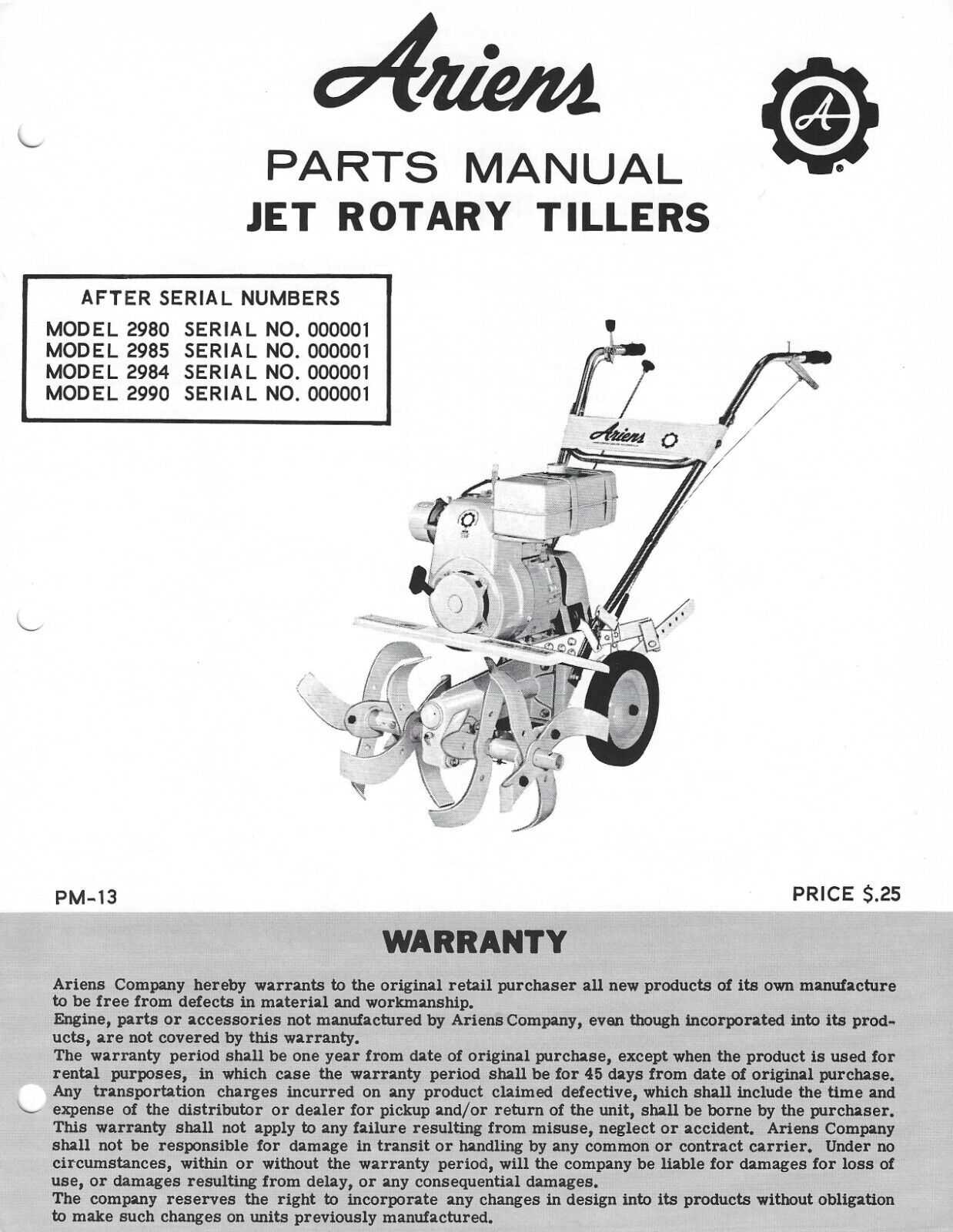

Understanding Honda Rototiller Parts Diagram for Effective Repairs

When maintaining your garden, knowing the essential elements of your cultivation equipment is crucial. A clear comprehension of the various components can significantly enhance the efficiency and longevity of your machine. This guide aims to shed light on the intricate parts that contribute to the optimal performance of your gardening tool.

Each element plays a vital role in the overall functionality, from the engine to the tines. By familiarizing yourself with these individual sections, you can make informed decisions about repairs and upgrades. This knowledge not only empowers you as a user but also helps in troubleshooting common issues that may arise during operation.

Visual aids are invaluable in this learning process. A well-structured representation of these components can simplify complex mechanisms and clarify their interactions. This resource is designed to help you navigate the layout and organization of the essential elements, ensuring you have a comprehensive understanding of your gardening equipment.

Understanding Honda Rototiller Components

Gaining insight into the essential elements of a garden tilling machine can significantly enhance its operation and maintenance. Each component plays a vital role in achieving efficient soil cultivation and overall performance.

Key Elements: Familiarity with the various sections allows for better troubleshooting and repairs. These include the engine, transmission, and tines, all contributing to the functionality of the machine.

Maintenance Tips: Regular inspection of these components not only prolongs the life of the equipment but also ensures optimal efficiency during use. Recognizing wear and tear can prevent costly repairs down the line.

Key Features of Honda Rototillers

This section highlights the essential attributes that set these garden machines apart, focusing on their innovative design, efficiency, and user-friendly operation. These features enhance performance, making them a preferred choice for both hobbyists and professionals in the gardening community.

Robust Engine Performance

Powerful engines are a hallmark of these cultivators, providing ample torque and speed for efficient soil preparation. The combination of durability and reliability ensures that users can tackle tough tasks without compromise.

Ergonomic Design

Designed with comfort and usability in mind, these tools feature adjustable handles and intuitive controls. This thoughtful approach minimizes fatigue during extended use, allowing for a more enjoyable gardening experience.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any mechanical equipment. By committing to consistent care, users can significantly extend the lifespan of their tools, preventing unnecessary breakdowns and costly repairs. This proactive approach not only enhances performance but also maximizes the return on investment.

