride. |

| Control Arms | Connect the vehicle’s chassis to the wheels, allowing for vertical movement. |

Brake System Configuration

The braking mechanism of machinery plays a critical role in ensuring safety and efficiency during operation. A well-structured system is essential for effective stopping power, contributing to overall performance. Understanding the configuration allows for better maintenance and enhanced functionality.

Key Components

At the heart of any braking system are the calipers, pads, and discs. These elements work together to create friction, which ultimately slows down or stops movement. Regular inspection and replacement of these components can significantly impact performance and safety.

System Maintenance

Routine upkeep is crucial for longevity and reliability. Ensuring proper fluid levels and checking for wear can help prevent issues. Proactive care can lead to an ultimate improvement in braking efficiency, safeguarding both the operator and the machine.

Cooling System Parts Overview

The cooling system plays a crucial role in maintaining optimal operating temperatures within machinery. It ensures that the engine runs efficiently by preventing overheating, thus enhancing performance and longevity. Understanding the components involved is essential for effective maintenance and troubleshooting.

Key Components

Major elements of the cooling setup include the radiator, water pump, thermostat, and hoses. Each part has a specific function that contributes to the overall efficiency of the system, working together to circulate coolant and dissipate heat generated during operation.

Maintenance Considerations

Regular inspection of these components is vital to prevent failures. Checking for leaks, ensuring proper fluid levels, and replacing worn-out parts can significantly enhance reliability and performance, ultimately extending the life of the machinery.

Fuel System Diagram Explained

The fuel system is a crucial component that ensures the effective delivery of fuel to the engine, optimizing performance and efficiency. Understanding its layout and functionality is essential for diagnosing issues and performing maintenance.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel needed for operation. |

| Fuel Pump | Delivers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Injectors | Atomize fuel for optimal combustion within the engine. |

| Fuel Lines | Transport fuel between components, ensuring efficient flow. |

By delving into each element, users can gain a comprehensive understanding of how the system operates and the ultimate importance of each part in achieving smooth engine functionality.

Exhaust System Components in Ford 5610

The exhaust system plays a crucial role in managing engine emissions and enhancing overall performance. Each component contributes to the efficient removal of gases produced during combustion, ensuring that the engine operates smoothly and complies with environmental standards.

Main Components

Key elements of this system include the manifold, which collects exhaust gases from the cylinders, and the downpipe that directs these gases toward the muffler. The muffler then reduces noise levels while allowing for a free flow of exhaust, which is essential for maintaining engine efficiency.

A properly functioning exhaust system not only improves performance but also enhances fuel efficiency and reduces harmful emissions. Regular maintenance and inspection of each component can lead to the ultimate longevity of the engine and its accessories.

Cab and Control Panel Layout

The arrangement within the operator’s compartment plays a crucial role in enhancing efficiency and comfort during operation. A well-structured layout allows for easy access to essential controls, ensuring that the user can focus on tasks without unnecessary distractions.

Key Components

- Steering Wheel

- Instrument Cluster

- Control Levers

- Pedals

- Switches

Ergonomic Considerations

- Accessibility of controls

- Visibility of instruments

- Comfortable seating position

- Minimized vibration and noise