Preventing Wear and Tear

Neglecting routine maintenance can lead to accelerated deterioration of vital components. Simple tasks, such as cleaning and lubrication, can mitigate friction and wear, allowing the machinery to operate smoothly for years. Early detection of issues often results in straightforward solutions rather than extensive repairs.

Enhancing Performance

Well-maintained equipment tends to function more efficiently, resulting in improved productivity. Regular checks and adjustments ensure that all elements are aligned and performing at their best, which ultimately translates to better results in any task undertaken. Prioritizing maintenance is a key factor in achieving optimal performance.

Common Issues with Rototiller Parts

Maintaining garden machinery is crucial for optimal performance, yet various challenges may arise over time. Identifying and addressing these common concerns can enhance efficiency and prolong the lifespan of your equipment. This section explores frequent issues encountered and provides insight into potential solutions.

Frequent Mechanical Problems

Mechanical failures are among the most common issues users face. These can stem from wear and tear or improper use. Key problems include:

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Troubles | Difficulty starting or unexpected shutdowns. | Check fuel levels, inspect spark plugs, and clean air filters. |

| Blades Dullness | Reduced cutting efficiency, leading to uneven soil tilling. | Sharpen or replace blades as necessary to maintain effectiveness. |

| Transmission Issues | Gear shifting problems or slipping during operation. | Examine the belt tension and lubricate moving parts regularly. |

Environmental and Operational Challenges

External factors can also impact the performance of garden tools. Understanding these influences is essential for effective maintenance:

| Factor | Description | Management Tips |

|---|---|---|

| Soil Type | Heavy clay or rocky soils can strain machinery. | Adjust speed settings and avoid overly compacted areas. |

| Weather Conditions | Moisture can affect operation and lead to rust. | Store equipment in a dry location and clean after use. |

| Overuse | Extended operation can lead to overheating and fatigue. | Implement regular breaks during prolonged use to prevent damage. |

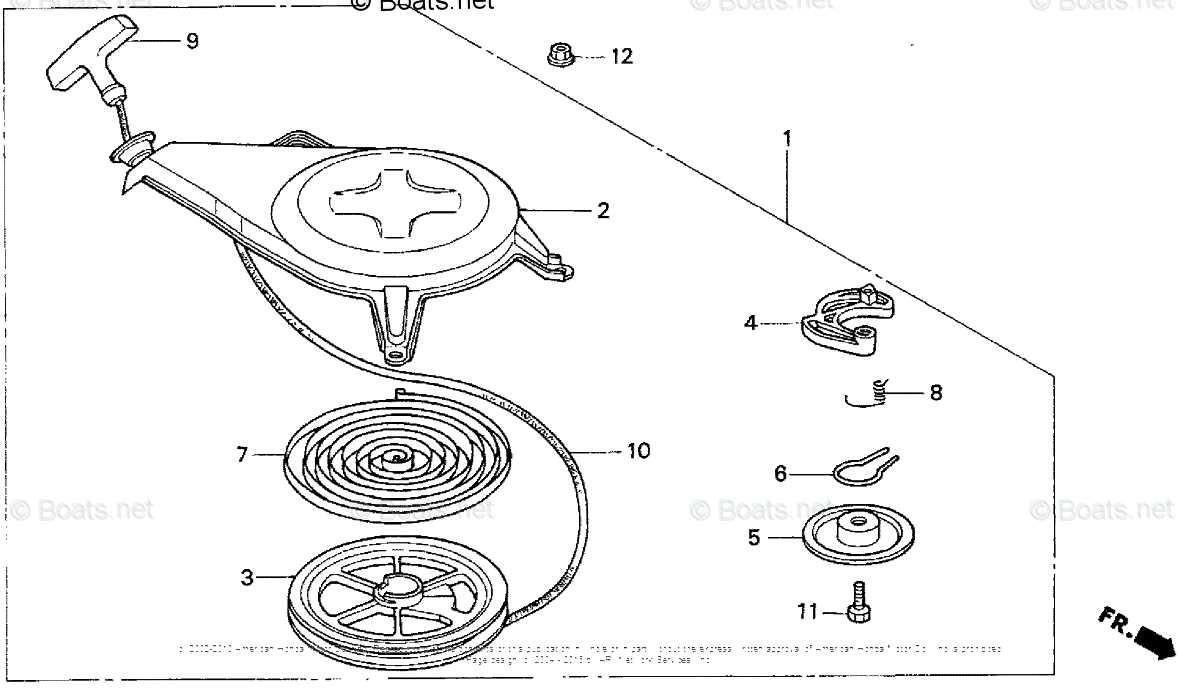

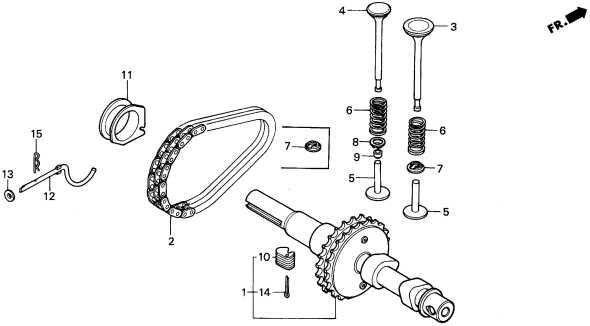

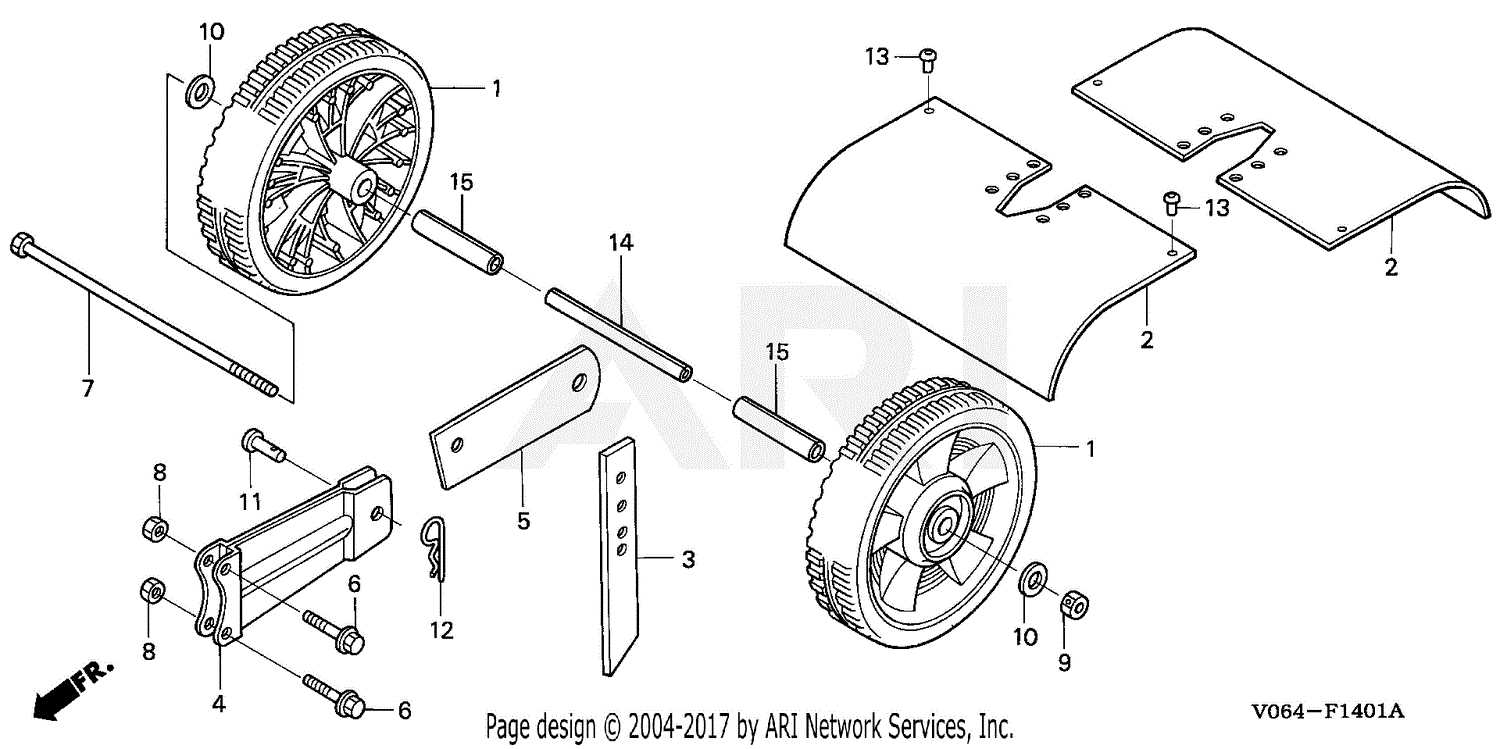

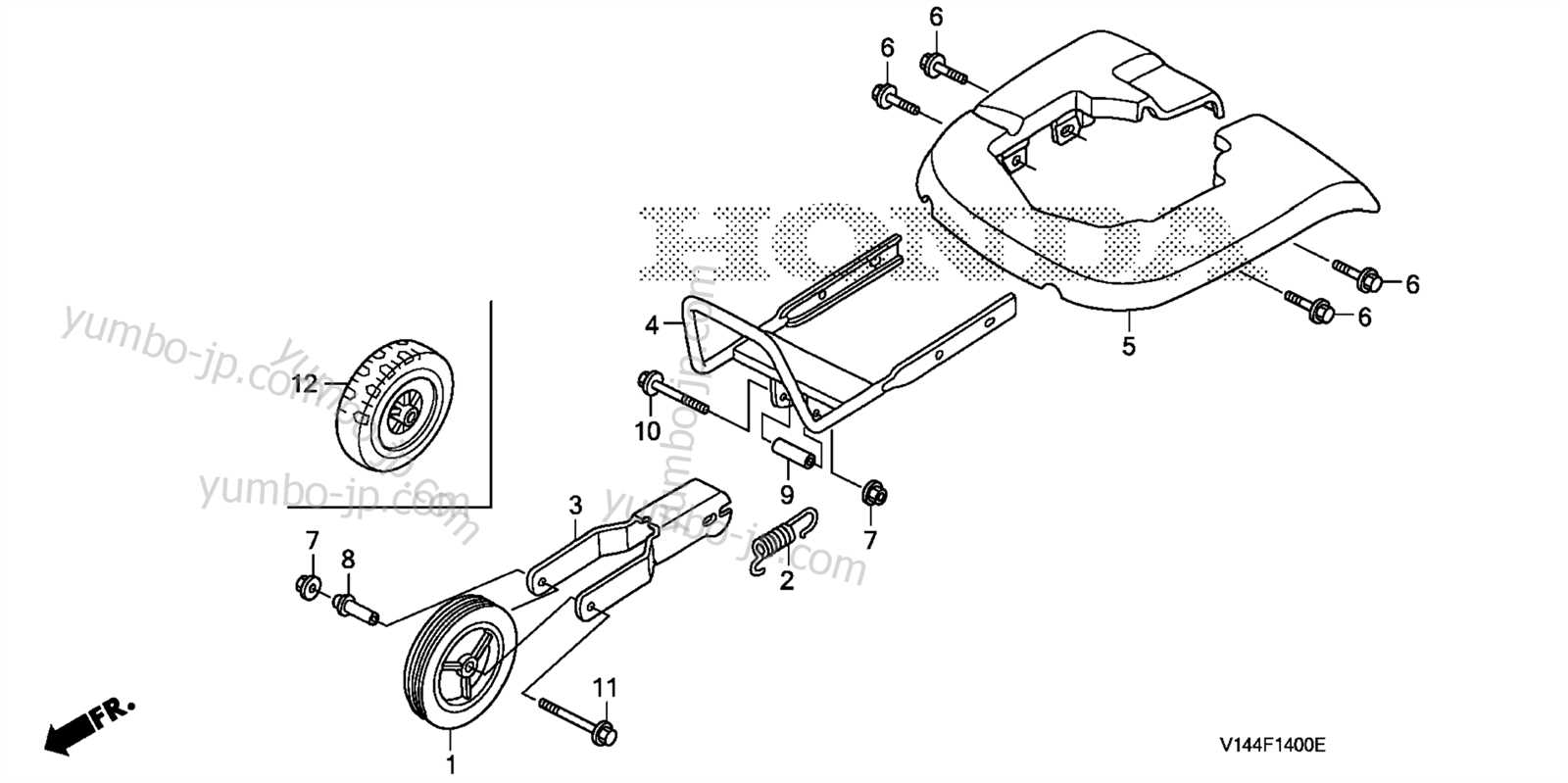

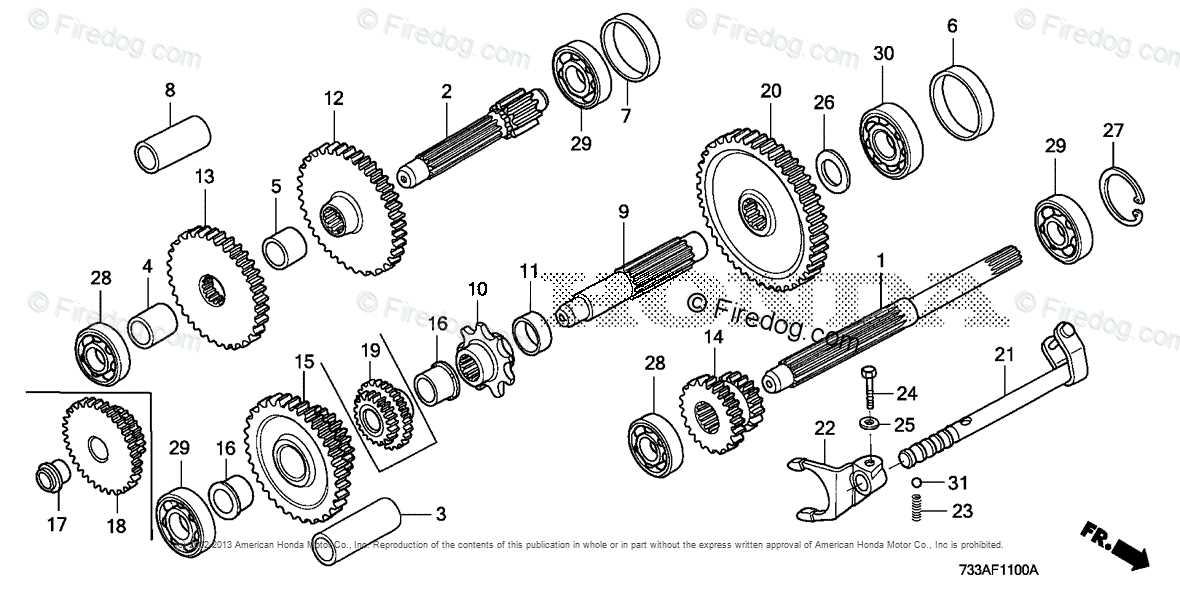

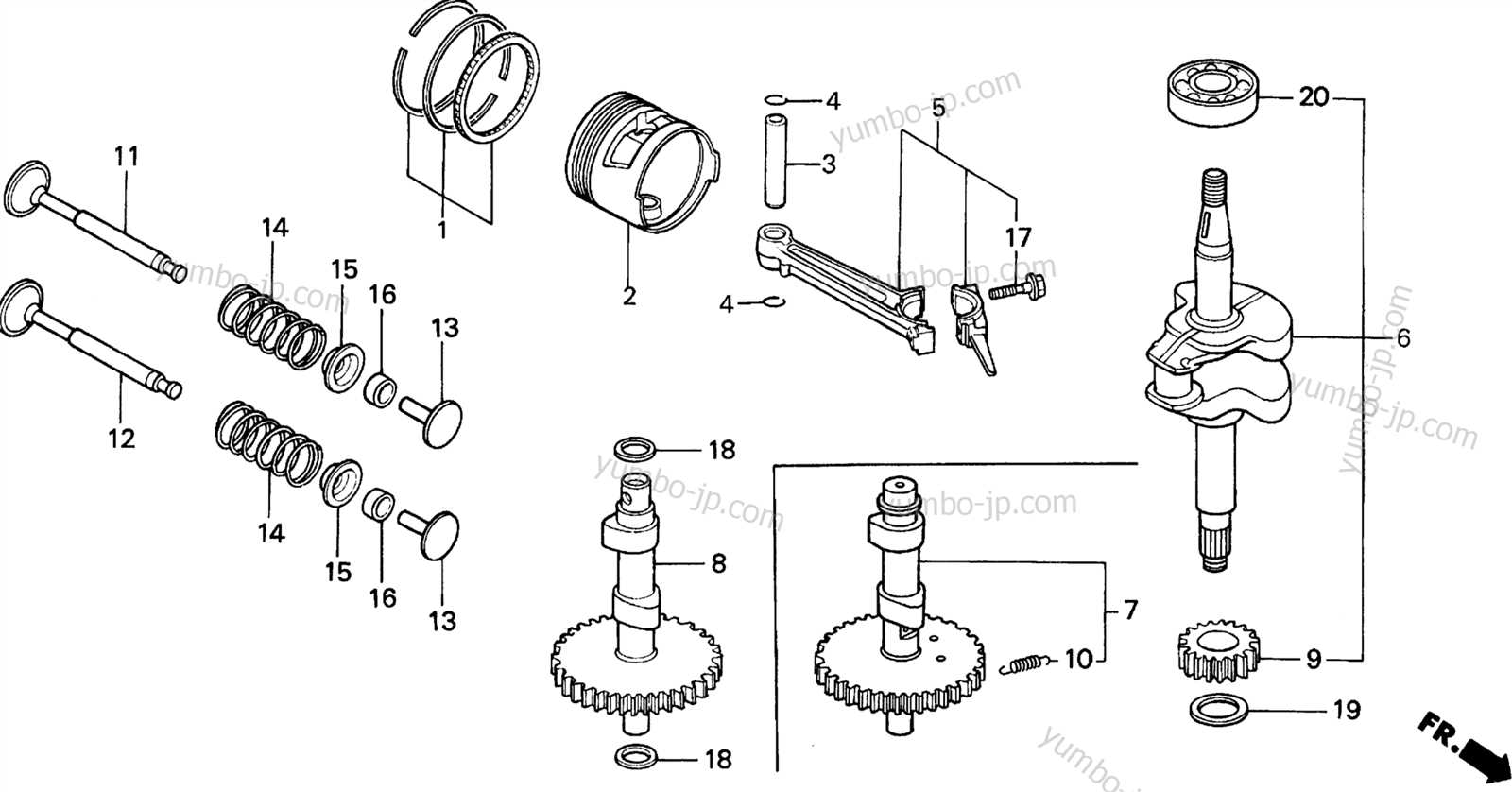

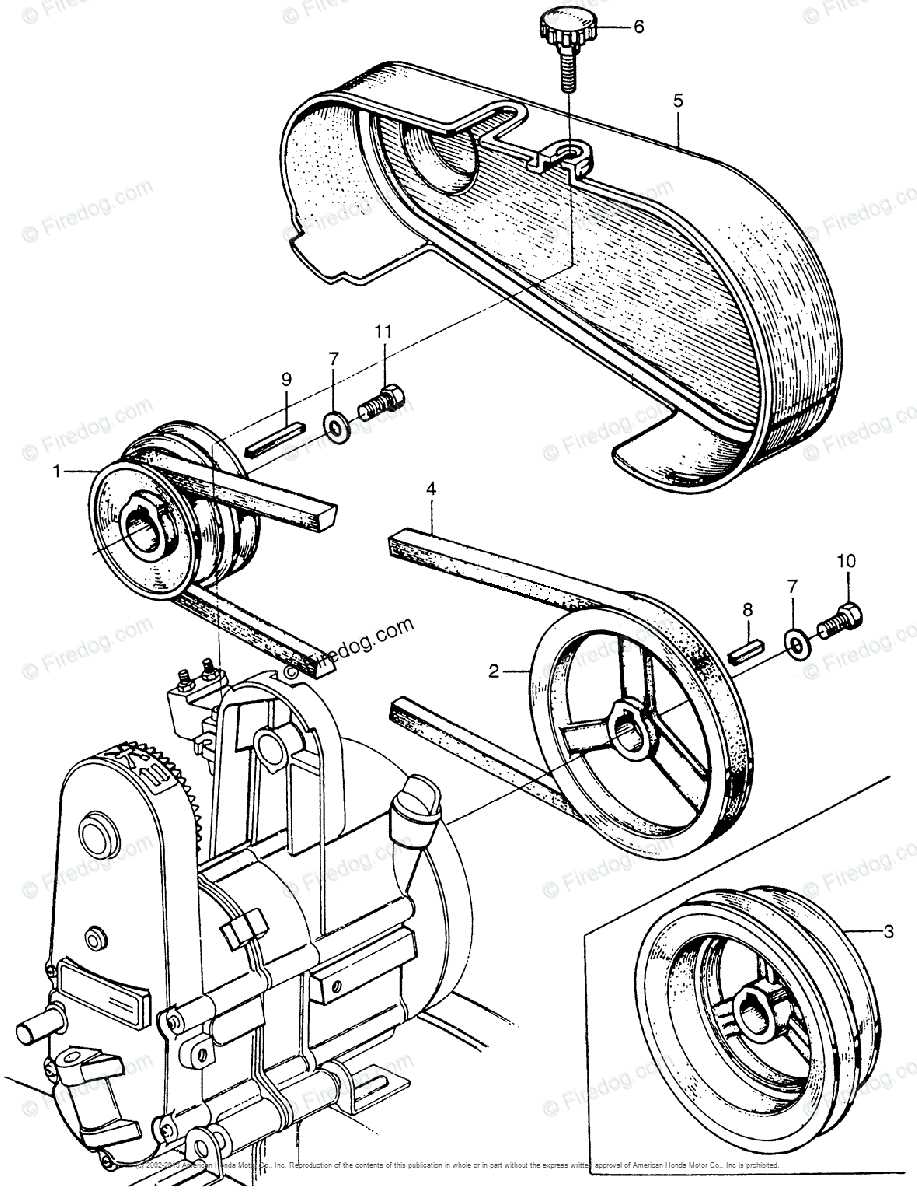

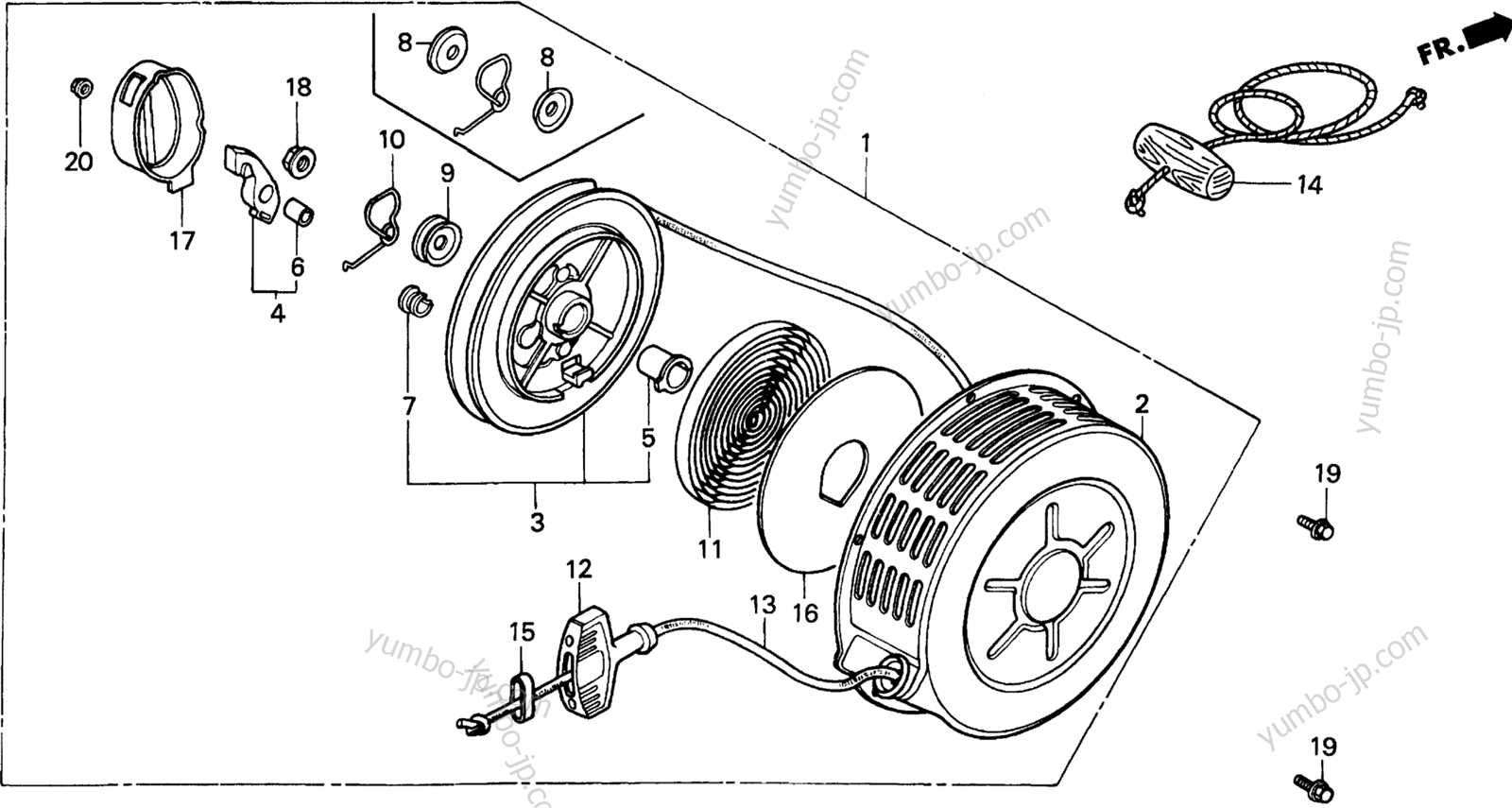

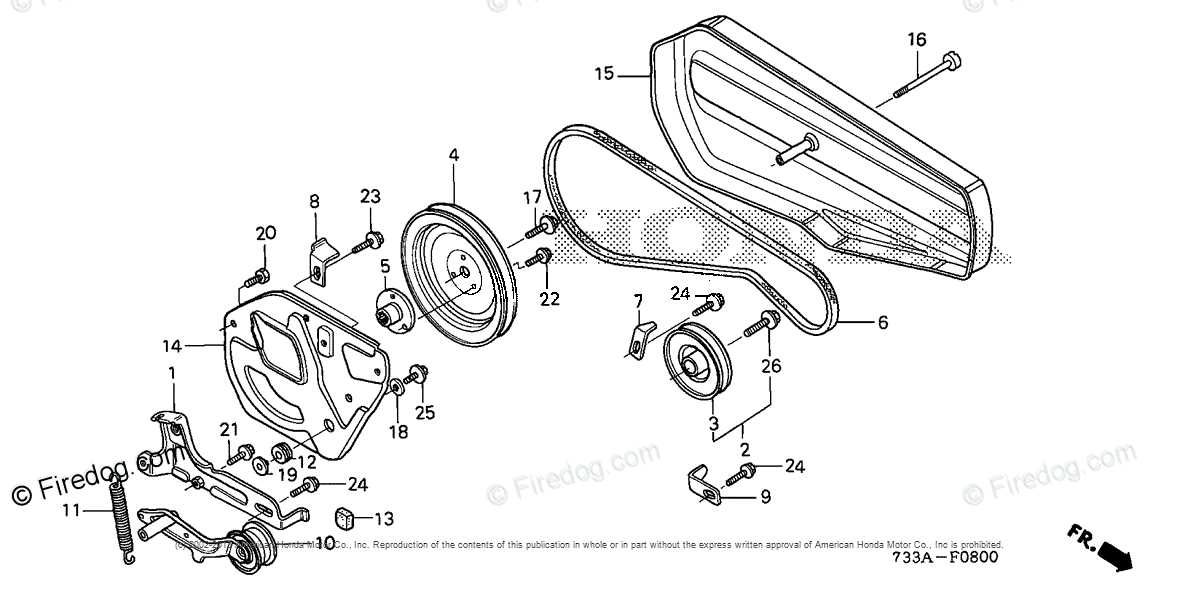

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repair tasks. This guide will help you navigate the symbols and layouts typically found in such illustrations, ensuring you can identify each element quickly and accurately.

Familiarizing with Symbols

Each component is usually represented by a specific symbol or number. Take the time to familiarize yourself with these representations, as they provide crucial information about the function and placement of each piece.

Referencing the Legend

Most illustrations include a legend or key that explains the various symbols used. Always refer to this section to gain a comprehensive understanding of the components, as it can clarify any confusion you might encounter.

Identifying Replacement Parts Easily

Understanding the components of your gardening tool is essential for effective maintenance and repairs. Recognizing specific elements will not only streamline your repair process but also enhance the longevity and performance of your equipment.

Steps to Identify Components

- Consult the User Manual: Start by reviewing the manual that came with your equipment. It often includes valuable information about individual elements and their functions.

- Check Online Resources: Various websites offer detailed information and visuals. Look for guides and videos that illustrate the assembly and function of each component.

- Visit Local Dealers: Engaging with local suppliers can provide insights. They often have firsthand knowledge and can assist in identifying the necessary elements.

Tips for Simplifying the Process

- Take Clear Photos: Document the current setup with photographs, making it easier to reference while searching for replacements.

- Create a List: Write down the names and numbers of the components you need to replace. This list will be useful when ordering or visiting stores.

- Join Online Forums: Participate in gardening communities. Many enthusiasts share their experiences and can help identify and source components.

Finding Genuine Honda Parts Online

In the quest for quality components for your outdoor equipment, sourcing authentic items is crucial. The availability of online resources makes it easier than ever to locate these essential elements, ensuring your machinery operates efficiently and effectively. This section will guide you through the process of identifying reliable sources for high-quality replacements.

Identifying Reputable Sources

When searching for genuine replacements, start by looking for authorized dealers or certified retailers. These sources typically offer a wide range of items that meet manufacturer specifications. Reading reviews and checking customer feedback can also provide insights into the reliability of a seller. Remember to look for websites that clearly state their authenticity and guarantee the quality of their offerings.

Utilizing Online Tools

Many manufacturers provide online tools to assist customers in finding the right components for their machinery. Utilize these resources by entering your equipment model or serial number. This will help you narrow down your search and ensure compatibility. Additionally, consider joining online forums or communities where fellow enthusiasts share their experiences and recommendations for sourcing genuine components.

In summary, securing authentic components for your outdoor machinery requires careful consideration of where to shop and how to verify the quality of the items. By following these guidelines, you can ensure that your equipment remains in top condition for years to come.

Tools Needed for Repairs

Having the right tools at your disposal is essential for effective maintenance and repair tasks. A well-equipped toolkit not only simplifies the process but also ensures that you can address any issues that arise efficiently. From basic implements to specialized equipment, each tool plays a crucial role in achieving optimal performance and longevity.

Basic Hand Tools: Start with fundamental items like screwdrivers, wrenches, and pliers. These are indispensable for loosening or tightening various components. A versatile set of these tools can save time and effort when performing routine checks or adjustments.

Power Tools: Electric drills and impact wrenches can significantly enhance your efficiency, particularly for more demanding repairs. They help in removing stubborn fasteners and making quick work of assembly tasks.

Measuring Instruments: Accurate measurements are vital for precise repairs. Tools such as calipers and tape measures ensure that components fit correctly and operate as intended.

Safety Gear: Don’t overlook the importance of personal protective equipment. Gloves, goggles, and masks protect against debris and harmful substances during repair work, promoting a safer environment.

Specialized Tools: Depending on the complexity of the repair, you may need unique tools tailored for specific tasks. These could include torque wrenches or diagnostic equipment, which can help identify and resolve issues that standard tools cannot address.

Investing in a comprehensive set of tools not only prepares you for immediate repairs but also contributes to a better understanding of the equipment’s functioning and maintenance needs.

Step-by-Step Repair Guide

Repairing your gardening equipment can be a straightforward task if you approach it methodically. This guide will walk you through essential steps to diagnose issues, replace worn components, and ensure your machine operates smoothly. Whether you are dealing with a malfunctioning engine or worn-out tools, following a structured process will simplify your repair journey.

Start by gathering the necessary tools and safety gear. Having the right equipment on hand will facilitate a smoother repair process. Wear gloves and protective eyewear to ensure safety while handling parts. Next, identify the specific problem by inspecting the machinery carefully. Look for signs of wear, leaks, or any unusual sounds that could indicate an underlying issue.

Once you’ve pinpointed the problem, refer to the service manual for guidance on disassembly and reassembly. Carefully follow the instructions to avoid damaging any components. It’s important to keep track of small pieces, so consider using labeled containers to organize them. After removing the faulty parts, compare them with new replacements to ensure compatibility.

Install the new components according to the manual, making sure everything fits securely. After reassembly, double-check all connections and tighten bolts as necessary. Before starting the machine, inspect your work to confirm that no tools have been left behind and that everything is in its proper place.

Finally, perform a test run to verify that the equipment is functioning correctly. Listen for any abnormal sounds and observe its performance. If everything operates as expected, you have successfully completed the repair. Regular maintenance checks will help extend the lifespan of your gardening equipment, ensuring it remains in top condition for future use.

Safety Precautions When Operating

Ensuring a safe working environment is essential when using any kind of gardening equipment. Adhering to safety measures helps prevent accidents and injuries, allowing you to focus on your tasks effectively. Before starting the machinery, familiarize yourself with the operational guidelines and precautions to enhance your safety during use.

General Safety Guidelines

Always prioritize safety by following these fundamental guidelines:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, sturdy footwear, and eye protection to safeguard against debris and injury. |

| Inspect Equipment | Check for any signs of damage or wear before operation. Ensure all parts are secure and functioning properly. |

| Clear Work Area | Remove any obstacles, rocks, or debris that may cause tripping or damage the machine. |

| Stay Alert | Maintain full attention while operating to quickly react to any potential hazards. |

Operational Safety Tips

Implement the following strategies to enhance safety during operation:

| Tip | Description |

|---|---|

| Keep Hands and Feet Clear | Avoid placing your hands or feet near moving parts to prevent injury. |

| Follow Manufacturer Instructions | Adhere strictly to the operational manual for safe usage and maintenance procedures. |

| Avoid Overexertion | Take breaks as needed and do not push the machinery beyond its intended capacity. |

| Turn Off When Not in Use | Always shut down the equipment when taking breaks or when it is not actively being used. |

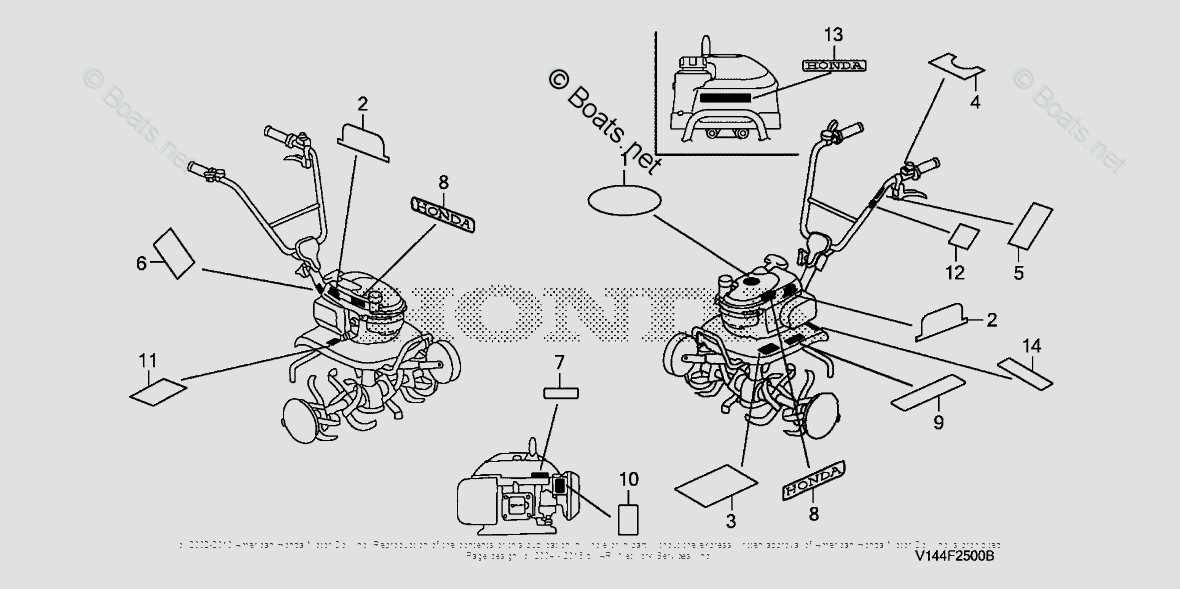

Comparing Different Honda Models

When evaluating various gardening machines from a well-known manufacturer, it’s essential to consider their unique features, capabilities, and suitability for different tasks. Each model is designed with specific user needs in mind, catering to diverse soil types, garden sizes, and overall gardening goals. Understanding the distinctions can help potential buyers select the most appropriate option for their requirements.

Performance and Power

One of the primary factors to compare among these devices is their performance and power output. Some models are equipped with robust engines, allowing them to handle tougher soil conditions and larger areas. Others may prioritize efficiency and ease of use, making them ideal for smaller gardens or less challenging terrains. Analyzing horsepower and torque specifications provides insight into how well each model can perform under varying circumstances.

Design and Ergonomics

The design and ergonomics of each option also play a significant role in user experience. Some units feature adjustable handlebars, lightweight constructions, and compact designs for enhanced maneuverability. Others may come with added safety features or specialized attachments that enhance their versatility. Considering how these elements affect usability can greatly influence a buyer’s satisfaction over time.

Upgrading Your Rototiller Effectively

Enhancing your gardening machine can significantly improve its efficiency and longevity. With the right modifications, you can transform its performance, making it more suited to your specific needs. This guide will explore practical steps to elevate your equipment’s capabilities, ensuring a more productive gardening experience.

Identifying Key Areas for Improvement

Before making upgrades, assess which components could benefit from enhancement. Focus on the following aspects:

- Engine Performance: Evaluate the engine’s power and responsiveness.

- Transmission: Consider whether a smoother gear system would enhance maneuverability.

- Cutting Tools: Examine the blades or tines for wear and efficiency.

- Comfort Features: Look at grips and controls for user-friendliness.

Recommended Upgrades

Implementing certain upgrades can lead to substantial improvements. Consider these options:

- Engine Enhancements: Upgrade to a more powerful engine to handle tougher soil conditions.

- Improved Blades: Replace old blades with high-quality alternatives designed for specific soil types.

- Transmission Adjustment: Modify the gearbox to provide better torque and speed control.

- Ergonomic Features: Add padded grips and adjustable handles for better comfort during operation.

By thoughtfully selecting upgrades, you can greatly enhance the effectiveness of your gardening equipment, making it a valuable ally in your outdoor endeavors.

Customer Support and Warranty Options

Ensuring satisfaction through reliable assistance and protection is crucial for any product owner. Comprehensive support services are designed to help users navigate issues and maintain optimal performance, while warranty options provide peace of mind regarding investment security.

Support Services: A dedicated team is available to address inquiries, offer troubleshooting guidance, and provide maintenance tips. Users can reach out via various channels, including phone, email, or live chat, ensuring quick and efficient resolutions.

Warranty Information: Most products come with a warranty that covers defects in materials and workmanship. This policy typically spans several years and guarantees that customers can receive necessary repairs or replacements at no additional cost during the coverage period.

Understanding support and warranty details empowers users to make informed decisions and enhances their overall experience with the product.